Comprehensive Guide to Honda GX240 Engine Parts with Diagram

In the realm of machinery, the intricate design of a specific power unit plays a pivotal role in its performance and longevity. Each individual element contributes to the overall functionality, ensuring seamless operation across various applications. By exploring these crucial components, one can gain deeper insights into the mechanics that drive efficiency.

Delving into the specifics of each segment reveals how they interact and support one another. From fuel delivery systems to ignition mechanisms, every aspect is interconnected, forming a cohesive unit that operates harmoniously. This ultimate understanding enhances maintenance and troubleshooting practices, allowing users to maximize performance and reliability.

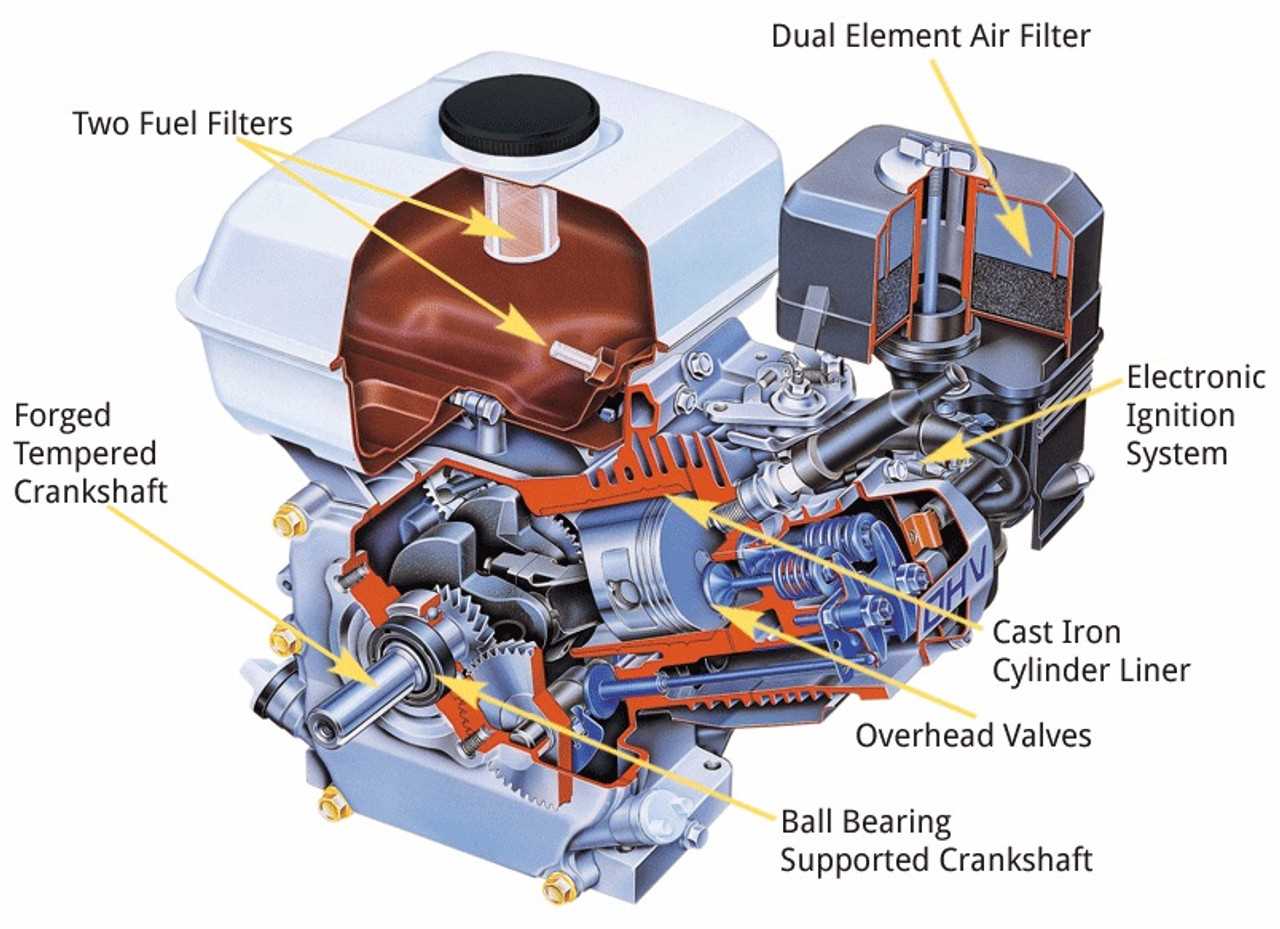

To further illustrate this complex structure, visual aids can be invaluable. Diagrams provide clarity, allowing enthusiasts and professionals alike to appreciate the layout and relationships between components. Such resources empower users to engage more effectively with their equipment, fostering a greater appreciation for engineering ingenuity.

