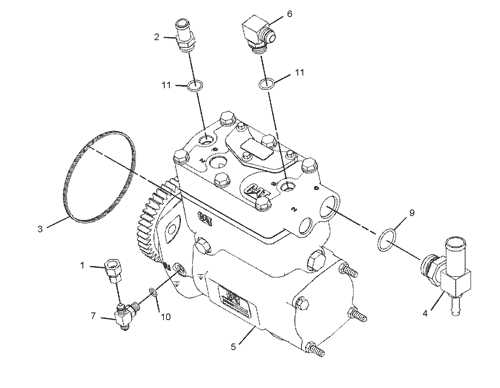

Caterpillar C15 Engine Parts Diagram Overview

When it comes to high-performance machinery, grasping the intricate structure and functioning of its components is essential for maintenance and troubleshooting. Each element plays a crucial role in the overall operation, contributing to efficiency and durability. This section aims to enhance your knowledge of these vital structures, ensuring optimal performance.

Visual representations of mechanical layouts can significantly aid in comprehending how different elements interact within complex systems. By analyzing these illustrations, users can quickly identify parts and their respective functions, facilitating better upkeep and repairs. This understanding ultimately leads to improved longevity and reliability.

In the following segments, we will delve into various components, illustrating their positions and relationships. Whether you are a technician, an enthusiast, or simply curious, mastering this knowledge is the ultimate step toward effective machinery management.

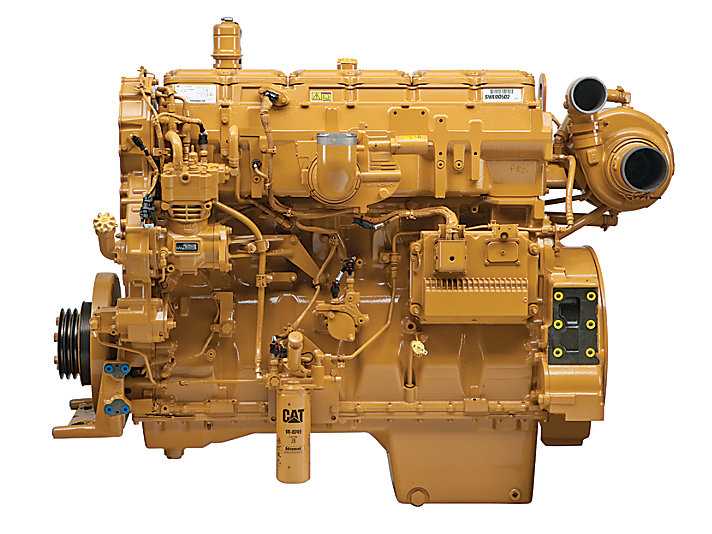

Caterpillar C15 Engine Overview

This section provides a comprehensive insight into a robust power unit designed for high performance in various applications. Renowned for its reliability and efficiency, this model has gained popularity in heavy-duty machinery, ensuring optimal functionality in challenging environments.

Key Features

Equipped with advanced technology, this power unit boasts impressive torque and horsepower ratings. Its durable construction allows it to withstand extreme conditions while maintaining fuel efficiency, making it a preferred choice among professionals.

Applications

This versatile unit is utilized across multiple sectors, including construction, mining, and transportation. Its adaptability ensures that it meets the diverse demands of different industries, proving essential for operational success.

