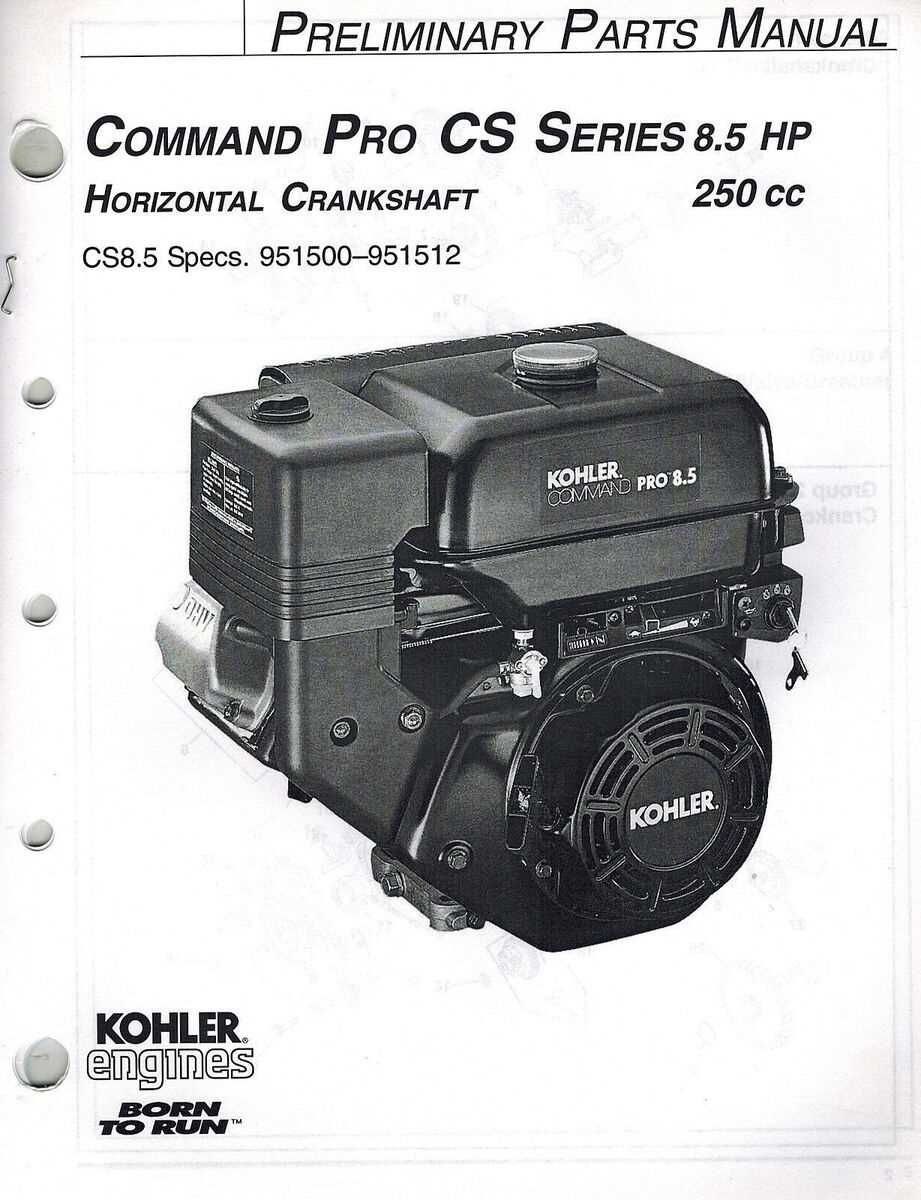

Kohler Command 23 HP Engine Parts Diagram Overview

In the world of outdoor machinery, the inner workings of a robust power unit are crucial for optimal performance. Each element plays a vital role, contributing to the overall functionality and efficiency of the system. Gaining insight into these components not only aids in troubleshooting but also enhances maintenance practices, ensuring longevity and reliability.

To effectively manage and service this particular model, it is essential to familiarize oneself with its intricate layout. By examining a detailed representation of its various components, users can identify each part’s function and significance. This knowledge empowers operators to make informed decisions during repairs and replacements, leading to better outcomes.

