Comprehensive Guide to Yanmar Engine Parts Diagram

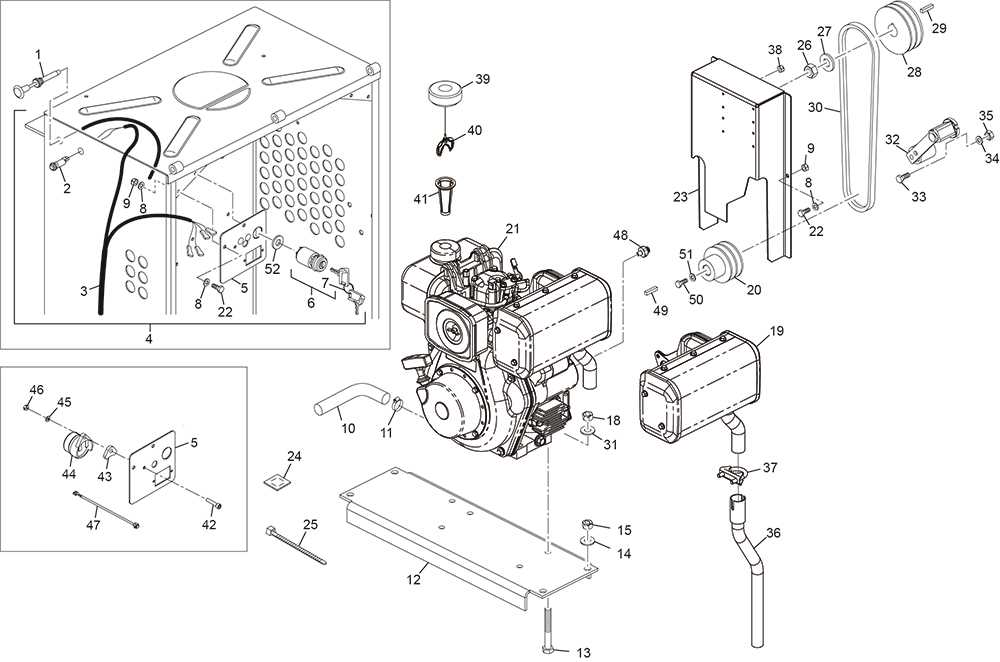

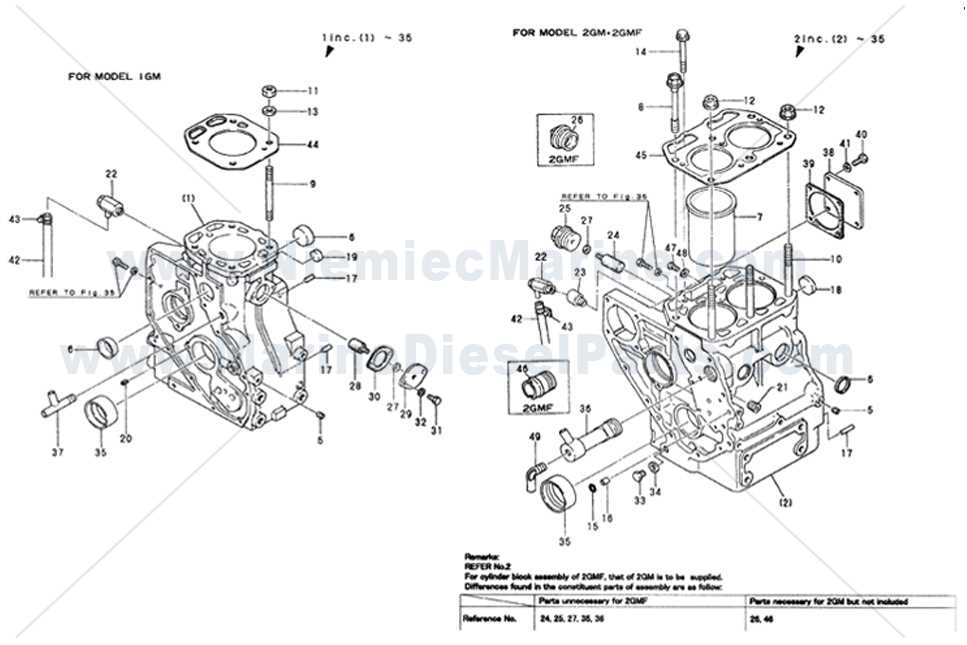

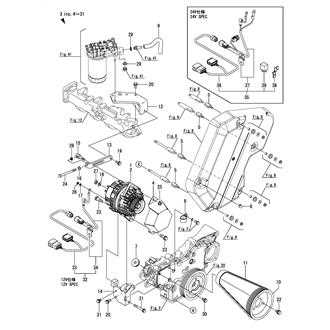

Exploring the intricate relationships and functionalities of mechanical systems can greatly enhance your knowledge of machinery. A thorough comprehension of each element’s role is essential for optimal performance and longevity. This section delves into the visual representation of these crucial