Understanding Honda GX240 Engine Parts

This section explores the essential components that contribute to the overall functionality of a small combustion mechanism. Each element plays a critical role in ensuring smooth operation and reliability, making it vital for users to grasp their significance.

| Component | Description |

|---|---|

| Cylinder | Houses the piston and facilitates the combustion process. |

| Piston | Moves within the cylinder to convert fuel energy into mechanical power. |

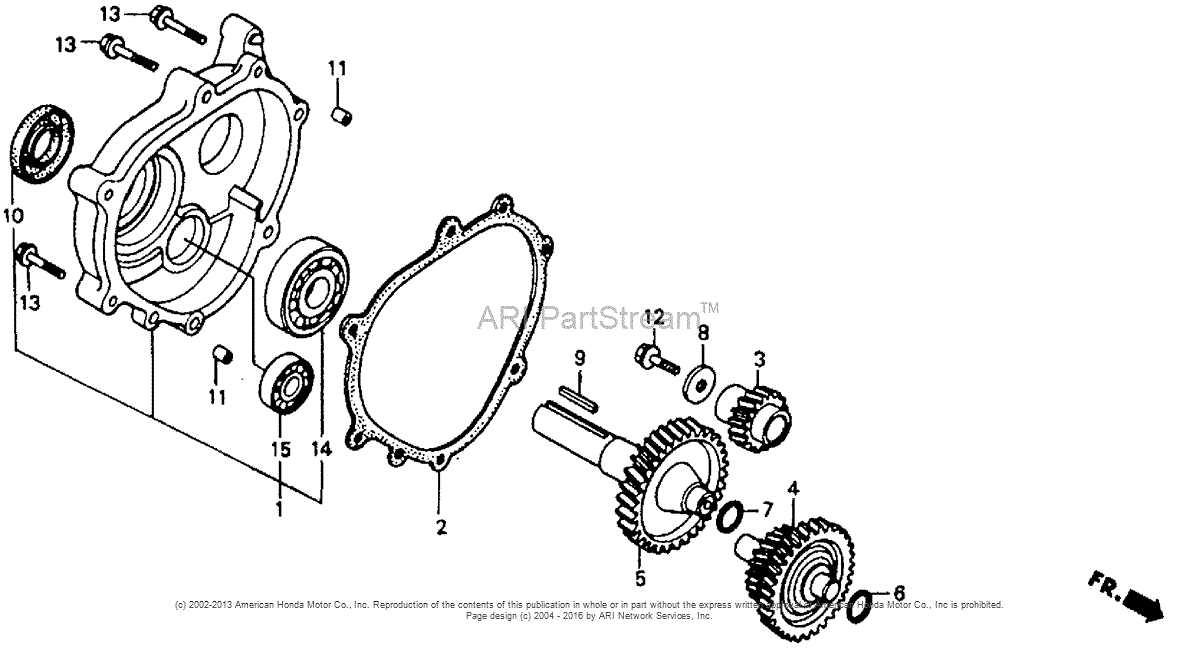

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Flywheel | Stores rotational energy and helps maintain engine speed. |

| Valves | Control the intake of air and fuel and the exhaust of gases. |

Understanding these components allows for better maintenance and troubleshooting, ensuring optimal performance in various applications.

Key Components of the GX240 Engine

This section explores the essential elements that contribute to the functionality and performance of a specific small power unit. Understanding these fundamental components is crucial for maintenance, troubleshooting, and overall efficiency.

Major Elements

Among the primary features are the combustion chamber, where fuel and air mix for ignition, and the crankshaft, which converts the linear motion into rotational power. Additionally, the cooling system plays a vital role in maintaining optimal operating temperatures, ensuring longevity and reliability.

Supporting Mechanisms

Another significant aspect includes the ignition system, which is responsible for initiating the combustion process. Furthermore, the fuel delivery system ensures that the correct amount of fuel reaches the combustion chamber, optimizing performance. Each of these components works in harmony to create a robust and efficient machine.

