Understanding the Parts Diagram of the Honda 6.5 HP Engine

In the realm of small machinery, having a clear grasp of the intricate elements that contribute to functionality is essential. Each component plays a vital role in ensuring optimal performance and longevity. This exploration delves into the various sections and features that make up a compact power unit, allowing users to enhance their knowledge and maintenance skills.

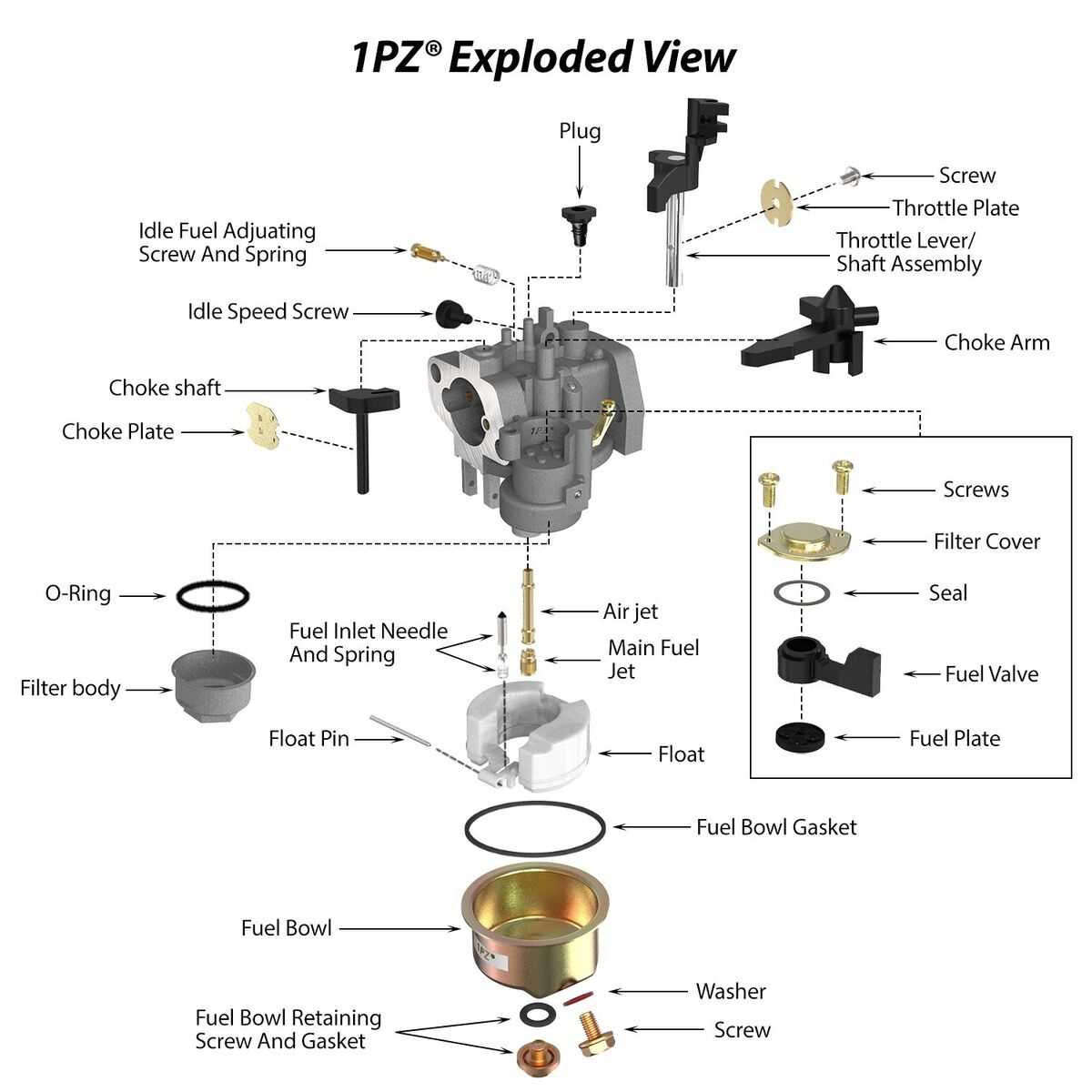

Visual aids serve as invaluable tools for comprehending the structure and arrangement of these crucial components. By examining a well-crafted illustration, individuals can identify the relationships between parts, making troubleshooting and repairs more efficient. Such resources not only clarify the assembly but also empower users to take proactive steps in their maintenance routines.

