Comprehensive VW 2.0 TDI Engine Parts Diagram Guide

In the realm of automotive engineering, comprehending the intricate assembly of a vehicle’s power unit is crucial for enthusiasts and professionals alike. This section delves into the essential elements that contribute to the efficient performance and reliability of Volkswagen’s renowned diesel variant. By exploring the various components, one can gain insights into how they interrelate to create a seamless driving experience.

Each section of the system plays a pivotal role, from the intricate fuel delivery mechanisms to the robust framework supporting optimal functionality. Understanding these vital elements allows for better maintenance and informed decision-making when it comes to repairs or upgrades. This exploration not only enhances knowledge but also fosters a deeper appreciation for the engineering prowess behind these machines.

With a closer look at the configuration and layout of these components, one can identify the pathways and interactions that facilitate power generation and efficiency. This understanding serves as a foundation for both troubleshooting and enhancing the performance of these remarkable vehicles.

Understanding the VW 2.0 TDI Engine

This section explores the intricacies of a popular power unit known for its efficiency and reliability. Delving into its construction and functionality offers valuable insights into how this machine operates, making it a preferred choice among enthusiasts and everyday drivers alike. Understanding the various components and their interactions can enhance appreciation for its engineering prowess.

Key Components and Their Functions

The assembly comprises several crucial elements, each playing a vital role in overall performance. The combustion chamber ignites fuel to generate power, while the fuel delivery system ensures optimal mixing and atomization. Additionally, the cooling and lubrication systems are essential for maintaining operational temperatures and minimizing friction, respectively.

Performance and Efficiency

This type of power unit is celebrated for its balance of power and fuel consumption. Its design promotes effective combustion, resulting in lower emissions and improved mileage. Understanding these features highlights why this configuration remains a popular choice in various vehicles, combining practicality with environmental considerations.

Key Components of the Engine

The functionality of a motor relies on a harmonious interplay of various vital elements. Each component plays a crucial role in ensuring optimal performance, efficiency, and longevity. Understanding these essential elements provides insight into how the system operates seamlessly.

- Cylinder Block: The foundational structure housing the cylinders and critical components.

- Pistons: Move within the cylinders, converting fuel energy into mechanical work.

- Crankshaft: Transforms the linear motion of the pistons into rotational energy.

- Camshaft: Controls the opening and closing of valves, coordinating airflow and fuel intake.

- Valves: Regulate the flow of air and fuel into the combustion chamber, and exhaust gases out.

- Fuel Injection System: Delivers the appropriate amount of fuel for combustion efficiency.

- Turbocharger: Enhances airflow into the combustion chamber for improved power output.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

Each of these elements contributes to the overall functionality, ensuring that the motor operates effectively under various conditions. Understanding their roles can help diagnose issues and improve maintenance practices.

