Comprehensive Guide to 5.3 Vortec Engine Parts Diagram

Delving into the intricate structure of a powerful automotive system reveals a fascinating interplay of various elements working in harmony. Each segment plays a crucial role in ensuring optimal functionality, enhancing performance, and contributing to overall efficiency. A thorough grasp of these components allows enthusiasts and professionals alike to appreciate the complexity involved in modern vehicular engineering.

Visual representations can significantly aid in comprehending how these different sections interconnect. By examining the layout and relationship between each component, one gains insights into the design principles that govern high-performance machinery. Understanding these configurations not only fosters a deeper appreciation for automotive technology but also equips individuals with the knowledge necessary for effective maintenance and upgrades.

Whether one is an aspiring mechanic or a seasoned professional, recognizing the essential features of a power system enhances the ability to troubleshoot issues and implement improvements. As we explore the specifics of this high-efficiency unit, we uncover the vital connections that contribute to its remarkable capabilities.

Understanding Vortec Engine Basics

This section delves into the fundamental components and workings of a specific type of powertrain used in various vehicles. By exploring its core elements, readers will gain insights into how these systems function and contribute to performance and efficiency. The design emphasizes a harmonious blend of power and reliability, making it a popular choice among enthusiasts and everyday drivers alike.

At the heart of this mechanical marvel lies a well-orchestrated assembly of features that enhances its capabilities. From the combustion chamber to the fuel delivery mechanism, each element plays a critical role in achieving optimal performance. Understanding these components can illuminate the intricacies of how power is generated and managed within the system.

Furthermore, examining the innovative technologies integrated into this design reveals advancements that have significantly improved its overall effectiveness. These innovations not only bolster performance but also ensure compliance with modern emission standards, showcasing a commitment to environmental responsibility while maintaining robust power output.

Ultimately, grasping the basics of this sophisticated system empowers users to appreciate its engineering prowess and the thought processes behind its construction, paving the way for informed decisions in maintenance, upgrades, and performance enhancements.

Key Components of Vortec Engines

Understanding the essential elements that contribute to the performance and efficiency of a modern power unit is crucial for enthusiasts and professionals alike. These crucial components work together to ensure optimal functionality, reliability, and longevity. Each element plays a unique role in the overall operation, impacting everything from fuel efficiency to power output.

Fuel Delivery System: This system is responsible for providing the necessary mixture of air and fuel for combustion. It includes components like the fuel injectors, fuel pump, and pressure regulator, which work in harmony to ensure precise fuel delivery under various operating conditions.

Ignition Assembly: The ignition assembly is vital for initiating the combustion process. It comprises spark plugs, ignition coils, and control modules that work together to generate a strong spark at the right moment, enhancing efficiency and performance.

Cooling Mechanism: Effective cooling is essential to maintain optimal operating temperatures. This system includes the radiator, water pump, and thermostat, which ensure that heat generated during operation is effectively dissipated, preventing overheating and potential damage.

Lubrication System: Proper lubrication reduces friction between moving parts, extending the lifespan of the unit. Key elements include the oil pump, oil filter, and various channels that distribute oil throughout the assembly, ensuring all critical areas are adequately lubricated.

Exhaust System: This system is responsible for directing exhaust gases away from the combustion chamber. It includes components such as the manifold, catalytic converter, and muffler, all designed to minimize emissions and optimize back pressure for improved performance.

By familiarizing oneself with these integral components, one can better appreciate the complexities involved in modern power units and their contributions to overall vehicle performance.

Common Applications of Vortec Engines

The versatile powertrains developed by the manufacturer are utilized in a wide array of vehicles and machinery, showcasing their adaptability and performance across different sectors. From personal transport to commercial use, these systems have made significant contributions to the automotive landscape.

Passenger Vehicles

These high-performance systems are commonly found in a variety of cars and trucks, offering a blend of efficiency and power. Their ability to deliver robust torque and horsepower makes them ideal for light-duty pickups and SUVs, catering to both everyday drivers and those needing additional towing capabilities.