Moreover, understanding how each element interacts within the system can significantly improve overall functionality. This knowledge facilitates informed decision-making, whether it involves repairs, upgrades, or simple routine checks. By familiarizing oneself with the layout and function of these components, users can ensure their equipment operates smoothly for years to come.

Understanding Honda 6.5 HP Engines

This section aims to provide a comprehensive overview of a popular small power unit known for its reliability and efficiency. These compact machines are widely utilized in various applications, making them a favored choice among users. Understanding their design and functionality can enhance maintenance practices and improve overall performance.

Key components play a crucial role in ensuring the optimal operation of these power sources. Familiarity with each part allows for better troubleshooting and servicing. Below is a table highlighting some essential components and their functions:

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts combustion pressure into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Ignition System | Initiates combustion by igniting the fuel-air mixture. |

| Fuel System | Supplies the necessary fuel to the combustion chamber. |

By delving into the intricacies of these components, users can better appreciate the engineering behind this power unit and ensure its longevity through proper care and maintenance.

Overview of Engine Specifications

This section provides a detailed look at the technical characteristics that define a specific type of power unit. Understanding these specifications is essential for assessing performance, compatibility, and maintenance needs.

Key Specifications

- Displacement: Refers to the total volume of all cylinders and affects power output.

- Compression Ratio: Indicates the ratio of the cylinder’s volume before and after compression, impacting efficiency and performance.

- Power Output: Measured in horsepower, this reflects the unit’s ability to perform work.

- Torque: The twisting force produced, crucial for applications requiring strong initial acceleration.

- Fuel Type: Specifies the kind of fuel required for optimal operation.

Performance Metrics

- Operational RPM: The range of revolutions per minute at which the unit functions effectively.

- Cooling System: Details whether air-cooled or liquid-cooled systems are employed.

- Lubrication Method: Discusses the type of lubrication system in use, essential for longevity.

- Weight: Total weight of the unit, which affects transportability and mounting options.

These attributes are vital for anyone looking to understand or utilize this type of machinery effectively.

Common Applications of Honda Engines

Powerful small machinery finds its place in a wide array of tasks, making it a versatile choice for both personal and professional use. These robust units are essential in various fields, including construction, gardening, and recreational activities. Their reliability and efficiency have established them as a preferred option across numerous sectors.

Residential Uses

In home settings, these compact power sources are often employed for lawn care, pressure washing, and small-scale construction tasks. Their ability to deliver consistent performance allows users to tackle a range of chores with ease.

Commercial Applications

For businesses, these units are invaluable in landscaping, equipment rental, and maintenance services. Their durability and fuel efficiency contribute to operational effectiveness, making them suitable for heavy-duty tasks.

| Application | Description |

|---|---|

| Lawn Mowers | Used for cutting grass and maintaining landscapes. |

| Generators | Provides backup power for homes and businesses. |

| Pressure Washers | Efficiently cleans surfaces using high-pressure water streams. |

| Construction Equipment | Drives tools and machines used on job sites. |

Key Components of Honda 6.5 HP Engine

This section explores the essential elements that contribute to the functionality and efficiency of a compact power unit. Understanding these vital components is crucial for maintenance and optimal performance, ensuring reliability in various applications.

Power Generation System

The power generation system is fundamental, comprising various components that work together to convert fuel into mechanical energy. This includes the ignition assembly, which initiates combustion, and the fuel delivery system, responsible for supplying the necessary fuel mixture to sustain operation.

