Understanding the Small Engine Parts Diagram for Better Maintenance

Exploring the intricate world of compact machinery reveals a fascinating array of components, each playing a vital role in the overall functionality of the system. A comprehensive understanding of these elements is essential for both enthusiasts and professionals alike. As we delve into this subject, we uncover how the interaction between various pieces contributes to the efficiency and performance of these mechanical wonders.

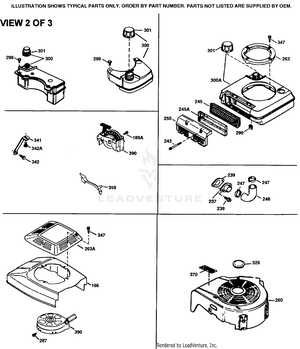

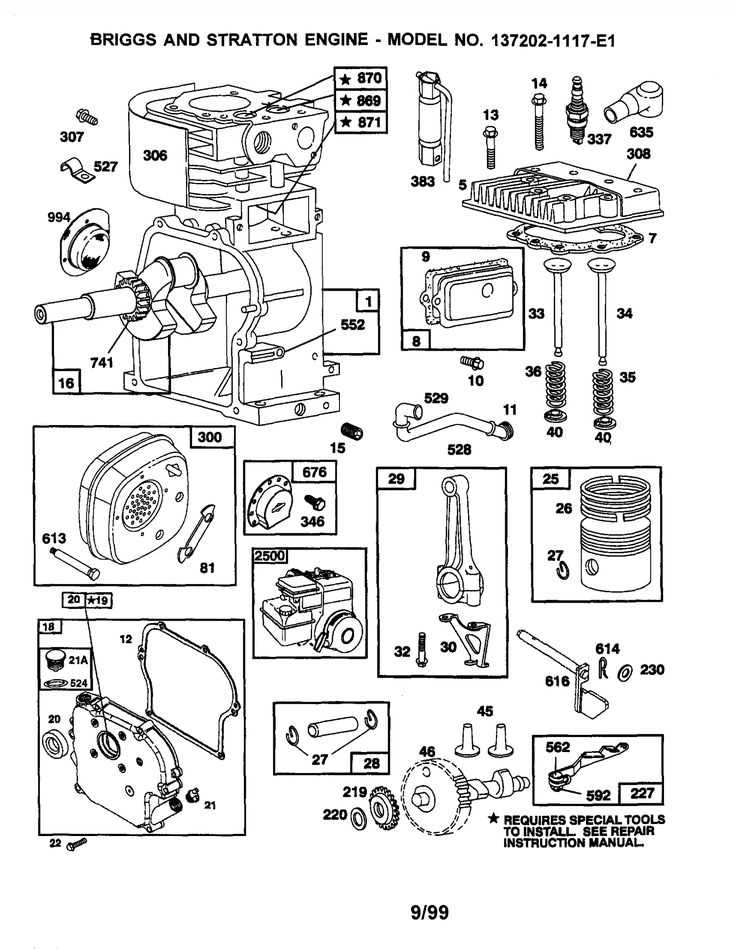

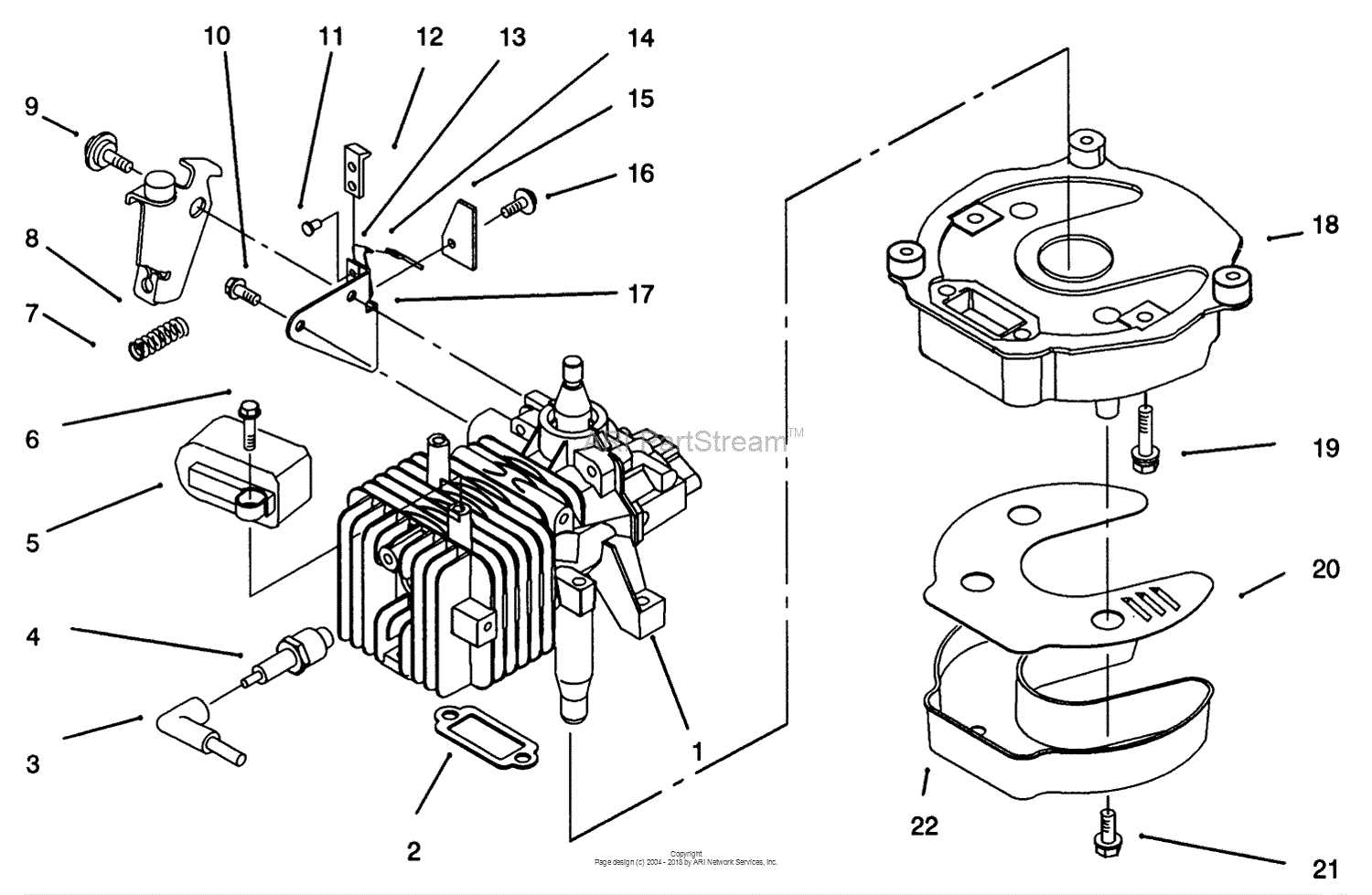

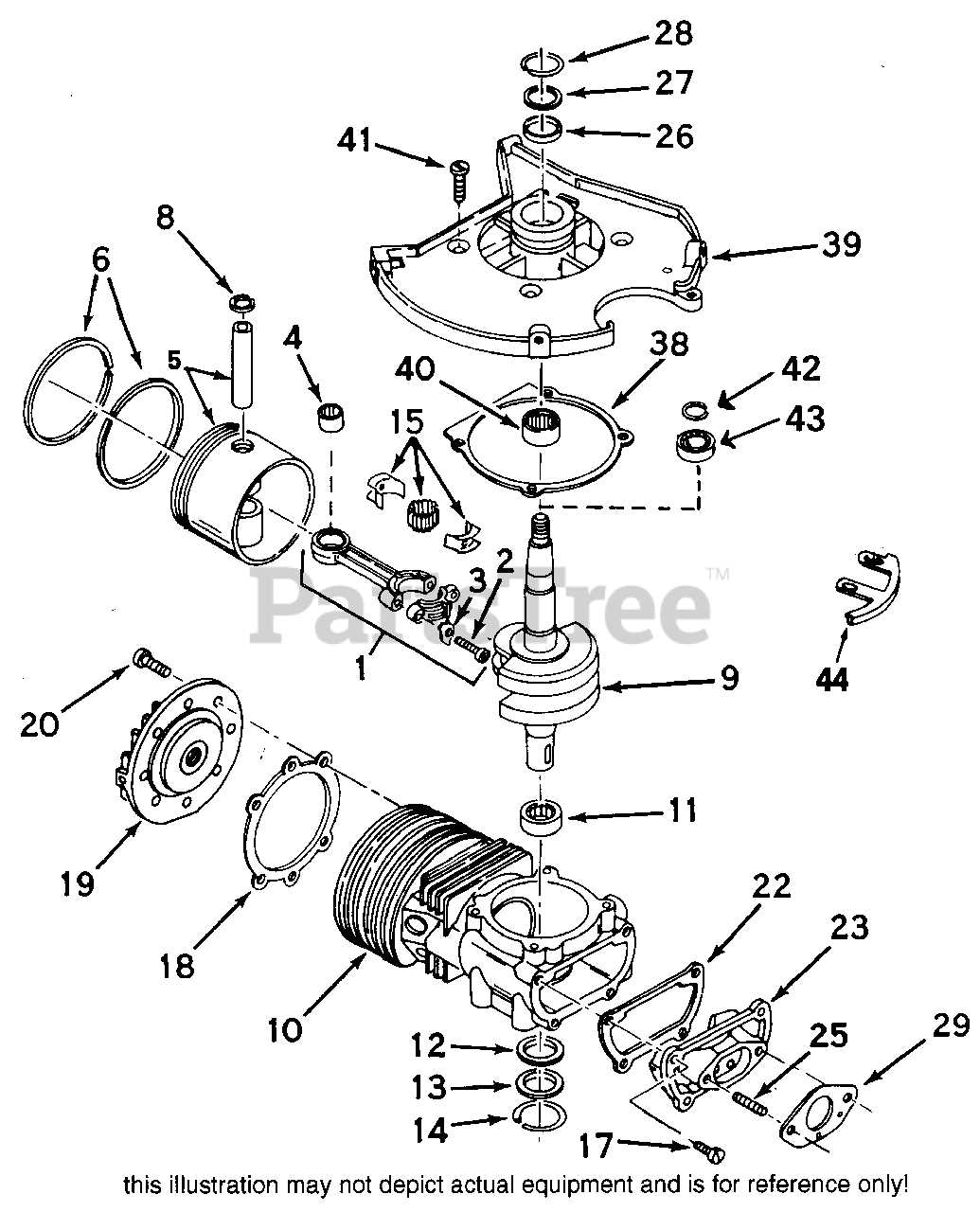

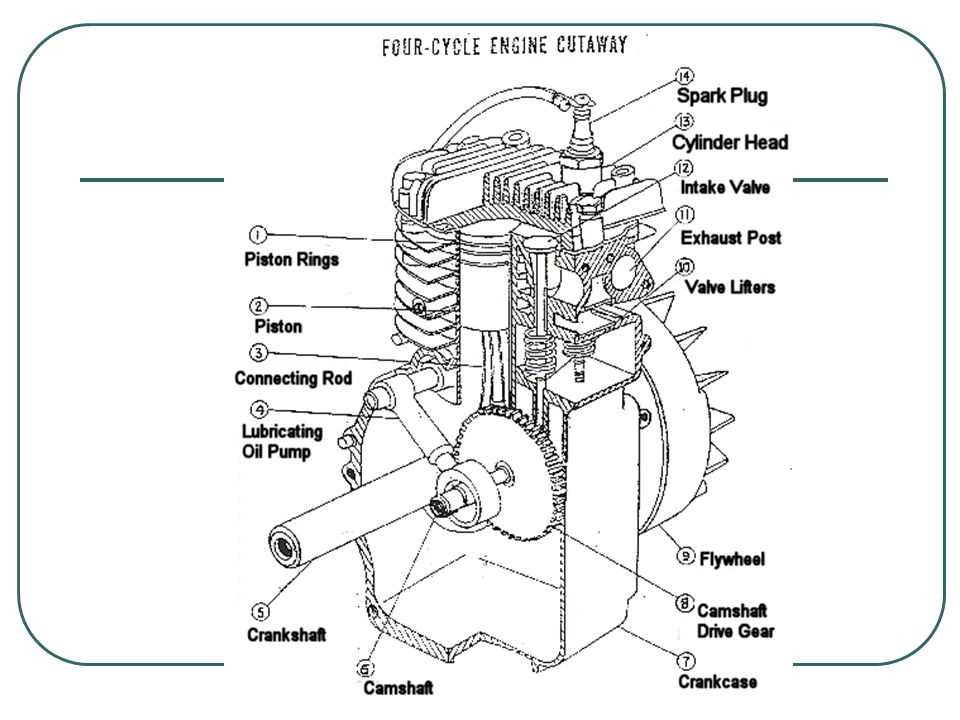

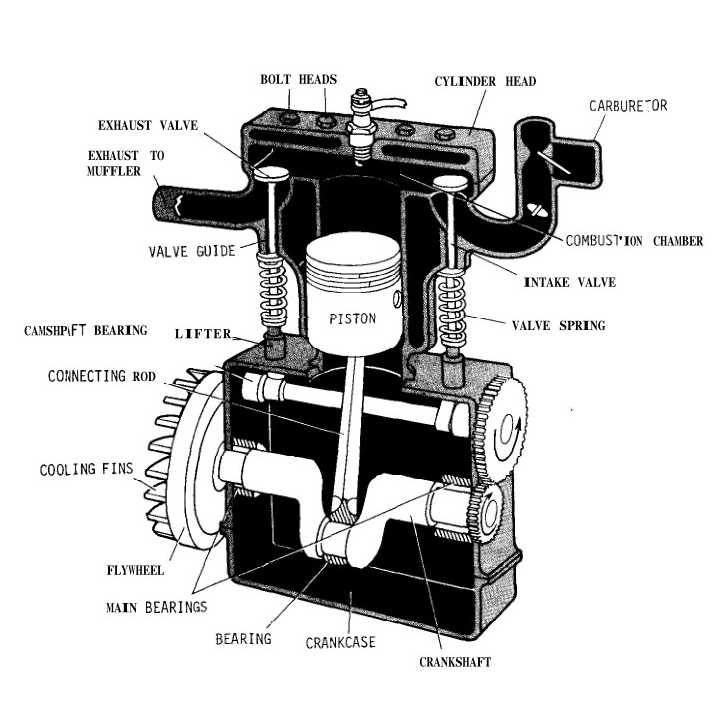

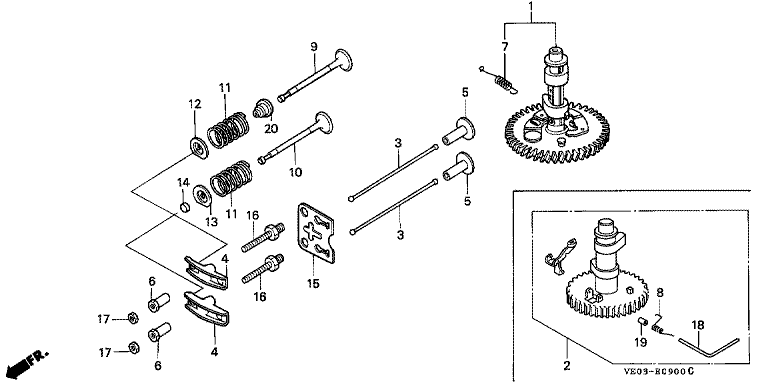

Visual aids serve as invaluable tools for grasping the complex relationships and arrangements within these assemblies. By examining structured illustrations, one can gain insights into how each element fits together, enhancing both maintenance practices and troubleshooting efforts. These representations simplify the learning process, making it accessible to individuals at all skill levels.

Moreover, familiarizing oneself with the layout of these components fosters a deeper appreciation for the craftsmanship and engineering that goes into their design. Each item is meticulously crafted to fulfill specific functions, and understanding this interdependence paves the way for improved operation and care. Ultimately, a well-rounded knowledge of these systems empowers users to make informed decisions regarding repairs and upgrades.

Understanding Small Engine Components

This section delves into the essential elements that contribute to the functionality of compact mechanical systems. Each component plays a critical role in ensuring optimal performance and reliability. By exploring these integral parts, we can gain a clearer picture of how they work together harmoniously.

Key Elements and Their Functions

Every mechanical assembly consists of various key elements that perform specific tasks. Understanding these functions is vital for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

