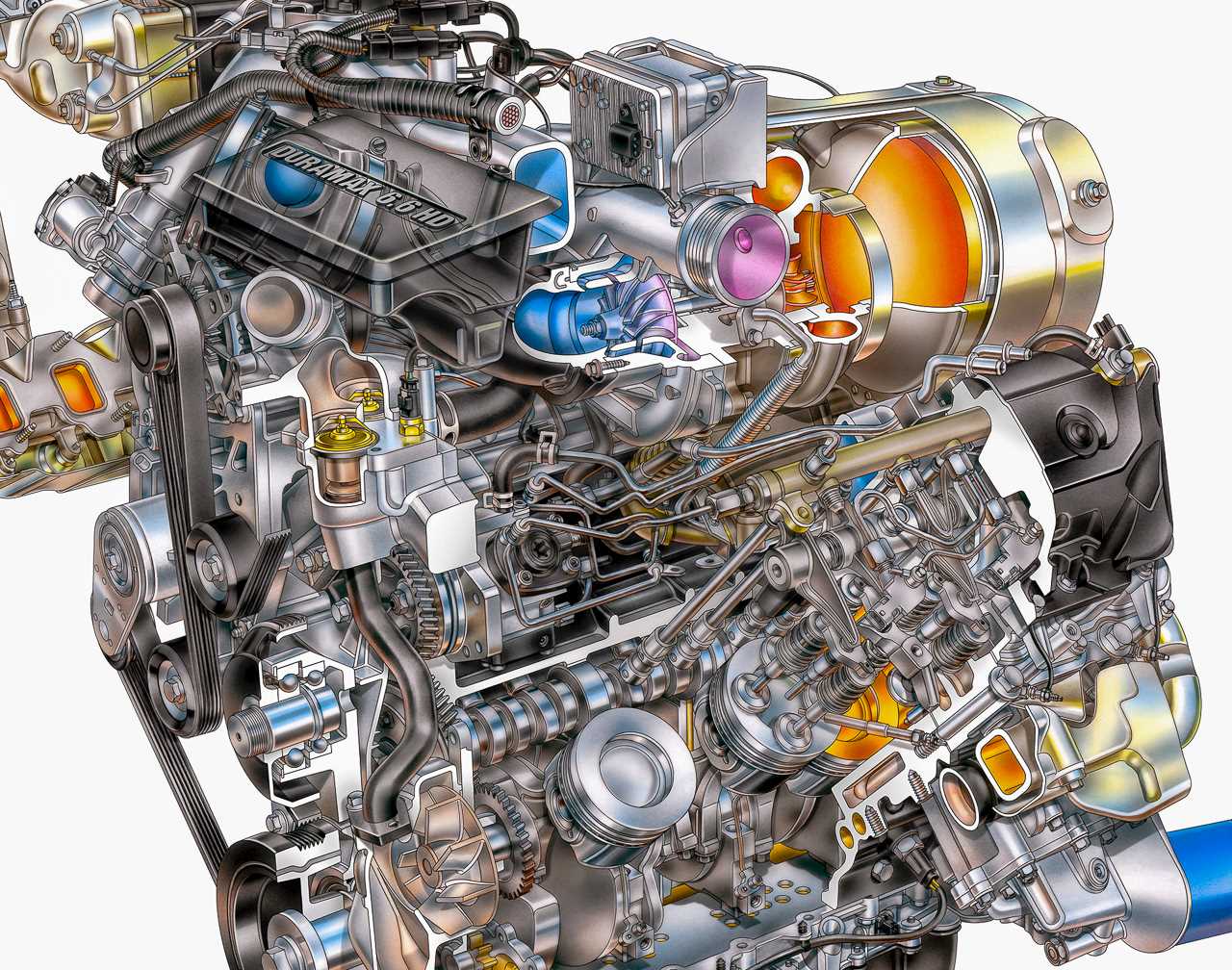

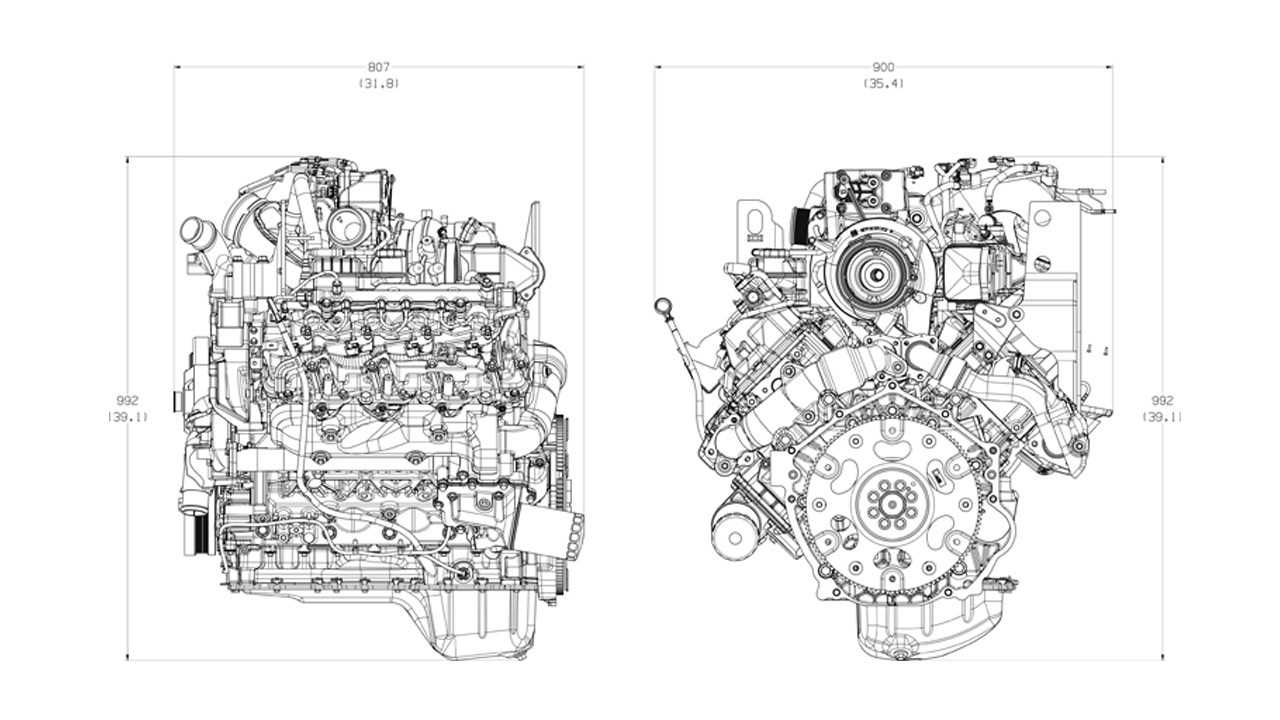

Lml Duramax Engine Parts Diagram Overview

In the realm of high-performance machinery, the intricacies of vital components play a crucial role in ensuring optimal functionality and reliability. A well-organized layout of these essential elements serves as a roadmap for enthusiasts and professionals alike, facilitating a deeper understanding of how each piece contributes to overall performance.

Comprehending the interrelationships among these components allows for more informed decisions when it comes to maintenance and upgrades. Enthusiasts and mechanics can delve into the specific roles that various sections play, enhancing both knowledge and skill in the care of powerful vehicles.

By exploring a detailed representation of these integral parts, one can appreciate the engineering brilliance behind heavy-duty systems. This examination not only illuminates the mechanics at play but also empowers users to optimize their machinery for ultimate performance and longevity.

Understanding the LML Duramax Engine

This section delves into the intricate workings of a robust power unit that has garnered a reputation for its performance and reliability. Designed for heavy-duty applications, this system is engineered to deliver substantial torque and horsepower while maintaining fuel efficiency. Comprehending its structure and functionality is essential for anyone looking to optimize its performance or engage in maintenance.

