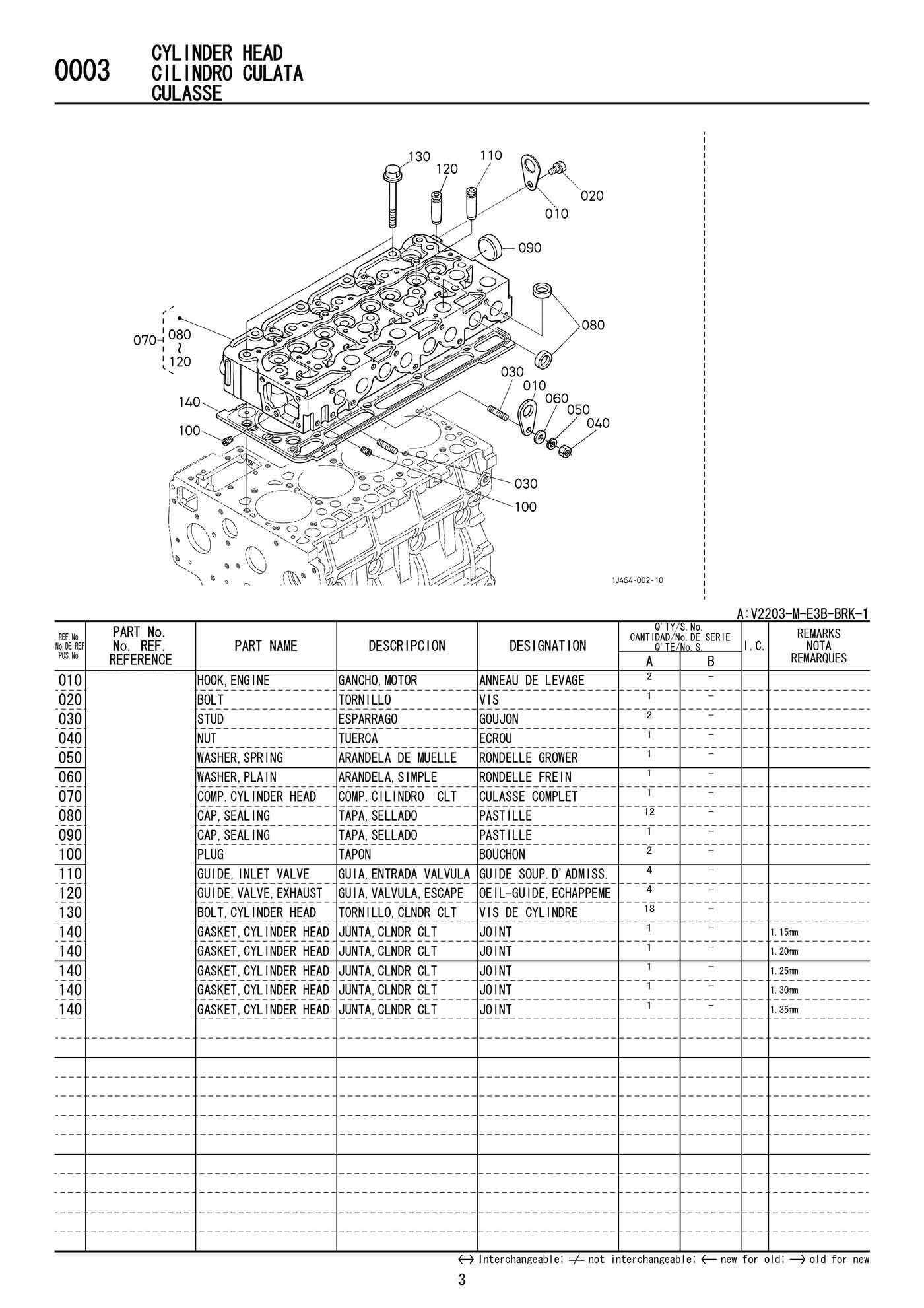

Kubota V2403 Engine Parts Diagram Overview

In the world of heavy-duty machinery, comprehending the intricacies of various mechanisms is crucial for optimal performance and maintenance. The internal workings of these powerful machines rely on a multitude of interconnected elements, each serving a specific purpose. By gaining insight into the structure and functionality of these components, operators and technicians can ensure longevity and efficiency.