components, offering insights that facilitate better maintenance and repair practices.

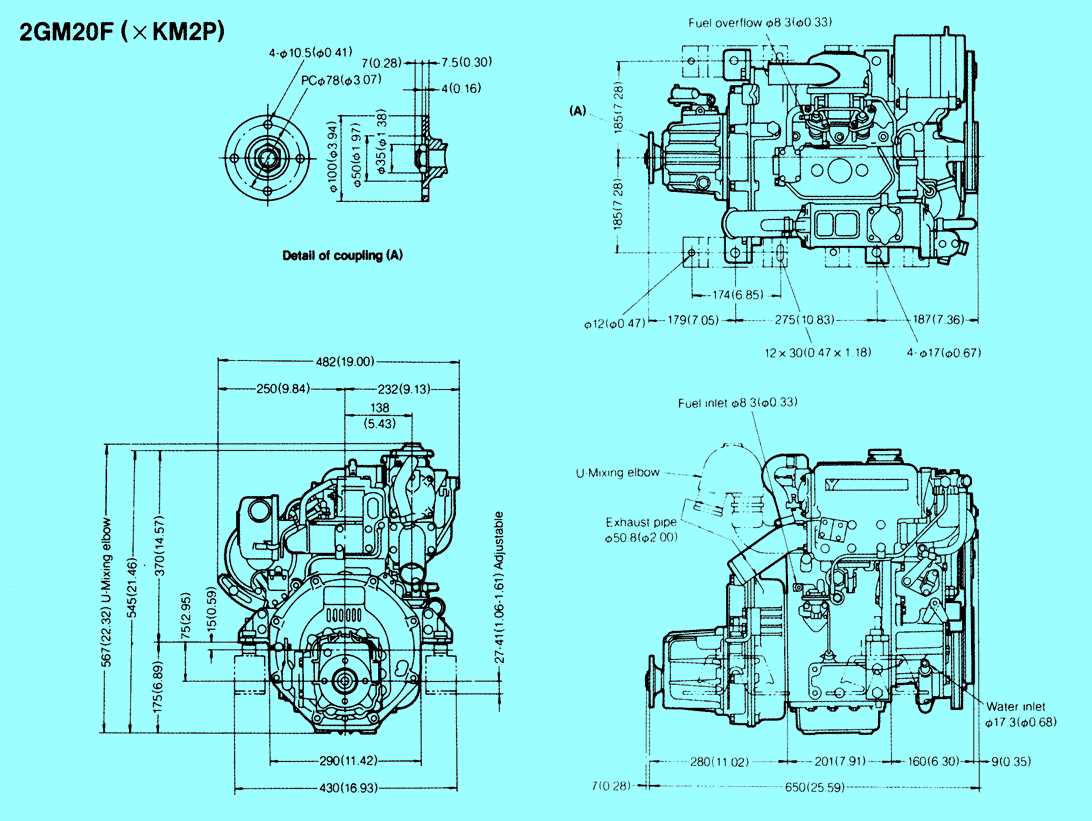

By examining these illustrations, users can identify the specific functionalities and arrangements of various sections. Such clarity aids in diagnosing issues and implementing solutions efficiently. Furthermore, having a clear reference can streamline the process of sourcing replacements and upgrades, ensuring your machinery operates at peak efficiency.