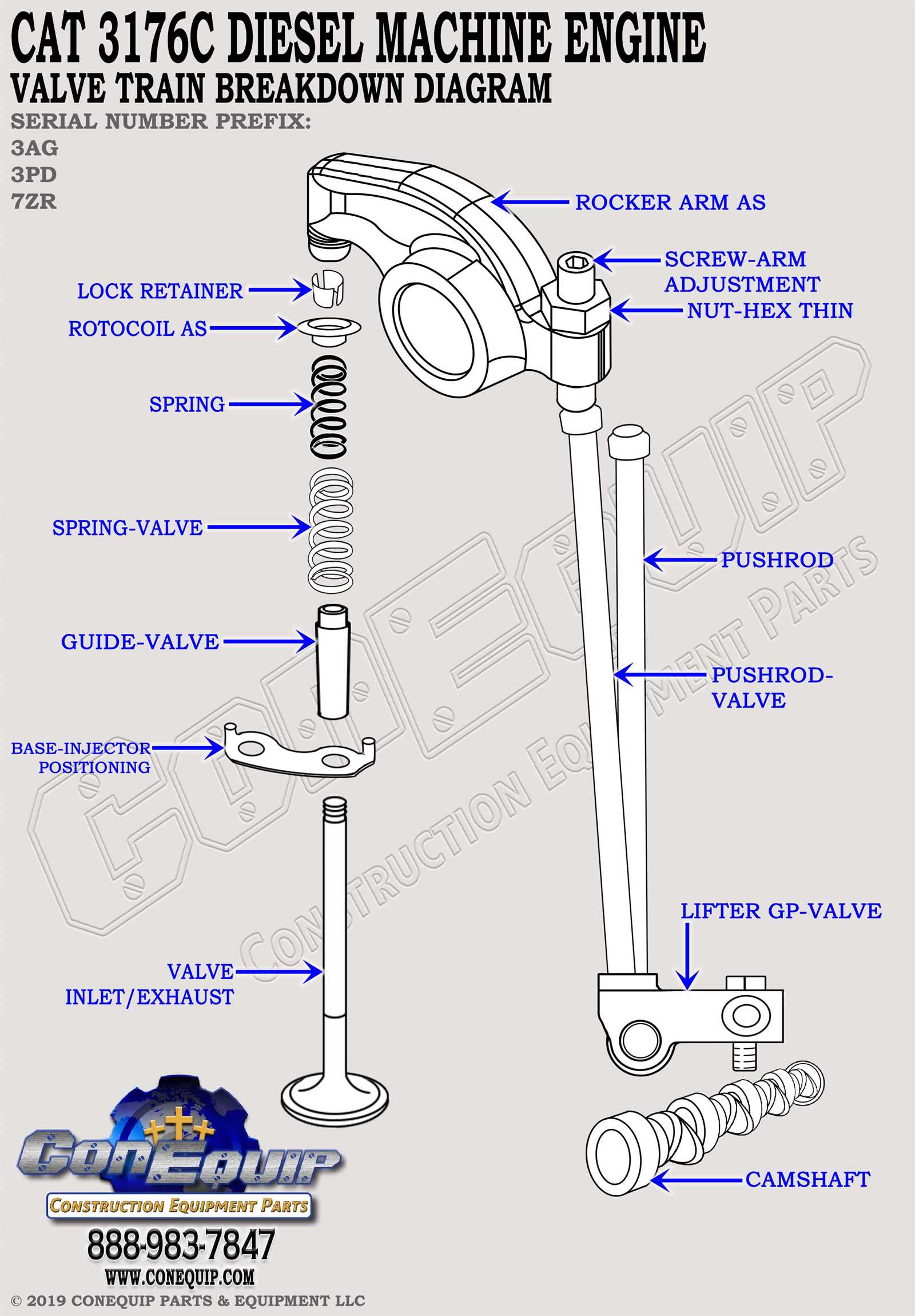

Understanding Engine Components

In the realm of machinery, the various elements that work together are crucial for optimal performance and longevity. Each component has a specific role, contributing to the overall functionality and efficiency of the system. Recognizing how these individual pieces interact can enhance comprehension and facilitate better maintenance practices.

Key Components and Their Functions

Among the primary elements are the combustion chambers, where the fuel-air mixture ignites, creating power. The crankshaft plays a pivotal role in converting this energy into mechanical movement. Additionally, the timing system ensures that all actions are synchronized, maximizing output and minimizing wear.

Maintenance and Care

Understanding these components is essential for effective upkeep. Regular checks can prevent unexpected failures and prolong the lifespan of the machinery. Familiarity with each section’s responsibilities allows operators to identify potential issues early, ensuring smooth operation and reducing repair costs.

Key Parts of the C15 Engine

This section focuses on the essential components that contribute to the functionality and performance of this powerful machine. Understanding these crucial elements is vital for maintenance and optimization, ensuring the unit operates smoothly and efficiently.

