Overhead Camshaft

How the Cylinder Block Functions

The core of any mechanical system that involves motion relies heavily on components designed to manage both power and heat. The cylindrical section plays a critical role in ensuring the smooth operation of these systems by housing essential elements that control combustion and movement. Without this crucial structure, maintaining efficient performance would be impossible.

Regulating Power Output

The cylindrical structure is designed to accommodate the up-and-down motion of various parts, ensuring that the transfer of power occurs without interruption. Its sturdy construction allows it to withstand high pressure while facilitating seamless energy flow. By maintaining proper alignment, this section ensures that the movement is both smooth and efficient, directly affecting the overall performance.

Heat Dissipation

One of the primary challenges faced by any moving system is the generation of heat. The cylinder block must not only support mechanical action but also regulate temperature. This is achieved through a system of cooling channels and materials that help dissipate heat, preventing overheating and maintaining optimal functioning under various conditions. Proper heat management ensures the longevity and reliability of the entire system.

The Role of the Carburetor in Performance

The carburetor plays a crucial role in determining how efficiently a two-wheeler operates. It carefully manages the mixture of air and fuel, directly impacting the power output and smoothness of the ride. When properly adjusted, it ensures that the balance between fuel consumption and energy produced is optimal, enhancing the overall performance.

Performance Optimization through the carburetor’s precise tuning can greatly affect acceleration and top speed. By allowing the correct amount of air to blend with fuel, the system maximizes energy output. Any imbalance, however, can lead to inefficiencies like sluggish acceleration or excessive fuel consumption.

Additionally, the carburetor’s adjustment influences not only fuel economy but also the longevity of various mechanical components. Proper maintenance and fine-tuning of this critical system help in maintaining steady performance over time.

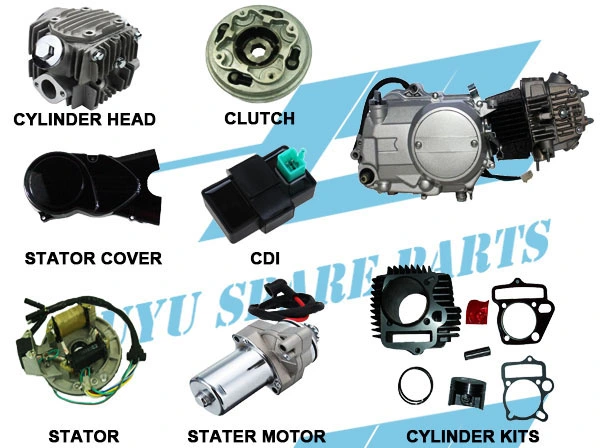

Ignition System and Its Parts

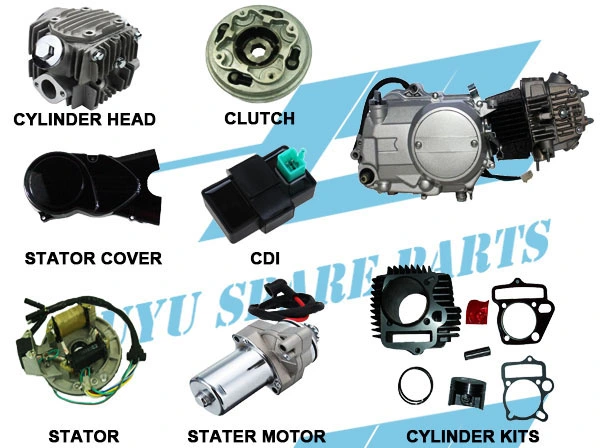

The ignition system plays a vital role in ensuring proper function by delivering the necessary energy for combustion. This crucial system involves several key elements that work in harmony to ignite the mixture at just the right time, allowing the motor to run smoothly.

Primary Components

The ignition process relies on a set of essential elements. Among these are the spark plug, which creates the spark, and the ignition coil, responsible for transforming low voltage into the high voltage needed for the spark plug to function. Other critical elements include wires and switches that manage the flow of electrical current.

How It Works

The system functions by using electrical energy stored in the battery, which is then converted into a high-voltage pulse. This pulse travels through the ignition coil and leads to the spark plug, where it ignites the air-fuel mixture. Precise timing and coordination are essential for the whole process to operate effectively.