The components of this powerhouse work in unison to convert fuel into kinetic energy. Each segment plays a critical role, from the fuel delivery system to the exhaust management, ensuring that the unit operates smoothly under various conditions.

| Component | Description |

|---|---|

| Fuel System | Responsible for delivering the right amount of fuel to the combustion chambers. |

| Turbocharger | Enhances airflow into the system, boosting power and efficiency. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

| Exhaust System | Facilitates the expulsion of gases while minimizing emissions. |

| Electrical System | Powers essential components and controls various functions. |

Understanding these key elements is vital for effective maintenance and enhancement of performance, ensuring that the unit remains at the top of its game for years to come.

Key Components of the LML Engine

The performance and efficiency of a modern powertrain rely heavily on its fundamental elements. Each component plays a vital role in ensuring optimal operation, from fuel delivery to air intake and exhaust management. Understanding these critical pieces allows for better maintenance and performance tuning, enhancing overall vehicle capability.

Fuel Delivery System

This system is crucial for supplying the necessary fuel to the combustion chambers. It includes injectors, pumps, and lines designed to handle high pressures and precise delivery. Efficient fuel atomization directly impacts power output and emissions, making this system a focal point for modifications and upgrades.

Turbocharger Assembly

The turbocharger significantly boosts the power output by compressing incoming air, allowing for more efficient combustion. This component not only improves performance but also enhances fuel efficiency. Its design and size can be tailored to meet specific power goals, making it an essential aspect of performance enhancements.

Common Issues with Duramax Engines

Many vehicle owners encounter specific challenges with their heavy-duty powertrains, leading to decreased performance and reliability. Understanding these prevalent problems is essential for effective maintenance and troubleshooting.

Fuel Injector Failures: One frequent concern involves malfunctions in the fuel delivery system. These issues can result in poor fuel atomization, causing rough idling and reduced power output.

Cooling System Leaks: Leaks within the cooling system can lead to overheating, which may result in severe damage if not addressed promptly. Regular checks can help identify these leaks early.

Turbocharger Problems: A malfunctioning turbocharger can significantly impact acceleration and overall efficiency. Common symptoms include unusual noises and decreased power.

Electrical System Glitches: Issues within the electrical components, such as sensors and wiring, can lead to erratic behavior or warning lights, complicating diagnostics.

Oil Consumption: Excessive oil usage can indicate internal wear or seal failures. Monitoring oil levels regularly can help catch this issue before it escalates.

Performance Upgrades for LML Engines

Enhancing the capabilities of your vehicle’s powertrain can lead to significant improvements in performance and efficiency. By investing in various modifications, enthusiasts can achieve a balance of power, torque, and reliability.

- Intake System: Upgrading to a high-flow intake can increase airflow, leading to better combustion and overall performance.

- Exhaust System: A performance exhaust allows for improved gas flow, reducing back pressure and enhancing power output.

- Tuning: Custom tuning can optimize fuel delivery and timing, resulting in noticeable gains in horsepower and torque.

- Turbocharger: Replacing the factory unit with a larger turbo can significantly boost power levels while maintaining efficiency.

- Cooling Solutions: Enhanced intercoolers help manage temperatures, allowing for sustained performance under heavy loads.

Implementing these upgrades can lead to the ultimate driving experience, transforming how your vehicle performs on the road.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle requires regular care and attention. Adopting a systematic approach to upkeep can greatly enhance performance and lifespan. Below are essential practices to consider.

- Regular oil changes: Keep the lubricant fresh to reduce wear and tear.

- Check fluid levels: Monitor coolant, transmission fluid, and brake fluid regularly.

- Tire maintenance: Ensure proper inflation and rotation for even wear.

- Filter replacements: Change air and fuel filters periodically to maintain efficiency.

- Inspection of belts and hoses: Look for signs of wear and replace as needed.

By implementing these strategies, you can delve deeper into the longevity of your vehicle, achieving ultimate reliability and performance.

