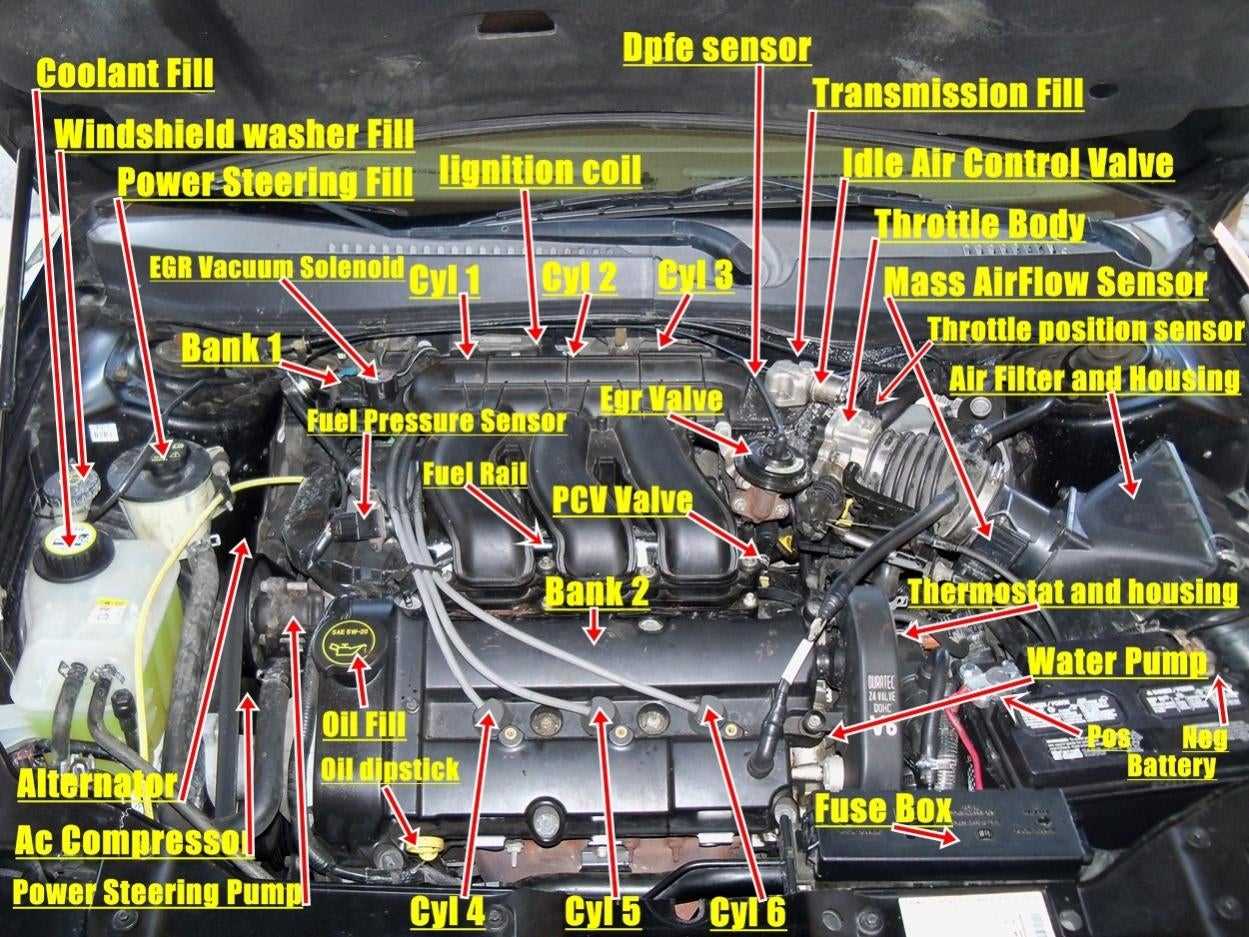

Essential Car Engine Parts Names Illustrated with Diagrams

The intricate system that powers modern vehicles consists of various crucial elements, each playing a vital role in ensuring optimal performance and efficiency. These components work in harmony to convert fuel into motion, making transportation both reliable and effective. Understanding these essentials not only enhances one’s appreciation of automotive technology but also empowers owners to maintain their vehicles more effectively.