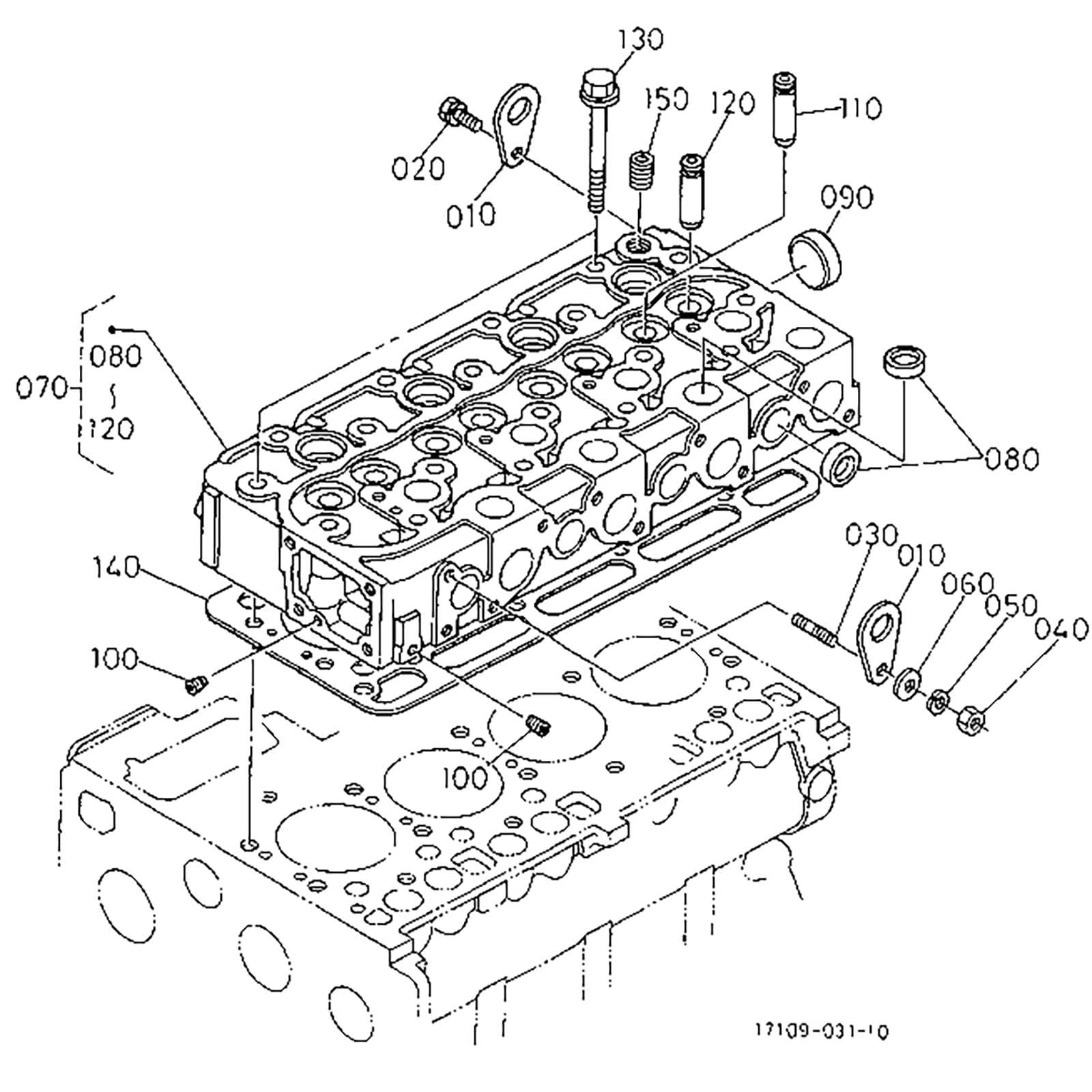

Visual representations of mechanical assemblies offer a valuable resource for anyone involved in the upkeep of industrial equipment. These illustrations highlight the arrangement and relationships between different units, facilitating a clearer understanding of their roles. Through careful analysis of these visuals, one can identify potential issues and streamline repair processes.

As you delve into the specifics of various machinery configurations, it becomes evident that knowledge of individual components enhances overall operational effectiveness. By familiarizing oneself with these illustrations, users can improve diagnostic skills and contribute to the seamless functioning of their equipment.

Kubota V2403 Engine Overview

This section provides a comprehensive overview of a specific four-cylinder power unit known for its reliability and efficiency. Designed for a variety of applications, this model stands out in the agricultural and industrial sectors due to its robust performance and durability.