Ultimately, a well-informed approach to understanding the structure and function of these mechanisms empowers operators to make knowledgeable decisions regarding their upkeep. Whether you’re a seasoned technician or a curious enthusiast, this guide aims to illuminate the complexities of the components you rely on daily.

Understanding Yanmar Engine Components

Grasping the intricacies of mechanical systems is essential for optimal performance and longevity. Each unit comprises various elements that work in harmony, ensuring efficient operation. Recognizing the roles of these components can greatly enhance maintenance practices and troubleshooting skills.

Each individual segment contributes to the overall functionality, whether it involves generating power, managing fluids, or facilitating movement. Familiarity with these parts not only aids in repairs but also empowers users to make informed decisions regarding upgrades and replacements.

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders and supporting the entire system. |

| Piston | A moving element that compresses the air-fuel mixture for combustion. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Fuel Injector | Delivers fuel into the combustion chamber at precise intervals. |

| Cooling System | Regulates temperature to prevent overheating and maintain efficiency. |

Importance of Engine Parts Diagrams

Visual representations of machinery components play a crucial role in understanding their functionality and interconnections. These illustrations serve as essential tools for both maintenance and repair, providing clarity on complex systems. When technicians and operators can visualize the layout and relationships of various elements, it significantly enhances their ability to diagnose issues and perform corrective actions efficiently.

Firstly, such visual guides help streamline the repair process. By clearly indicating the placement and configuration of each component, they reduce the likelihood of errors during reassembly. This is particularly vital in intricate systems where small misalignments can lead to significant operational problems.

Moreover, these representations facilitate effective communication among team members. When everyone has access to the same visual reference, it fosters a shared understanding of tasks and responsibilities, thereby improving collaboration and reducing misunderstandings.

Lastly, having access to these illustrations enhances training programs for new employees. They serve as valuable educational tools, allowing newcomers to familiarize themselves with the machinery and its workings before engaging in hands-on activities. This foundational knowledge ultimately leads to a safer and more productive work environment.

Types of Yanmar Engines Explained

This section delves into the various categories of internal combustion systems manufactured by a renowned company. These machines are widely used across multiple industries, each offering unique features tailored to specific applications. Understanding the classifications can help users make informed choices based on performance requirements and operational conditions.

Classification by Fuel Type

- Diesel Systems: Known for their efficiency and durability, these units are commonly employed in marine and agricultural settings.

- Gasoline Systems: Typically lighter and less complex, they are often found in smaller vehicles and equipment.

- Hybrid Models: Combining traditional fuels with electric power, these are increasingly popular for their reduced emissions and fuel savings.

Classification by Size and Power Output

- Compact Units: Ideal for small boats and garden machinery, they provide sufficient power for light tasks.

- Mid-range Units: Balancing performance and efficiency, these are used in construction and commercial applications.

- Heavy-duty Systems: Designed for demanding environments, they are often utilized in large vessels and industrial machines.

Key Parts in Yanmar Engines

Understanding the essential components of a high-performance machine is crucial for efficient operation and maintenance. Each element plays a specific role in ensuring that the overall system functions smoothly, contributing to longevity and reliability. Familiarity with these crucial elements enables better diagnostics and repair processes.

Major Components Overview

Among the primary elements are the fuel delivery systems, which manage the flow of energy source, and the cooling mechanisms that prevent overheating. These critical sections work in tandem to support optimal functionality.

