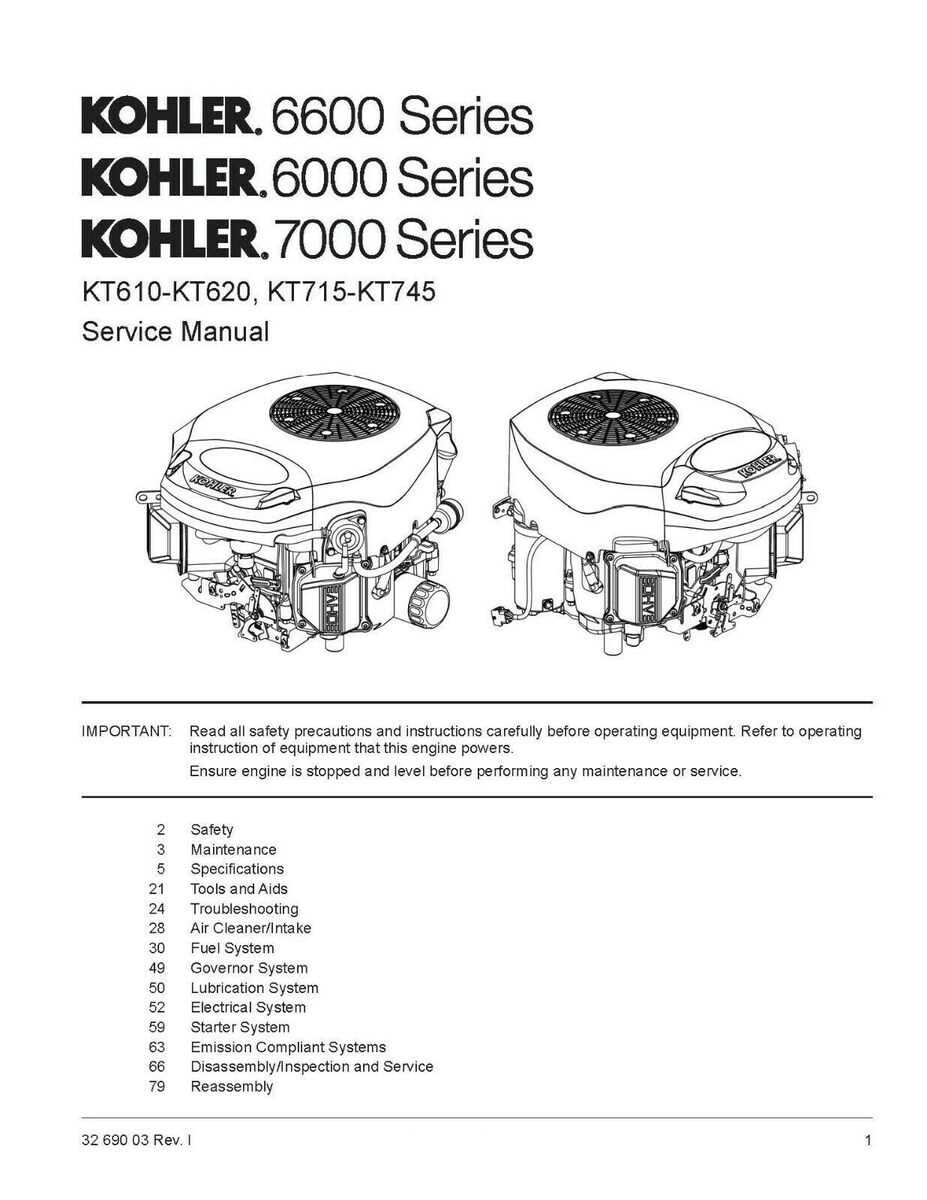

Comprehensive Guide to 26 HP Kohler Engine Parts Diagram

In the realm of small machinery, the efficient operation of power units plays a crucial role in ensuring optimal performance. To achieve this, a comprehensive knowledge of various components is essential, as each part contributes to the overall functionality and reliability of the system. This exploration will shed light on the intricate relationships among these elements.

Identifying each element within a power unit allows for better maintenance and troubleshooting. By understanding how these components interact, users can enhance their operational capabilities and prolong the lifespan of their machinery. This knowledge is vital for both enthusiasts and professionals alike.

