Comprehensive Guide to AR-15 Exploded Parts Diagram

In the realm of modern weaponry, a comprehensive grasp of individual components is essential for both enthusiasts and professionals. The intricate assembly of these mechanisms showcases a blend of engineering and design, reflecting the technological advancements in firearm production.

Visual representations play a crucial role in enhancing one’s knowledge. By examining a detailed illustration of a weapon’s assembly, one can better appreciate how each segment interrelates and contributes to the overall functionality. This understanding aids in maintenance, customization, and troubleshooting.

Furthermore, delving into the various elements not only illuminates the complexity involved but also highlights the importance of safety and proper handling. Each component has a specific purpose, and recognizing this can lead to more informed usage and responsible ownership.

Understanding the AR-15 Structure

This section explores the intricate design and components that make up a popular firearm. A comprehensive grasp of its assembly is essential for enthusiasts and users alike, providing insights into functionality and maintenance.

Main Components

- Receiver

- Barrel

- Stock

- Trigger mechanism

- Gas system

Functionality Overview

Each element plays a vital role in the overall operation, contributing to accuracy and reliability. Understanding how these components interact can enhance user experience and safety.

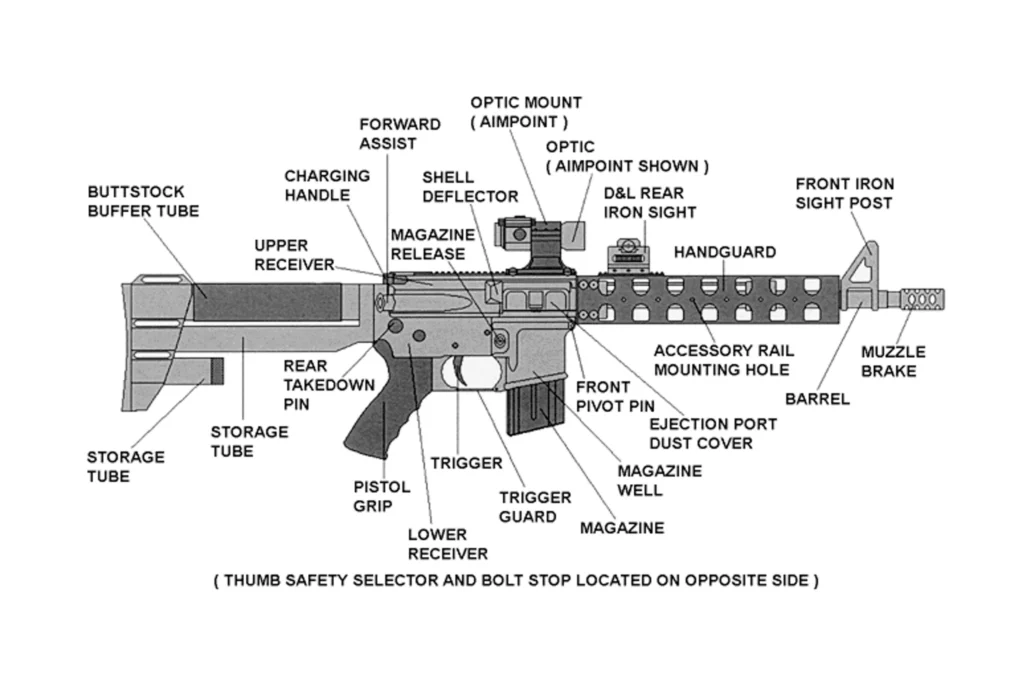

Key Components of the AR-15

The architecture of this firearm consists of several essential elements that contribute to its functionality and performance. Understanding these components is crucial for enthusiasts and users alike.

- Receiver: The core structure that houses the operating mechanisms.

- Barrel: Responsible for directing the projectile and influencing accuracy.

- Stock: Provides support and stability during operation.

- Handguard: Protects the shooter’s hand and allows for accessory attachments.

- Gas System: Manages the cycling of the action and reliability.

Each of these components plays a pivotal role in ensuring optimal performance and user experience.