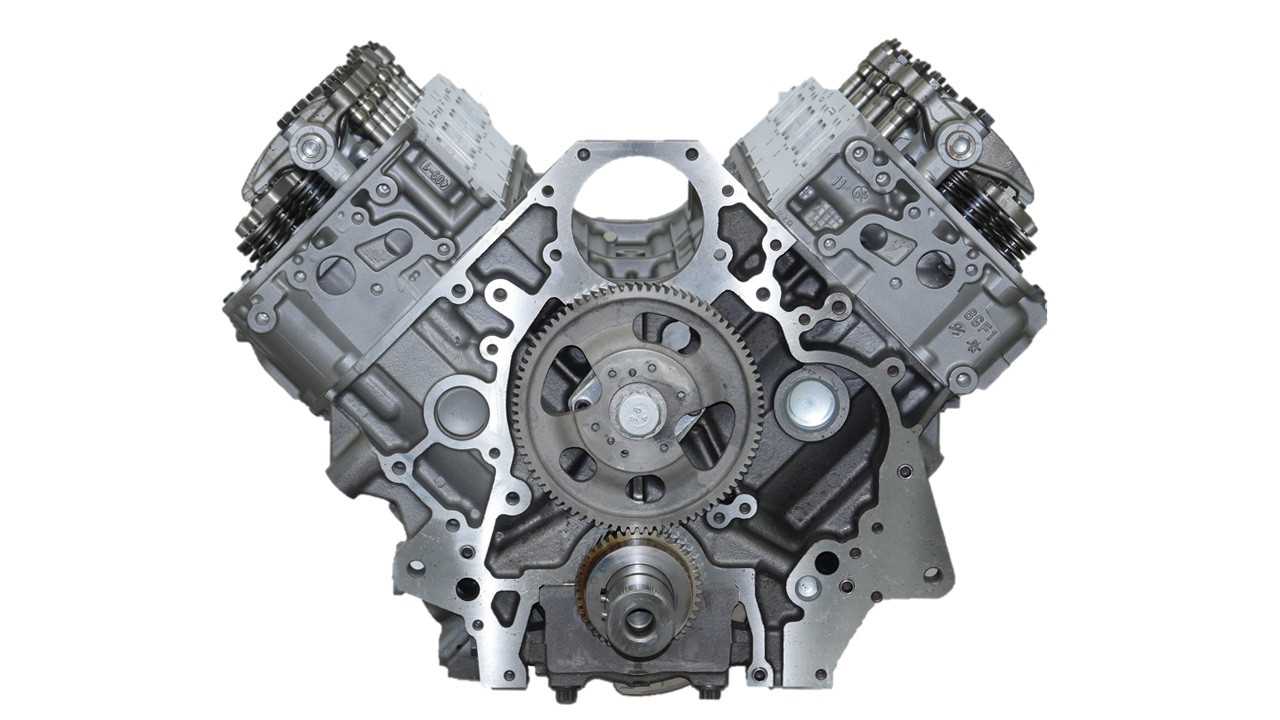

Comparing LML with Other Duramax Versions

This section explores the differences between various powertrains designed for heavy-duty applications. Each iteration showcases distinct advancements in performance, efficiency, and technology, reflecting the evolution of automotive engineering.

The variant discussed here boasts improved fuel efficiency and reduced emissions compared to its predecessors. Notably, it features advanced fuel injection systems and enhanced turbocharging, which contribute to its superior power output.

In contrast, earlier models may prioritize simplicity and reliability, making them appealing for certain applications. While they may lack some modern enhancements, their proven track record ensures lasting popularity among enthusiasts and professionals alike.

Ultimately, the choice between these different generations hinges on specific needs, whether it’s raw power, efficiency, or advanced technology. Understanding these distinctions allows users to make informed decisions tailored to their requirements.

Importance of Quality Replacement Parts

Using high-quality components for repairs and maintenance is crucial for the longevity and performance of any machinery. Ensuring that replacements are reliable can prevent future issues, enhance efficiency, and ultimately save time and money.

Benefits of Quality Components

Investing in superior replacements offers numerous advantages:

| Benefit | Description |

|---|---|

| Durability | Longer lifespan and reduced need for frequent replacements. |

| Performance | Improved efficiency and smoother operation. |

| Safety | Minimized risk of failures that could lead to accidents. |

Conclusion

Choosing top-notch replacements is essential for maintaining functionality and safety, ultimately contributing to the overall success of your machinery.