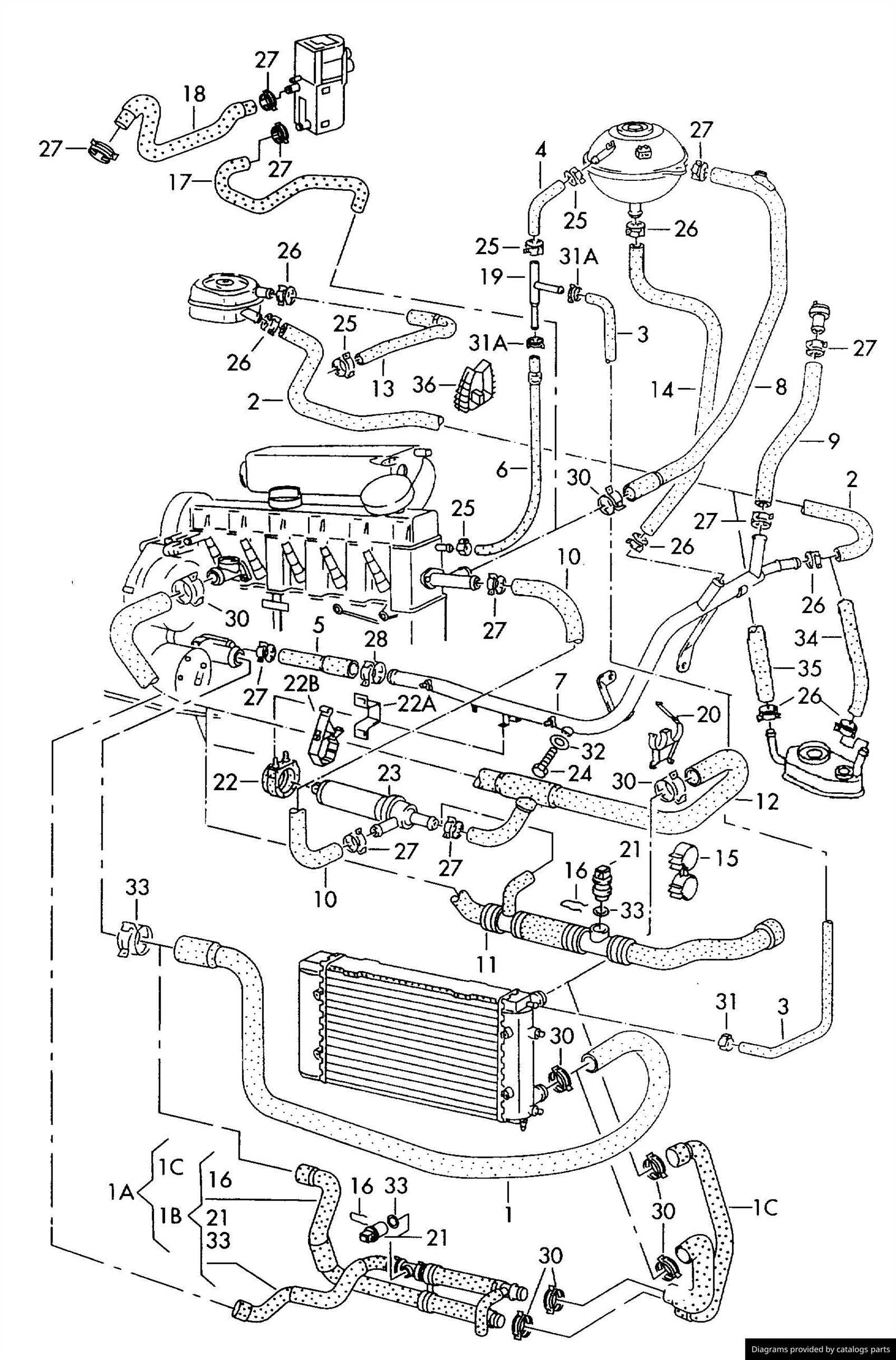

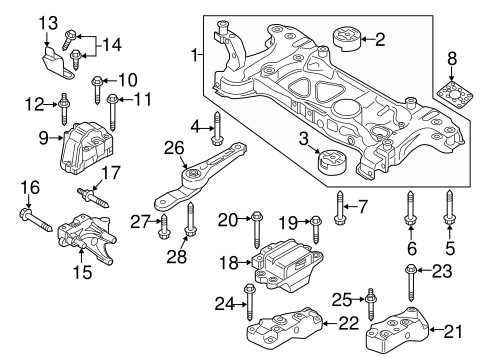

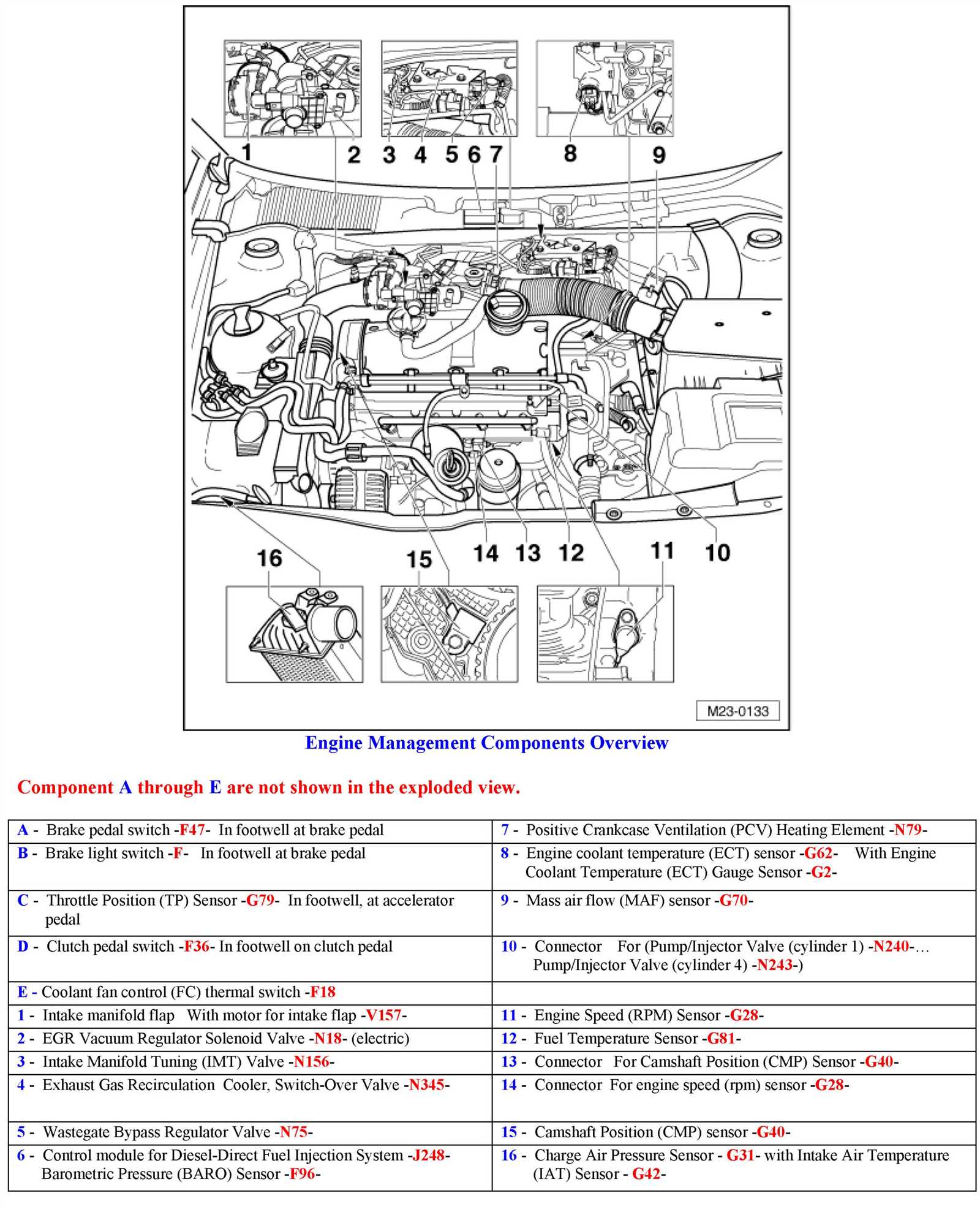

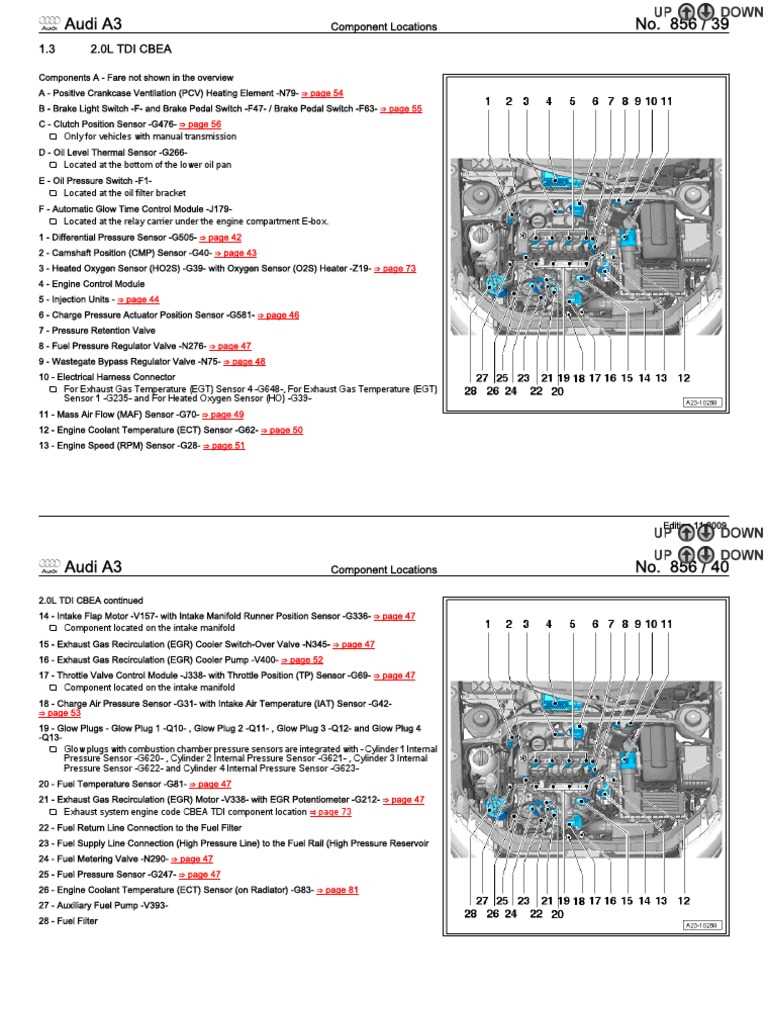

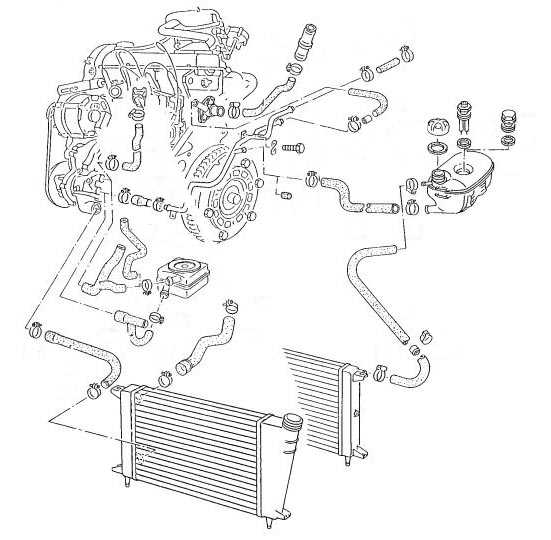

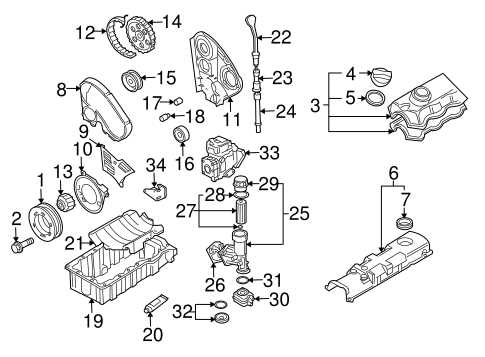

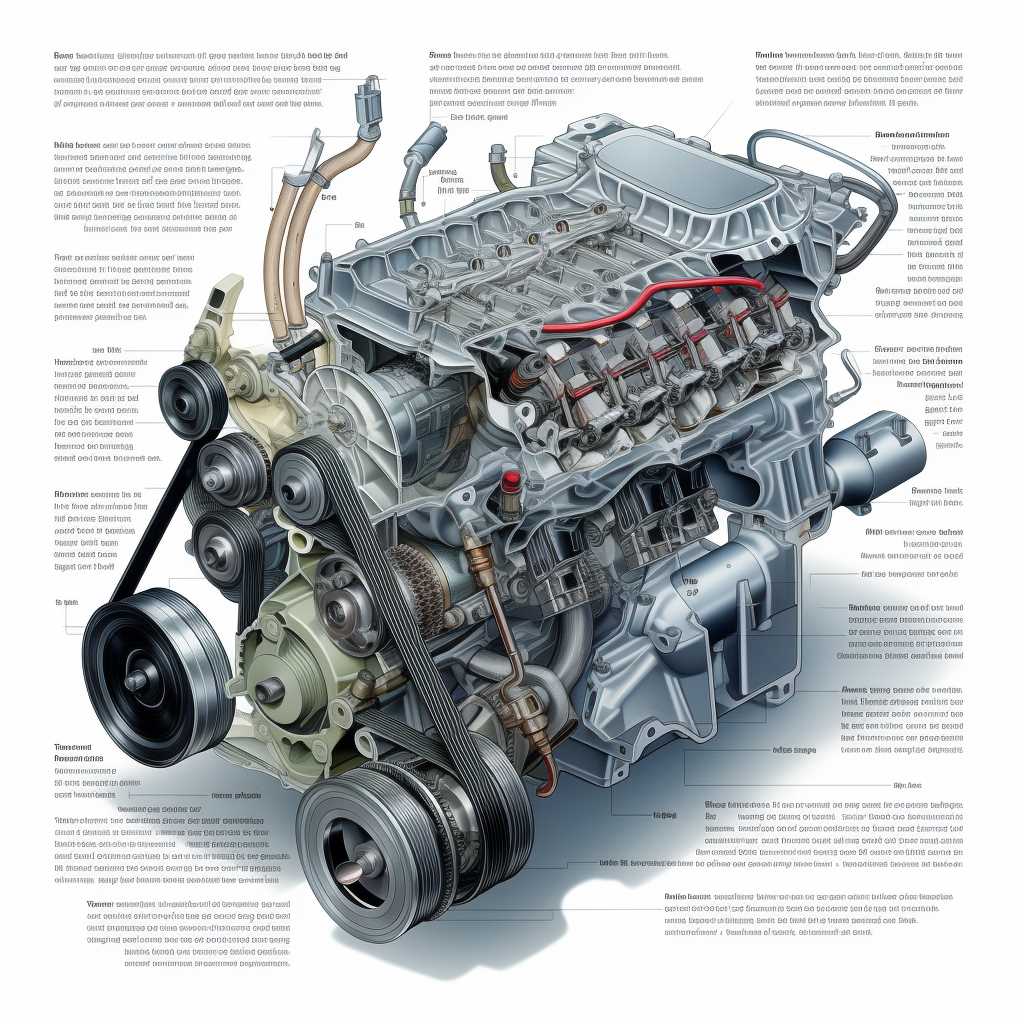

Visual Overview of Engine Parts

This section provides a detailed look at the various components that contribute to the functionality of a modern power unit. Understanding these elements is essential for anyone interested in automotive mechanics or looking to enhance their knowledge of vehicle operation.

At the core of this assembly lies the structure that facilitates combustion, generating the necessary power. Surrounding it are systems designed for fuel delivery, air intake, and exhaust management, each playing a pivotal role in ensuring optimal performance. Additionally, auxiliary mechanisms are present to support lubrication, cooling, and electrical supply, all of which are crucial for maintaining efficiency and longevity.

Visual representations of these components can significantly aid in grasping their interconnections and functions. By exploring these illustrations, one can better appreciate how each unit interacts within the larger framework, leading to improved diagnostics and maintenance practices.