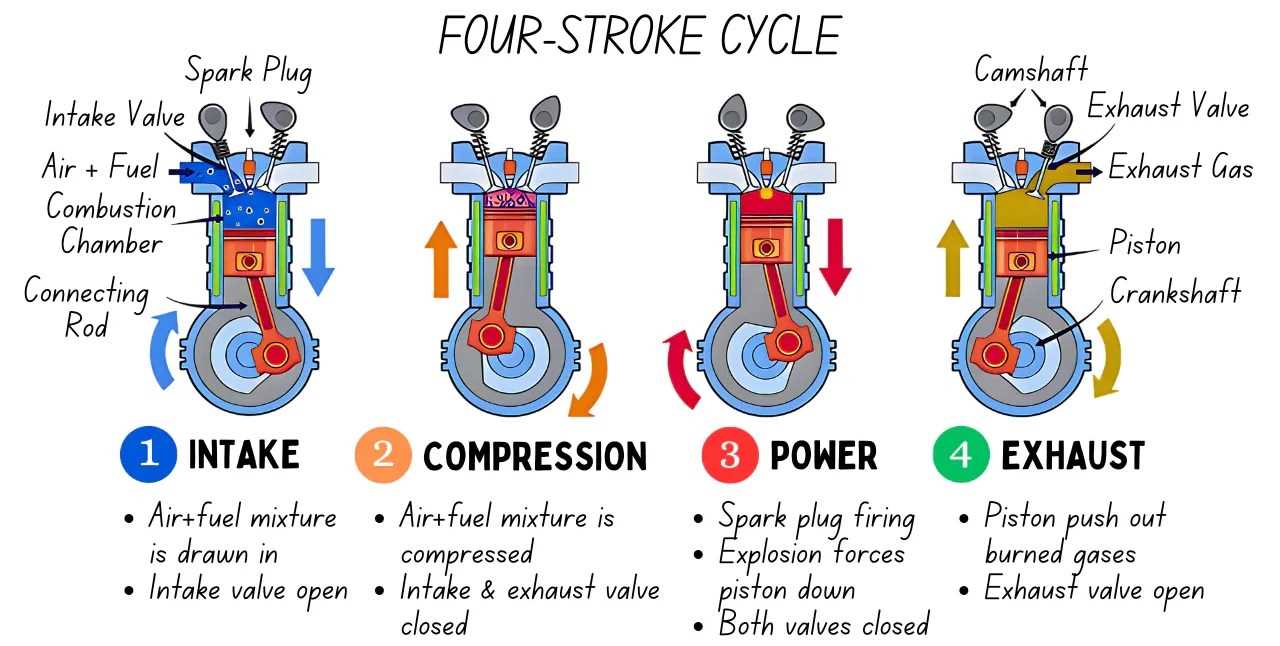

| Cylinder | Houses the combustion process and facilitates movement. |

| Piston | Translates combustion energy into mechanical motion. |

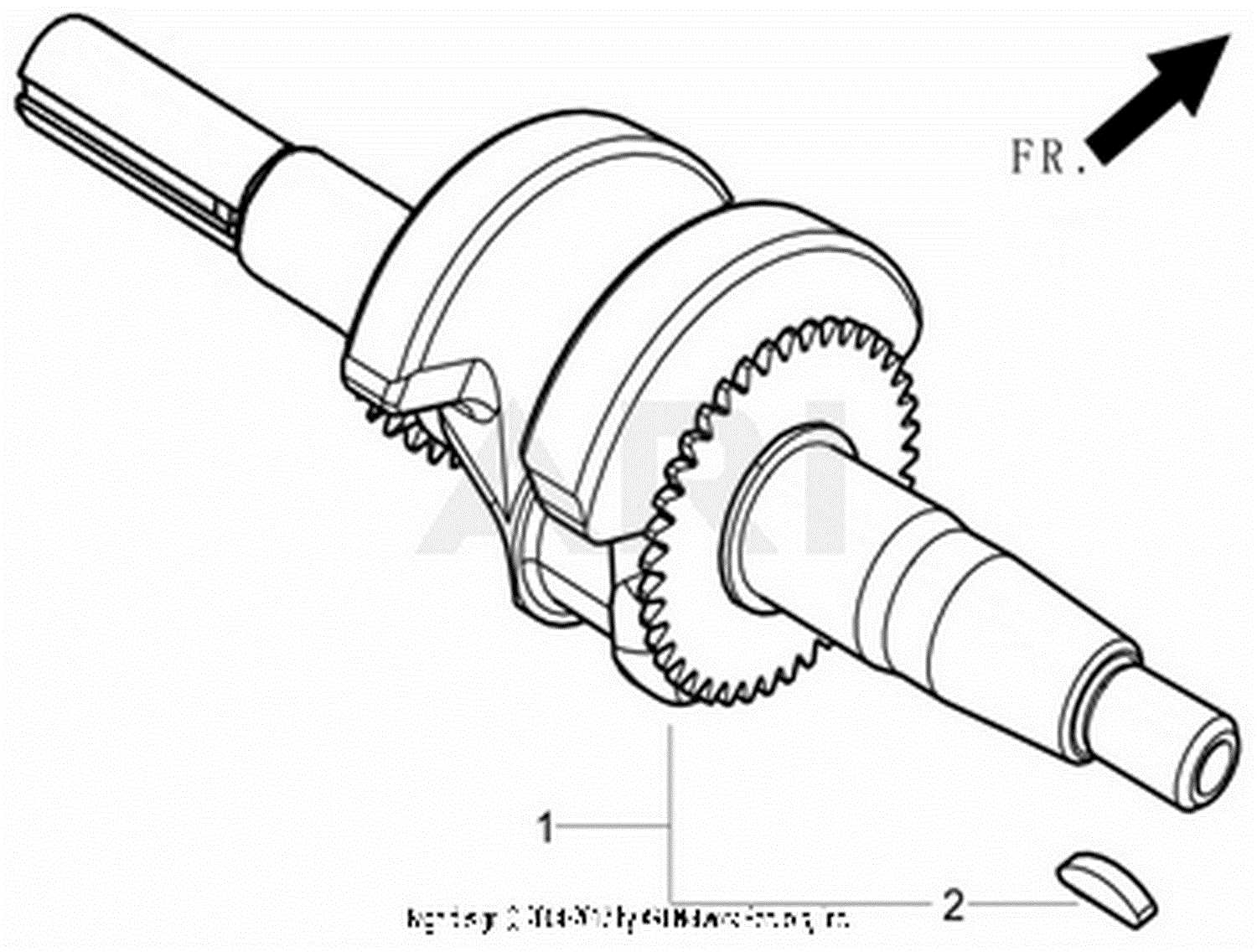

| Crankshaft | Converts linear motion of the piston into rotational force. |

| Spark Plug | Ignites the fuel-air mixture for combustion. |

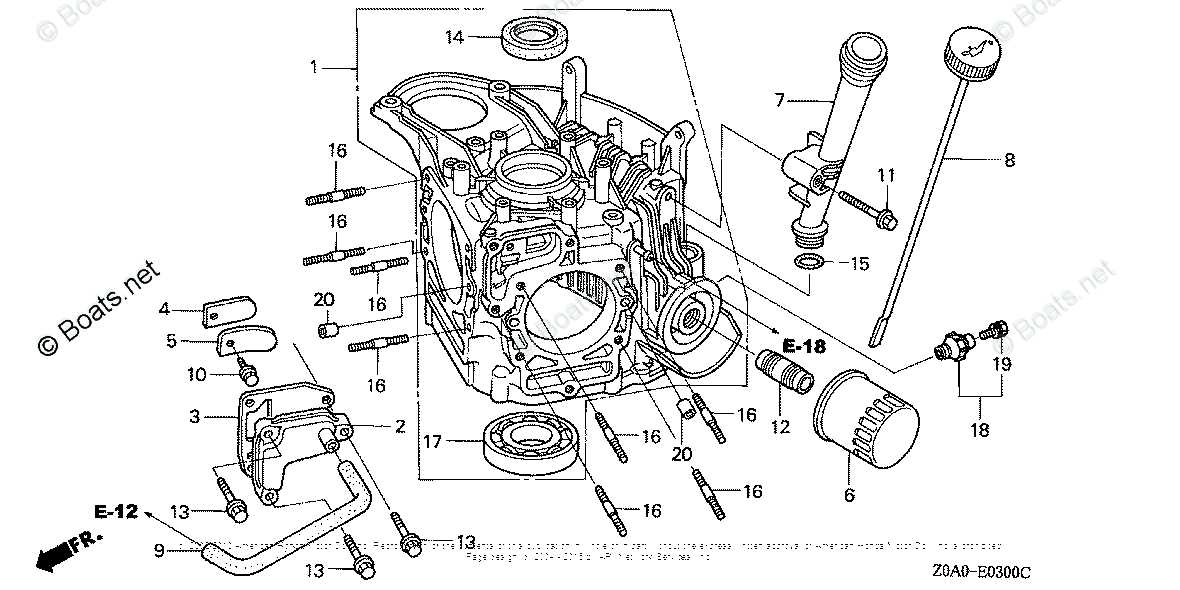