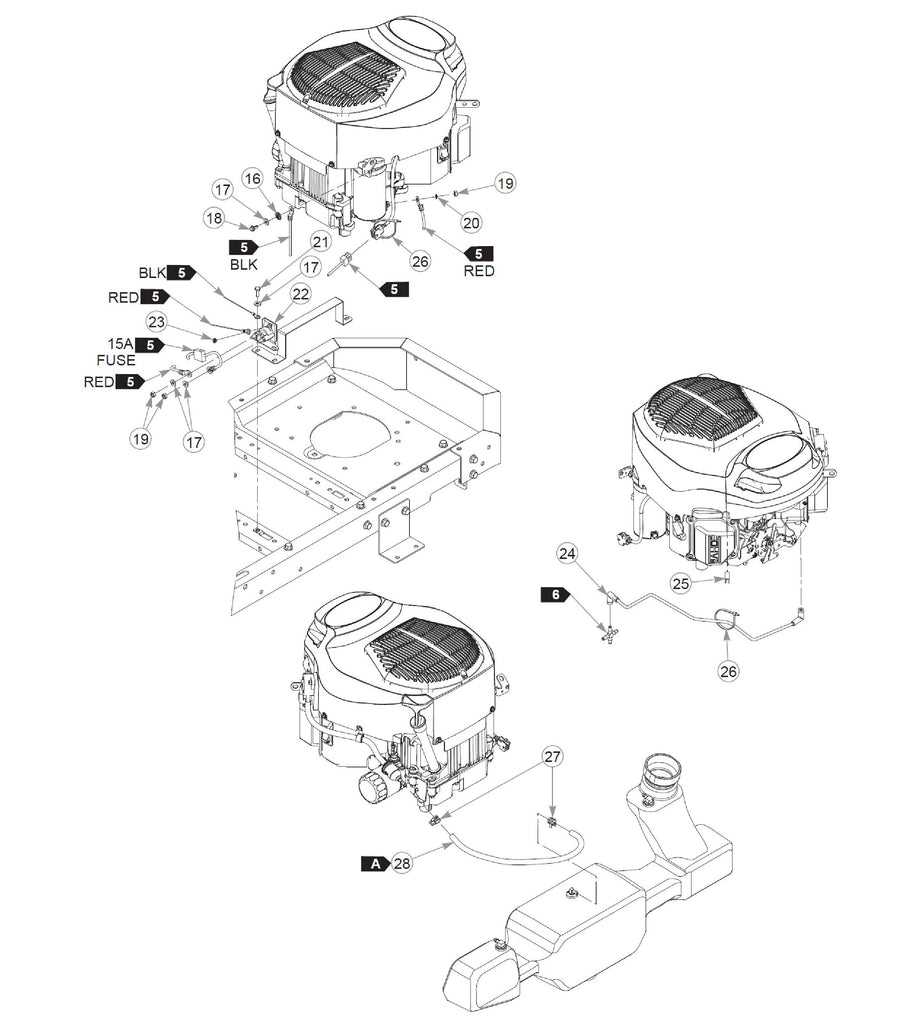

As we delve into the specifics, it becomes evident that a well-organized visual representation of these components can serve as the ultimate reference tool. This will aid in recognizing potential issues and facilitate a smoother repair process. Join us as we navigate through the essential aspects of this powerful machinery.

Understanding the 26 HP Kohler Engine

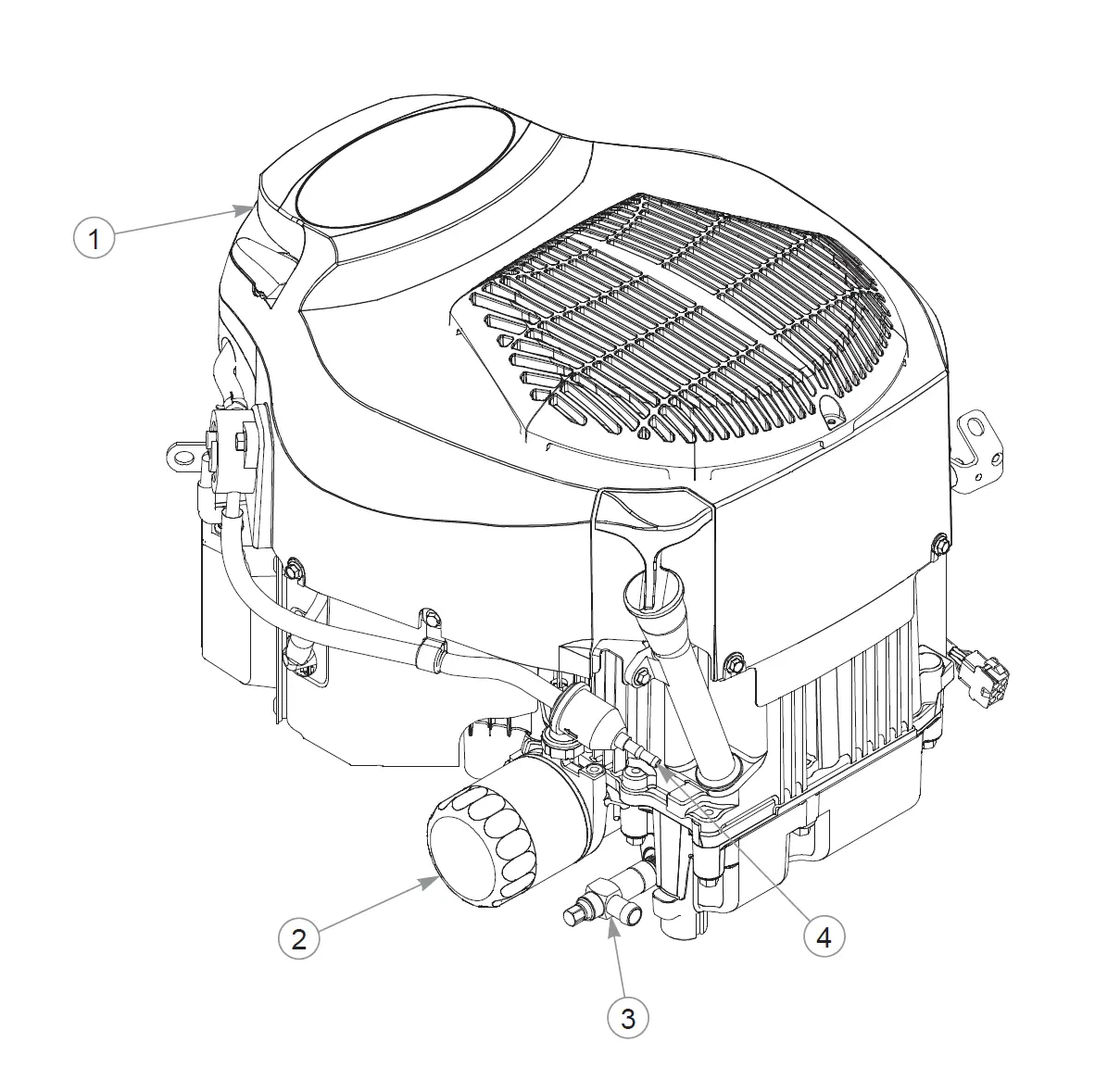

This section delves into the essential features and functionalities of a powerful outdoor machine, renowned for its efficiency and reliability. The focus here is on the key components that contribute to its robust performance in various applications, ensuring smooth operation and longevity.

Key Features

Several characteristics define this machinery, such as its high torque, ease of maintenance, and fuel efficiency. These attributes make it suitable for both residential and commercial tasks, providing the ultimate power needed for demanding jobs.