Key Features

This power unit is characterized by its compact design and impressive output. Key features include:

- Four-cylinder configuration

- Liquid cooling system

- Direct injection technology

- Low emissions profile

Applications

Utilized in a diverse range of machinery, this model is commonly found in agricultural equipment, construction vehicles, and generators. Its versatility makes it suitable for both light and heavy-duty operations.

| Specification | Value |

|---|---|

| Displacement | 2.4 L |

| Power Output | 50-70 HP |

| Torque | 150 Nm |

| Weight | 200 kg |

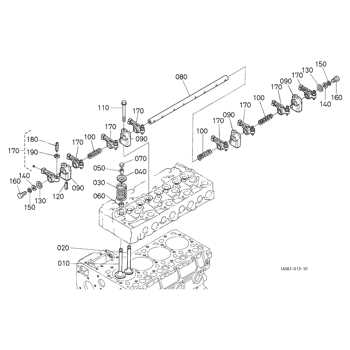

Key Components of the V2403 Engine

The intricate machinery of this power unit is composed of several essential elements that work in harmony to deliver optimal performance. Each component plays a crucial role in ensuring the efficient operation and reliability of the overall system.

1. Cylinder Block: This foundational structure houses the cylinders and supports various other components. Its durability is vital for maintaining compression and managing heat.

2. Pistons: These moving parts convert fuel combustion into mechanical energy. Their design and material significantly influence performance and efficiency.

3. Crankshaft: Acting as the heart of the mechanism, it transforms the linear motion of the pistons into rotational movement, enabling power transmission to other systems.