Component Specifications

| Component | Description |

|---|---|

| Fuel Pump | Responsible for delivering fuel to the combustion chamber efficiently. |

| Cooling System | Regulates the temperature to prevent overheating during operation. |

| Crankshaft | Converts linear motion into rotational motion, driving the machinery. |

| Injectors | Atomize fuel for optimal combustion, enhancing performance and efficiency. |

| Filter | Removes impurities from fuel and air to ensure clean operation. |

How to Read Engine Diagrams

Understanding technical illustrations is crucial for anyone involved in machinery maintenance or repair. These visual representations convey complex information about components and their relationships. By grasping how to interpret these graphics, you can efficiently identify issues, plan repairs, and enhance your knowledge of mechanical systems.

Key Elements to Identify

When examining a technical illustration, several essential elements should be noted:

| Element | Description |

|---|---|

| Symbols | Graphic representations of components, often standardized for clarity. |

| Labels | Text descriptions that provide names and specifications of parts. |

| Lines | Indicate connections and relationships between various elements. |

| Legend | A key that explains symbols and color codes used within the illustration. |

Steps to Interpret Effectively

To effectively decode these illustrations, follow these steps:

1. Start by reviewing the legend to familiarize yourself with the symbols used.

2. Identify the main components and their labels to understand the overall structure.

3. Trace the lines connecting elements to see how they interact with each other.

4. Pay attention to any notes or special instructions that may accompany the illustration.

By practicing these techniques, you can enhance your ability to analyze and utilize technical visuals for improved understanding and troubleshooting of machinery.

Common Issues with Engine Parts

Understanding the typical challenges that can arise with mechanical components is crucial for maintaining optimal performance. Various factors can lead to malfunctions, affecting reliability and efficiency. Addressing these concerns proactively can save time and resources in the long run.

Wear and Tear

Over time, regular use can lead to significant deterioration of crucial elements. Friction and heat can cause surfaces to degrade, resulting in decreased functionality. Implementing a routine inspection schedule can help identify signs of wear before they escalate into major problems.

Fluid Leaks

Another prevalent issue involves leaks from seals or gaskets, which can compromise system integrity. Regular monitoring of fluid levels is essential, as even minor leaks can lead to serious complications if left unchecked. Early detection and timely repairs are vital in preventing extensive damage.

Maintenance Tips for Yanmar Engines

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By adhering to a systematic maintenance schedule, you can prevent potential issues and enhance performance. Here are some key practices to consider for optimal care.

Routine Checks

- Inspect fluid levels regularly, including oil, coolant, and fuel.

- Monitor for any signs of leaks or unusual noises.

- Clean air filters to promote better airflow and efficiency.

Scheduled Servicing

- Change the oil and replace filters at recommended intervals.

- Schedule periodic checks of belts and hoses for wear and tear.

- Ensure electrical connections are secure and corrosion-free.

Implementing these tips will not only extend the lifespan of your machinery but also enhance its overall reliability and performance.

Identifying Genuine Yanmar Parts

Ensuring the authenticity of components is crucial for maintaining optimal performance and longevity of machinery. Counterfeit or substandard items can lead to inefficiencies and costly repairs. Therefore, recognizing genuine components is essential for operators and mechanics alike.

Visual Inspection

One of the simplest methods to determine authenticity is through a detailed visual examination. Genuine components often feature specific markings or logos that are consistent across the brand’s offerings. Pay attention to finishing quality and color consistency, as authentic products typically exhibit a higher level of craftsmanship compared to imitations.

Packaging and Documentation

Authentic components are usually packaged with care, including brand-specific labeling and documentation. Check for certificates of authenticity or warranty information, as reputable manufacturers provide this to support their products. If the packaging seems subpar or lacks detailed information, it may indicate a non-genuine item.

Tools Needed for Engine Repairs

When it comes to performing maintenance on machinery, having the right implements is essential for ensuring efficiency and accuracy. Proper tools not only facilitate the repair process but also help in preventing potential damage to components during disassembly and reassembly.

Basic Hand Tools are the foundation of any repair task. Wrenches, pliers, and screwdrivers should be readily available in various sizes to accommodate different fasteners. A reliable set of these tools is crucial for loosening and tightening parts securely.