Cooling and Lubrication Mechanisms

Effective cooling and lubrication are critical for preventing overheating and reducing wear. The cooling system typically includes a fan and fins to dissipate heat, while the lubrication mechanism ensures that moving parts are adequately lubricated to minimize friction and extend the lifespan of the unit.

How to Read Engine Parts Diagrams

Understanding technical illustrations is crucial for anyone working with machinery. These visuals provide essential information about the components and their arrangement, enabling efficient assembly, maintenance, or repair. Familiarity with the symbols and layout will enhance your ability to interpret these resources effectively.

Key Elements of Technical Illustrations

- Labels: Each component is typically labeled to identify its function or part number, making it easier to locate and reference specific items.

- Connections: Arrows or lines often indicate how parts are interconnected. Understanding these links is vital for assembling or troubleshooting.

- Views: Diagrams may present multiple views (e.g., top, side, or exploded view) to give a comprehensive understanding of the layout.

Tips for Effective Interpretation

- Familiarize yourself with common symbols used in illustrations.

- Cross-reference the visual with any accompanying text or manuals for clarification.

- Practice by studying various diagrams to improve your proficiency over time.

Importance of Genuine Parts Usage

Utilizing authentic components is crucial for maintaining optimal performance and longevity of machinery. When replacement elements are sourced from reputable manufacturers, users can ensure reliability and efficiency, reducing the likelihood of breakdowns and enhancing overall functionality.

Choosing original replacements over generic alternatives can significantly impact the overall operation. Genuine components are designed to meet specific standards, offering better compatibility and reduced wear over time. This not only preserves the integrity of the equipment but also safeguards against potential safety hazards.

Moreover, employing original items often results in cost savings in the long run. While imitation options may appear attractive due to lower upfront prices, their inferior quality can lead to more frequent repairs and replacements, ultimately increasing expenses. Therefore, investing in authentic components is not just a matter of quality but also a wise financial decision.

Additionally, using original elements helps maintain warranty coverage and ensures that any claims remain valid. Many manufacturers require that authentic components be used to uphold warranty agreements, making it imperative for users to consider the long-term implications of their choices.

In summary, the significance of using original components cannot be overstated. They provide enhanced performance, safety, and reliability, making them an essential consideration for anyone invested in maintaining their machinery effectively.

Maintenance Tips for Honda Engines

Regular upkeep is essential for optimal performance and longevity of your machinery. Implementing a structured maintenance routine can prevent breakdowns and enhance efficiency.

- Check and change the oil frequently to ensure smooth operation.

- Inspect air filters regularly and replace them as needed to maintain airflow.

- Examine spark plugs for wear and replace them to ensure proper ignition.

- Clean or replace fuel filters to keep the fuel system clear.

Additionally, consider these advanced practices:

- Maintain proper coolant levels to prevent overheating.

- Inspect belts and hoses for signs of wear or damage.

- Regularly test the battery and electrical connections for reliability.

By following these guidelines, you can extend the lifespan of your machinery and ensure it runs at peak performance.

Replacing Engine Parts Effectively

When it comes to enhancing performance through component replacement, understanding the process is essential. Each step must be approached with precision to ensure optimal functionality and longevity.

Preparation Steps

- Gather necessary tools and components.

- Consult the specific manual for guidance.

- Ensure a clean and organized workspace.

Replacement Process

- Disconnect power sources to prevent accidents.

- Carefully remove the existing component, taking note of connections.

- Install the new item, ensuring a secure fit.

- Reconnect all connections and check for proper alignment.

- Test functionality to verify successful installation.

Troubleshooting Common Engine Issues

Addressing frequent mechanical problems requires a systematic approach to identify and resolve malfunctions. By understanding the typical symptoms and implementing effective diagnostic steps, you can enhance performance and longevity.