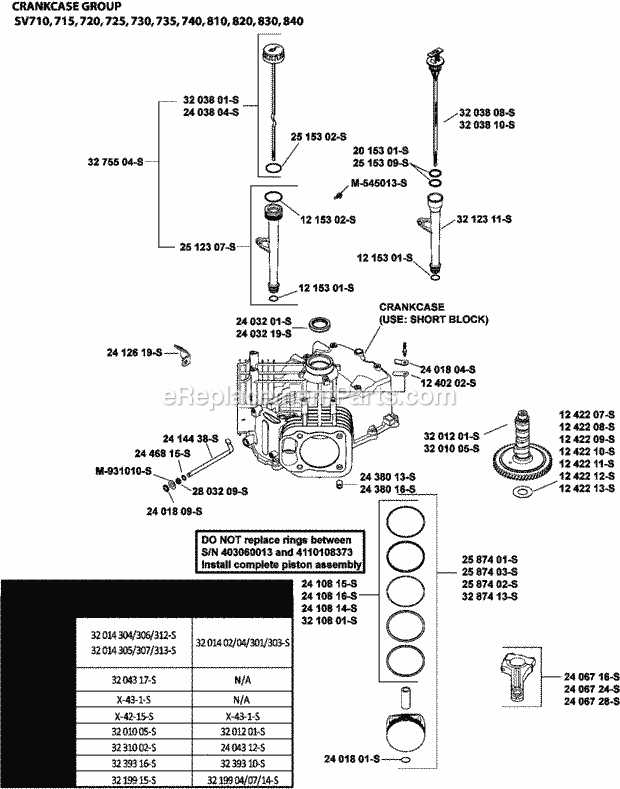

Component Overview

Understanding the various elements that constitute this powerhouse is vital. Below is a table highlighting some of the crucial components and their roles:

| Component | Function |

|---|---|

| Cylinder | House the combustion process, providing necessary power. |

| Piston | Convert energy from fuel into mechanical motion. |

| Crankshaft | Transform linear motion into rotational force. |

| Valves | Regulate the intake of air and fuel, as well as exhaust. |

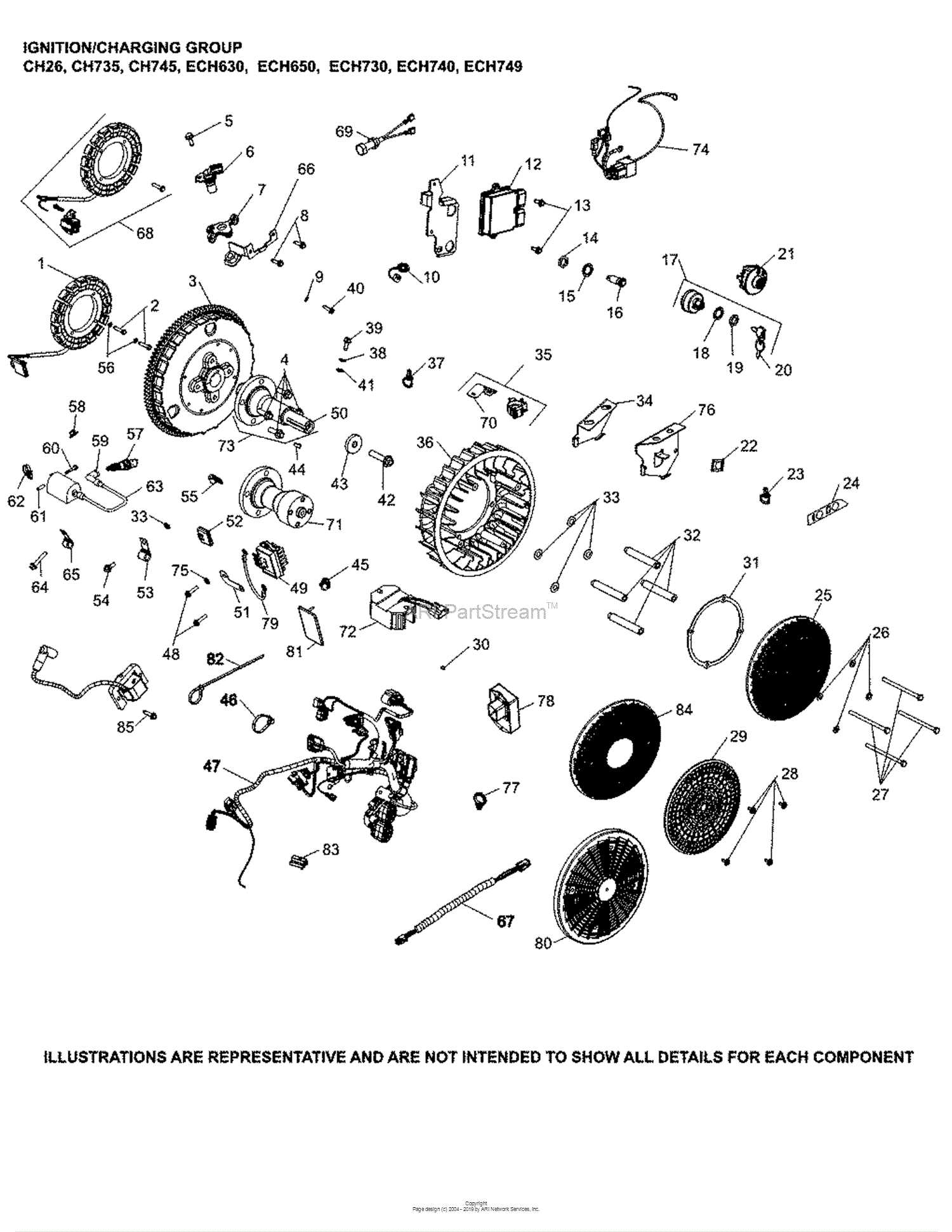

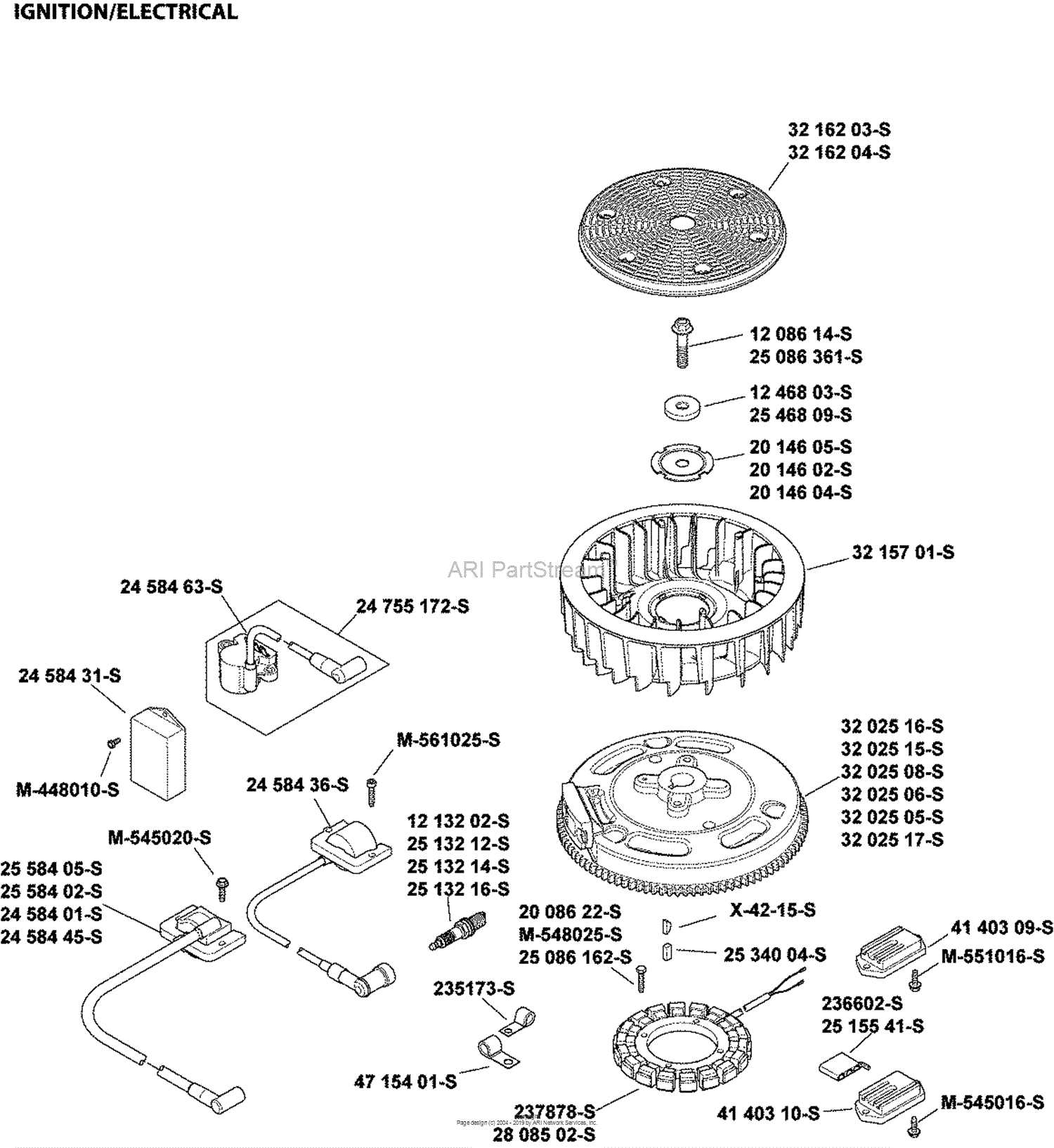

Key Components of Kohler Engines

This section explores the essential elements that contribute to the functionality and performance of small power units. Understanding these components is crucial for maintenance and optimization, ensuring longevity and reliability in various applications.

