Lawn Mower Engine Parts Diagram Explained

In the world of outdoor maintenance, the effectiveness of your tools hinges on the intricate design and functionality of their individual elements. Every piece plays a critical role in ensuring that the machinery operates smoothly and efficiently, allowing for a well-manicured landscape. Familiarity with these components can enhance your ability to troubleshoot issues and maintain optimal performance.

Delving into the structure of your gardening equipment reveals a network of interconnected mechanisms. Each segment, from the power source to the cutting mechanism, contributes to the overall operation. By grasping how these elements interact, you can better appreciate the engineering behind your trusted companion in yard care.

Moreover, understanding the layout of these essential components can be invaluable when it comes to repairs and upgrades. Whether you’re looking to replace a worn part or simply want to enhance your device’s capabilities, having a clear visualization of how everything fits together is key to making informed decisions. Embracing this knowledge empowers you to take control of your gardening tasks with confidence.

Lawn Mower Engine Overview

This section provides a comprehensive look at the essential components that drive the performance of a grass cutting machine. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal functionality and longevity of the device.

| Component | Function |

|---|---|

| Power Source | Generates energy to propel the machine and its cutting mechanism. |

| Air Filter | Filters the air entering the combustion chamber, ensuring clean operation. |

| Fuel System | Stores and delivers fuel to the power source for efficient combustion. |

| Ignition System | Ignites the fuel-air mixture, initiating the power cycle. |

| Cooling Mechanism | Regulates temperature to prevent overheating during operation. |

| Exhaust System | Expels combustion byproducts, maintaining performance efficiency. |

Essential Components of Engine Design

Understanding the fundamental elements of mechanical design is crucial for anyone involved in the development or maintenance of various types of machinery. These integral components work together to ensure optimal performance, efficiency, and longevity of the overall system. A solid grasp of these essentials not only aids in troubleshooting but also enhances the ability to innovate and improve existing designs.

Core Mechanisms

At the heart of any mechanical system lies a series of core mechanisms that drive functionality. These mechanisms include structures that convert energy into motion, facilitating the desired output. Each element is carefully crafted to withstand forces and pressures, contributing to the reliability of the entire assembly. The interaction between these mechanisms determines the effectiveness and efficiency of the machine.

Supporting Structures

In addition to the core mechanisms, various supporting structures play a pivotal role in ensuring stability and alignment. These components help maintain the integrity of the system under operational stresses, minimizing wear and tear. Properly designed supports are essential for maintaining precise tolerances, which are vital for optimal performance. Without these foundational elements, even the most sophisticated mechanisms could fail to function as intended.

Understanding Engine Types for Mowers

Different types of power units can significantly impact the performance and efficiency of grass cutting machines. Familiarity with these variations is essential for choosing the right model for your needs.

Here are some common types of power units found in these machines:

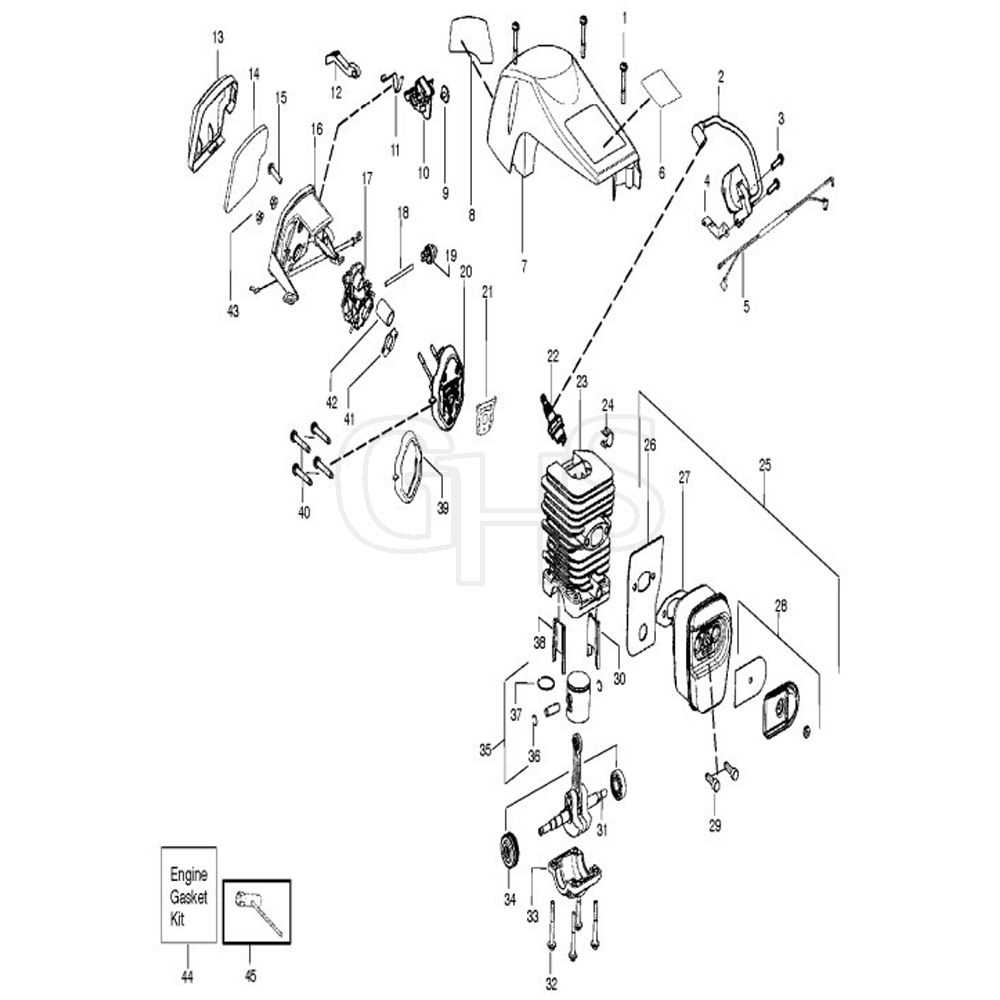

- Two-Stroke: Known for their simplicity and lightweight design, these units are often used in smaller machines. They typically require a mixture of fuel and oil.

- Four-Stroke: These are more common in larger, more robust machines. They offer better fuel efficiency and lower emissions, operating on a separate oil and fuel system.

- Electric: Powered by batteries or directly from a power source, electric models are quieter and more environmentally friendly, making them suitable for residential areas.

- Gasoline: These units provide powerful performance and are often preferred for their ability to handle tougher jobs, although they may require more maintenance.

Understanding the characteristics of each type can guide users in selecting the most suitable option based on their requirements and preferences.