Exploring the fundamental components can reveal a wealth of information about how mechanics operate and interact. Each element has a specific function, contributing to the overall efficacy of the system. From ignition systems to fuel delivery mechanisms, recognizing these individual roles allows for a deeper insight into the engineering marvels that facilitate our daily commutes.

To aid in this exploration, visual representations are invaluable. Diagrams serve as a guide, illustrating the relationships and arrangements of these essential elements. Accompanied by detailed explanations, such resources can enhance one’s understanding and facilitate learning for enthusiasts and novices alike.

Essential Car Engine Components Explained

Understanding the key components of a vehicle’s power unit is crucial for both enthusiasts and everyday users. Each element plays a vital role in the overall functionality and efficiency, contributing to performance and longevity. Below is a detailed examination of these fundamental elements, illustrating their significance in the mechanics of motion.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides structural support. |

| Pistons | Convert fuel energy into mechanical work by moving up and down. |

| Cylinder Head | Covers the top of the cylinders, containing vital components such as valves. |

| Valves | Regulate the intake of air-fuel mixture and the exhaust of combustion gases. |

| Camshaft | Controls the timing of valve openings and closings. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber. |

| Ignition System | Initiates combustion by creating a spark at the right moment. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

| Exhaust System | Directs and treats the gases produced during combustion, minimizing emissions. |

Each of these components works in harmony, showcasing the intricate design and engineering that allows for smooth operation and reliability on the road.

Understanding Engine Functionality Basics

The core principle behind any machine designed for propulsion lies in its ability to convert fuel into motion. This process involves a series of intricate components working in harmony to produce power efficiently. A fundamental grasp of how these mechanisms interact provides insight into overall performance and maintenance requirements.

Power Generation Process

At the heart of propulsion lies the transformation of chemical energy into mechanical energy. This begins with the introduction of fuel and air into a confined space, where they undergo a controlled reaction. The resulting force drives components that ultimately translate this energy into movement.

Key Components and Their Roles

Several critical elements contribute to the effective functioning of this system. Intake systems facilitate the entry of the necessary mixture, while combustion chambers allow for the reaction to take place. Following this, exhaust systems expel byproducts, ensuring the cycle can continue without obstruction. Understanding each component’s role clarifies how they collectively maintain optimal operation.

Key Parts of an Internal Combustion Engine

An internal combustion mechanism consists of several essential components that work in harmony to facilitate the conversion of fuel into kinetic energy. Understanding these crucial elements helps to appreciate how this complex system operates effectively.

- Combustion Chamber: The space where fuel and air mix and ignite, producing high-pressure gases.

- Piston: A cylindrical element that moves up and down within the chamber, transferring force to the crankshaft.

- Crankshaft: A rotating shaft that converts linear motion from the pistons into rotational energy.

- Valves: Components that regulate the intake of air and the expulsion of exhaust gases, ensuring efficient operation.

- Camshaft: A shaft that operates the valves, synchronized with the movement of the pistons.

Each component plays a significant role in the overall function of the system, contributing to the performance and efficiency of the entire setup.

- Fuel Injection System: Responsible for delivering the correct amount of fuel into the combustion chamber.

- Ignition System: Produces a spark that ignites the air-fuel mixture, initiating the combustion process.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

- Exhaust System: Channels waste gases away from the chamber, minimizing emissions and noise.

A thorough understanding of these integral components provides insight into the mechanics of this dynamic system, showcasing the interplay between each element to achieve efficient power generation.

Types of Engine Diagrams to Explore

Understanding the various visual representations of mechanical systems is essential for anyone looking to grasp their intricacies. Each type of illustration serves a unique purpose, helping enthusiasts and professionals alike to visualize and analyze different aspects of these complex structures.