In this exploration, we will delve into the specifics of the 23 HP power unit, breaking down its essential elements. Understanding how these individual pieces interact will provide a clearer perspective on achieving peak performance and reliability in outdoor applications.

Kohler Command Engine Overview

This section provides an insightful look into a popular power unit known for its reliability and efficiency. Designed to meet the demands of various applications, this machine has gained recognition in the industry for its robust performance and innovative features.

Key Features

The standout qualities of this power source include high torque, ease of maintenance, and advanced cooling mechanisms. With a focus on durability, it is equipped with components that ensure optimal functioning in diverse environments. Its engineering allows for minimal vibration and noise, enhancing user experience.

Applications

This versatile power unit is suitable for a wide range of uses, from lawn care to heavy machinery. Its adaptability makes it a preferred choice among professionals and hobbyists alike. The ability to handle tough tasks without compromising on performance sets it apart in a competitive market.

Key Features of 23 HP Engine

This section highlights the significant characteristics that define a 23 horsepower unit, emphasizing its design and functionality tailored for various applications.

- Power Output: Delivers a robust 23 horsepower, suitable for demanding tasks.

- Reliability: Engineered for durability, ensuring consistent performance over time.

- Fuel Efficiency: Optimized for economical fuel consumption, reducing operating costs.

- Compact Design: Space-saving layout allows for easy installation in diverse machinery.

- Low Vibration: Advanced engineering minimizes vibrations, enhancing user comfort and prolonging equipment lifespan.

- Maintenance Accessibility: User-friendly layout simplifies routine maintenance and servicing tasks.

- Versatile Applications: Ideal for a wide range of uses, from landscaping to agricultural equipment.

In summary, the unique features of this powerful unit contribute to its popularity across various industries, making it a reliable choice for professionals and enthusiasts alike.