Fuel System and Its Importance

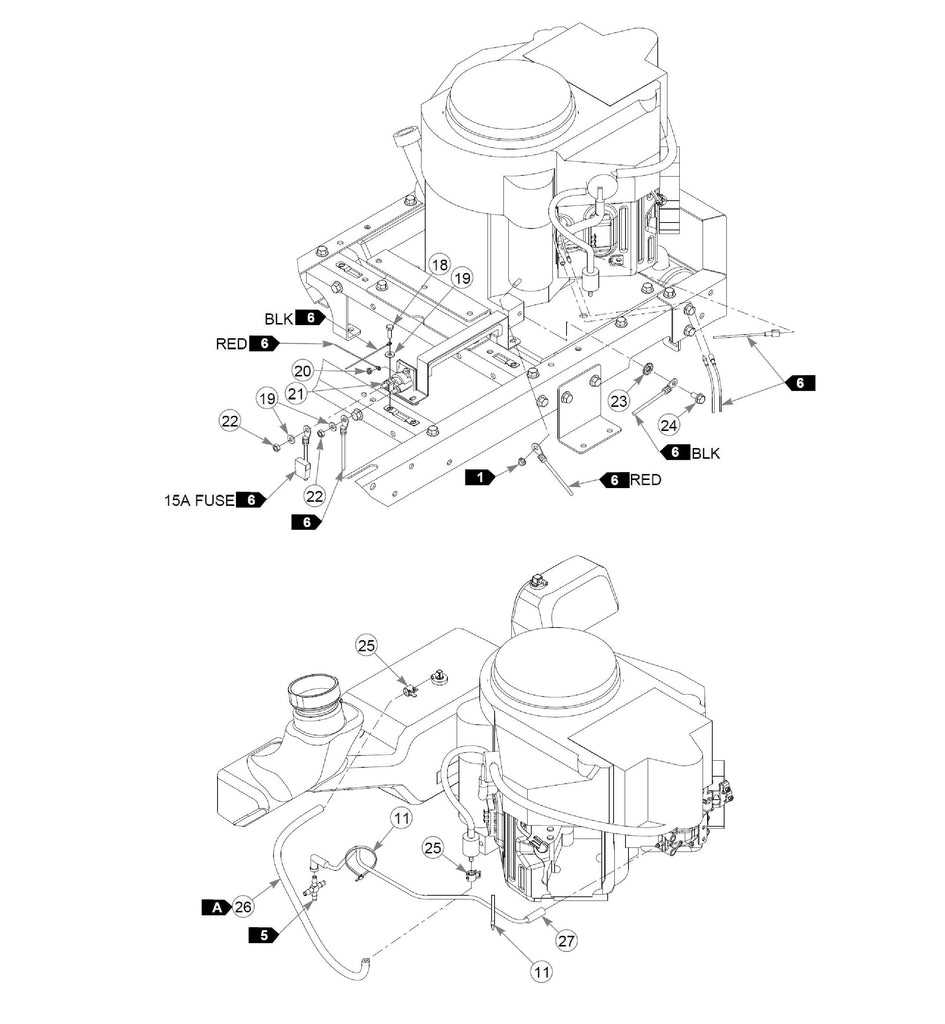

The fuel system is a crucial component that ensures optimal performance and efficiency in any mechanical apparatus. It plays a vital role in delivering the necessary energy to facilitate smooth operation. Understanding its significance helps in maintaining the longevity and reliability of the machine.

Components of the Fuel System

Typically, this system comprises several key elements, including the fuel tank, pump, filter, and delivery lines. Each part works in harmony to ensure that the fuel is stored, transported, and filtered effectively, providing the necessary supply to the combustion chamber. A well-maintained fuel system prevents issues such as clogging and inefficiency, which can lead to performance degradation.

Significance of Regular Maintenance

Regular upkeep of the fuel system is essential to avoid potential failures and enhance performance. Neglecting this aspect can result in significant operational challenges, including reduced power output and increased emissions. Ensuring that all components are clean and functioning properly not only maximizes efficiency but also contributes to the overall health of the machinery.