Commercial and Industrial Applications

Beyond personal vehicles, these power sources are also integral to numerous commercial and industrial platforms. They are often used in larger trucks and vans, providing the reliability needed for heavy hauling and transportation. Additionally, their presence in equipment like generators and lawn care machinery highlights their functionality in diverse operational environments.

| Application | Vehicle Type | Benefits |

|---|---|---|

| Light-Duty Trucks | Pickup Trucks | High torque, towing capacity |

| SUVs | Sport Utility Vehicles | Efficiency and versatility |

| Commercial Vehicles | Delivery Vans | Durability, reliability |

| Generators | Portable Power Units | Consistent power output |

| Lawn Equipment | Riding Mowers | Fuel efficiency, performance |

Benefits of Vortec Engine Design

The innovative design of modern power units offers numerous advantages, making them a popular choice for various applications. Enhanced performance, efficiency, and reliability are just a few key aspects that contribute to their widespread acclaim. These advancements not only elevate the driving experience but also optimize fuel consumption and reduce emissions.

Improved Performance

One of the most significant benefits of this cutting-edge configuration is the remarkable power output it delivers. The optimized airflow and combustion process allow for a smoother and more responsive acceleration. This design ensures that the vehicle can handle a variety of driving conditions with ease, enhancing overall handling and stability.

Fuel Efficiency

Another compelling advantage lies in the ability to maximize fuel efficiency. With advanced engineering techniques, these power units reduce fuel consumption without sacrificing power. This not only leads to cost savings for drivers but also contributes to a smaller environmental footprint, aligning with modern sustainability goals.

