Kubota D1105 Engine Components Overview

Understanding the components and structure of mechanical assemblies is crucial for ensuring the longevity and efficiency of various machines. This section provides an in-depth exploration of how key elements work together to deliver seamless functionality in complex systems. By breaking down the individual units, we gain insights into their roles within the broader setup.

Proper maintenance and periodic inspections are essential for any machinery. Familiarizing oneself with the specific layout and connection points helps avoid costly repairs. The following discussion will cover the foundational elements that make up these intricate systems, guiding users through each segment with clarity.

Whether you’re performing repairs or simply looking to enhance your understanding, this guide offers a clear breakdown of the crucial components, making it easier to navigate the technical aspects of mechanical structures.

Understanding the Kubota D1105 Engine Layout

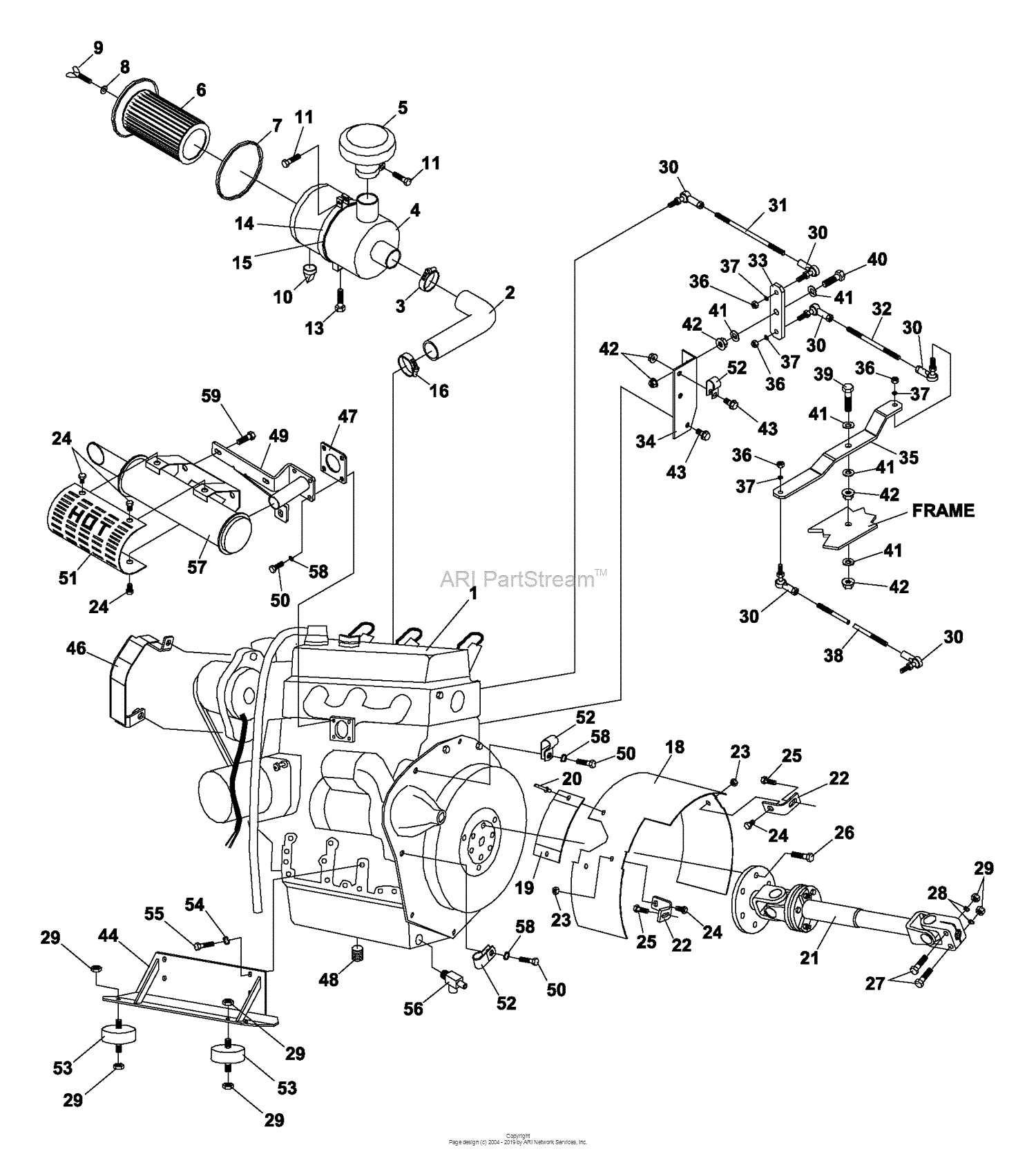

The internal structure of this compact power unit is thoughtfully designed to balance efficiency and durability. Its components are arranged to ensure smooth operation, optimal fuel combustion, and effective heat management. Understanding how various elements are positioned allows for better maintenance and troubleshooting of mechanical systems.

Each section of the motor is intricately connected, from the intake to the exhaust, creating a seamless flow that maximizes performance. Knowing the layout will help in identifying key areas related to fuel delivery, cooling, and exhaust pathways, which are essential for optimal functionality.

Key Components of the D1105 Engine