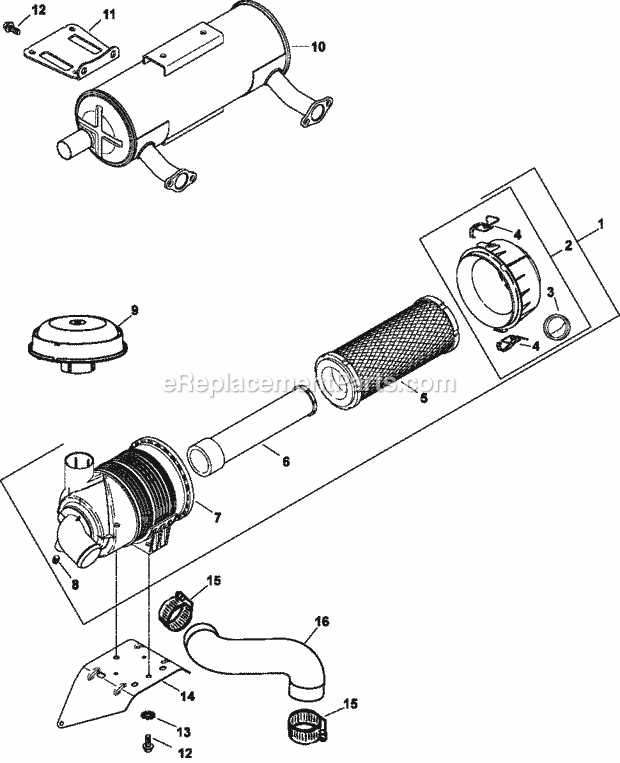

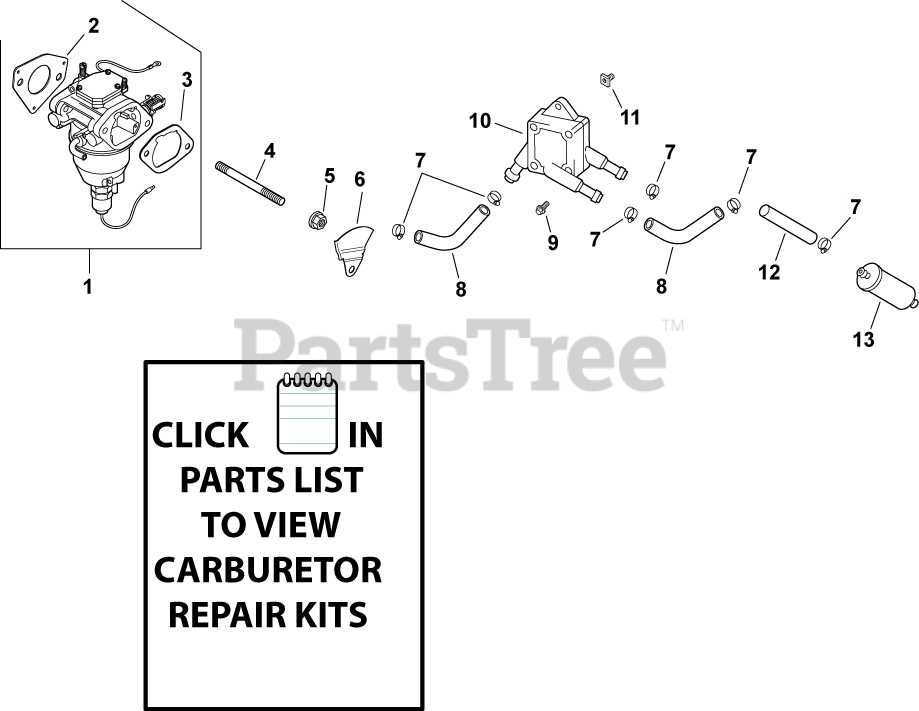

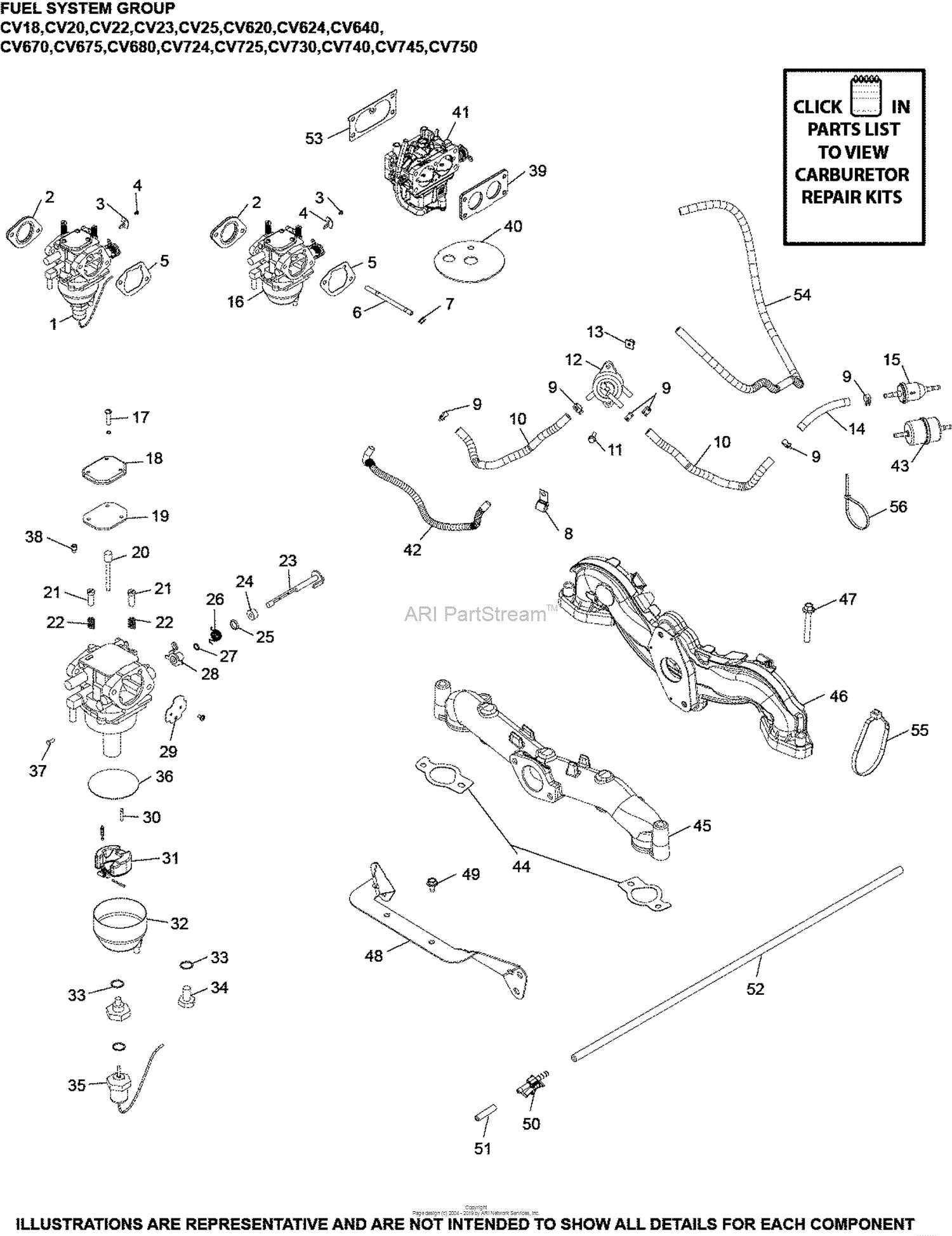

Understanding Engine Parts Diagram

Comprehending the layout of mechanical components is crucial for maintenance and repair tasks. A visual representation serves as a guide, illustrating the relationships and functions of various elements within the machinery. By familiarizing oneself with this schematic, individuals can enhance their troubleshooting skills and ensure proper servicing of the system.

Such a representation typically includes multiple sections, each detailing specific components and their respective roles. These visuals can significantly simplify the process of identifying parts and understanding how they interact. Below is a basic overview of common components often found in these illustrations.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix for combustion. |

| Piston | A moving part within the cylinder that compresses the mixture. |

| Crankshaft | Converts the linear motion of the piston into rotational motion. |

| Valves | Control the intake of air and fuel and the exhaust of gases. |

| Ignition System | Initiates combustion by generating a spark. |

By mastering the intricacies of this visual tool, users can better approach maintenance tasks with confidence and precision.

Importance of Engine Maintenance

Regular upkeep of machinery is crucial for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also prevents unexpected breakdowns, saving time and resources in the long run. A well-maintained system operates smoothly, providing reliability and reducing the risk of costly repairs.

Benefits of Routine Care

Consistent attention to maintenance tasks leads to improved functionality and safety. Regular inspections can identify potential issues before they escalate, while preventative measures ensure that components work harmoniously together. This proactive approach minimizes wear and tear, extending the lifespan of the entire unit.

Cost-Effectiveness