Exhaust System Overview for GY6 Engines

The exhaust system plays a vital role in ensuring optimal performance and efficiency. It is responsible for managing gases produced during the combustion process, guiding them safely away from the system, while minimizing harmful emissions. Understanding how this setup functions can help in maintaining proper functionality and improving overall output.

Main Components of the Exhaust System

The system consists of several interconnected elements that work together to streamline the removal of gases. Each part contributes to reducing noise and regulating pressure, ensuring smooth operation.

- Muffler: Reduces noise levels by controlling the sound of exhaust gases as they exit.

- Header Pipe: Connects to the combustion chamber, directing the flow of gases outwards.

- Gaskets: Provide seals between components to prevent leaks and ensure efficient gas flow.

Exhaust System Maintenance Tips

Proper upkeep of the exhaust system is essential for longevity and reliable performance. Regular inspections and timely replacements are key to avoiding issues.

- Check for leaks around joints and connections.

- Replace worn-out gaskets and seals immediately.

- Ensure the muff

The Cooling Mechanism Explained

The process of temperature regulation is vital for maintaining optimal performance and longevity in any mechanical system. This involves several components working together to dissipate excess heat generated during operation. Understanding this intricate mechanism provides insights into the efficiency and reliability of the system.

In many motorized vehicles, the cooling system primarily functions to ensure that temperatures remain within a safe range. By circulating a coolant through designated channels, the system absorbs heat and prevents overheating. This allows for smooth operation and enhances overall functionality.

| Component |

Function |

| Radiator |

Dissipates heat from the coolant to the air. |

| Water Pump |

Circulates the coolant throughout the system. |

| Thermostat |

Regulates coolant flow based on temperature. |

| Cooling Fans |

Enhance airflow through the radiator. |

| Coolant Reservoir |

Holds excess coolant for the system. |

By comprehensively understanding these components and their roles, users can appreciate the significance of a well-maintained temperature regulation system. Regular checks and maintenance can prevent failures, ensuring that the machine operates efficiently.