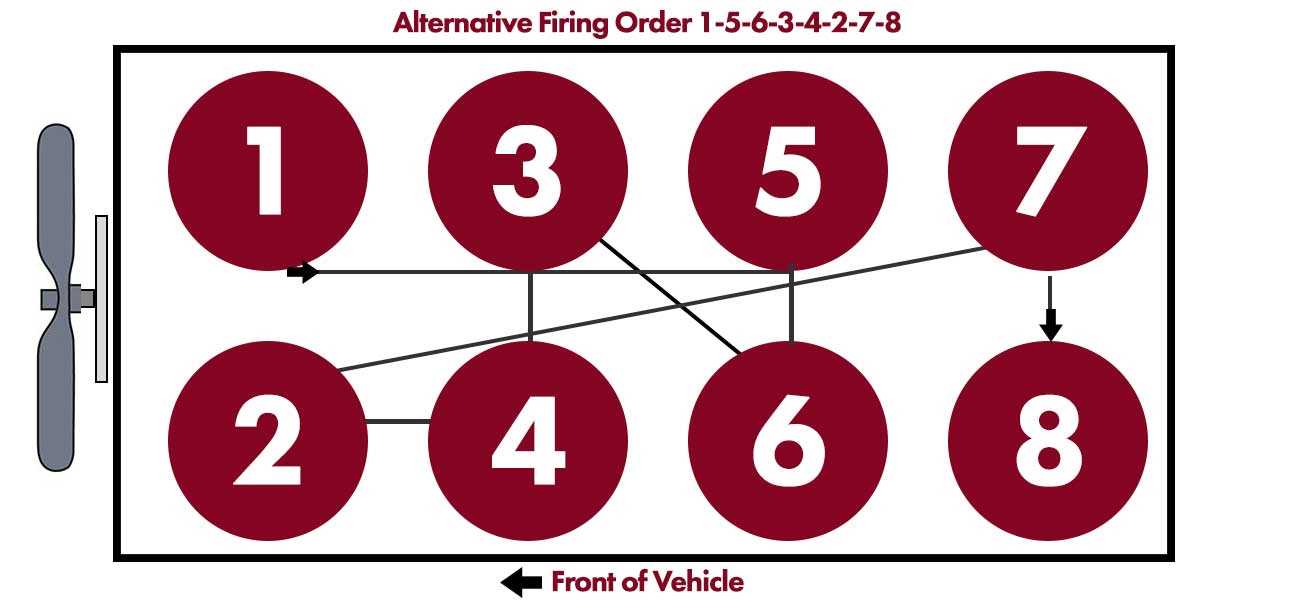

How to Read Engine Diagrams

Understanding technical illustrations related to machinery can significantly enhance your comprehension of how components function together. These visuals serve as a roadmap, guiding users through complex systems by presenting information in a clear and organized manner. Familiarizing yourself with these representations will allow you to troubleshoot issues more effectively and perform maintenance with greater confidence.

Start by identifying the various symbols and notations used in the illustration. Each symbol typically represents a specific element, such as a mechanical part or a fluid pathway. Familiarize yourself with a legend if provided, as it can offer crucial insights into what each icon signifies.

Next, pay attention to the layout. Most diagrams are arranged to depict the flow of operation, with directional arrows indicating how components interact. Understanding the sequence can help you visualize the process and pinpoint potential areas of concern during repairs or upgrades.

Finally, make note of any labels and annotations. These can offer additional context, including specifications and operational guidelines. By piecing together the information presented in the illustration, you will gain a comprehensive understanding of the system at hand, ultimately empowering you to address challenges more effectively.