At the heart of the unit lies the combustion chamber, where fuel mixes with air to generate power. The piston, connected to the crankshaft, converts this energy into mechanical motion. Additionally, the cooling system is indispensable, regulating temperature to prevent overheating.

The lubrication system ensures all moving parts function harmoniously by reducing friction, while the fuel delivery mechanism accurately supplies the necessary fuel. Lastly, the exhaust system effectively channels away byproducts, maintaining optimal performance.

Function of the Fuel System

The fuel system plays a crucial role in the overall performance and efficiency of a mechanical unit. It is responsible for storing, filtering, and delivering the proper amount of fuel to facilitate optimal combustion. This process ensures that the power generation mechanism operates smoothly and reliably, enhancing overall functionality.

In essence, the fuel system can be divided into several key components, each serving a specific purpose in the fuel management process. Understanding these parts helps to appreciate their contributions to the system’s effectiveness.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel until needed for combustion. |

| Fuel Pump | Transfers fuel from the tank to the injection system. |

| Fuel Filter | Removes impurities from the fuel to protect the injection system. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber. |

| Pressure Regulator | Maintains optimal fuel pressure for efficient operation. |

Each element within the fuel system must function effectively to ensure that the unit operates at peak performance, contributing to overall efficiency and reliability.

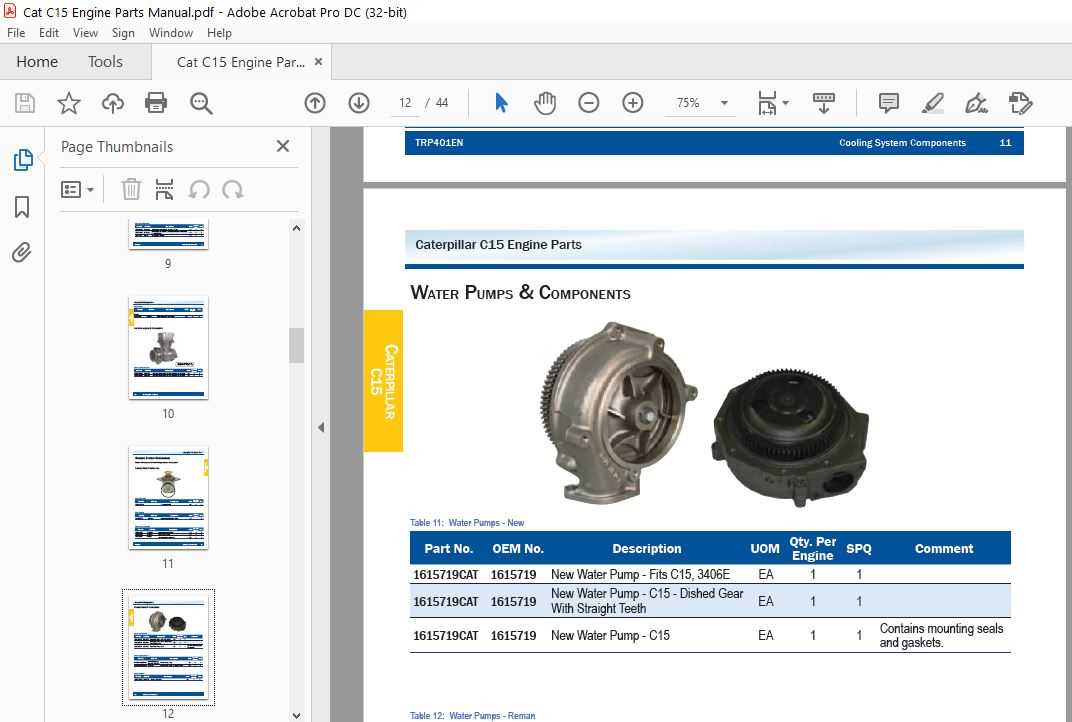

Importance of the Cooling System

The cooling system plays a crucial role in maintaining optimal performance and longevity of mechanical systems. Its primary function is to regulate temperature, preventing overheating, which can lead to significant damage and reduced efficiency. A well-designed cooling mechanism ensures that all components operate within their designated temperature range, promoting reliability and stability.