Common Symptoms and Solutions

- Difficulty Starting:

- Check fuel levels and quality.

- Inspect the ignition system for faults.

- Examine the air filter for blockages.

- Unusual Noises:

- Listen for rattling, which may indicate loose components.

- Check for signs of wear on belts and bearings.

- Overheating:

- Verify coolant levels and condition.

- Inspect for any obstructions in cooling passages.

Preventative Measures

- Regular maintenance checks.

- Keep the fuel system clean.

- Monitor operating conditions closely.

Differences Between Honda Engine Models

When exploring various models produced by a renowned manufacturer, it becomes evident that distinctions arise in design, performance, and functionality. These variations cater to different applications and user preferences, ensuring that each variant meets specific needs.

Power Output: One of the primary differences lies in the horsepower ratings, which can significantly impact the overall performance. Higher-rated models often provide enhanced capabilities, suitable for demanding tasks.

Fuel Efficiency: Certain variants prioritize fuel consumption, offering improved mileage. This aspect is crucial for users seeking cost-effective and environmentally friendly options.

Weight and Size: The physical dimensions and weight of different models also vary. Compact options are ideal for portability, while larger ones might be better for stability and power delivery.

Features and Technology: Advancements in technology can differentiate models, with some including features such as electric start or advanced cooling systems, enhancing user experience and convenience.

Understanding these differences enables users to select the most suitable option for their specific requirements, ultimately optimizing performance and satisfaction.

Best Practices for Engine Storage

Proper preservation of machinery is essential to ensure optimal performance and longevity. Following best practices for storage can prevent deterioration, corrosion, and mechanical failures. Implementing a few simple strategies can make a significant difference when it’s time to bring the equipment back into action.

Preparation Before Storage

- Clean the exterior thoroughly to remove dirt, grease, and debris.

- Change the lubricants and fluids to prevent contamination and oxidation.

- Drain fuel to avoid residue buildup and potential gumming in the system.

- Inspect and repair any wear or damage before putting the machinery away.

Ideal Storage Conditions

- Choose a dry, cool environment to minimize humidity and temperature fluctuations.

- Use a cover to protect from dust and debris, but ensure it allows for ventilation.

- Store away from direct sunlight to prevent heat-related damage.

- Consider elevating the unit off the ground to avoid moisture exposure.

By adhering to these guidelines, you can safeguard your equipment, ensuring it remains in excellent condition and ready for use when needed.

Resources for Engine Repair Manuals

Accessing comprehensive guides for maintenance and troubleshooting can significantly enhance the repair experience for small machinery. These resources often include detailed instructions, schematics, and recommendations to facilitate efficient repairs and ensure longevity.

Online Platforms

Several websites offer downloadable manuals and repair tips. Platforms such as iFixit and Repair Clinic provide a wealth of user-generated content, tutorials, and forums where enthusiasts share their insights and experiences. These sites can be invaluable for both novice and experienced technicians.

Community Forums and Groups

Engaging with community forums can be a great way to gather information and seek advice. Websites like Reddit and specialized groups on social media often have sections dedicated to machinery repair, where users can delve into discussions and find answers to specific queries. These communities foster collaboration and the sharing of knowledge, enhancing the overall repair process.

Finding Reliable Honda Parts Suppliers

When searching for trustworthy suppliers of components, it’s essential to consider various factors that ensure quality and reliability. The right source can make a significant difference in the performance and longevity of your machinery.

Here are some key aspects to keep in mind when looking for dependable vendors:

- Reputation: Check online reviews and testimonials to gauge the credibility of the supplier.

- Certification: Ensure that the provider meets industry standards and certifications.

- Product Range: A wide selection of items indicates a well-established supplier.

- Customer Service: Responsive support can greatly assist with inquiries and issues.

- Pricing: Compare prices across different suppliers to ensure competitive rates without compromising quality.

By focusing on these factors, you can enhance your chances of finding a reliable source for your component needs.