Specialized Equipment might also be required depending on the complexity of the job. For instance, torque wrenches are invaluable for applying precise pressure when securing fasteners, while oil filters and compression gauges can aid in diagnostics and maintenance checks.

Safety Gear should never be overlooked. Protective eyewear, gloves, and sturdy footwear are necessary to shield against potential hazards that can arise during repairs. Ensuring personal safety is as important as the task at hand.

Having a well-organized workspace is equally important. A clean, clutter-free area equipped with a sturdy workbench allows for efficient workflow, making it easier to manage tools and parts without confusion.

In conclusion, a combination of essential hand tools, specialized equipment, safety gear, and an organized workspace is vital for successfully executing maintenance tasks. Investing in quality implements and creating a conducive environment will significantly enhance repair outcomes.

Replacement Parts: When to Buy

Understanding the optimal moments for procuring new components is essential for maintaining peak performance and longevity of your machinery. This involves recognizing signs of wear and tear, as well as knowing when preventative measures can save you from more significant issues down the line.

Signs of Wear and Tear

Frequent indications that it might be time to replace a component include unusual noises, decreased efficiency, or visible damage. Monitoring performance closely can help you identify these red flags early. Addressing issues promptly not only ensures smoother operation but also helps prevent further complications.

Preventative Measures

In addition to reacting to existing problems, consider implementing a regular maintenance schedule. This proactive approach allows for timely replacements before any failures occur, ultimately extending the life of your equipment. By keeping an eye on usage patterns and operational demands, you can make informed decisions about when to invest in new components.

Investing in quality replacements can lead to better reliability and efficiency, making it a crucial aspect of machinery upkeep. Staying vigilant and informed ensures that you make the right choices at the right times.

FAQs About Yanmar Engine Diagrams

This section addresses common inquiries regarding technical schematics related to specific machinery. Understanding these illustrations can significantly aid in maintenance and troubleshooting, ensuring optimal performance and longevity.

Common Questions

- What information can I find in these illustrations?

- Component locations

- Assembly instructions

- Connection details

- Maintenance tips

- Are these resources available for all models?

- Most major models have accompanying visuals.

- Older or less common types may have limited documentation.

- How can I access these visual resources?

- Manufacturer’s website

- Authorized dealers

- Online forums and communities

Tips for Using the Illustrations

- Always refer to the correct model and version.

- Use high-resolution images for clarity.

- Cross-reference with maintenance manuals when necessary.

Resources for Further Learning

Expanding your knowledge about mechanical systems can significantly enhance your understanding and skills. Various resources are available to deepen your expertise, whether you are a beginner or an experienced technician. This section provides valuable references that cater to diverse learning styles and preferences.

Books and Manuals: Comprehensive literature is crucial for anyone looking to grasp the intricacies of machinery. Look for well-reviewed manuals and technical guides that cover operational principles and maintenance procedures. These texts often include detailed illustrations and step-by-step instructions, making complex concepts more accessible.

Online Courses: Numerous platforms offer courses focused on mechanical principles and diagnostics. These interactive sessions allow you to learn at your own pace while providing practical exercises to reinforce your understanding. Check for courses that include video tutorials and hands-on projects for a more immersive experience.

Forums and Community Groups: Engaging with others who share your interests can be incredibly beneficial. Online forums and community groups provide a space for discussions, troubleshooting tips, and knowledge sharing. Participating in these communities can expose you to real-world experiences and solutions.

Manufacturer Websites: Exploring the official sites of manufacturers can yield valuable information, including technical specifications, maintenance tips, and downloadable resources. Many companies offer support documents that can enhance your understanding of their products.

Videos and Webinars: Visual learning can be highly effective, especially when it comes to understanding mechanical operations. Platforms like YouTube host a plethora of instructional videos, while webinars often feature industry experts discussing current trends and techniques. These resources can provide insights that enhance theoretical knowledge with practical applications.

Utilizing these various educational tools will not only broaden your understanding but also equip you with the skills necessary to tackle challenges confidently.