Investing time and resources into systematic maintenance can significantly reduce overall expenses. By addressing minor concerns early, you avoid more significant problems that require expensive interventions. Moreover, maintaining efficiency helps conserve fuel and energy, leading to further savings over time.

Common Issues with Kohler Engines

When it comes to small power units, several common challenges can arise, affecting performance and reliability. Understanding these issues can help users maintain their equipment effectively and ensure longevity. Addressing these concerns promptly is key to avoiding more serious complications down the line.

Fuel System Problems

One prevalent issue involves the fuel delivery mechanism. Clogged filters or degraded fuel lines can lead to insufficient fuel reaching the combustion chamber, causing poor performance or stalling. Regular maintenance, including replacing filters and inspecting hoses, can mitigate these problems.

Electrical System Failures

Another common challenge relates to the electrical components. Faulty spark plugs, dead batteries, or worn ignition systems can prevent the unit from starting or cause intermittent performance issues. Regular checks and timely replacements of these components can ensure smooth operation.

How to Identify Parts Easily

Understanding the components of your machinery can enhance maintenance efficiency and reduce downtime. Familiarizing yourself with the various elements can streamline troubleshooting and repairs, ensuring you always have the right replacements on hand.

Here are some effective strategies to recognize and locate individual components:

- Consult Manuals: Always refer to the user manual specific to your machinery model. It usually contains detailed illustrations and descriptions of each element.

- Utilize Online Resources: Many websites offer visual aids and community forums where users share insights and diagrams. These can be invaluable for visual identification.

- Take Photos: Document the setup before disassembly. This helps you remember where each piece belongs when reassembling.