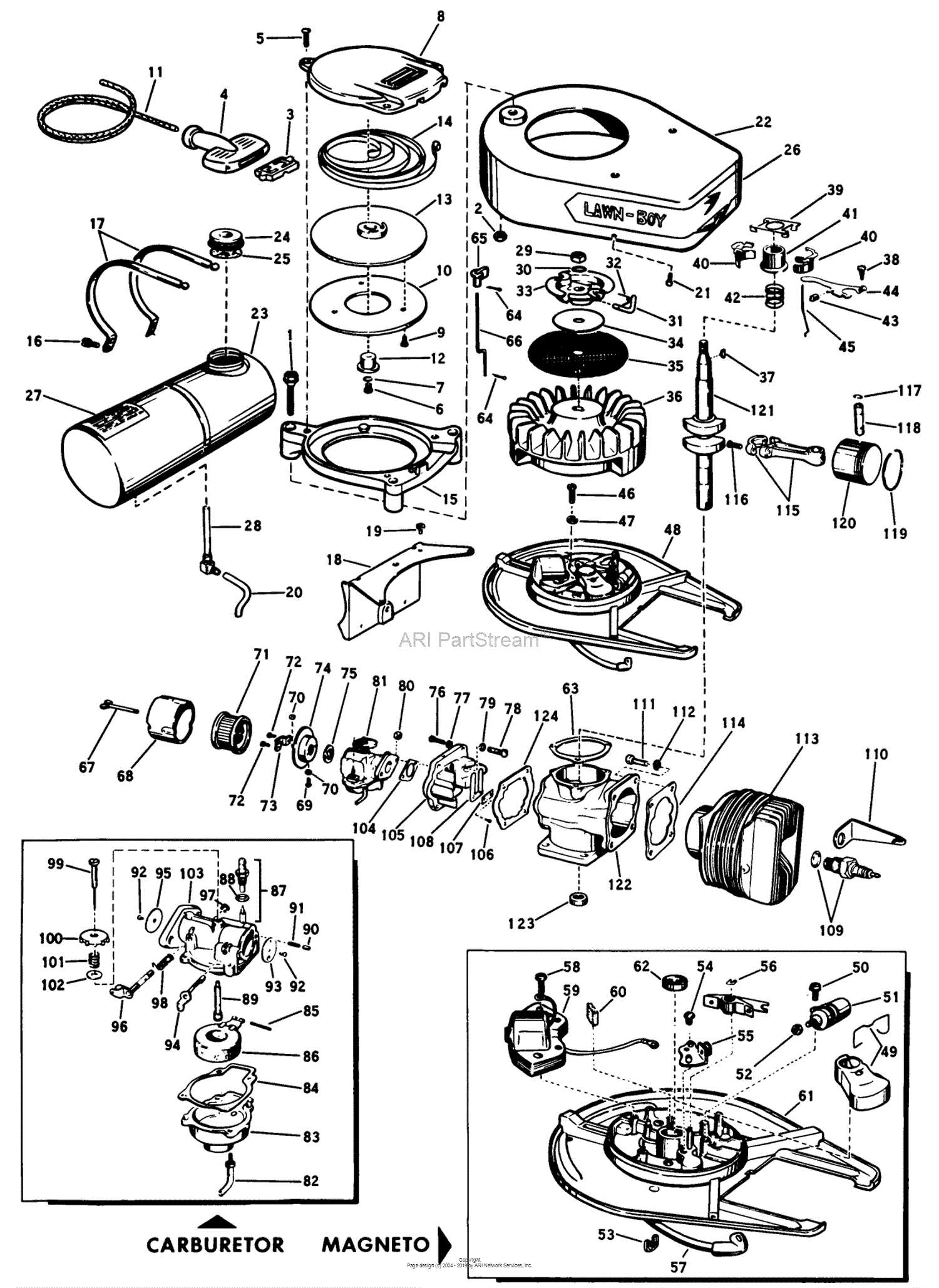

Ignition System Functionality Explained

The ignition system plays a crucial role in the operation of various machinery, ensuring the initiation of combustion processes necessary for power generation. Its primary function is to create a spark at the right moment, igniting the air-fuel mixture and facilitating the engine’s performance.

In essence, the system comprises several key components that work harmoniously together. The spark plug is vital, as it produces the electric spark required to ignite the fuel. The coil generates high voltage, sending electricity to the spark plug. Additionally, the distributor ensures that the spark is delivered to the correct cylinder in the correct sequence, optimizing efficiency and performance.

Moreover, the ignition timing is critical; it determines when the spark occurs in relation to the piston’s position, significantly affecting power output and fuel consumption. Any misalignment in this timing can lead to poor performance, increased emissions, and potential engine damage.

Ultimately, understanding the functionality of the ignition system is essential for troubleshooting and maintenance, as it ensures reliable operation and longevity of the machinery.

Cooling Mechanisms in Lawn Mower Engines

Effective thermal management is crucial for optimal performance and longevity of small power units. These mechanisms ensure that the operating temperature remains within safe limits, preventing overheating and subsequent damage. Various strategies are employed to dissipate heat generated during operation, allowing for efficient functionality.