Common Issues with AR-15 Parts

Understanding the frequent challenges associated with specific components is essential for maintaining optimal performance and safety. Various issues can arise from wear and tear, improper installation, or manufacturing defects. Identifying these common problems can help ensure reliability and longevity.

Wear and Tear

Over time, certain elements may experience degradation due to regular use. This can lead to malfunctions or reduced efficiency. Regular inspection and timely replacement are crucial to prevent serious complications.

Installation Errors

Improper assembly can result in critical failures. Following manufacturer guidelines closely and utilizing the correct tools can mitigate these risks. Always double-check alignment and torque specifications to ensure safe operation.

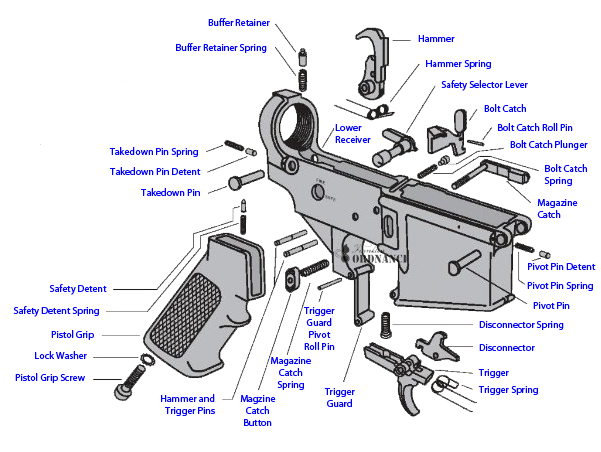

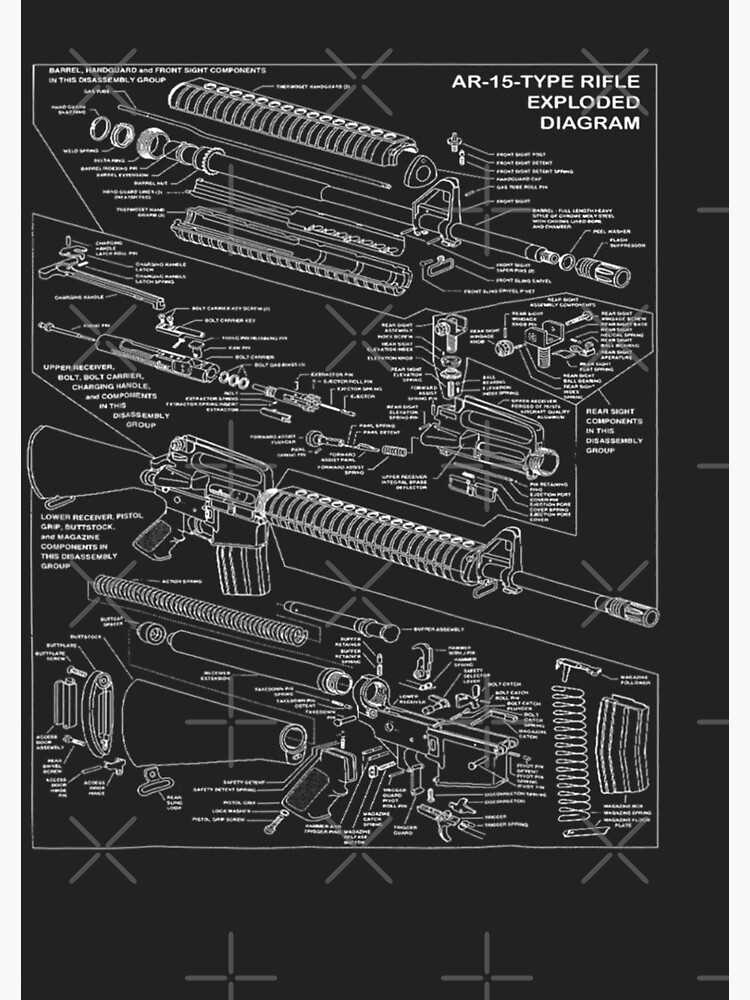

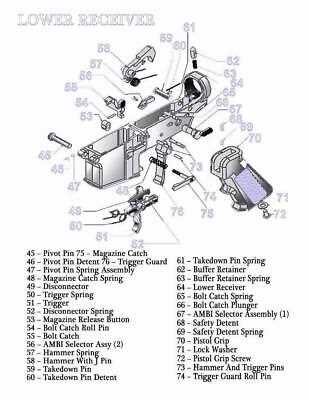

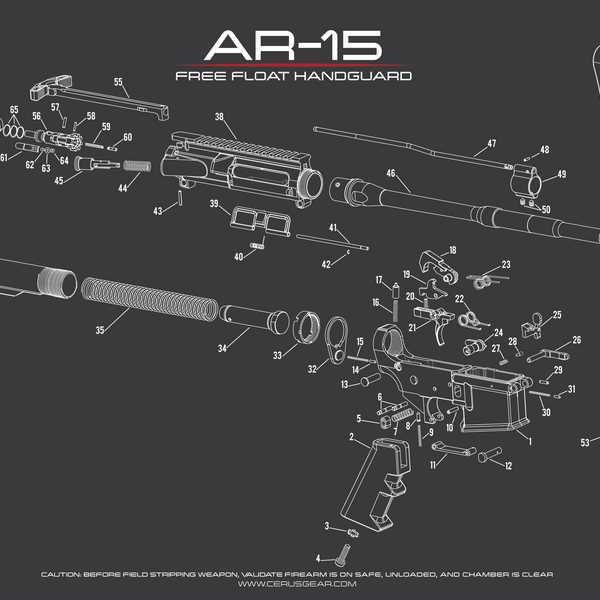

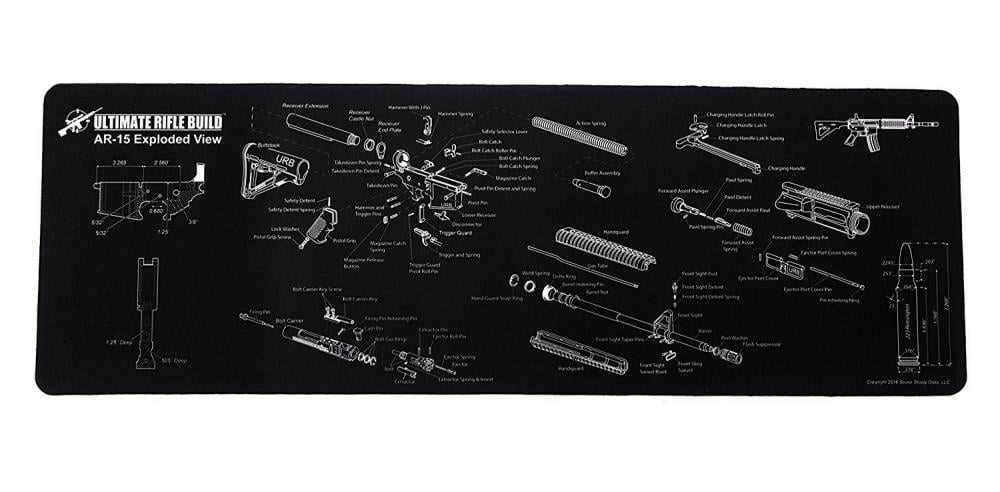

Benefits of an Exploded Diagram

Visual representations that detail components and their relationships provide clarity and understanding, making complex systems more approachable. Such illustrations are invaluable for both learners and seasoned professionals, enhancing comprehension and facilitating effective communication.

Enhanced Understanding

- Breaks down intricate structures into manageable segments.

- Highlights the function and positioning of each element.

- Facilitates quick reference during assembly or maintenance.

Improved Communication

- Provides a universal language for technical discussions.

- Reduces ambiguity by illustrating clear relationships.

- Assists in training new team members effectively.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to constructing a firearm, focusing on clarity and precision throughout the assembly process. Following these guidelines will ensure each component is properly installed, resulting in a reliable and functional weapon.