This section highlights the primary elements found within a modern compact power unit, focusing on its mechanical structure and operational roles. Each part plays a vital role in ensuring efficiency, durability, and performance in various applications. Understanding these core elements helps in maintaining and optimizing the unit for long-term functionality.

One of the central features is the combustion chamber, where energy is generated through controlled fuel ignition. Another key aspect is the cooling system, responsible for maintaining optimal temperatures during operation. Additionally, the fuel delivery system ensures precise control over fuel intake for improved efficiency.

The lubrication system is crucial for reducing friction between moving parts, while the exhaust mechanism channels gases away from the unit. These interconnected components work together seamlessly, ensuring smooth and reliable performance in demanding environments.

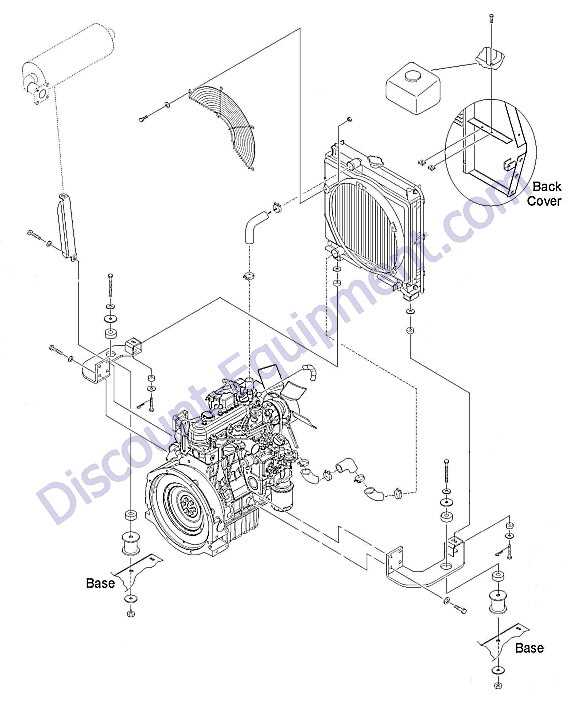

How the Cooling System Works

The cooling system is designed to maintain an optimal temperature by removing excess heat generated during operation. It ensures the machinery continues to function effectively while preventing overheating, which can cause damage to various components. The process involves circulating a liquid coolant through specific channels to absorb heat and release it through a designated mechanism.

Key Components

The system comprises several critical parts that work together to manage temperature efficiently. These include a coolant reservoir, a network of hoses, and a heat exchanger, among others. Each of these components plays a unique role in regulating the thermal balance.