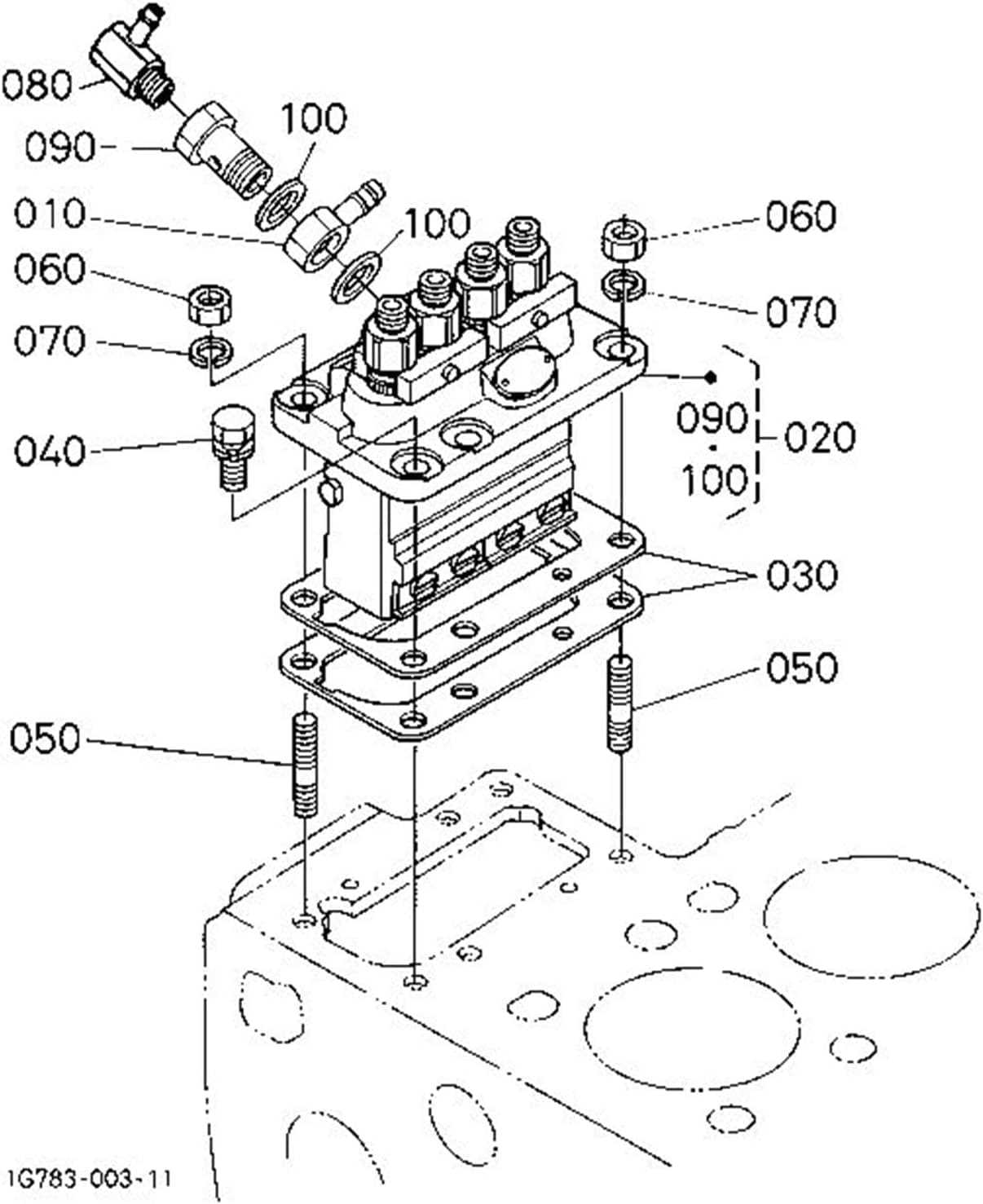

4. Fuel Injection System: This assembly ensures precise delivery of fuel to the combustion chamber, enhancing efficiency and reducing emissions. Accurate timing is essential for optimal performance.

5. Cooling System: This network of components manages the temperature of the unit, preventing overheating and ensuring sustained operation under various conditions. Effective cooling is critical for longevity.

6. Lubrication System: This system reduces friction between moving parts, ensuring smooth operation and minimizing wear. Proper lubrication extends the lifespan of the unit.

7. Exhaust System: Responsible for directing exhaust gases away from the combustion area, this system also contributes to noise reduction and efficiency in the operation.

Understanding these integral components helps in appreciating the engineering that enables reliable and effective performance across diverse applications.

Understanding Engine Parts Functionality

Comprehending the various components of a power unit is essential for anyone interested in mechanics or maintenance. Each element plays a crucial role in ensuring that the machine operates smoothly and efficiently. By exploring the functionality of these components, one can appreciate how they interact to produce power and facilitate movement.

The core of any power unit is its ability to convert fuel into energy. This transformation involves several key elements that work in unison. For instance, the combustion chamber is where the fuel ignites, creating the force needed to drive the pistons. These pistons, in turn, transfer motion to the crankshaft, ultimately generating rotational power.

Supporting components also play vital roles. The cooling system prevents overheating by circulating fluid, while the lubrication system reduces friction between moving parts, ensuring longevity and reliability. Additionally, the intake and exhaust mechanisms regulate airflow, allowing for efficient combustion and minimizing harmful emissions.

Understanding these functionalities helps in troubleshooting issues and performing effective maintenance. When one recognizes how each component contributes to the overall operation, it becomes easier to identify potential problems and implement timely solutions.

Common Issues with V2403 Components

Mechanical systems often encounter various challenges that can affect their overall performance and longevity. Understanding these common problems is crucial for effective maintenance and timely interventions. This section explores frequent issues associated with specific components, helping users identify and address potential failures.

1. Overheating: A prevalent issue is overheating, which can stem from inadequate coolant circulation or malfunctioning thermostats. Regular checks on cooling systems are essential to prevent severe damage.

2. Oil Leaks: Leaks can occur due to worn gaskets or seals. Identifying oil stains under the machinery can indicate the need for immediate attention to avoid lubrication failures.

3. Electrical Failures: Faulty wiring or corroded connectors often lead to electrical malfunctions. Ensuring clean and secure connections can mitigate many issues.

4. Fuel Delivery Problems: Clogged filters or malfunctioning injectors can hinder fuel flow, resulting in performance issues. Regular maintenance of the fuel system is vital for optimal operation.

5. Noise and Vibration: Unusual sounds or vibrations may signal worn bearings or misaligned components. Early detection can prevent more significant mechanical failures.

By being aware of these typical challenges, operators can take proactive measures to maintain efficiency and prolong the lifespan of their machinery.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring peak efficiency and longevity of your machinery. Adopting a proactive approach to maintenance not only enhances performance but also minimizes the likelihood of unexpected breakdowns. Here are several strategies to consider for optimal operation.

- Routine Inspections: Conduct frequent visual checks to identify wear and tear. Look for any signs of leaks, corrosion, or loose components.

- Fluid Levels: Regularly monitor and maintain proper fluid levels, including coolant and lubrication, to prevent overheating and friction-related damage.

- Filter Replacement: Change filters as recommended by the manufacturer. Clean air and fuel filters improve efficiency and protect internal components.

- Belts and Hoses: Inspect belts for signs of fraying and hoses for leaks. Replace them as needed to avoid costly failures.

- Cleanliness: Keep the surroundings clean and free from debris. Accumulated dirt can lead to overheating and reduced performance.

By implementing these practices, you can ensure that your machinery operates smoothly and reliably, ultimately extending its service life and enhancing productivity.