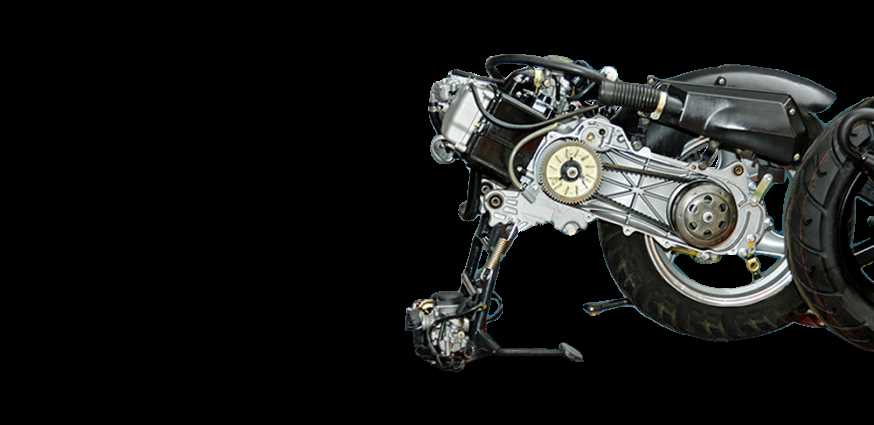

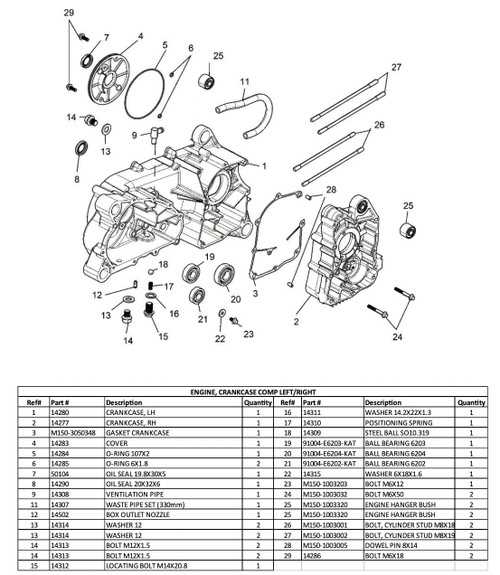

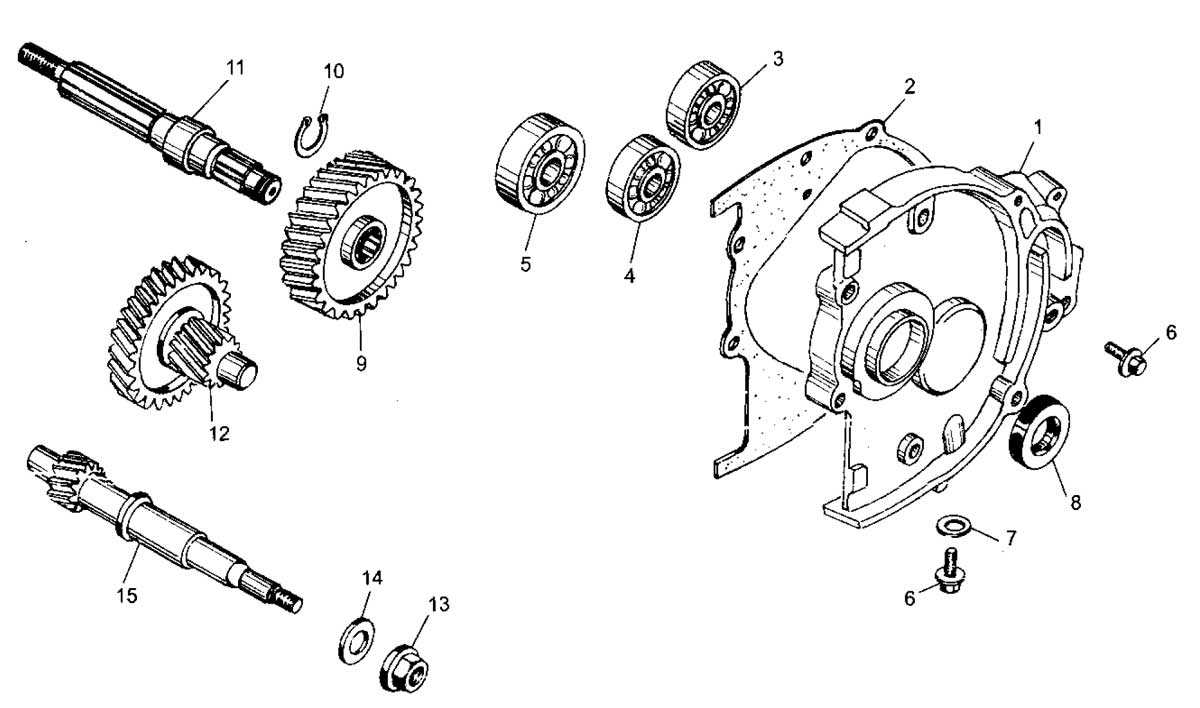

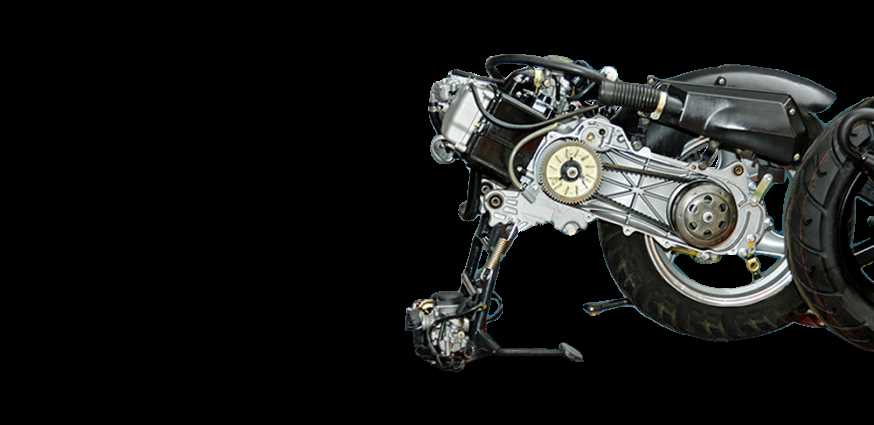

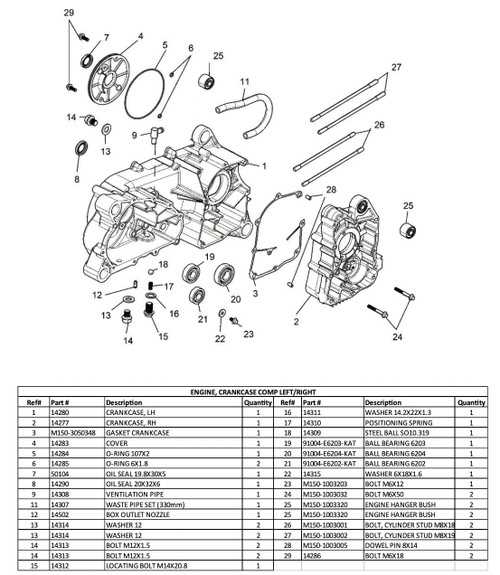

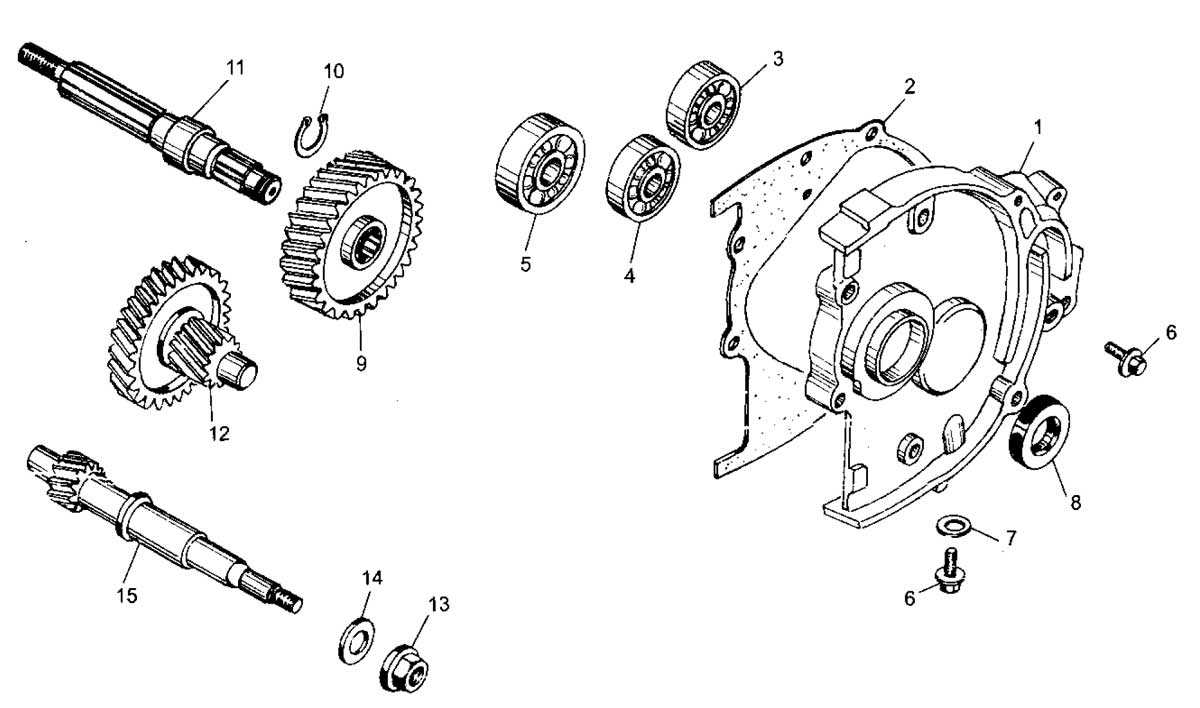

Transmission Parts and Their Functions

The transmission system plays a crucial role in the operation of any vehicle, facilitating the transfer of power from the propulsion mechanism to the wheels. Understanding the various components within this system and their specific functions is essential for maintaining optimal performance and efficiency. Each element contributes to the seamless functioning of the whole assembly, ensuring that energy is transmitted effectively during operation.

Key Components of the Transmission System

Several key elements comprise the transmission framework. These include the clutch, gears, and output shaft, each serving distinct purposes. The clutch enables the driver to engage or disengage the drive mechanism, allowing for smooth gear shifts. The gears are responsible for adjusting the torque and speed, while the output shaft transmits the adjusted power to the wheels, propelling the vehicle forward.