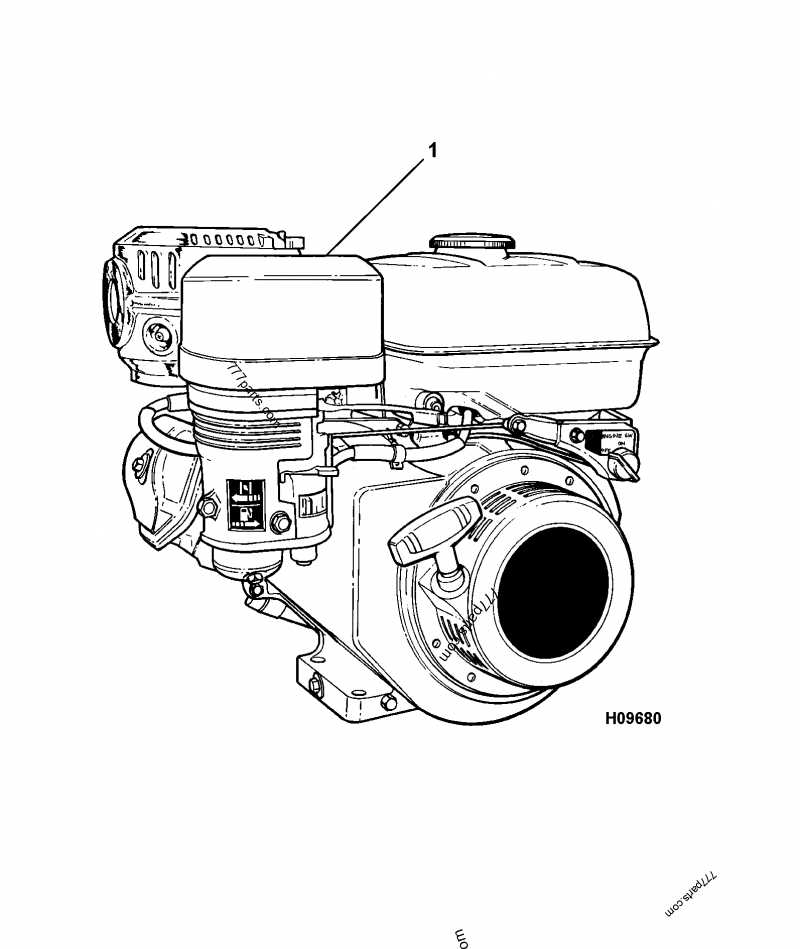

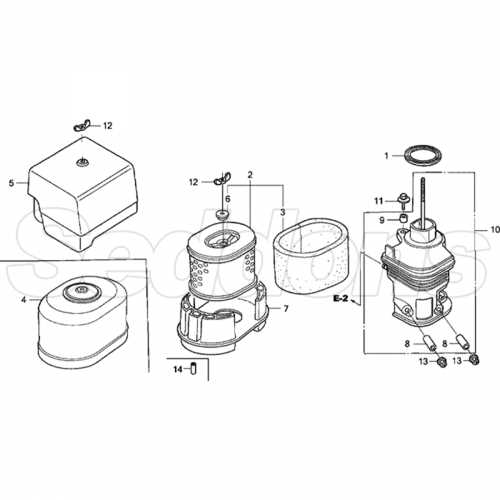

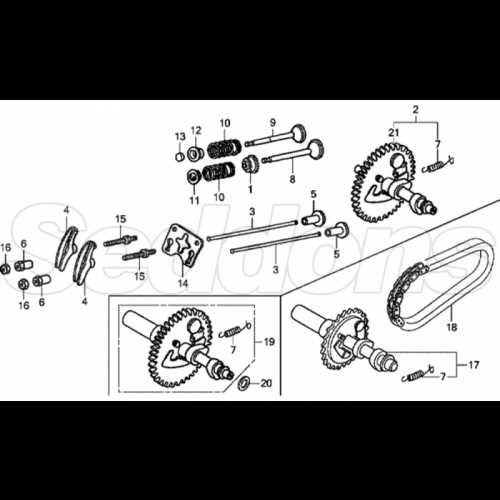

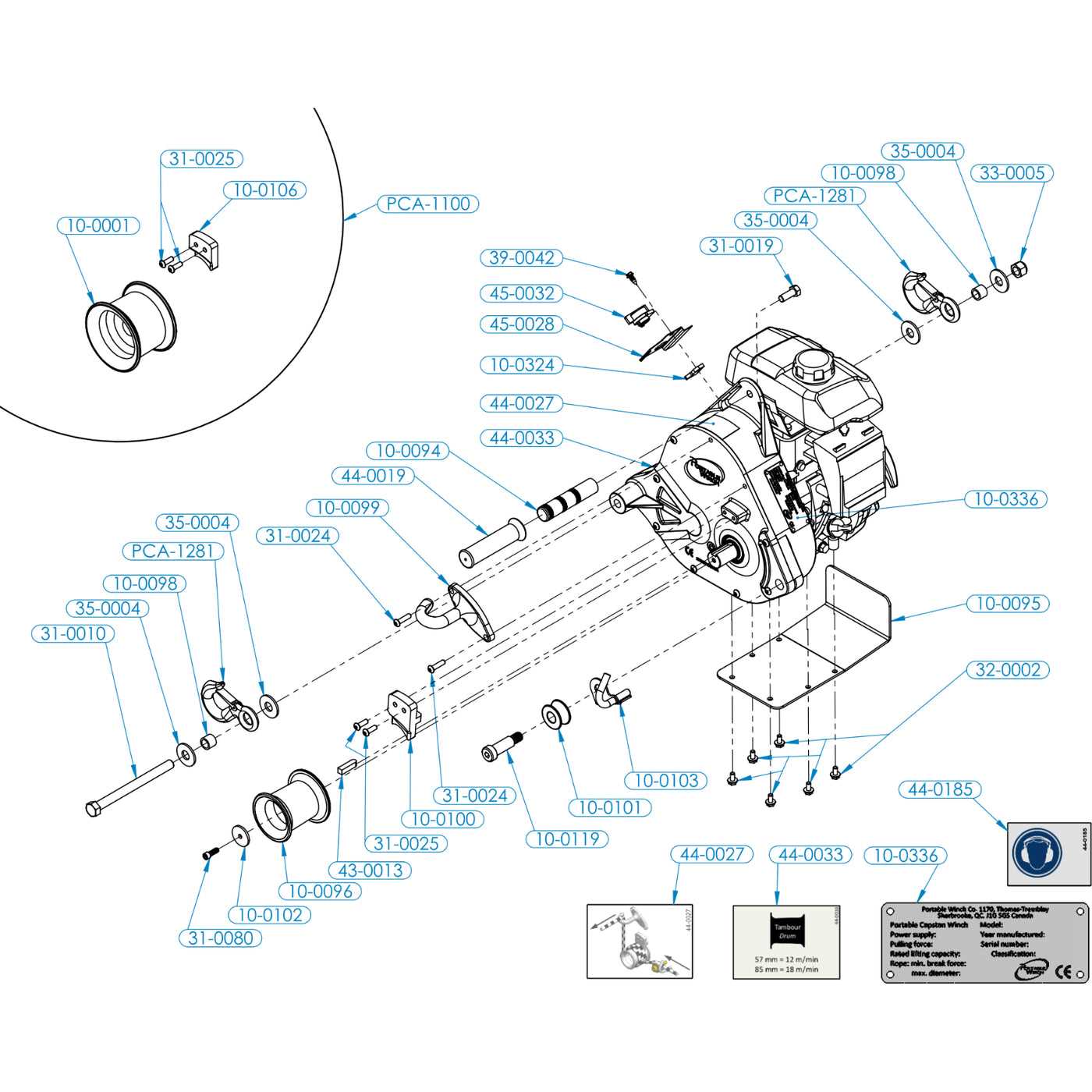

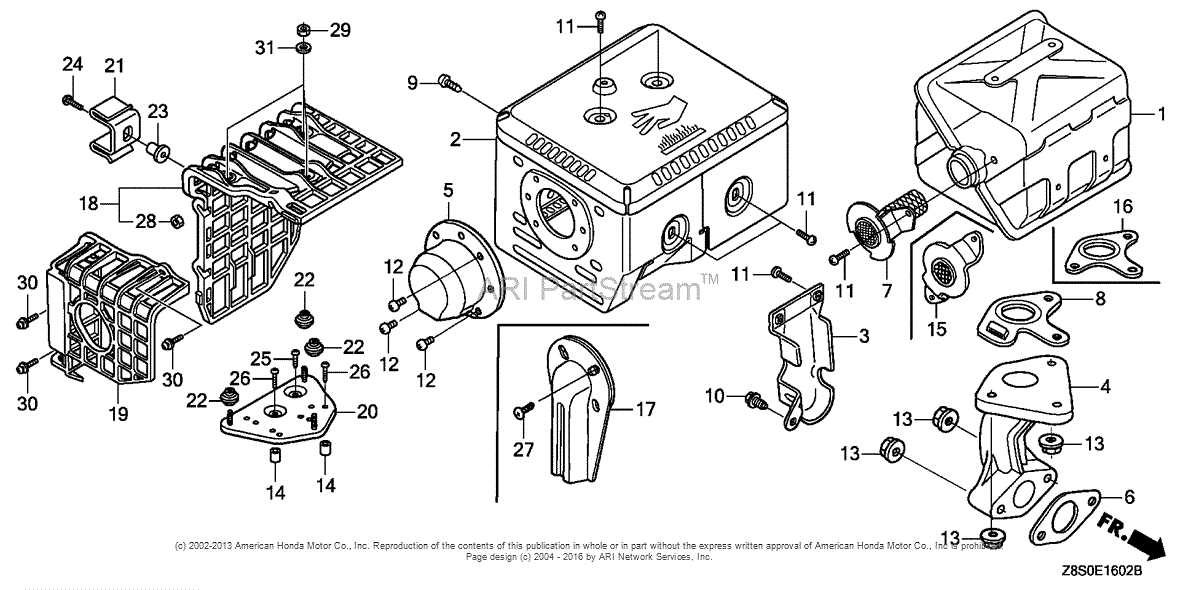

Visual Diagram of Engine Parts

This section provides a comprehensive visual representation that highlights the various components within a power unit. Understanding the layout and function of each element is crucial for maintenance and repair, ensuring optimal performance and longevity.

The illustration showcases key segments, illustrating their arrangement and interconnections. Each part plays a vital role, contributing to the overall functionality of the machine. Familiarity with this visual guide can enhance troubleshooting and facilitate effective servicing.

Maintenance Tips for Longevity

Ensuring the durability and reliability of mechanical systems requires regular attention and care. By following specific guidelines, users can enhance performance and extend the lifespan of their equipment. This section outlines key maintenance practices that can make a significant difference over time.

Regular Inspection