Core Elements

- Cylinders

- Pistons

- Crankshafts

- Valves

Supporting Mechanisms

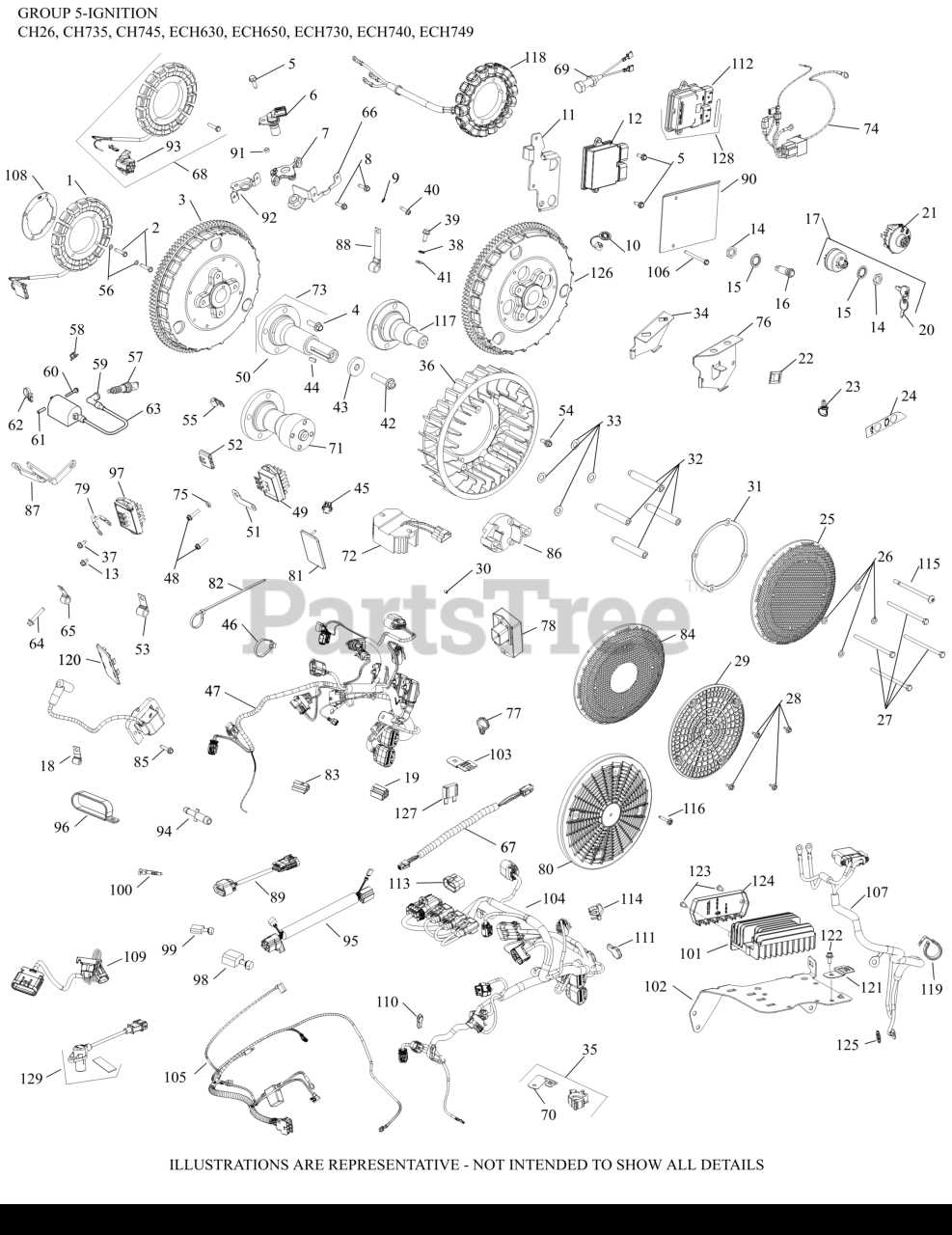

- Ignition System

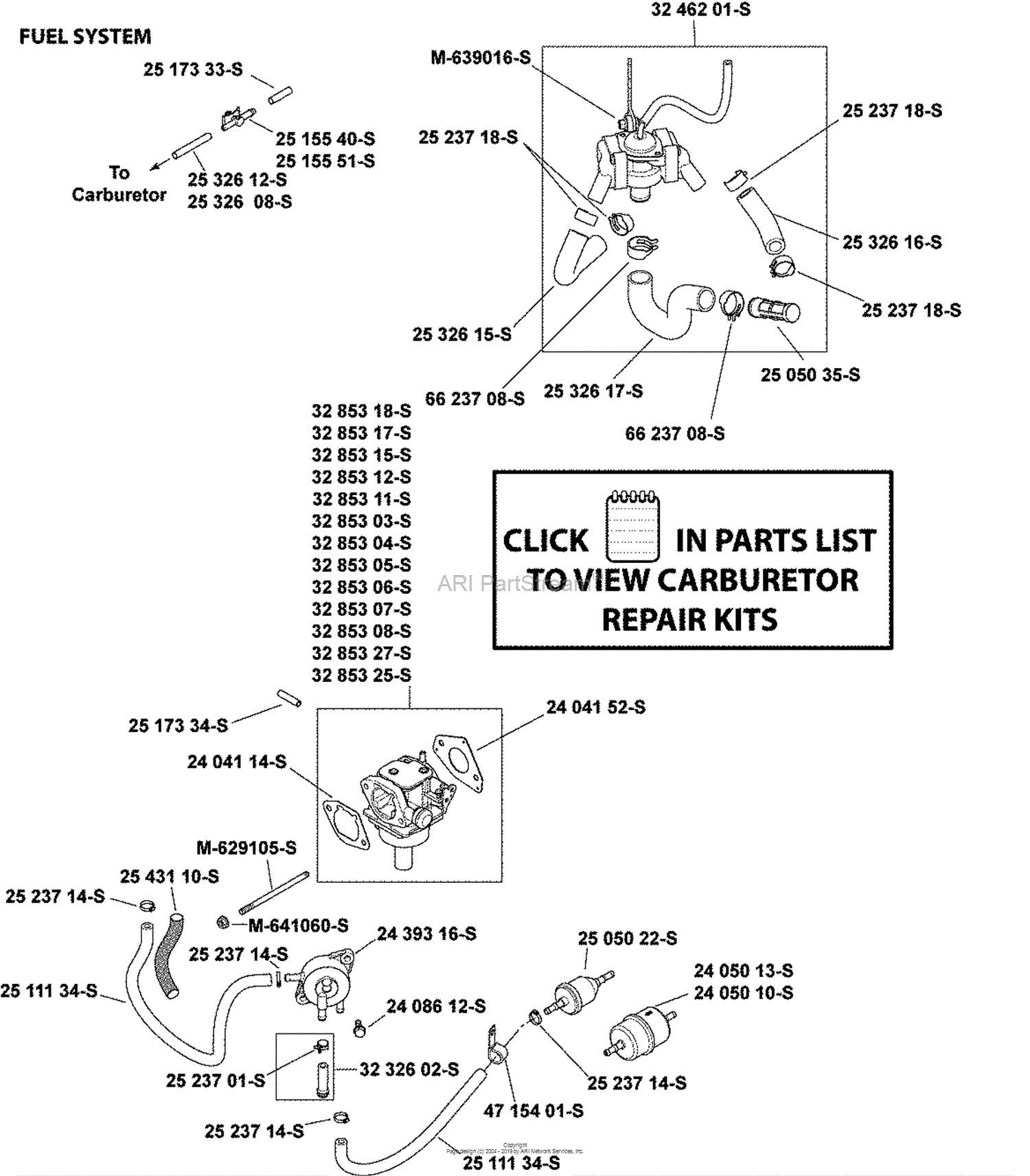

- Fuel Delivery Components

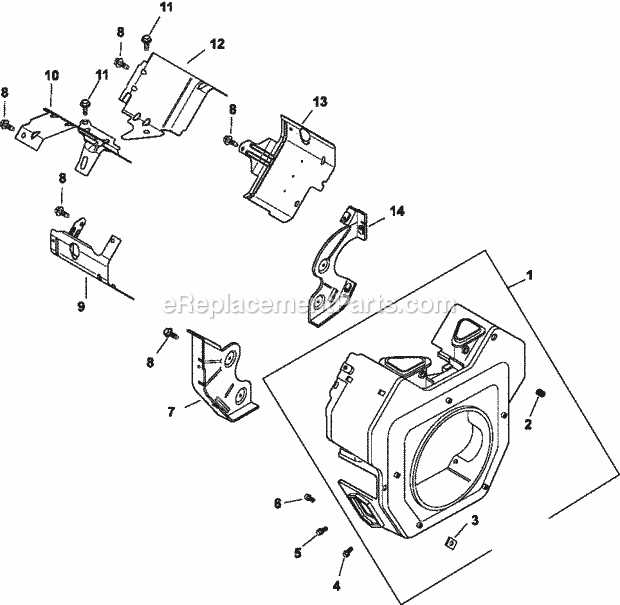

- Cooling Systems

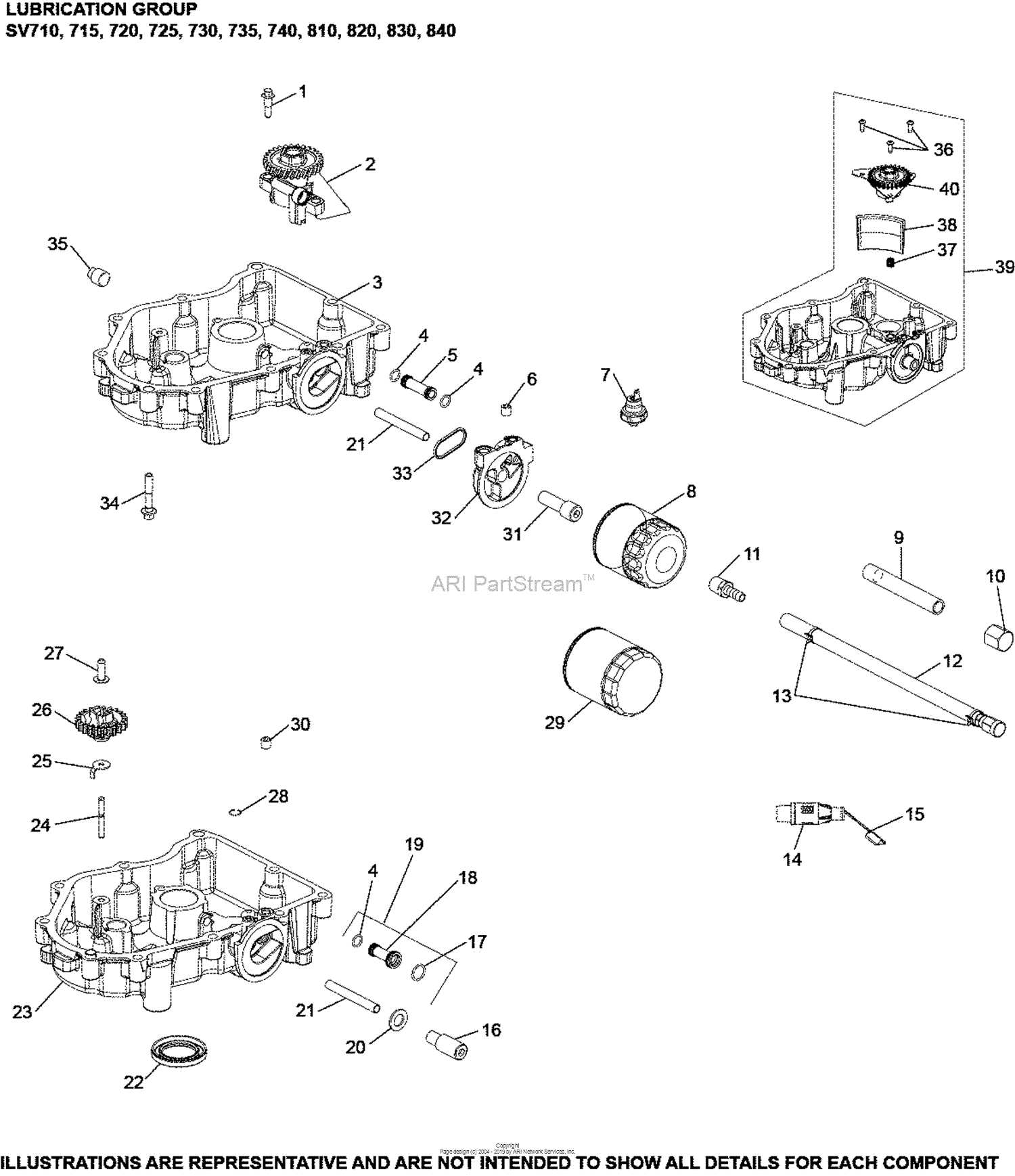

- Lubrication Systems

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of machinery and equipment. Neglecting this essential practice can lead to diminished performance, increased wear and tear, and ultimately, premature failure. By investing time and resources into routine care, users can significantly enhance the reliability and durability of their machines.

Here are several key reasons why maintenance should be a priority:

- Prevention of Breakdowns: Consistent checks can identify potential issues before they escalate into significant problems.

- Efficiency Improvement: Well-maintained machines operate more smoothly, resulting in better performance and fuel efficiency.

- Cost Savings: Regular maintenance can help avoid costly repairs and replacements in the long run.

- Safety Assurance: Proper upkeep ensures that all safety mechanisms function correctly, protecting users and operators.

- Resale Value: Equipment that has been well cared for often retains its value better, making it more attractive to potential buyers.

Incorporating a maintenance routine not only prolongs the life of machinery but also enhances overall productivity. Emphasizing care and attention can lead to a more reliable and efficient operation, ensuring that equipment serves its purpose effectively for years to come.