- Label Components: As you remove parts, label them clearly. This prevents confusion and ensures you know which items to replace or repair.

- Join Forums: Engage with communities focused on similar machinery. Experienced users can provide tips on identifying and sourcing components.

By employing these methods, you can simplify the process of recognizing and sourcing essential elements for your machinery, making maintenance tasks more manageable and efficient.

Tools for Engine Repair and Maintenance

Proper upkeep and restoration of mechanical units require a diverse set of tools. These instruments not only enhance efficiency but also ensure precision in every task. Understanding which tools are essential can greatly impact the longevity and performance of your machinery.

Essential Hand Tools

Basic hand tools form the foundation of any maintenance toolkit. Items such as wrenches, screwdrivers, and pliers are indispensable for disassembling components and securing connections. A high-quality ratchet set can make it easier to tackle stubborn fasteners, while torque wrenches ensure that bolts are tightened to the manufacturer’s specifications, preventing damage or failure.

Power Tools and Equipment

In addition to hand tools, power tools play a crucial role in repair tasks. Devices like drills and impact wrenches can significantly reduce the time required for projects. A reliable grinder is useful for smoothing rough edges or cutting through metal, while a quality compressor can power pneumatic tools for added efficiency. Investing in these items enhances both speed and accuracy in maintenance work.

Where to Find Replacement Parts

When it comes to maintaining and repairing outdoor machinery, locating the right components is crucial for optimal performance. Fortunately, several resources can help you find the necessary items to keep your equipment running smoothly.

- Authorized Dealers: These establishments often have a comprehensive selection of official components and knowledgeable staff who can assist with your needs.

- Online Retailers: Websites specializing in outdoor equipment often offer a wide array of replacements. Be sure to check for customer reviews and ratings to ensure reliability.

- Local Hardware Stores: Many community hardware shops carry common components and can order specific items if needed.

- Salvage Yards: For those seeking cost-effective solutions, salvage yards can be a treasure trove of usable parts.

- Manufacturer’s Website: The official site may provide detailed listings of available items along with pricing and availability.

By exploring these options, you can effectively source the necessary components to enhance the longevity and efficiency of your machinery.

Best Practices for Engine Longevity

Ensuring the long-lasting performance of any mechanical system requires adherence to a set of well-defined practices. By following these guidelines, users can significantly enhance reliability, efficiency, and overall lifespan, minimizing the risk of breakdowns and costly repairs.

Regular Maintenance

Routine checks and services are crucial for optimal functionality. Consider the following:

- Perform oil changes at recommended intervals to maintain lubrication.

- Inspect air filters and replace them as needed to ensure proper airflow.

- Check spark plugs regularly and replace them if they show signs of wear.

- Keep cooling systems clean and free from debris to prevent overheating.

Operating Practices

How a machine is used greatly impacts its durability. To prolong its lifespan, keep in mind these operating strategies:

- Avoid overloading beyond the specified capacity.

- Allow the system to warm up before heavy usage to ensure optimal performance.

- Utilize appropriate fuel and lubricants as recommended by the manufacturer.

- Monitor performance regularly and address any irregularities promptly.

Upgrading Your Engine Performance

Enhancing the efficiency and power of your machinery can lead to a significant improvement in overall functionality. By implementing a series of modifications and updates, you can achieve a more robust and responsive system. This section delves into various strategies that can be employed to boost performance effectively.

One of the most impactful changes you can make is to evaluate and replace specific components. Upgrading elements such as the fuel delivery system, exhaust mechanisms, and ignition components can yield noticeable results. Below is a table outlining key areas to focus on when considering enhancements:

| Component | Benefits of Upgrading |

|---|---|

| Air Filter | Improved airflow leading to better combustion and efficiency. |

| Fuel Pump | Increased fuel delivery ensuring optimal performance under load. |

| Ignition System | Enhanced spark for a more complete fuel burn, boosting power. |

| Exhaust System | Reduced back pressure allowing for improved exhaust flow and efficiency. |

| Cooling System | Better heat management to prevent overheating and maintain performance. |

By systematically assessing these components and making informed choices, you can maximize the potential of your machinery. This proactive approach not only enhances performance but can also extend the lifespan of the entire system.