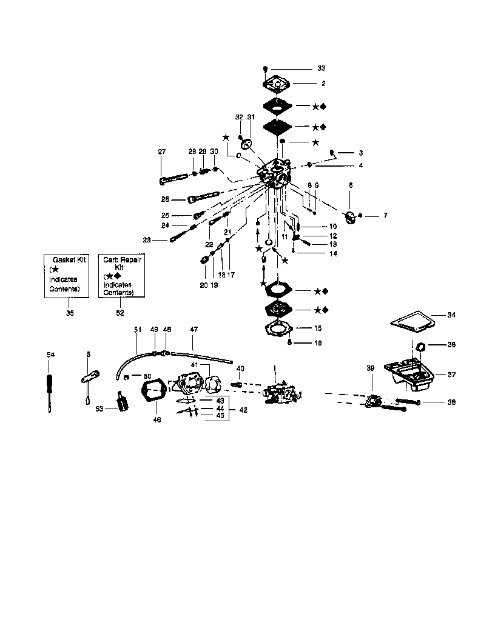

| Fuel System | Delivers the necessary fuel to the combustion chamber. |

Importance of Maintenance

Regular upkeep of these vital components is crucial for ensuring longevity and efficiency. Neglecting any element can lead to decreased performance or complete failure. Familiarity with each component allows for better diagnostics and timely interventions.