Common Issues with Kohler Engines

Many users encounter various challenges when operating small power units. Recognizing these frequent problems can help ensure better performance and longevity. Addressing these issues promptly can save time and prevent costly repairs.

| Issue | Symptoms | Solutions |

|---|---|---|

| Starting Problems | Failure to start, clicking noise | Check battery charge, inspect starter connections |

| Overheating | Unusual noises, loss of power | Inspect cooling fins, ensure proper airflow |

| Fuel Leaks | Visible fuel around unit, strong odor | Examine fuel lines, replace damaged components |

| Excessive Vibration | Shaking during operation | Check mounting bolts, inspect blade balance |

How to Identify Engine Parts

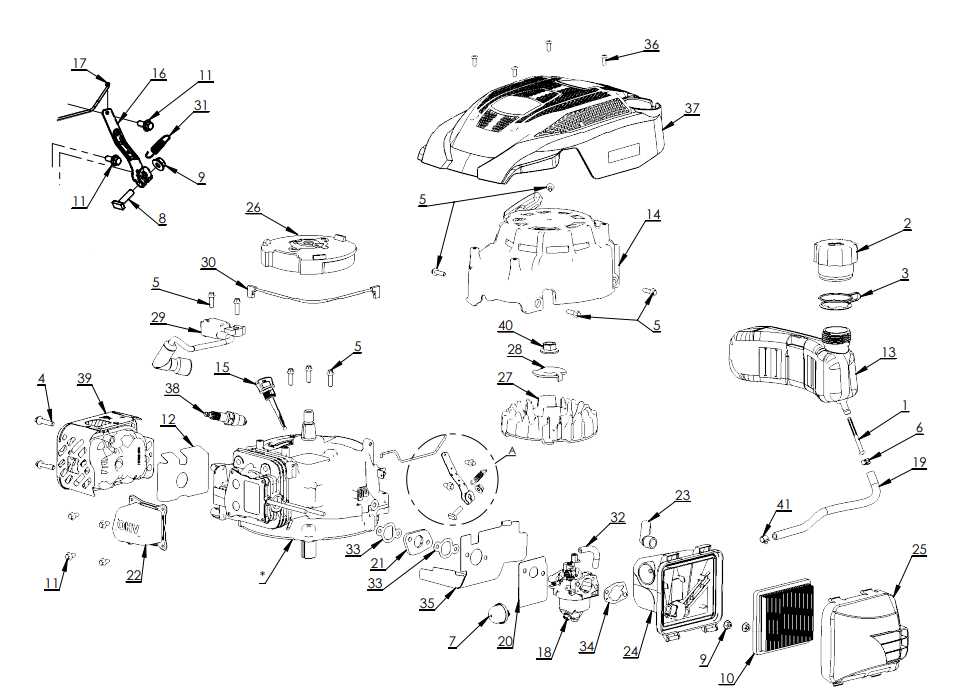

Understanding the components of a machine is essential for effective maintenance and repair. By recognizing various elements, you can enhance performance and ensure longevity. Familiarity with terminology and appearance will significantly simplify the process of identification.

Common Components

Begin by familiarizing yourself with the following essential elements:

- Block: The main structure that houses other components.

- Crankshaft: Converts linear motion into rotational force.

- Piston: Moves up and down within the cylinder, generating power.

- Valves: Control the intake and exhaust of gases.

- Flywheel: Stabilizes rotation and stores energy.

Identification Tips

To accurately identify components, consider the following strategies:

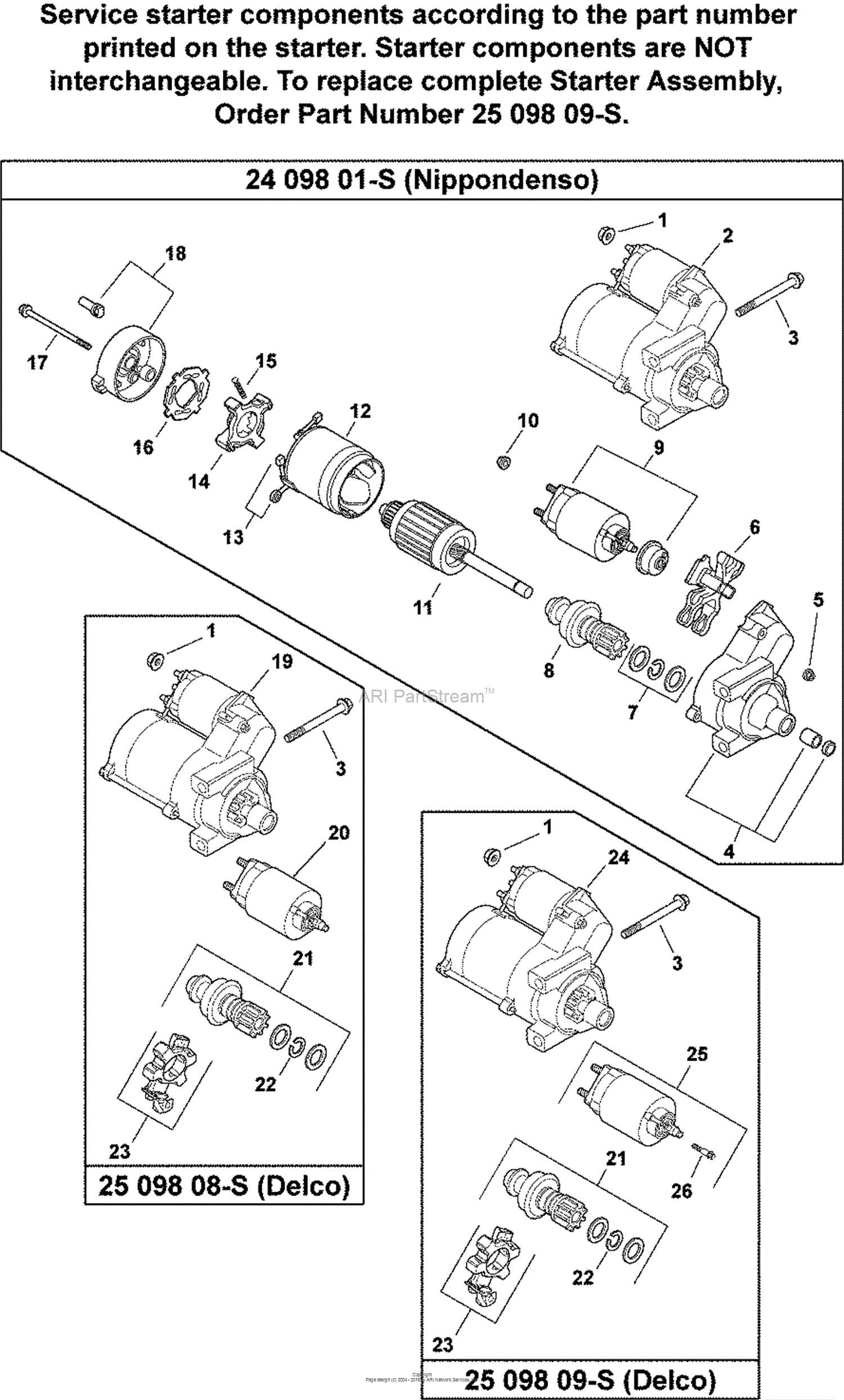

- Consult Manuals: Reference guides often include labeled illustrations.