Cooling Process Overview

The liquid coolant absorbs heat as it flows through the system. Once heated, it moves to the exchanger, where it releases the absorbed warmth into the surrounding air. This cycle repeats continuously, ensuring consistent temperature regulation during operation.

| Component | Function |

|---|---|

| Coolant Reservoir | Stores the liquid coolant |

| Hoses | Transport the coolant throughout the system |

| Heat Exchanger | Dissipates the heat absorbed by the

Lubrication System: Essential Parts

The lubrication system plays a crucial role in maintaining the proper functioning of various mechanical components. By ensuring smooth movement and reducing friction, it helps extend the life of essential mechanisms, while also preventing overheating and excessive wear. Main ComponentsThe primary elements of the lubrication setup include pumps, which circulate the oil through the machinery, and filters, that keep contaminants out. These components work in tandem to provide constant lubrication, ensuring that moving parts remain protected and operate efficiently. Supporting ElementsAdditional key features include oil passages, which direct the lubricant to critical areas, and coolers, that manage the temperature of the fluid to prevent breakdown. Together, these elements are essential in sustaining optimal performance and longevity of the system. Fuel Delivery Mechanism Overview

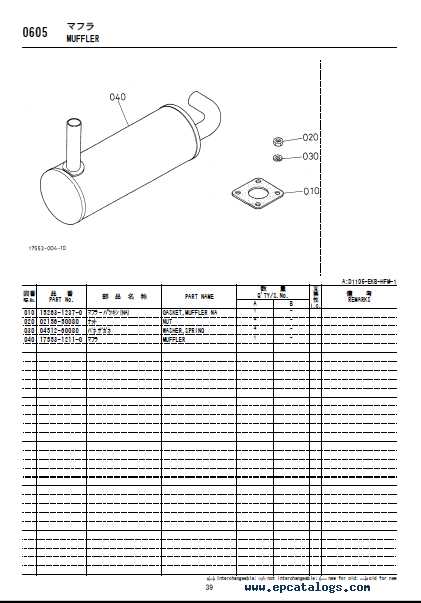

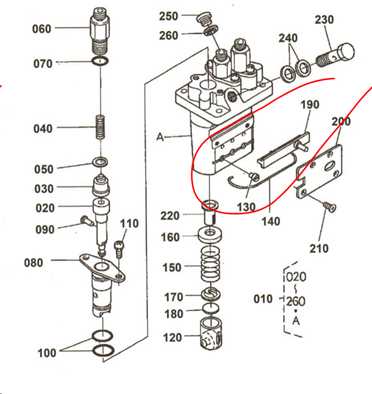

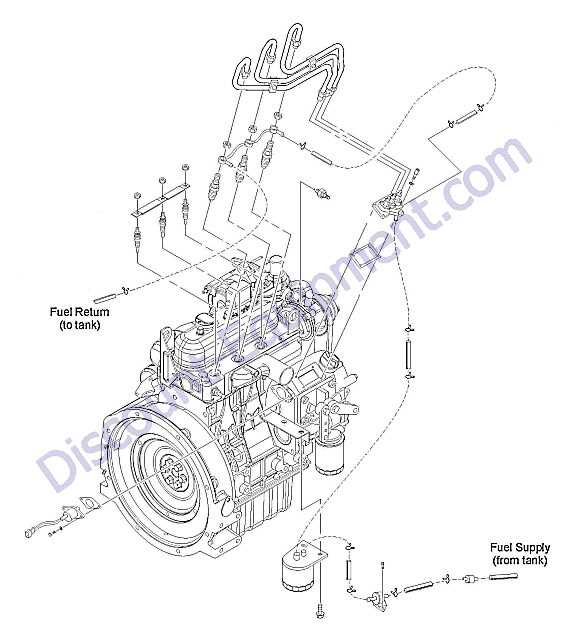

The fuel system plays a crucial role in providing consistent and reliable power. It ensures that the right amount of fuel is delivered efficiently for optimal performance, making the machinery run smoothly and effectively. Understanding the flow of fuel from the storage tank to the combustion chamber is essential for maintenance and troubleshooting. Components and FunctionsSeveral interconnected parts contribute to the system’s efficiency, including pumps, injectors, and filters. Each element is designed to ensure clean fuel reaches its destination without interruptions, supporting continuous operation under varying conditions. Fuel Flow ProcessThe process starts with fuel being drawn from the tank through a series of filters and then pressurized by the pump. Once pressurized, it moves through injectors that precisely deliver the necessary quantity into the combustion chamber, ensuring an optimal mixture for ignition. Exhaust System and Related PartsThe exhaust system is a crucial component responsible for managing emissions and reducing engine noise. It is composed of multiple interconnected parts that work together to direct exhaust gases safely out of the machine. Understanding the function and layout of these components helps in maintaining efficiency and performance.