Importance of Small Engine Diagrams

Visual representations play a crucial role in understanding the components and functionality of various machinery. They serve as invaluable tools for both novices and experts, allowing for easier identification and comprehension of intricate systems.

Enhanced Understanding

By providing a clear layout of each element, these illustrations help users grasp how individual components interact. This clarity is essential for effective maintenance and troubleshooting, ultimately leading to improved performance.

Streamlined Repairs

When faced with mechanical issues, having a visual reference significantly simplifies the repair process. Users can quickly locate necessary items and follow step-by-step instructions, minimizing downtime and maximizing efficiency.

Types of Small Engine Parts

Understanding the various components is crucial for effective maintenance and operation. Each element plays a significant role in the overall functionality and efficiency of the machinery, influencing performance and longevity.

| Component | Description |

|---|---|

| Cylinder | Houses the piston and is essential for compression. |

| Piston | Moves up and down within the cylinder, creating power. |

| Crankshaft | Transforms linear motion into rotational motion. |

| Ignition System | Initiates combustion through spark generation. |

| Fuel System | Delivers the necessary fuel to the combustion chamber. |

| Cooling System | Prevents overheating by dissipating excess heat. |

How to Read Engine Diagrams

Understanding technical illustrations can significantly enhance your comprehension of mechanical systems. These visual representations serve as essential tools, providing insight into the relationships and functions of various components. Familiarity with their layout and symbols is crucial for effective interpretation.

Firstly, familiarize yourself with the legend or key that accompanies the illustration. This section often defines the symbols and lines used, enabling you to identify different elements easily. Colors may also indicate specific functions or categories, so pay attention to these details.

Next, take note of the orientation and scale of the representation. Recognizing how components are arranged will help you understand their connectivity and the overall flow of the system. Arrows typically indicate movement or direction, guiding you through the process depicted.

Finally, practice makes perfect. Regularly referring to these illustrations will build your confidence and enhance your ability to decode complex structures. As you grow more accustomed to the format and terminology, interpreting these visuals will become second nature.

Common Small Engine Repairs

When it comes to maintaining outdoor machinery, understanding frequent issues can save time and money. Various components can wear down or malfunction, leading to performance problems. Addressing these challenges promptly ensures optimal functionality and longevity of the equipment.

Here are some typical repairs that enthusiasts often encounter:

| Issue | Possible Causes | Repair Solutions |

|---|---|---|

| Starting Problems | Clogged fuel lines, faulty spark plug | Clean or replace fuel lines, inspect and replace spark plug |

| Overheating | Insufficient oil, blocked air filter | Add oil, clean or replace air filter |

| Loss of Power | Worn-out components, dirty carburetor | Inspect and replace worn parts, clean carburetor |

| Excessive Vibration | Loose or damaged mounting, imbalanced blades | Tighten or replace mounts, balance blades |

Being aware of these common issues and their solutions can empower operators to perform effective maintenance and keep their machines running smoothly.

Tools Needed for Engine Maintenance

Proper upkeep of mechanical systems requires a variety of essential implements that ensure efficiency and longevity. Having the right tools at hand not only simplifies the maintenance process but also enhances overall performance.

Wrenches are crucial for tightening and loosening bolts, making them indispensable for adjustments. Screwdrivers in various sizes and types allow for precision work on different components. Additionally, a reliable socket set offers versatility in tackling various fasteners.

For thorough cleaning, a brush and compressor can effectively remove debris and ensure optimal function. Moreover, a multimeter is invaluable for diagnosing electrical issues, helping to maintain peak performance.

Investing in high-quality tools ultimately saves time and effort, allowing for more efficient upkeep of your mechanical systems.

Identifying Parts by Diagram Labels

Understanding the labels on visual representations is crucial for effective maintenance and repair. These identifiers provide essential information that helps individuals recognize components and their functions, facilitating a smoother workflow in various mechanical tasks.