Types of Cooling Systems

There are two primary cooling systems utilized in small power units: air cooling and liquid cooling. Each system has its own advantages and applications based on the design and intended use of the machine.

| Cooling Type | Advantages | Applications |

|---|---|---|

| Air Cooling | Lightweight, simpler design, lower maintenance | Smaller, portable machines |

| Liquid Cooling | More efficient heat management, quieter operation | Larger, high-performance units |

Importance of Cooling Mechanisms

Maintaining proper temperatures not only enhances performance but also extends the lifespan of the equipment. Overheating can lead to critical failures, making effective cooling systems essential for reliable operation. Understanding the principles behind these mechanisms helps users select the right model for their needs and ensures proper maintenance practices are followed.

Air Filters and Engine Performance

Effective filtration is crucial for optimal functionality in various machinery. The quality of airflow directly impacts the overall efficiency and longevity of the system. Ensuring that the intake remains clean enhances performance, reduces wear, and minimizes maintenance needs.

Importance of Clean Filtration

When air filters are clogged or dirty, they restrict the flow of oxygen necessary for combustion. This inefficiency can lead to poor performance, increased fuel consumption, and higher emissions. Regular maintenance and timely replacements are essential to maintain the desired operational standards.

Effects on Performance Metrics

| Condition | Performance Impact |

|---|---|

| Clean Filter | Maximized airflow, improved combustion |

| Dirty Filter | Reduced airflow, decreased power output |

| Damaged Filter | Contaminants enter, leading to potential damage |

In conclusion, maintaining clean filtration systems is vital for enhancing performance and ensuring the machinery operates efficiently over time. Regular checks and replacements can prevent costly repairs and prolong the lifespan of the equipment.

Oil Systems: Maintenance and Importance

The lubrication system plays a crucial role in ensuring the smooth operation of machinery. Proper maintenance of this system is vital for optimal performance, longevity, and reliability. Understanding its components and functions can help in maintaining the overall health of the equipment.

Regular monitoring and maintenance of the lubrication system can prevent unnecessary wear and tear, ultimately saving time and resources. A well-functioning system reduces friction, dissipates heat, and protects against corrosion, making it essential for any machinery.

| Maintenance Task | Description | Frequency |

|---|---|---|

| Check Oil Levels | Ensure the lubricant is at the correct level to avoid overheating and damage. | Weekly |

| Change Oil | Replace old lubricant to maintain optimal performance and prevent sludge buildup. | Every 50 hours of operation |

| Inspect Filters | Check and clean or replace filters to ensure proper flow and cleanliness of the lubricant. | Monthly |

| Look for Leaks | Regularly check for leaks to prevent loss of lubricant and potential damage. | Weekly |

Neglecting the lubrication system can lead to severe consequences, including equipment failure and costly repairs. Prioritizing maintenance not only enhances performance but also extends the life of the machinery, making it a vital aspect of operational success.

Common Wear Parts in Engine Systems

In the realm of mechanical systems, certain components are prone to degradation due to constant use and operational stresses. Understanding these elements is crucial for maintaining optimal functionality and prolonging the lifespan of the machinery.

Filters are essential for ensuring that contaminants do not interfere with performance. Over time, they can become clogged, leading to reduced efficiency and potential damage if not replaced regularly.

Seals and gaskets play a vital role in preventing leaks and maintaining pressure within the system. These components are susceptible to wear and tear from heat and friction, making periodic inspection and replacement necessary to avoid costly repairs.

Belts are another common component that faces significant strain. Their durability is often tested under varying loads, and signs of cracking or fraying indicate that they need to be addressed to prevent failure during operation.

Spark plugs are critical for ignition and performance. Over time, they can accumulate deposits or wear down, leading to inefficient combustion and reduced power output. Regular replacement can enhance overall efficiency and responsiveness.

Rings, which help maintain compression and prevent oil from entering the combustion chamber, are also subject to wear. As they degrade, they can lead to increased oil consumption and decreased performance, necessitating timely replacements to keep the system running smoothly.

By focusing on these commonly worn components, users can ensure that their machinery operates efficiently and reliably, minimizing downtime and maximizing productivity.