- Use Online Resources: Websites and forums provide valuable insights and visuals.

- Label Components: If disassembling, label parts for easy reassembly.

- Seek Expert Advice: Connect with professionals or enthusiasts for guidance.

By employing these techniques, you can become proficient in recognizing and understanding the vital components of your machinery.

Tools Needed for Engine Repair

Repairing machinery requires a specific set of instruments to ensure efficiency and accuracy. Having the right tools not only simplifies the task but also enhances safety and effectiveness during the process.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening fasteners. |

| Screwdriver Set | Essential for handling screws of various types. |

| Pliers | Used for gripping, bending, and cutting. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Socket Set | Facilitates access to hard-to-reach bolts. |

| Multimeter | For diagnosing electrical issues. |

| Oil Filter Wrench | Helps in removing and installing oil filters. |

Step-by-Step Repair Guide

This guide aims to provide a comprehensive approach to troubleshooting and fixing mechanical issues in small power units. By following these detailed steps, users can effectively restore functionality and ensure optimal performance.

Start by gathering the necessary tools and materials for the repair process. A clean workspace is crucial to avoid losing any small components. Ensure that you have safety gear, such as gloves and goggles, to protect yourself during the repair.

Next, identify the specific problem by observing the unit’s performance. Listen for unusual sounds, check for leaks, or note any irregular behaviors. Document your findings, as this will assist in diagnosing the issue accurately.

Once the problem is identified, consult the relevant manuals or resources for specific guidance. Disassemble the unit carefully, keeping track of each component’s placement. Use labeled containers for screws and small parts to prevent confusion during reassembly.

Inspect each part for wear and damage. Replace any faulty components with high-quality replacements to ensure longevity. Clean all surfaces thoroughly to remove dirt and debris before reassembly.

After replacing necessary parts, reassemble the unit methodically, following your documentation. Ensure everything is securely fastened and properly aligned. Double-check all connections to prevent future issues.

Finally, conduct a test run to verify that the repairs were successful. Monitor the unit closely for any signs of malfunction. Regular maintenance will further enhance the performance and lifespan of your equipment.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward task when you know where to look. Various sources offer a range of options, from online retailers to local suppliers, ensuring you find what you need with ease.

Online Marketplaces: Websites like eBay and Amazon often have a vast selection of components. Searching with specific terms can yield excellent results and competitive pricing.

Specialty Retailers: Consider checking with stores dedicated to outdoor power equipment. They often stock a wide variety of necessary components and can provide expert advice.

Manufacturer Websites: Visiting the official site of the machinery can lead you to genuine replacements, ensuring compatibility and reliability.

Local Dealerships: Many areas have authorized dealerships that can supply genuine components. Establishing a relationship with a local dealer can be beneficial for future needs.

Online Forums and Communities: Engaging with enthusiasts in online forums can provide recommendations on where to find specific items, often including tips on best practices for installation.

By exploring these avenues, you can ensure that you acquire the right components for optimal performance.

Upgrading Your Kohler Engine

Enhancing the performance of your machinery can significantly improve its efficiency and longevity. By focusing on specific upgrades, you can elevate the overall functionality and reliability of your equipment. This section will explore essential modifications that can lead to improved output and better operation.

Performance Enhancements

One of the most effective ways to boost performance is by upgrading the fuel system. Replacing the stock carburetor with a high-performance version can lead to improved air-fuel mixture, resulting in increased power. Additionally, installing a premium air filter allows for better airflow, which enhances combustion and overall performance.

Durability Improvements

To ensure longevity, consider reinforcing key components with aftermarket upgrades. Using high-quality gaskets and seals can prevent leaks and maintain optimal operating conditions. Furthermore, investing in a better cooling system, such as an upgraded radiator, can help manage temperatures effectively, protecting vital parts from excessive heat.

By implementing these modifications, you can achieve a noticeable difference in how your machinery performs, ultimately leading to a more efficient and reliable experience.

Comparing Kohler to Other Brands

When evaluating various power solutions, it’s essential to consider the differences in performance, reliability, and maintenance among leading manufacturers. Each brand offers distinct advantages that cater to different user needs and preferences, making the selection process crucial for optimal outcomes.

Performance is often a primary factor in choosing a manufacturer. Some brands are renowned for their high-output capabilities, while others focus on fuel efficiency and lower emissions. Understanding these strengths can help users identify the best fit for their specific applications.

Reliability is another critical aspect. Certain manufacturers have built a reputation for durability and longevity, which can significantly impact long-term satisfaction and cost-effectiveness. Researching user reviews and expert evaluations can provide insights into which brands consistently perform well over time.

Additionally, maintenance requirements can vary widely. Some brands may offer more accessible servicing options or require less frequent attention, making them appealing for users who prefer convenience. Others might demand specialized knowledge, which could affect overall usability.

Ultimately, assessing these factors–performance, reliability, and maintenance–will lead to a more informed choice, ensuring that users select the right solution to meet their needs effectively.

Tips for Efficient Engine Performance

Maximizing the functionality of your machinery requires a few strategic practices. By understanding and implementing key techniques, you can enhance performance and ensure longevity.

Regular Maintenance

- Check and replace filters regularly.

- Inspect fluid levels and top off as needed.

- Clean air intake systems to prevent blockages.

Optimal Usage Practices

- Use the recommended fuel type for best results.

- Avoid overloading to maintain efficiency.

- Allow for proper warm-up before heavy use.