- Block Diagrams: Simplified representations highlighting major components and their relationships.

- Schematic Diagrams: Detailed layouts illustrating the flow of fluids and electrical connections.

- Exploded Views: Showcasing individual elements separated to demonstrate assembly and interaction.

- Cutaway Diagrams: Providing a cross-sectional view to reveal internal mechanisms.

Each diagram type offers a unique perspective, allowing users to delve deeper into the mechanics and enhance their understanding of these intricate systems.

Importance of Engine Parts Identification

Recognizing the components of a power unit is crucial for efficient maintenance and repair. Proper identification enables individuals to address issues promptly, ensuring longevity and optimal performance. Understanding these elements also enhances overall mechanical knowledge, allowing for informed decision-making during service.

Enhanced Maintenance Efficiency

When individuals can accurately identify each segment, routine checks and repairs become more straightforward. This efficiency minimizes downtime and reduces the likelihood of extensive damage.

Informed Decision-Making

Knowledge of specific functionalities aids in selecting the right replacement or upgrade. This understanding can lead to better performance and satisfaction with the vehicle’s capabilities.

| Component | Function |

|---|---|

| Piston | Converts pressure into mechanical energy |

| Crankshaft | Transforms linear motion into rotational motion |

| Camshaft | Regulates valve timing |

How to Read Engine Diagrams Effectively

Understanding technical illustrations can greatly enhance your knowledge and skills. These visuals provide essential insights into the various components and their interrelations, allowing for a clearer grasp of how everything functions together. Mastering the interpretation of these illustrations will enable you to troubleshoot and maintain systems more effectively.

Key Elements to Focus On

- Symbols: Familiarize yourself with the common icons used. Each symbol represents a specific component or function.

- Connections: Pay attention to lines and arrows that indicate relationships and flow. They show how elements interact.

- Labels: Look for annotations that provide additional information. These can clarify the role of each component.

- Scale: Consider the size representation. Understanding scale helps in visualizing real-life dimensions.

Steps to Analyze Visuals

- Start with an overview. Get a general idea of the layout before diving into specifics.

- Identify key components by locating symbols and labels.

- Trace connections. Follow lines to understand how parts interact with each other.

- Refer to a legend or key if available. It can help clarify unfamiliar symbols.

- Practice by comparing with real-life examples to reinforce your understanding.

By honing your ability to read these illustrations, you will enhance your practical knowledge and be better prepared for hands-on tasks.

Common Engine Issues and Solutions

Many individuals encounter various challenges related to their vehicles, often stemming from underlying mechanical malfunctions. Understanding these common problems and their potential remedies can enhance performance and longevity. This section explores typical issues and effective solutions to keep your machine running smoothly.

Overheating

Excessive heat can lead to severe damage if not addressed promptly. Regular checks on coolant levels, thermostat function, and radiator integrity are essential. If overheating persists, consider flushing the cooling system or replacing faulty components.

Unusual Noises

Strange sounds can indicate mechanical failure or wear. Listen for knocking, rattling, or hissing noises, which may suggest issues like loose belts, worn bearings, or exhaust leaks. Regular maintenance and timely inspections can help identify and resolve these concerns before they escalate.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s core mechanisms requires consistent care and attention. Proper upkeep can significantly extend the lifespan of essential components and enhance overall performance. Here are some key practices to consider for optimal functioning.

| Tip | Description |

|---|---|

| Regular Oil Changes | Frequent replacement of lubricant prevents buildup and reduces friction. |

| Check Fluid Levels | Monitor coolant, brake, and transmission fluids to ensure they are at appropriate levels. |

| Inspect Filters | Replace air and fuel filters periodically to maintain efficiency and performance. |

| Tire Maintenance | Ensure proper tire pressure and tread depth to support balanced handling and safety. |

| Regular Tune-Ups | Schedule inspections to address minor issues before they escalate into major problems. |

Engine Parts and Their Functions Explained

Understanding the components that make up a power-generating mechanism is essential for grasping how they operate efficiently. Each segment plays a crucial role in the overall functionality, contributing to performance, fuel efficiency, and longevity. This section aims to clarify the specific duties of these individual segments and their importance in the system.