Conducting periodic evaluations is crucial for identifying potential issues before they escalate. Regular checks can help in detecting wear and tear, ensuring all components function optimally. Focus on areas that are prone to stress and failure.

Proper Lubrication

Keeping moving elements well-lubricated minimizes friction and reduces the risk of overheating. Use high-quality lubricants and adhere to recommended intervals for application to maintain smooth operation.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Lubrication | Every 20 hours |

| Filter Replacement | Every 50 hours |

| Fuel System Check | Every 100 hours |

Common Issues and Solutions

Every mechanical system faces challenges that can hinder performance and efficiency. Identifying these common problems is crucial for maintaining optimal functionality. This section will explore frequent issues encountered, along with practical solutions to address them effectively.

Issue 1: Difficulty Starting

This issue may arise from a drained power source or fuel supply problems. Solution: Check the battery charge and inspect fuel lines for blockages.

Issue 2: Overheating

Excessive heat can lead to serious damage if not managed. Solution: Ensure adequate cooling fluid levels and clean any obstructions in the cooling system.

Issue 3: Unusual Noises

Strange sounds can indicate internal wear or loose components. Solution: Conduct a thorough inspection of all moving parts and tighten any loose fittings.

Issue 4: Poor Performance

Reduced output may stem from clogged filters or worn components. Solution: Replace air and fuel filters regularly and assess any parts that show signs of deterioration.

Replacement Parts Overview

This section provides an essential look at components that are crucial for maintaining optimal performance and longevity of your machinery. Understanding the variety of available items and their functions can help ensure efficient operation and timely repairs.

Key Components

Among the most significant items are the fuel delivery systems, ignition mechanisms, and cooling elements. Each of these plays a vital role in overall functionality, and selecting the right replacements is imperative for seamless operation.

Choosing the Right Items

When sourcing components, consider quality and compatibility. Reliable suppliers offer a range of options, allowing users to delve into specific needs and make informed decisions for the ultimate maintenance experience.