Importance of Proper Maintenance

Regular upkeep of the transmission components is vital for preventing potential issues that could lead to decreased performance or failure. Routine inspections, fluid changes, and timely repairs help ensure that the transmission functions efficiently, extending the lifespan of the overall system and enhancing the driving experience.

Fuel System Components Breakdown

The fuel delivery mechanism plays a critical role in ensuring optimal performance and efficiency. It encompasses various elements that work synergistically to facilitate the flow of combustible material from the tank to the combustion chamber. Understanding these components is essential for effective maintenance and troubleshooting.

| Component |

Description |

| Fuel Tank |

A reservoir that stores the combustible fluid until it is needed. |

| Fuel Pump |

A device that moves the fluid from the tank to the engine, ensuring consistent pressure. |

| Fuel Filter |

A filtration system that removes impurities from the fluid, protecting other components. |

| Carburetor / Fuel Injector |

Mechanisms that mix the fluid with air in the proper ratio for efficient combustion. |

| Throttle Body |

Controls the amount of air-fuel mixture entering the combustion chamber, influencing power output. |

How the Clutch Affects Operation

The functionality of a vehicle greatly relies on the performance of its friction components, which are crucial for transferring power from the power source to the wheels. This section explores how these elements influence overall performance and responsiveness.

When the friction system engages, it plays a significant role in managing power delivery. A well-functioning assembly ensures smooth acceleration and efficient energy transfer. Conversely, a malfunctioning unit can lead to issues such as slippage or delayed response, impacting overall vehicle performance.

- Power Transfer: The connection between the power source and the drive mechanism is pivotal. A responsive assembly allows for immediate and efficient energy transfer, enhancing acceleration and handling.

- Heat Management: The friction elements generate heat during operation. Adequate heat dissipation is essential to prevent overheating, which can lead to wear and decreased effectiveness.

- Wear and Longevity: Regular maintenance and timely replacement of worn components can prolong the lifespan of the system, ensuring consistent performance over time.

- Adjustability: Some systems allow for adjustments to cater to different performance needs, providing flexibility for various driving conditions.

In summary, the effectiveness of the friction assembly significantly impacts the vehicle’s operational capabilities, influencing both performance and reliability.

Electrical Wiring Essentials for GY6 Engines

Understanding the fundamentals of electrical connections is crucial for optimal performance and reliability in small motor systems. Properly organized wiring ensures that power is efficiently transmitted to various components, enhancing functionality and minimizing potential issues. Knowledge of essential wiring principles aids in diagnosing and repairing common electrical faults.

Key elements include the battery, which serves as the primary power source, and the ignition system, responsible for initiating the combustion process. Additionally, the wiring harness plays a vital role by grouping together multiple wires, simplifying installation and maintenance. Ensuring correct connections and utilizing quality materials can significantly impact the system’s overall efficiency.

Moreover, familiarizing oneself with common electrical symbols and color codes is beneficial when working with wiring schematics. This knowledge aids in troubleshooting and making informed decisions during modifications or repairs. Regular inspection of connections and components can prevent wear and tear, contributing to longevity and consistent performance.

Valve Timing and Its Importance

Understanding the synchronization of various components in a mechanical system is crucial for optimal performance. This synchronization ensures that the movements of certain elements occur at precise moments, allowing for efficient operation and minimizing the risk of malfunction. Proper timing can significantly influence power output, fuel efficiency, and overall longevity of the system.

In the realm of mechanical systems, the timing of valves plays a pivotal role. It dictates how well the intake and exhaust gases are managed, which directly affects the efficiency and effectiveness of the entire mechanism. Inadequate timing can lead to suboptimal performance, resulting in power loss, increased emissions, and even severe damage.

| Timing Aspect |

Impact on Performance |

| Open Duration |

Influences the amount of air-fuel mixture entering and exhaust gases exiting. |

| Overlap |

Affects the transition between intake and exhaust strokes, impacting efficiency. |

| Lift Height |

Determines the volume of gases that can flow, impacting power output. |

Monitoring and adjusting the timing of these components can lead to remarkable improvements in functionality. Therefore, understanding this concept is essential for anyone involved in the maintenance or enhancement of mechanical systems.

|