| Benefit | Description |

|---|---|

| Performance | Enhanced power output and acceleration response. |

| Efficiency | Optimized fuel consumption leading to cost savings. |

| Reliability | Durable construction ensuring long-term operation. |

| Versatility | Suitable for various applications and driving conditions. |

How to Read Engine Diagrams

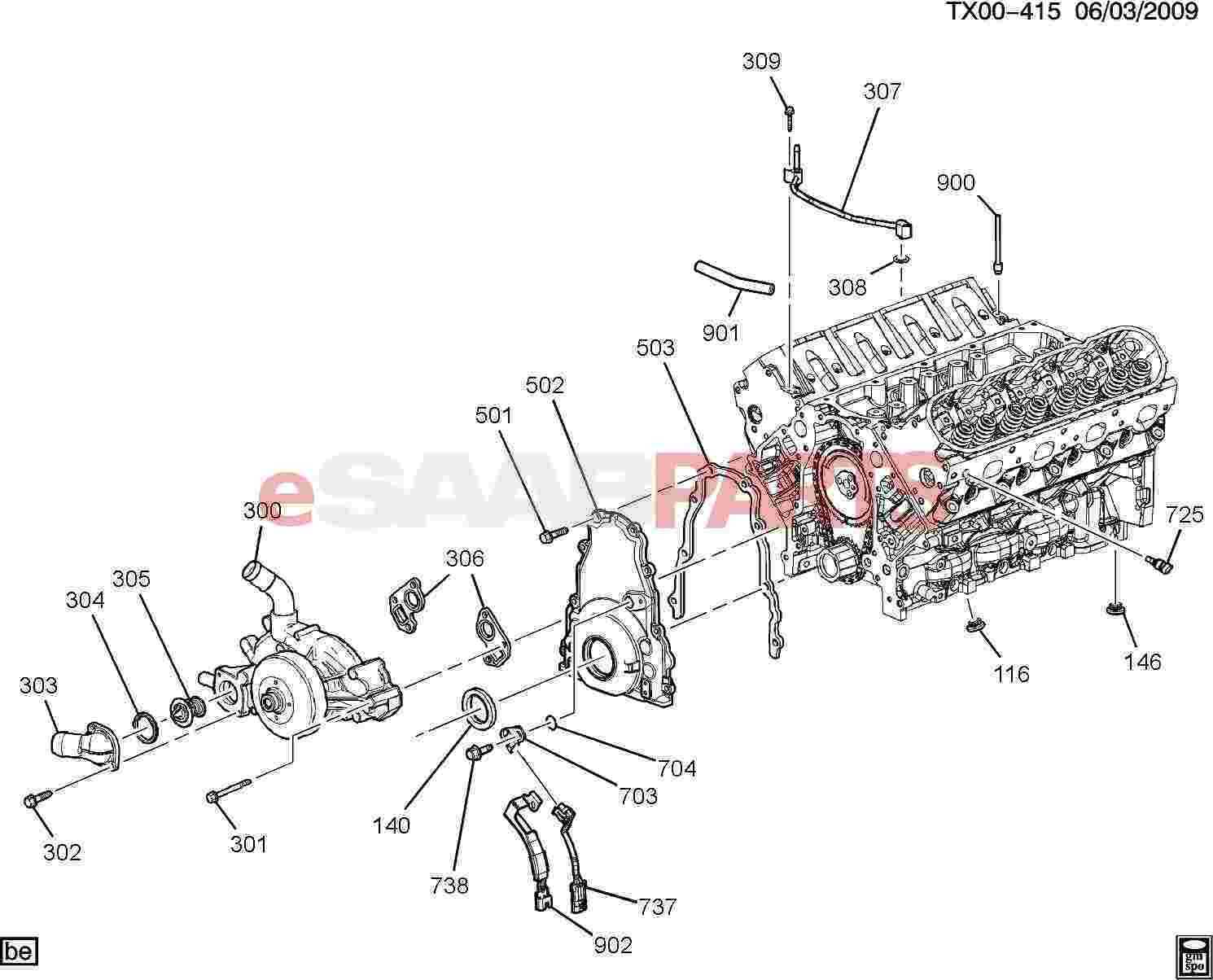

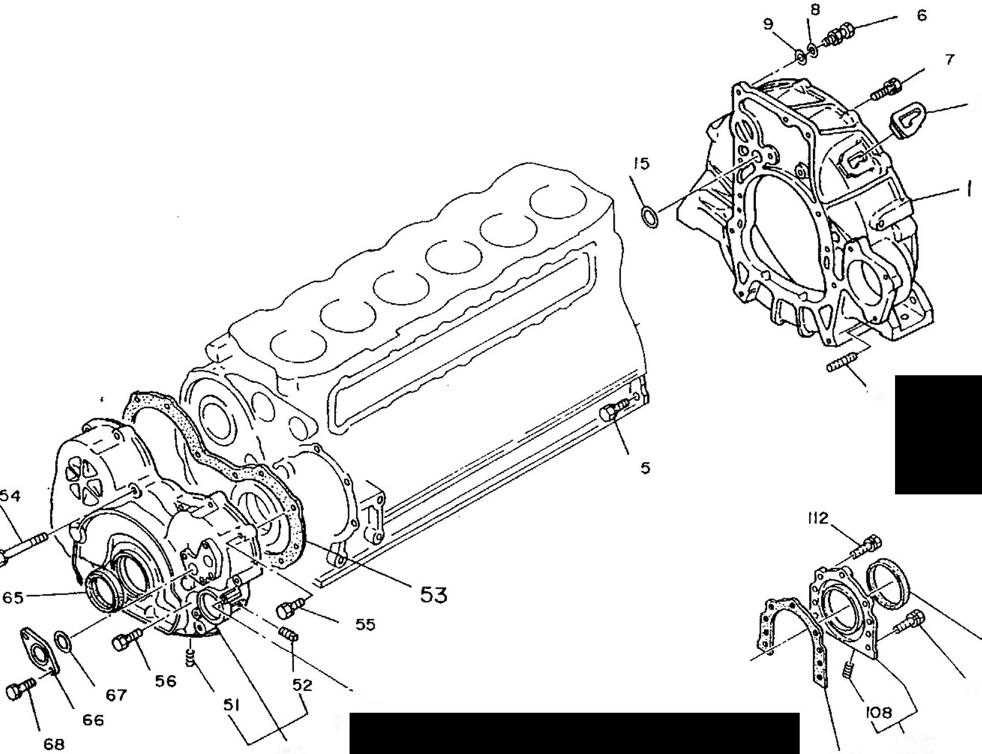

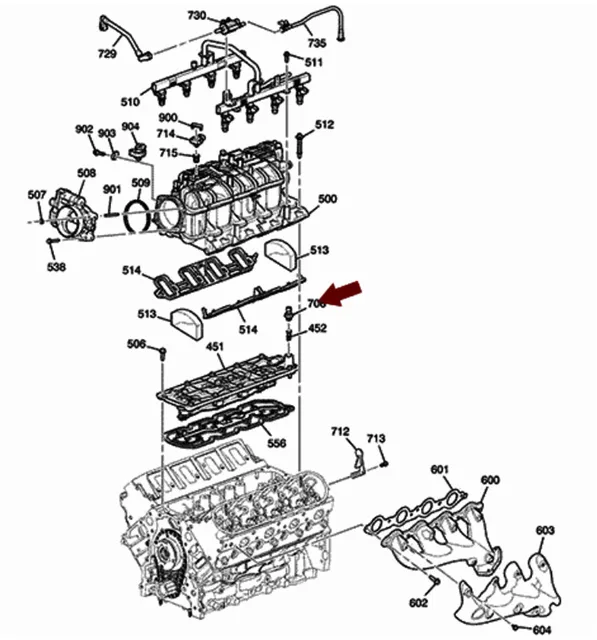

Understanding technical illustrations related to mechanical systems can be daunting, yet essential for maintenance and repair tasks. These visual representations convey crucial information about various components and their interconnections, making them invaluable resources for both novices and seasoned mechanics alike.