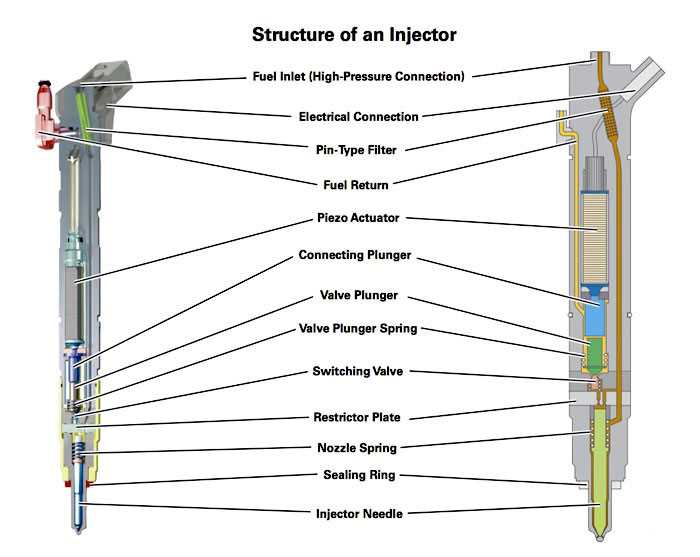

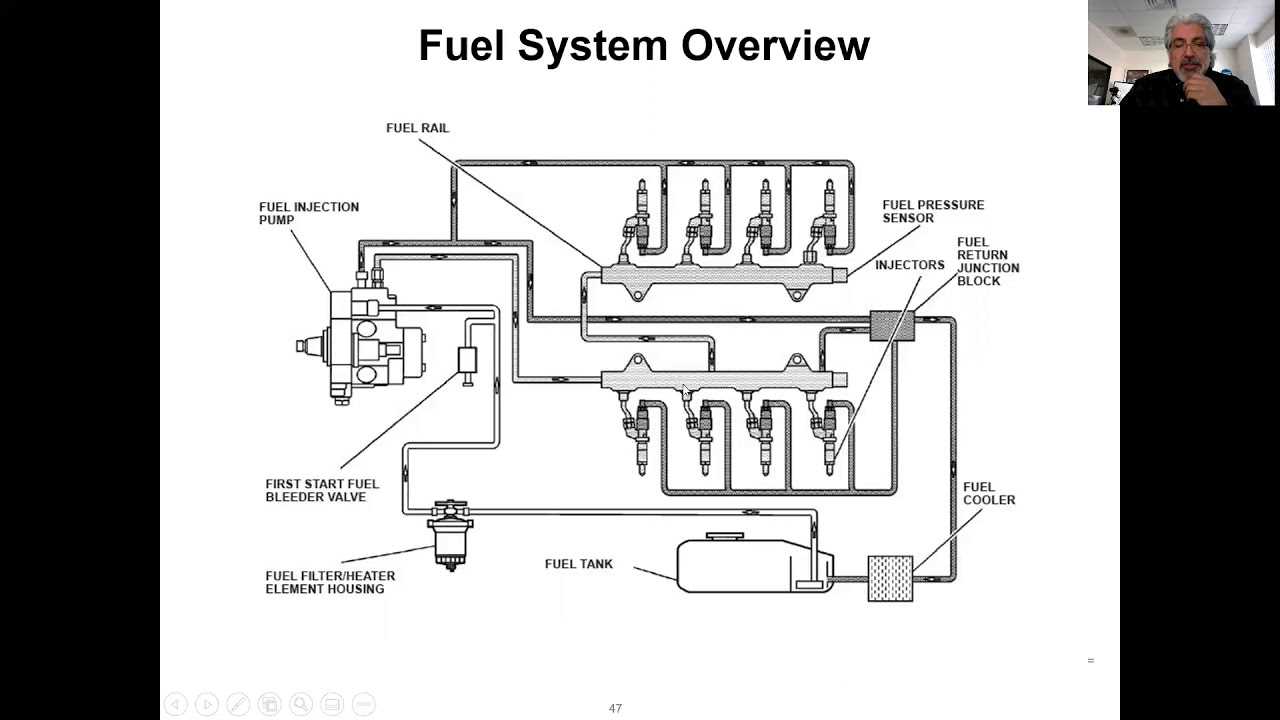

Fuel System Details of LML

The fuel delivery mechanism plays a critical role in the overall performance and efficiency of a high-performance vehicle. Understanding the intricacies of this system can greatly enhance maintenance and operational knowledge. This section delves into the essential components and their functions, providing insight into how they contribute to the smooth functioning of the power unit.