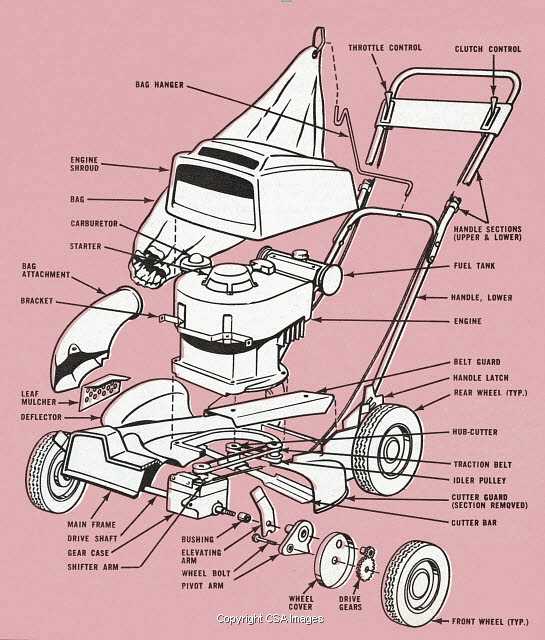

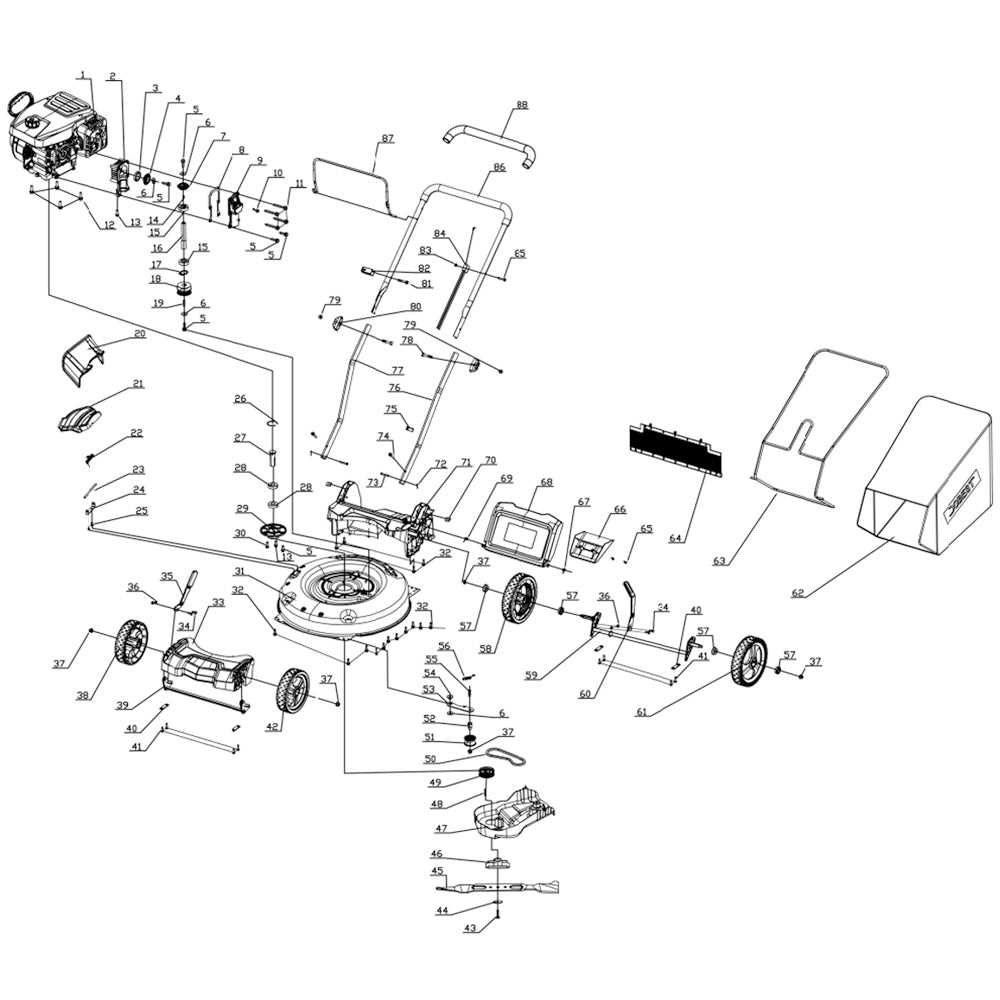

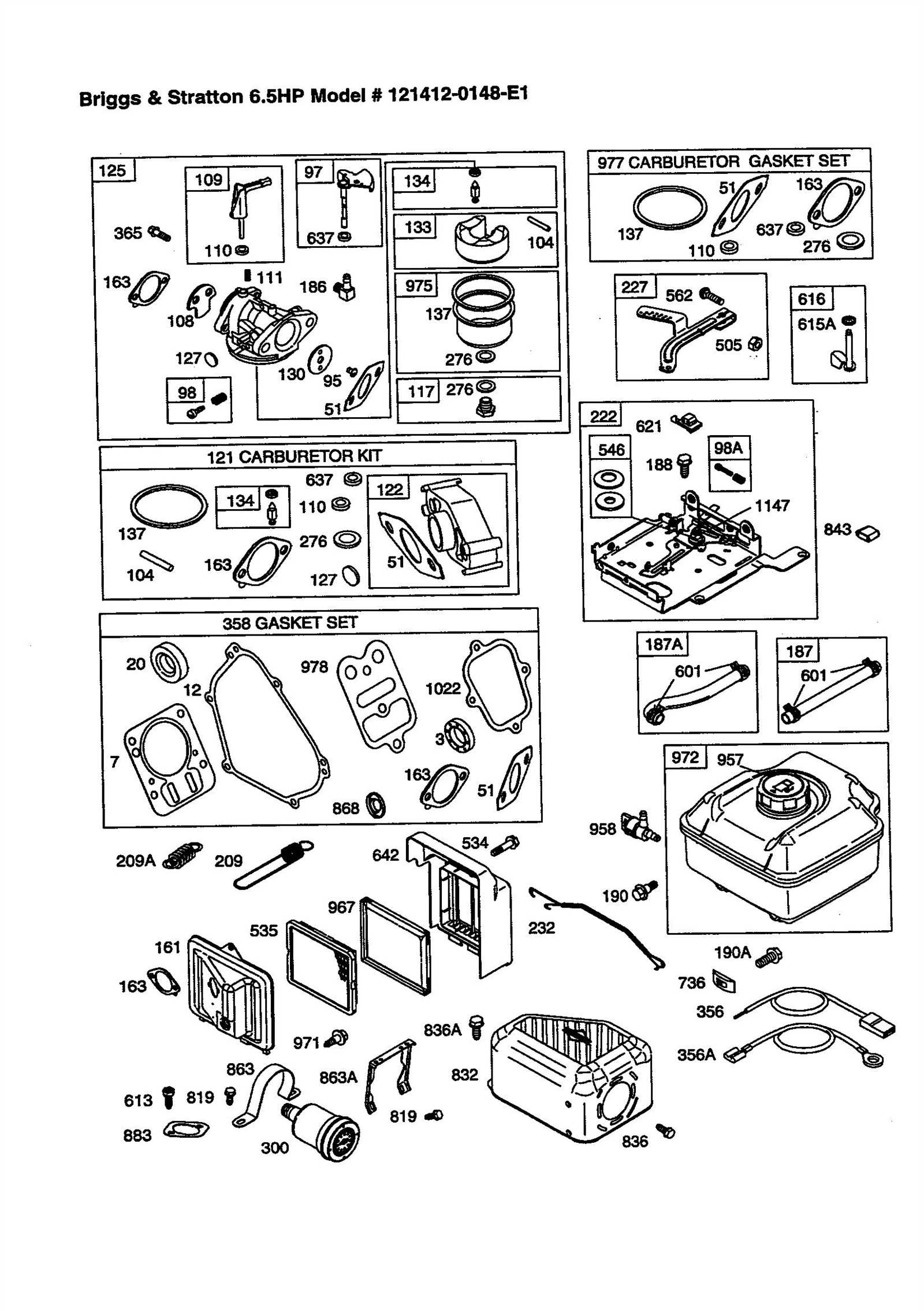

Engine Diagrams: Reading and Understanding

Interpreting visual representations of mechanical components is essential for effective maintenance and repair. These illustrations serve as valuable guides, allowing individuals to navigate the intricate relationships between various elements within a power unit. A clear comprehension of these visuals enhances one’s ability to troubleshoot issues and perform accurate assessments.