Choosing Quality Aftermarket Parts

When considering alternatives for essential components, it’s vital to prioritize durability and reliability. Opting for high-quality replacements can significantly impact performance and longevity, ensuring that your machinery operates smoothly under various conditions.

Start by researching reputable manufacturers known for their commitment to excellence. Reading reviews and seeking recommendations from experienced users can provide valuable insights into the reliability of specific brands. Additionally, it’s important to check for certifications and quality standards that verify the authenticity and performance of the items you plan to purchase.

Price is another factor to consider; while it may be tempting to choose the cheapest option, investing a bit more in superior quality often pays off in the long run. Consider the potential costs of frequent replacements or repairs due to inferior components. Ultimately, selecting high-quality alternatives can lead to better performance, reduced maintenance issues, and a more satisfying user experience.

Assembly Instructions for DIY Repairs

When tackling maintenance tasks on your small machinery, having clear guidance is essential for achieving successful outcomes. This section outlines step-by-step instructions to assist you in the reassembly process, ensuring that everything fits together seamlessly and operates efficiently.

Preparation Steps

Before beginning, gather all necessary tools and components. A clean workspace will help you stay organized. Review your user manual for any specific guidelines related to the model you are working on. Ensure you have a thorough understanding of each component and its function, as this knowledge will streamline the assembly process.

Assembly Process

Start by laying out all the components in a logical order. Begin with the larger assemblies and work your way to smaller pieces. Carefully align each part according to the specifications outlined in your reference materials. Take your time to avoid forcing any components together, as this can lead to damage. Once everything is positioned correctly, secure each part using the appropriate fasteners, ensuring they are tightened to the recommended torque specifications.

After completing the assembly, double-check your work to confirm that everything is in place and functioning as intended. Properly executed repairs will not only enhance performance but also extend the lifespan of your equipment.

Comparing GX240 with Other Models

This section explores the distinctions between a specific model and its counterparts, highlighting their unique characteristics and applications. Understanding these differences can aid in selecting the right option for various tasks.

Key points of comparison include:

- Performance: Each variant exhibits different power outputs and torque levels, affecting their suitability for diverse applications.

- Fuel Efficiency: Variations in fuel consumption can significantly impact operational costs over time.

- Maintenance Requirements: Some models demand more frequent servicing, while others may offer easier upkeep.

- Weight and Size: The physical dimensions can influence portability and installation options in various settings.

- Cost: Price differences can play a crucial role in decision-making, especially for budget-conscious consumers.

When evaluating these aspects, it is essential to consider the specific needs of the user. For instance, if high torque is necessary for heavy-duty applications, one might favor a model designed for that purpose, even if it comes at a higher cost. Conversely, if lightweight and portability are priorities, a more compact version could be more advantageous.

Ultimately, the choice depends on a careful assessment of these factors, ensuring the selected model aligns with the intended use and operational expectations.

Performance Enhancements and Modifications

Improving the efficiency and output of small machinery can significantly elevate its capabilities, making it more suitable for demanding tasks. By implementing specific upgrades and adjustments, enthusiasts can unlock the full potential of their equipment, enhancing overall performance and durability.

Common Upgrades

Several modifications can lead to noticeable improvements. Air filters and exhaust systems are among the most effective changes. Upgrading to a high-performance air filter allows for better airflow, while a refined exhaust setup can reduce back pressure, resulting in enhanced power delivery. Additionally, tuning the carburetor can optimize the air-fuel mixture, contributing to a smoother operation and increased torque.

Advanced Modifications

For those seeking even greater enhancements, consider performance camshafts and piston upgrades. These components can significantly alter timing and compression ratios, yielding higher power outputs. Furthermore, employing a lightweight flywheel can improve throttle response and acceleration, creating a more agile and responsive machine.

Resources for Further Learning

For those seeking to enhance their understanding and skills related to small machinery, a variety of resources are available. Exploring literature, online courses, and community forums can significantly aid in gaining knowledge and practical insights.

Books and Manuals

Consider investing in comprehensive manuals and textbooks that cover mechanical fundamentals. These resources often provide detailed illustrations and step-by-step instructions, making them valuable for both beginners and seasoned enthusiasts.

Online Courses and Communities

Numerous platforms offer online courses that delve into maintenance and repair techniques. Additionally, engaging with community forums can facilitate discussions, where individuals share tips and experiences, ultimately enriching your learning journey.