Functionality of Major Components

This section delves into the essential functions of the primary elements that contribute to the overall performance of the power unit. Understanding these functions is crucial for maintaining efficiency and reliability in automotive applications.

| Component | Function |

|---|---|

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber for optimal combustion. |

| Turbocharger | Increases the intake air pressure, enhancing the power output without significantly enlarging the unit. |

| Intercooler | Reduces the temperature of compressed air from the turbocharger, improving efficiency and performance. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion, providing power to the drivetrain. |

| Cylinder Head | Houses the intake and exhaust valves, facilitating air flow in and out of the combustion chamber. |

| Oil Pump | Circulates lubricant throughout the assembly, minimizing friction and preventing overheating. |

Common Issues with Engine Parts

Maintaining optimal performance in automotive machinery often hinges on the reliability of various components. Frequent complications can arise from wear and tear, environmental factors, and manufacturing inconsistencies. Understanding these common challenges is crucial for effective maintenance and longevity.

One prevalent concern involves overheating, which can stem from insufficient coolant circulation or a failing thermostat. This issue can lead to severe damage if not addressed promptly. Another common problem is excessive oil consumption, typically caused by worn seals or piston rings, leading to reduced efficiency and potential engine failure.

Additionally, electrical failures are frequent, often linked to battery issues or faulty wiring. These failures can disrupt crucial functions and compromise overall performance. Lastly, unusual noises or vibrations may indicate misalignments or imbalances within moving components, warranting immediate inspection to prevent further complications.

Replacement Parts for VW 2.0 TDI

When it comes to maintaining the performance and reliability of your Volkswagen, understanding the essential components is crucial. Ensuring that each element functions optimally not only enhances the driving experience but also prolongs the lifespan of your vehicle. This section delves into the vital components that may require replacement over time, along with considerations for quality and compatibility.

Common Components Needing Replacement

- Fuel injectors

- Turbocharger

- Oil filters

- Timing belts

- Water pumps

- Intercoolers

Choosing Quality Components

When selecting replacements, prioritize high-quality alternatives. Genuine parts are often recommended, but there are reliable aftermarket options available. Consider the following:

- Check compatibility with your specific model.

- Read reviews and seek recommendations.

- Evaluate warranties and return policies.

By ensuring that you use appropriate replacements, you can maintain your vehicle’s performance and efficiency for years to come.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle requires consistent care and attention. By implementing a few simple practices, you can significantly extend the lifespan and reliability of its core components, allowing for smoother operation and fewer unexpected repairs.

Regularly checking fluid levels, such as oil and coolant, is essential for maintaining optimal performance. Make it a habit to inspect these fluids and replace them as needed, adhering to the manufacturer’s recommendations. This helps prevent overheating and minimizes wear on critical systems.

Another key aspect of upkeep involves timely replacement of filters. Air and fuel filters play a crucial role in maintaining efficiency and protecting against contaminants. Changing these filters at specified intervals will contribute to improved performance and longevity.

Tire care should not be overlooked. Regularly checking tire pressure and tread depth can enhance fuel efficiency and ensure safe handling. Rotating tires as recommended can also promote even wear and prolong their lifespan.

Additionally, keeping the exterior and interior clean helps prevent rust and deterioration. Washing the vehicle regularly and applying protective coatings can shield against environmental factors that may cause damage over time.

Finally, listen to your vehicle. Any unusual noises or performance issues should be addressed promptly. Early detection of potential problems can save time and money in the long run, ensuring a smooth and reliable driving experience.

Aftermarket vs. OEM Components

The choice between replacement components from original manufacturers and those produced by third-party companies can significantly impact performance, reliability, and overall cost. Understanding the differences between these options is crucial for informed decision-making when maintaining or upgrading a vehicle.

OEM components are designed and produced by the same manufacturer that made the original components for the vehicle. They ensure a precise fit and are often seen as a reliable choice due to their adherence to the original specifications. This means that they typically maintain the quality and performance standards expected by the vehicle maker.

On the other hand, aftermarket components are created by independent manufacturers and can vary widely in quality and price. Some aftermarket options offer improved performance or enhanced features, making them attractive to enthusiasts looking for upgrades. However, buyers must exercise caution, as not all aftermarket products meet the same rigorous standards as their OEM counterparts.