These components must be inspected regularly to ensure optimal function and prevent damage to other mechanical Understanding the Engine Block DesignThe core structure of a motor’s power system lies in the block, which serves as the foundation for all major components. Its architecture is designed to withstand extreme pressure, manage internal heat, and house essential moving parts. Understanding the layout and function of this critical component offers insight into the overall durability and efficiency of the machine. Main Features of the BlockThe block is crafted from durable materials, often cast iron or aluminum alloy, ensuring it can handle high temperatures and mechanical stress. Key areas within the block are carefully engineered to maintain balance and minimize wear over time.

Internal Passageways and Design ConsiderationsWithin the block, intricate networks of channels manage the fl Air Intake and Filtration ComponentsEffective air intake and filtration systems are crucial for maintaining optimal performance and longevity. These components ensure that clean air enters the combustion chamber while protecting the internal mechanisms from harmful debris. Understanding their structure and function can help in troubleshooting and maintenance efforts. Primary Air Intake SystemThe air intake system is responsible for drawing air into the system. This air is crucial for the combustion process, where it mixes with fuel for ignition. Proper air intake is essential for achieving the desired power output and efficiency.

Filtration Mechanism

Filtration plays a vital role in ensuring that only clean air reaches sensitive parts. The filtration system prevents dust, dirt, and other particles from entering the intake system, which could potentially damage internal components.

The Importance of Proper Gasket SealingEffective sealing is a critical aspect of ensuring the longevity and optimal performance of any mechanical assembly. Proper gasket installation and sealing prevent fluid and gas leaks, minimize wear and tear, and help maintain system integrity under various operating conditions. Why Proper Sealing MattersWhen sealing components are correctly installed, they create a tight barrier that prevents harmful leaks. This is essential for maintaining the system’s efficiency and protecting against contamination. A poorly sealed joint, on the other hand, can lead to several issues:

Factors Affecting Gasket PerformanceThe effectiveness of gasket seals depends on multiple factors:

Common Replacement Parts for the D1105Routine maintenance and timely replacements are essential to ensure optimal performance. Over time, certain components may wear out or degrade, requiring attention. Below are the most commonly replaced elements that help maintain reliability and efficiency, ensuring that the machinery operates smoothly for longer periods. Fuel Filters are crucial for keeping the fuel system clean and preventing contaminants from entering the combustion chamber. These should be checked regularly to ensure they are not clogged, which could result in engine performance issues. Oil Filters play a significant role in maintaining the quality of the lubricating oil. A blocked oil filter can lead to poor lubrication, which may cause excessive wear on vital internal components. Air Filters ensure that only clean air enters the intake system. Dirty or clogged air filters can lead to reduced efficiency, poor combustion, and potentially even damage to the internal mechanisms due to the intake of dust and debris. Belts and Pulleys often experience wear due to friction and strain over time. Replacing these components when they show signs of damage or wear can prevent operational failures and maintain smooth functioning. Water Pumps are vital for maintaining the cooling system. A malfunctioning water pump can result in overheating, which can damage internal parts. Replacing it when necessary helps avoid severe issues down the line. Maintenance Tips for LongevityProper upkeep is essential for extending the lifespan of your machinery and ensuring optimal performance. Regular maintenance not only prevents costly repairs but also helps maintain efficiency over time. By following a few key steps, you can ensure that your equipment runs smoothly and reliably for years to come.

Incorporating these routine checks into your schedule will help your equipment perform at its best and provide long-lasting reliability. Regular attention to these areas ensures minimal downtime and maximizes the investment in your machinery. |