To effectively interpret these illustrations, one should start by familiarizing themselves with the symbols and notations used. Each symbol typically represents a specific component, while lines indicate relationships or connections between them. Learning these conventions is key to deciphering the overall structure.

Next, pay attention to the labeling. Components are often annotated with unique identifiers or numbers that correspond to detailed descriptions found in accompanying documentation. Cross-referencing these labels helps in gaining a deeper understanding of each part’s function within the system.

Additionally, it’s important to consider the orientation and layout of the illustration. Understanding how the parts fit together in a three-dimensional space can aid in visualizing the assembly process. Analyzing the flow of fluids or energy through the system can also provide insight into operational mechanics.

Finally, practice is essential. The more you work with these visual aids, the more proficient you will become. Whether for troubleshooting or enhancing knowledge, mastering the skill of reading technical illustrations will significantly enhance your mechanical expertise.

Identifying Parts in Vortec Engines

Understanding the various components of a power unit is essential for both enthusiasts and professionals. Each element plays a crucial role in ensuring optimal performance and efficiency. Familiarity with these elements can lead to better maintenance and enhancement of the unit’s capabilities.

Here are key components to recognize:

- Intake Manifold: Responsible for directing air-fuel mixture to the cylinders.

- Throttle Body: Controls the amount of air entering the combustion chamber.

- Fuel Injectors: Deliver fuel directly into the combustion chamber for precise mixing.

- Ignition Coil: Provides the necessary spark to ignite the air-fuel mixture.

- Cylinder Heads: Houses valves and combustion chambers, playing a vital role in air flow.

Identifying and understanding these components can significantly enhance one’s ability to troubleshoot issues and optimize performance. For effective analysis, it’s beneficial to consult detailed schematics and manuals that illustrate the arrangement and function of each component.

In addition, familiarizing oneself with the layout of the system helps in recognizing signs of wear or malfunction. Regular inspections and maintenance can prolong the lifespan and improve the functionality of the overall system.

Maintenance Tips for Vortec Engines

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s power source. Implementing a systematic maintenance routine can help prevent costly repairs and enhance reliability. Here are some valuable suggestions to keep in mind.

- Check fluid levels regularly: Maintain appropriate levels of oil, coolant, and transmission fluid to ensure smooth operation.

- Change oil and filters: Replace oil and filters according to the manufacturer’s recommendations to promote efficient lubrication.

- Inspect belts and hoses: Look for signs of wear, cracking, or fraying, and replace any damaged components promptly.

- Monitor cooling system: Keep an eye on the radiator, hoses, and coolant to prevent overheating issues.

- Examine air intake: Clean or replace air filters as necessary to ensure optimal airflow and engine performance.

By following these maintenance practices, you can significantly enhance the performance and durability of your vehicle’s power unit.

Vortec Engine vs. Other Engine Types

The comparison of various powertrains highlights distinct characteristics that cater to different driving experiences and requirements. Each configuration presents unique benefits and challenges, influencing performance, efficiency, and reliability.

One significant advantage of the discussed variant is its robust design, which typically leads to enhanced torque delivery. This feature makes it particularly appealing for applications demanding substantial hauling capabilities or off-road performance.

In contrast, alternative systems may focus on fuel efficiency or high-rev performance, catering to a different segment of enthusiasts. These engines often employ advanced technologies such as turbocharging or hybrid systems to maximize output while minimizing consumption.

Durability is another area where the former stands out, frequently incorporating heavy-duty components that contribute to a longer lifespan. This resilience can be a decisive factor for consumers prioritizing longevity and lower maintenance costs.

Ultimately, the choice among these various types depends on specific needs–whether it be for everyday commuting, heavy-duty work, or spirited driving. Understanding the distinctions aids buyers in making informed decisions that align with their driving preferences.

Performance Upgrades for Vortec Engines

Enhancing the capabilities of a specific power unit can significantly elevate driving experience and overall performance. Various modifications can be made to achieve higher horsepower, improved torque, and better efficiency. This section outlines several popular upgrades that can optimize your vehicle’s performance.