Heat management is essential for preventing wear and tear. When temperatures rise excessively, materials can expand and warp, leading to failures that may require costly repairs. Furthermore, elevated heat levels can affect the viscosity of lubricants, compromising their ability to protect moving parts. Therefore, effective temperature control is vital for the overall health of the system.

Additionally, a functioning cooling mechanism enhances performance by allowing for optimal power output. Systems that run too hot can experience reduced efficiency, resulting in lower output and increased fuel consumption. By ensuring that all components stay cool, the system can operate at its peak, maximizing productivity.

In summary, the significance of an efficient cooling solution cannot be overstated. It safeguards against overheating, prolongs the lifespan of components, and improves overall operational efficiency. Regular maintenance and monitoring of the cooling system are imperative for sustained performance.

Common Electrical Components Explained

Understanding the various electrical components found in machinery is crucial for effective maintenance and troubleshooting. Each element plays a specific role in ensuring smooth operation, and familiarity with their functions can greatly enhance performance and reliability.

Relays

Relays act as switches that control a circuit by opening and closing in response to an electrical signal. They help manage high-current circuits by using a low-power signal to operate them, ensuring safety and efficiency.

Sensors

Sensors are devices that detect changes in the environment and convert them into signals that can be read by a control system. Common types include temperature, pressure, and proximity sensors, each playing a vital role in monitoring and optimizing system performance.

Exploring the Lubrication System

The lubrication system plays a crucial role in maintaining optimal performance and longevity of machinery. By ensuring that all moving components are adequately coated with oil, it reduces friction, minimizes wear, and prevents overheating. This system is vital for enhancing efficiency and reliability in operations.

Key Components

Essential elements of the lubrication mechanism include the oil pump, filters, and channels. The pump circulates oil throughout the system, while filters remove impurities, ensuring clean fluid reaches critical areas. The channels facilitate the flow of lubricant to various components, providing necessary protection against damage.

Importance of Regular Maintenance

Consistent maintenance of the lubrication system is imperative. Regular checks and timely oil changes can prevent potential failures and extend the lifespan of machinery. Monitoring oil levels and quality also contributes significantly to the overall health and efficiency of the equipment.

Maintenance Tips for C15 Parts

Regular upkeep is essential for ensuring optimal performance and longevity of crucial components. By following a few straightforward guidelines, users can enhance the reliability and efficiency of their machinery.

- Conduct routine inspections to identify wear and tear early.

- Keep all areas clean and free of debris to prevent damage.

- Replace worn components promptly to avoid further issues.

Additionally, consider the following:

- Follow manufacturer recommendations for lubrication schedules.

- Use high-quality fluids and filters to ensure maximum protection.

- Monitor operating conditions closely for any irregularities.

By adhering to these practices, operators can maintain efficiency and reduce the risk of unexpected failures.

Identifying Wear and Tear Signs

Recognizing indicators of degradation in mechanical systems is essential for maintaining optimal performance and extending longevity. Regular inspections can help pinpoint issues before they escalate, ensuring smooth operation and reducing costly repairs.

Here are some common signs to look for:

- Unusual Noises: Listen for knocking, grinding, or squealing sounds that may indicate component damage.

- Excessive Vibration: Noticeable shaking during operation can suggest imbalances or misalignments.

- Fluid Leaks: Puddles or stains beneath the unit may point to seal failures or other leaks.

- Discoloration: Darkened or burnt areas on surfaces can signify overheating or inadequate lubrication.

- Cracks and Fractures: Visual inspections should include checking for visible damage on structural components.

Timely identification of these signs is crucial. Consider implementing a regular maintenance schedule to facilitate early detection and mitigate potential issues.

Replacement Parts Availability

When it comes to maintaining high-performance machinery, having access to essential components is crucial for ensuring longevity and efficiency. This section explores the options available for sourcing the necessary replacements.

Several avenues exist for acquiring these critical items:

- Authorized Dealers: Often provide genuine components that meet the original specifications, ensuring compatibility and reliability.

- Aftermarket Suppliers: Offer a wide range of alternatives, which can be cost-effective while still delivering quality performance.

- Online Retailers: An extensive selection can be found on various e-commerce platforms, enabling convenient shopping from home.