Diagram Interpretation for Beginners

Understanding a visual representation of mechanical components can be challenging for newcomers. However, with a bit of guidance, anyone can learn to decipher these illustrations effectively. This section aims to break down the essentials of reading and interpreting such visuals, focusing on the relationships and functions of various elements.

First, it’s important to familiarize yourself with the common symbols and notations used in these visuals. Recognizing what each symbol represents can significantly enhance your comprehension and enable you to grasp complex interactions more easily.

| Symbol | Description |

|---|---|

| Circle | Typically indicates a component or unit within the system. |

| Arrow | Shows the direction of flow or movement. |

| Dashed Line | Represents a connection that is not rigid or permanent. |

| Box | Often denotes a junction or a control point. |

Next, it’s beneficial to pay attention to the layout. Components are usually arranged in a way that reflects their operational sequence. By following the path of arrows and lines, you can trace how each part interacts with others and contributes to the overall function.

Finally, practice is essential. Regularly reviewing and interpreting different representations will build your confidence and familiarity with this essential skill. As you gain experience, you will find it easier to understand increasingly complex visuals.

Parts Replacement Process Explained

Understanding the procedure for substituting components is crucial for maintaining optimal functionality. This process ensures that all units operate seamlessly, enhancing overall performance and reliability. Familiarity with the steps involved can significantly reduce downtime and improve efficiency.

The replacement procedure typically involves several key stages, each requiring careful attention to detail. Below is a structured overview of these essential steps:

| Step | Description |

|---|---|

| 1 | Assessment: Evaluate the condition of the component and identify the need for replacement. |

| 2 | Preparation: Gather necessary tools and new components, ensuring compatibility with existing systems. |

| 3 | Removal: Carefully detach the old unit, taking care not to damage surrounding structures. |

| 4 | Installation: Position the new component accurately and secure it following manufacturer guidelines. |

| 5 | Testing: Conduct thorough checks to verify that the new unit functions correctly within the system. |

By adhering to these steps, one can ensure a successful transition to new components, ultimately contributing to improved operation and longevity.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for maintaining optimal performance and longevity. Genuine items ensure compatibility and reliability, reducing the risk of malfunction and costly repairs. This section highlights reliable sources where you can find the right elements for your equipment.

Authorized Dealers

One of the most dependable avenues for acquiring authentic components is through authorized dealers. These retailers are certified to sell original items and often have knowledgeable staff who can assist with any inquiries regarding selection and installation. They typically offer warranties, ensuring peace of mind with your purchases.

Online Marketplaces

Another option is to explore reputable online marketplaces that specialize in machinery components. Websites that focus on heavy equipment often provide a wide selection of genuine products along with user reviews and ratings. When purchasing online, always verify the seller’s credibility and ensure they offer return policies for added security.

Aftermarket vs. OEM Parts Comparison

When it comes to maintaining machinery, the choice between original components and alternative offerings is a significant decision for many operators. Understanding the differences in quality, cost, and availability can help in making an informed choice that best suits specific needs.

Quality and Performance

Original components are typically manufactured to the exact specifications set by the original manufacturer, ensuring optimal compatibility and reliability. In contrast, alternative options can vary in quality. While some aftermarket products may meet or exceed the performance of original offerings, others might not align with the required standards, potentially leading to issues down the line.

Cost Considerations

One of the primary advantages of alternative components is their often lower price point. This can provide significant savings, especially for extensive maintenance or repairs. However, it’s essential to weigh these savings against the potential risks associated with lower-quality options. Investing in original components can offer peace of mind, knowing that the parts will function as intended.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | Consistent, high-quality standards | Varies; some meet or exceed standards, others do not |

| Cost | Generally higher | Usually lower, potential for savings |

| Warranty | Often includes warranty coverage | Varies; may not offer warranty |

| Availability | Limited to specific distributors | Widely available from multiple sources |

Benefits of Using Kubota Parts

Opting for original components for your machinery ensures superior performance and longevity. High-quality replacements are designed specifically for your equipment, resulting in enhanced efficiency and reliability. When you choose authentic offerings, you invest in the seamless operation and overall durability of your machinery.

Quality Assurance

One of the primary advantages of utilizing genuine components is the assurance of quality. These items undergo rigorous testing to meet industry standards, which means they are less likely to fail. When using original offerings, you can trust that they will function optimally and withstand demanding conditions.

Cost-Effectiveness

While initial costs may be higher, the long-term savings associated with authentic components are significant. They typically require fewer replacements and repairs over time, resulting in lower maintenance expenses. Additionally, enhanced efficiency can lead to savings on fuel and operational costs, making the investment worthwhile.