Components Overview: The fuel assembly consists of various crucial elements, including the pump, injectors, and fuel lines. Each component is designed to ensure precise fuel flow and optimal combustion, thereby maximizing power output and minimizing emissions. The quality of these components directly influences the longevity and reliability of the entire system.

Fuel Pump: The heart of the fuel delivery setup, the pump is responsible for transporting the fuel from the tank to the injectors. Its performance is vital for maintaining the required pressure and flow rate, ensuring that the combustion process is efficient.

Injectors: These components atomize the fuel, allowing for a more complete and efficient burn. Their design and functionality significantly affect performance characteristics, including throttle response and overall fuel efficiency. Regular inspection and cleaning can prevent clogs and maintain optimal performance.

Fuel Lines: These conduits connect the various components of the fuel system, ensuring a seamless flow of fuel. The integrity of these lines is crucial, as leaks can lead to performance issues and safety hazards.

In summary, a thorough understanding of the fuel delivery system is essential for anyone looking to optimize the performance and reliability of their vehicle. Regular maintenance and attention to the individual components can lead to significant improvements in efficiency and longevity.

Cooling System Insights for Duramax

The cooling mechanism is crucial for maintaining optimal performance and longevity in high-output machinery. Understanding the components and their interactions can significantly enhance efficiency and prevent overheating issues.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant, maintaining temperature. |

| Water Pump | Circulates coolant through the system to regulate temperature. |

| Thermostat | Controls coolant flow based on temperature to ensure proper heating. |

| Coolant Reservoir | Stores excess coolant and helps maintain system pressure. |

| Cooling Hoses | Transport coolant to and from various components. |

Regular maintenance of these elements is essential to prevent overheating and ensure the system operates effectively, ultimately extending the lifespan of the machinery.

Electrical Components in LML Engines

The electrical systems in modern powertrains play a crucial role in ensuring optimal performance and efficiency. These components work together to facilitate various functions, from starting the system to managing fuel delivery and emission controls. Understanding the significance of each electrical element can enhance maintenance and troubleshooting efforts.

| Component | Function |

|---|---|

| Starter Motor | Initiates the combustion cycle by cranking the system. |

| Alternator | Generates electrical power to recharge the battery and supply the system. |

| ECM (Engine Control Module) | Monitors and regulates engine operations for efficiency and performance. |

| Fuel Injectors | Deliver precise amounts of fuel into the combustion chamber. |

| Ignition Coil | Transforms battery voltage to a higher voltage for spark generation. |

| Sensors (e.g., MAF, EGR) | Provide data to the ECM for optimal operation adjustments. |

Each of these electrical components is integral to the overall functionality, working in concert to ensure that the powertrain operates smoothly and efficiently under various conditions. Proper understanding and maintenance of these systems can lead to prolonged service life and enhanced performance.

Popular Aftermarket Parts for LML

When enhancing performance and reliability, enthusiasts often turn to various upgrades designed to optimize their vehicles. These modifications can significantly improve overall functionality and driving experience.

Intake Systems: Upgrading the air intake can boost airflow and increase power. High-performance systems are engineered to maximize efficiency, allowing for better combustion.

Exhaust Upgrades: Enhanced exhaust systems can reduce back pressure and improve sound. This modification not only boosts performance but also contributes to a more aggressive tone.

Tuning Modules: Performance chips or tuners allow for fine-tuning of the vehicle’s parameters. These tools can unlock additional horsepower and torque while optimizing fuel efficiency.

Fuel Injectors: High-flow injectors are vital for those seeking increased performance. Upgrading these components ensures the optimal amount of fuel is delivered for enhanced power output.

Cooling Solutions: Enhanced radiators and intercoolers help maintain optimal temperatures, preventing overheating and prolonging the lifespan of critical components.