- Local Salvage Yards: Can be a treasure trove for those seeking refurbished or used components at a fraction of the new part cost.

It’s essential to consider the quality and warranty options when selecting suppliers, as these factors can greatly impact the overall performance and reliability of the machinery.

For anyone undertaking repairs or upgrades, understanding the availability of replacements is key to effective maintenance strategies.

Comparative Analysis with Other Engines

This section explores the key distinctions and similarities among various power units, focusing on performance, efficiency, and maintenance requirements. Understanding these factors can guide users in making informed decisions based on their specific needs.

Performance Metrics

- Torque output

- Horsepower ratings

- Fuel consumption efficiency

When evaluating different systems, consider how these metrics impact overall functionality and suitability for various applications.

Maintenance and Durability

- Frequency of required service

- Availability of replacement components

- Expected lifespan under normal operating conditions

A comprehensive analysis of upkeep can highlight long-term cost implications and operational reliability, essential for any user aiming for optimal performance.

Tools for Engine Disassembly

Disassembling a mechanical unit requires a well-organized approach and the right tools to ensure efficiency and safety. A variety of instruments are essential for the careful removal and handling of components. Here, we explore the indispensable tools that make this process smoother and more effective.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts and nuts. Ensure you have a complete set to accommodate different sizes.

- Screwdrivers: A range of flathead and Phillips screwdrivers will help with various screws encountered during disassembly.

- Pliers: Needle-nose and locking pliers are useful for gripping and holding small parts securely.

- Torque Wrench: This tool is crucial for applying the correct amount of torque to fasteners, preventing over-tightening or damage.

In addition to these basic tools, consider the following specialized instruments:

- Impact Wrench: Ideal for loosening stubborn bolts quickly, reducing manual effort and time.

- Pullers: These are necessary for removing gears and bearings without causing damage.

- Scrapers: Useful for cleaning surfaces and removing old gaskets before reassembly.

Finally, having a reliable work surface and proper safety equipment cannot be overstated. A clean, well-lit area allows for better visibility and organization, while gloves and goggles ensure personal protection during the process.

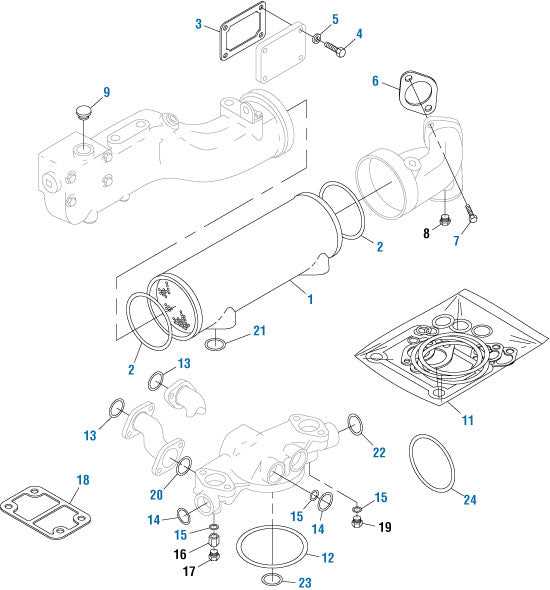

Ultimate Guide to Engine Diagrams

Understanding the inner workings of mechanical systems is essential for anyone involved in maintenance or repair. This comprehensive guide will provide insights into the visual representations that help users identify and comprehend the various components of complex machinery. With these illustrations, one can navigate through assemblies, troubleshoot issues, and optimize performance effectively.

Importance of Visual Representations

Visual aids are invaluable tools in the field of mechanics. They serve multiple purposes:

- Facilitate quick identification of elements.

- Enhance comprehension of assembly and disassembly processes.

- Support effective troubleshooting by showing connections and configurations.

Key Components to Focus On

When studying visual guides, it’s crucial to pay attention to specific aspects:

- Labels and Legends: Ensure every part is clearly marked to avoid confusion.

- Connection Points: Identify where components interact, which is vital for maintenance.

- Flow Diagrams: Understand how fluids or energy circulate through the system.

By mastering these elements, individuals can enhance their proficiency in handling machinery and extend the lifespan of their equipment.