- Cold Air Intake: Replacing the factory air intake with a high-performance cold air system can improve airflow, allowing for better combustion and increased power output.

- High-Performance Exhaust System: Upgrading to a more efficient exhaust system reduces back pressure and enhances exhaust flow, which can result in better performance and a more aggressive sound.

- ECU Tuning: Custom tuning of the electronic control unit can optimize fuel delivery and ignition timing, maximizing the performance potential of the unit.

- Upgraded Camshaft: Installing a performance camshaft can alter the engine’s valve timing and lift, leading to increased horsepower and torque at higher RPMs.

- Performance Headers: Aftermarket headers can improve exhaust flow, reducing restrictions and enhancing overall efficiency.

These modifications can yield substantial improvements in power and responsiveness. When considering enhancements, it’s crucial to ensure that components are compatible and installed correctly for optimal results.

Common Issues with Vortec Parts

Understanding the typical challenges associated with various components can help in effective maintenance and enhance performance. These components, often found in a range of vehicles, may experience several recurring problems that can impact their functionality.

Frequent Problems

- Oil Leaks: Seals and gaskets may wear out, leading to oil seepage and potential engine damage.

- Overheating: Inefficient cooling systems can result in excessive heat, affecting overall performance.

- Fuel Delivery Issues: Clogs in fuel injectors or pumps can hinder proper fuel flow.

- Electrical Failures: Wiring and connectors may degrade over time, causing misfires or starting issues.

Prevention and Maintenance

- Regular Inspections: Conducting routine checks can help identify potential issues before they escalate.

- Timely Replacements: Replacing worn-out seals, gaskets, and filters ensures optimal performance.

- Fluid Changes: Regularly changing oil and coolant can prevent overheating and mechanical failures.

- Electrical System Care: Maintaining wiring and connections can prevent many electrical-related problems.

Repairing Vortec Engine Components

Maintaining the integrity of internal mechanisms is crucial for optimal performance and longevity. A thorough understanding of the individual components and their functionality aids in effective repairs and enhancements.

Before commencing repairs, it’s essential to gather the right tools and materials. Proper preparation ensures a smoother process and better results.

- Diagnostic Tools: Use to identify issues accurately.

- Replacement Materials: Acquire high-quality components that meet specifications.

- Standard Hand Tools: Wrenches, sockets, and screwdrivers are necessary for disassembly and assembly.

Follow a systematic approach to address repairs:

- Assessment: Evaluate the condition of each component and pinpoint specific problems.

- Disassembly: Carefully take apart the assembly to access the components needing attention.

- Cleaning: Remove dirt and debris from parts to ensure they function properly.

- Replacement: Install new or refurbished components where necessary.

- Reassembly: Put everything back together meticulously, ensuring all fasteners are secure.

After repairs, testing is critical to confirm that everything operates as intended. Regular maintenance checks can prevent future issues and extend the lifespan of the system.