To begin with, familiarizing oneself with the basic symbols and notations used in these representations is crucial. Each symbol typically denotes a specific component, while lines and arrows indicate connections and movements. Understanding these conventions will empower users to grasp the functionality of each part and its role within the whole assembly.

Additionally, it’s important to pay attention to the scale and orientation of the representation. Proportions and angles can provide insight into how components interact under various operating conditions. Analyzing these details helps in predicting potential wear and tear or identifying areas that may require attention.

Finally, cross-referencing the visual with textual resources can enhance understanding. Manuals often accompany these illustrations, offering descriptions and specifications that complement the visual cues. This holistic approach ensures a comprehensive grasp of the system, ultimately leading to improved performance and longevity.

Troubleshooting Engine Issues Effectively

When encountering difficulties with your machine’s performance, a systematic approach can save time and resources. Understanding common symptoms and their potential causes is essential for efficient resolution. This guide aims to provide insight into identifying and rectifying typical complications that may arise during operation.

Start by observing the machine’s behavior. Unusual sounds, vibrations, or a lack of power can indicate underlying problems. Regularly check for signs of wear or damage, as these can significantly affect performance. Documenting any anomalies will help in diagnosing the issue more effectively.

Next, inspect fuel quality and supply. Stale or contaminated fuel can lead to poor performance. Ensure that the fuel system is clean and functioning properly. If issues persist, examine the ignition system. A malfunctioning spark mechanism can prevent proper combustion, leading to starting difficulties or erratic operation.

Don’t overlook the importance of airflow and cooling. Blockages in air filters or cooling systems can cause overheating and reduced efficiency. Regular maintenance, including cleaning or replacing filters, can prevent these issues from escalating.

Finally, consult a service manual or seek expert advice for complex problems. Sometimes, the root cause may not be immediately apparent, and professional assistance can provide clarity and solutions. By following these steps, you can enhance your troubleshooting skills and maintain optimal performance.

Upgrades for Enhanced Engine Efficiency

Improving performance in outdoor machinery involves strategic enhancements that optimize functionality and energy use. These modifications can lead to a noticeable boost in operational effectiveness, ensuring tasks are completed more swiftly and with reduced fuel consumption.

Fuel System Enhancements

Upgrading the fuel system is a critical step towards improved performance. Consider installing a high-efficiency fuel filter and a premium quality carburetor. These components can significantly enhance fuel delivery and atomization, ensuring a more complete combustion process. This not only maximizes power output but also minimizes emissions, contributing to a cleaner environment.

Ignition System Improvements

An upgraded ignition system can provide more reliable starting and improved throttle response. Installing a high-performance spark plug and ignition coil can enhance the combustion process, leading to increased torque and horsepower. These upgrades ensure that the combustion chamber operates at peak efficiency, resulting in better overall performance and longevity of the machinery.

Safety Features in Lawn Mower Engines

When it comes to the machinery that helps maintain your outdoor spaces, ensuring user safety is paramount. Modern devices incorporate various mechanisms designed to minimize risks and protect users from potential hazards during operation. Understanding these features can significantly enhance safe usage and maintenance practices.

Emergency Stop Mechanisms

One of the primary safety enhancements is the emergency stop mechanism, which allows users to quickly disable the machine in case of an unexpected incident. This feature can prevent accidents and injuries by providing a swift response option, ensuring that the equipment can be halted immediately when necessary.

Protective Guards and Shields

Another critical aspect is the implementation of protective guards and shields. These barriers serve to shield users from debris and moving parts, reducing the likelihood of accidents. Such safety measures are vital in creating a safer working environment, enabling individuals to focus on their tasks without unnecessary concerns about potential dangers.