The heart of the mechanism, responsible for converting fuel into motion, relies heavily on the combustion chamber. Here, the mixture of air and fuel ignites, creating the force needed to drive the entire system. Supporting this are pistons, which move in response to the explosions, translating linear motion into rotational energy.

The crankshaft takes this rotational energy and converts it into usable power, transferring it to the drive system. Meanwhile, the camshaft coordinates the timing of valve openings and closings, ensuring optimal airflow and combustion efficiency. Additionally, the timing belt synchronizes these two crucial components, maintaining harmony in their operations.

Cooling systems play a vital role in regulating temperature, preventing overheating and ensuring stable performance. Lubrication systems minimize friction between moving elements, enhancing efficiency and reducing wear. Each of these components works in concert, showcasing the complexity and ingenuity behind modern mechanisms.

In summary, each segment serves a distinct purpose, collectively ensuring the system operates smoothly and effectively. A deeper understanding of these components reveals the intricate design that allows for high performance and reliability.

Comparative Analysis of Engine Types

This section explores the various forms of internal combustion mechanisms, highlighting their distinct characteristics, advantages, and limitations. Understanding these differences aids in making informed choices based on performance needs and environmental considerations.

Types of Internal Combustion Mechanisms

- Gasoline Mechanisms

- Diesel Mechanisms

- Rotary Mechanisms

- Hybrid Mechanisms

Key Factors for Comparison

- Efficiency: Examines fuel utilization and overall performance.

- Emissions: Analyzes environmental impact and regulatory compliance.

- Maintenance: Considers the complexity and frequency of service requirements.

- Power Output: Evaluates performance capabilities under various conditions.

Resources for Engine Part Diagrams

Understanding the intricate components of a vehicle’s power unit is essential for both enthusiasts and professionals. Access to quality resources can significantly enhance one’s knowledge and repair skills.

- Online Databases: Websites dedicated to automotive repair often feature extensive libraries of illustrations and schematics.

- Technical Manuals: Printed or digital manuals provide detailed views and descriptions of specific assemblies.

- Video Tutorials: Platforms like YouTube offer visual guides that showcase assembly and disassembly procedures.

- Forums and Community Groups: Online communities can be invaluable for sharing resources and insights from fellow enthusiasts.

Utilizing these resources can lead to a deeper understanding and more efficient maintenance practices.

Future Innovations in Engine Design

The landscape of propulsion technology is poised for transformative changes, driven by advancements in materials, energy sources, and design methodologies. As the quest for efficiency and sustainability intensifies, innovative solutions are emerging, promising to redefine performance and environmental impact. This section explores potential breakthroughs that may shape the future of vehicular mobility.

Emerging Technologies

Numerous groundbreaking technologies are on the horizon, offering fresh perspectives on propulsion systems. From alternative energy sources to enhanced computational models, the potential for significant improvements is vast. Key innovations include:

| Innovation | Description |

|---|---|

| Electric Propulsion | Utilizing advanced batteries and electric motors to achieve higher efficiency and reduced emissions. |

| Hydrogen Fuel Cells | Converting hydrogen into electricity, providing a clean alternative that produces only water vapor as a byproduct. |

| Composite Materials | Implementing lightweight, high-strength materials to improve efficiency and performance without compromising durability. |

| Smart Systems | Integrating artificial intelligence to optimize performance, enhance diagnostics, and improve user interaction. |

Design Innovations

Revolutionary design concepts are also emerging, aimed at maximizing efficiency and performance. These include:

- Modular structures that allow for easy upgrades and repairs.

- 3D printing techniques for rapid prototyping and custom component manufacturing.

- Bio-inspired designs that mimic nature’s efficiency to enhance aerodynamics and fuel usage.

The future of propulsion systems promises to be an exciting amalgamation of technology and creativity, paving the way for smarter, cleaner, and more efficient mobility solutions.