Key Components and Their Functions

Each label corresponds to a specific element, detailing its role within the overall assembly. Familiarity with these labels can greatly enhance troubleshooting efficiency.

| Label | Component Name | Function |

|---|---|---|

| A1 | Piston | Converts pressure into mechanical energy |

| B2 | Cylinder | Houses the piston for movement |

| C3 | Crankshaft | Transforms linear motion into rotational motion |

Importance of Accurate Identification

Correctly interpreting these labels ensures that users can quickly pinpoint issues and apply the necessary repairs. A strong grasp of this labeling system ultimately leads to more efficient maintenance practices.

Maintenance Tips for Small Engines

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By following a few straightforward guidelines, you can prevent issues and enhance efficiency. Consistent attention to maintenance can save time and resources in the long run.

Key Maintenance Practices

Focus on these vital practices to keep your equipment running smoothly:

| Task | Frequency |

|---|---|

| Check oil level | Every use |

| Inspect filters | Monthly |

| Clean air intake | Every season |

| Examine spark plug | Every 25 hours |

| Sharpen blades | As needed |

Additional Tips

Always use high-quality fuel and store your machinery in a dry place to prevent corrosion. Keeping your tools organized and having a scheduled maintenance plan will ensure that everything runs without a hitch.

Where to Find Diagrams Online

Locating visual references for mechanical components can greatly enhance your understanding and repair efforts. Various online resources provide access to detailed illustrations, helping enthusiasts and professionals alike. Here are some valuable places to explore.

Online Resources

- Manufacturer Websites: Many brands offer official documentation that includes comprehensive visuals of their products.

- Forums and Communities: Engaging with online groups can lead to shared resources, including illustrations and tips from experienced users.

- DIY Websites: Numerous sites dedicated to repair projects often feature helpful visuals that can aid in troubleshooting.

Search Strategies

- Utilize specific search terms related to the component you need.

- Explore image search engines for a variety of visual references.

- Check video platforms; many tutorials include clear visuals and explanations.

Signs of Wear and Tear

Recognizing the indicators of deterioration is crucial for maintaining optimal performance and longevity of machinery. Various symptoms may emerge over time, signaling that components require attention or replacement.

Common Indicators

- Unusual noises during operation

- Decreased efficiency and power output

- Increased fuel consumption

- Visible leaks or fluid loss

- Excessive vibration

Visual Cues

- Discoloration or burnt surfaces

- Cracks or fractures on surfaces

- Corrosion or rust formation

- Worn-out seals or gaskets

Upgrading Small Engine Components

Enhancing various mechanical elements can lead to improved performance, efficiency, and longevity. By selecting superior materials and designs, enthusiasts can optimize functionality and responsiveness. This process not only elevates overall capability but also contributes to a more enjoyable experience.

Consideration of upgrades should involve evaluating specific areas such as fuel delivery, airflow, and ignition systems. Each enhancement can result in significant gains, from increased power output to reduced emissions. Researching compatible components is crucial to ensure seamless integration and optimal results.

Ultimately, upgrading elements requires a balance of investment and anticipated benefits. Those willing to delve into this endeavor will often find that the rewards justify the efforts involved. By thoughtfully selecting upgrades, users can tailor their machines to meet personal performance goals.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a mindful approach to ensure personal safety and the protection of equipment. Adhering to certain guidelines can significantly reduce risks associated with the repair process.

Proper Gear and Tools

Wearing appropriate protective gear, such as gloves and safety glasses, is crucial. Ensure that all tools are in good condition and suited for the job to prevent accidents during repairs.

Work Environment

Maintain a clean and organized workspace. Clear any clutter to avoid tripping hazards, and ensure adequate lighting to enhance visibility. Being aware of your surroundings can help you avoid potential mishaps.

Frequently Asked Questions about Small Engines

This section addresses common inquiries related to compact mechanical devices used in various applications. Understanding these topics can enhance your knowledge and improve your experience with maintenance and troubleshooting.

What are the common issues faced by these devices?

Users often encounter challenges such as starting difficulties, irregular performance, and overheating. Regular maintenance and timely inspections can help mitigate these problems and ensure optimal functionality.

How can I extend the lifespan of my equipment?

Proper care and routine servicing are essential for longevity. This includes regular oil changes, air filter replacements, and adherence to the manufacturer’s guidelines. Additionally, storing the machinery in a dry, sheltered environment can prevent corrosion and other forms of damage.