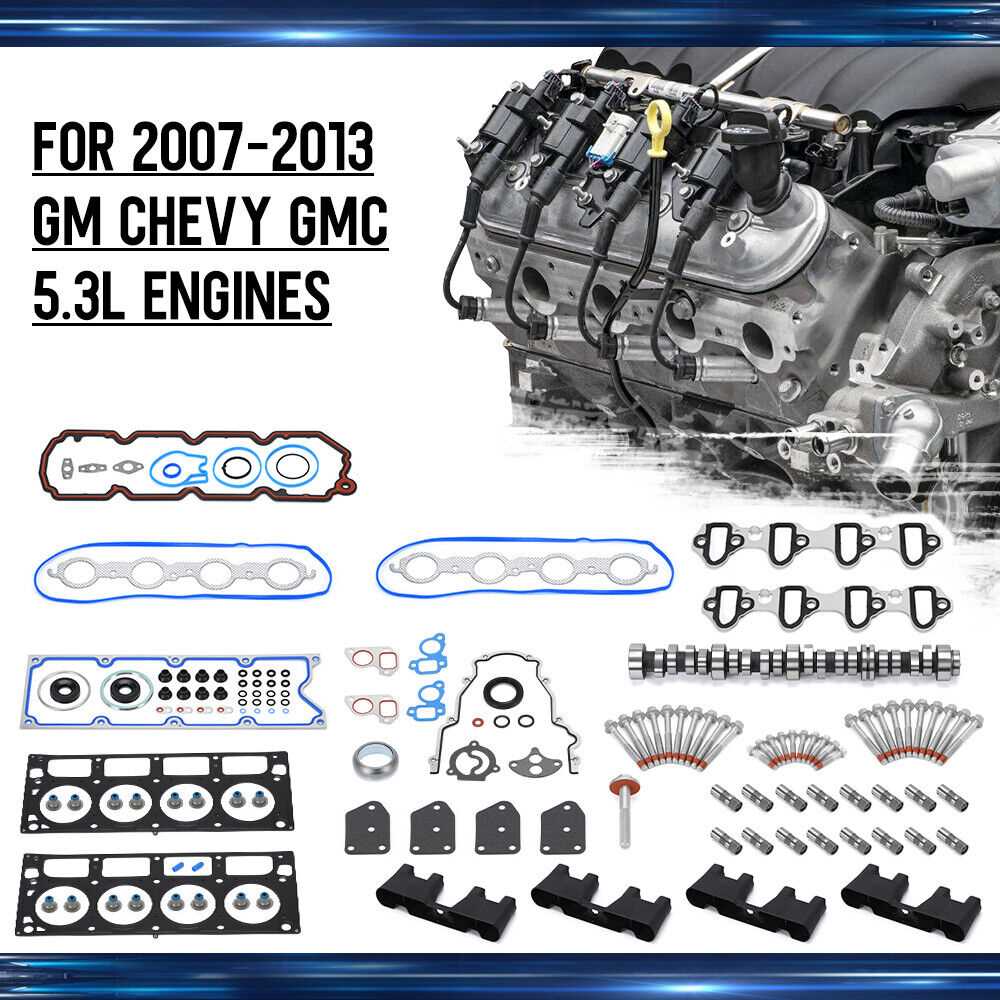

Aftermarket Parts for Vortec Engines

When enhancing performance and reliability, many enthusiasts turn to alternative components designed to elevate the capabilities of their vehicles. The market is flooded with options that promise increased efficiency, power, and durability. Selecting the right enhancements can make a significant difference in overall performance and driving experience.

Types of Aftermarket Enhancements

Various categories of enhancements cater to different needs and preferences. Below are some popular options:

- Intake Systems: Upgraded air intake systems improve airflow, leading to better combustion and increased horsepower.

- Exhaust Components: High-performance exhaust systems reduce back pressure, enhancing power output and giving a more aggressive sound.

- Tuning Chips: These devices optimize fuel maps and ignition timing, allowing for improved performance and fuel efficiency.

- Cylinder Heads: Aftermarket cylinder heads can provide better airflow and increased compression ratios, resulting in enhanced performance.

- Camshafts: Upgraded cam profiles can change the engine’s power band, making it more responsive at higher RPMs.

Benefits of Upgrading

Investing in these components offers several advantages:

- Enhanced Performance: Many upgrades can significantly increase horsepower and torque.

- Improved Fuel Efficiency: Certain modifications can lead to better fuel economy, saving money in the long run.

- Customization: Upgrades allow for a more personalized driving experience, tailored to individual preferences.

- Increased Durability: Many aftermarket options are designed to withstand higher stress levels, prolonging the lifespan of the vehicle.

Choosing the right enhancements can transform the driving experience, making it essential to research and select high-quality alternatives that suit specific goals and driving styles.

Future of Vortec Engine Technology

The advancement of internal combustion technology promises to revolutionize performance and efficiency in automotive applications. As manufacturers strive to meet stringent environmental standards while enhancing power delivery, innovations in design and materials are crucial for achieving these goals. This section explores potential developments that could redefine traditional powertrains and their impact on future mobility.

Innovative Materials and Design

Future advancements may focus on the use of lightweight materials and advanced manufacturing techniques. By incorporating composites and alloys, manufacturers can reduce weight, thereby improving fuel efficiency without sacrificing durability. Additionally, 3D printing technology may enable more complex geometries, allowing for enhanced airflow and combustion efficiency.

Hybrid and Electrification Integration

The integration of hybrid systems is likely to play a significant role in the evolution of traditional power sources. By combining electric and conventional propulsion methods, vehicles can achieve better fuel economy and reduced emissions. This transition will require a rethinking of conventional architectures to accommodate new power sources seamlessly.

| Aspect | Current Focus | Future Potential |

|---|---|---|

| Materials | Steel and Aluminum | Composites and Alloys |

| Performance | Power Output | Efficiency and Responsiveness |

| Emissions | Reduction Strategies | Zero Emission Solutions |

| Powertrain | Conventional Systems | Hybrid and Electric Integration |