Ultimately, the decision between these two types of components should consider factors such as budget, intended use, and personal preferences. While OEM products may provide peace of mind, aftermarket alternatives can offer unique benefits that align with specific needs.

Performance Enhancements Available

For those looking to elevate the capabilities of their vehicle, a variety of enhancements can significantly boost efficiency and responsiveness. These upgrades can transform the driving experience, providing not only increased power but also improved handling and fuel efficiency.

Upgraded Air Intake Systems: One of the simplest modifications involves enhancing airflow to the combustion chamber. By replacing the stock system with a high-performance intake, enthusiasts can achieve better throttle response and increased horsepower.

Exhaust Modifications: A free-flowing exhaust can reduce back pressure, allowing for improved exhaust gas evacuation. This change often results in a more aggressive sound and a noticeable increase in performance.

Chip Tuning: Reprogramming the vehicle’s control unit can unlock additional power and torque. This adjustment optimizes fuel delivery and timing, leading to a more dynamic driving experience.

Upgraded Turbochargers: For those seeking substantial gains, installing a larger or more efficient turbo can provide a significant boost in power. Coupled with proper tuning, this modification can dramatically enhance acceleration and overall performance.

Suspension Enhancements: Improved handling can be achieved through upgraded suspension components. By installing performance shocks and springs, drivers can enjoy better road grip and cornering stability, making the vehicle feel more agile.

In summary, a range of modifications exists to enhance performance, offering enthusiasts the opportunity to customize their driving experience while maximizing power and efficiency.

Tools Required for Repairs

When undertaking maintenance or restoration tasks on your vehicle, having the right instruments is crucial for efficiency and success. This section outlines the essential equipment that will facilitate the repair process, ensuring that you can tackle each task with confidence.

- Basic Hand Tools:

- Wrenches (both metric and imperial)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and standard)

- Socket set with ratchet

- Specialized Tools:

- Torque wrench for precise fittings

- Oil filter wrench for easy removal

- Compression tester for diagnostics

- Timing belt tool kit if applicable

- Safety Equipment:

- Gloves to protect hands

- Safety goggles to shield eyes

- Fume mask for toxic substances

- Organizational Tools:

- Magnetic trays to hold small parts

- Labeling system for bolts and components

- Toolbox or cart for easy access

Equipped with these tools, you will be prepared to handle various challenges, ensuring a smoother repair experience and better results overall.

Understanding Engine Diagrams

Comprehending the layout of automotive components is essential for anyone involved in vehicle maintenance or repair. Visual representations serve as a vital tool, providing insights into the intricate relationships and functions of various elements within the power unit. This knowledge not only aids in troubleshooting but also enhances overall efficiency during servicing.

The Importance of Visual Representations

Visual aids offer a clear perspective on how different components interact. By breaking down complex assemblies into manageable sections, they facilitate a deeper understanding of mechanics. For technicians, these illustrations become a roadmap, guiding them through the processes of disassembly, inspection, and reassembly.

Key Elements to Consider

When analyzing these visuals, focus on the connections between components, such as flow paths and operational sequences. Critical elements often include fuel delivery systems, air intake configurations, and exhaust setups. Recognizing these aspects not only streamlines repairs but also helps in predicting potential issues before they escalate.

Resources for Further Learning

Understanding the intricacies of automotive mechanisms can significantly enhance your knowledge and skills in the field. Here are various resources that provide valuable insights, tutorials, and detailed information for enthusiasts and professionals alike.

Books

- Automotive Technology: A Systems Approach – A comprehensive guide covering various systems in vehicles.

- How Cars Work – An easy-to-understand book that breaks down complex concepts.

- Fundamentals of Automotive Technology – Offers in-depth explanations and practical applications.

Online Courses

- Coursera – Features courses on vehicle mechanics and repair techniques.

- edX – Offers programs from top universities focusing on automotive engineering.

- Udemy – Hosts a variety of classes on specific maintenance skills and diagnostics.

Utilizing these resources will help you build a solid foundation and stay updated on the latest advancements in the automotive sector.