-

Gather Required Tools and Materials:

- Wrenches

- Screwdrivers

- Torque wrench

- Cleaning supplies

- Safety equipment

-

Prepare the Workspace:

- Choose a clean, organized area

- Ensure proper lighting

- Keep safety equipment within reach

-

Begin with the Lower Assembly:

- Attach the trigger mechanism

- Install the magazine well

- Secure the pistol grip

-

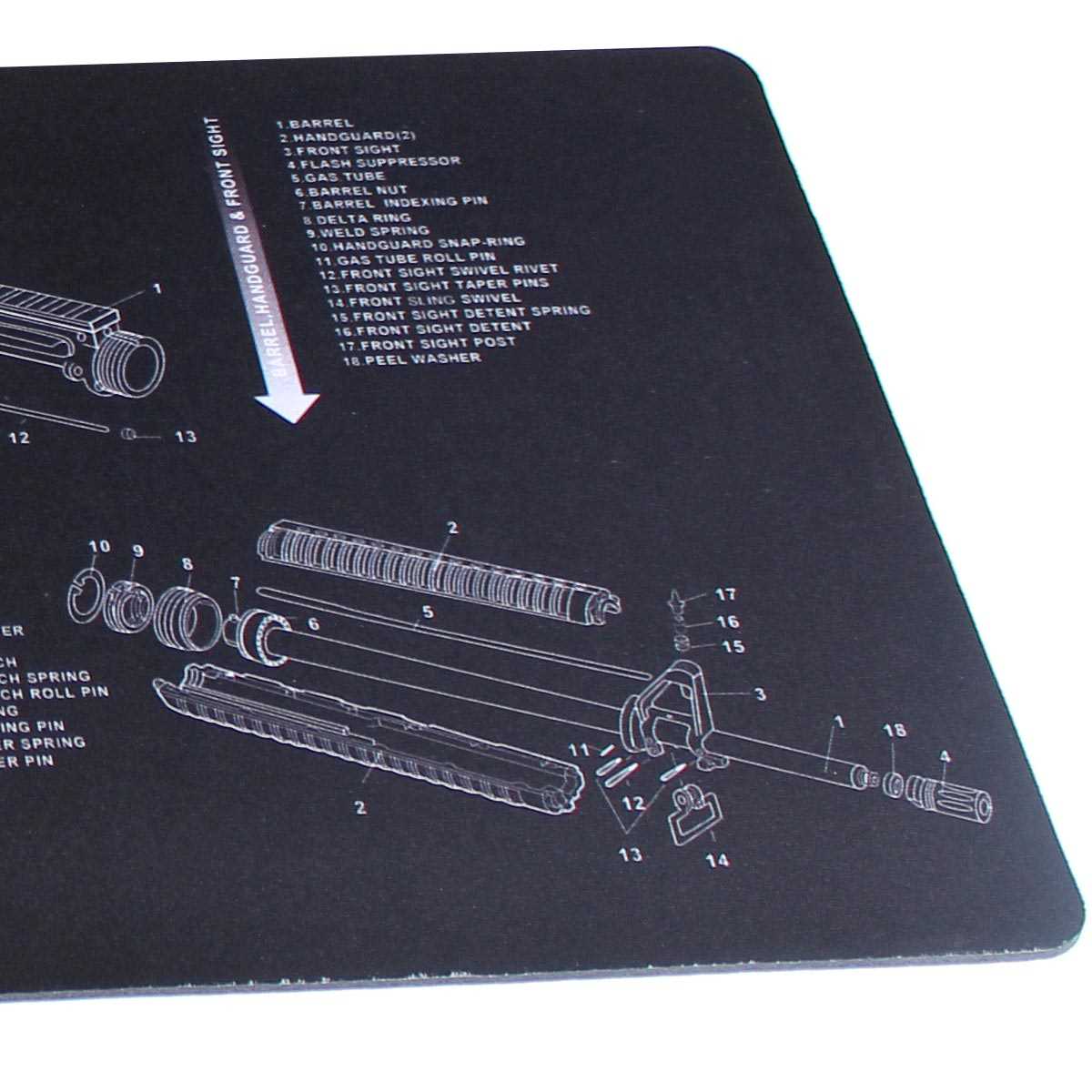

Proceed to the Upper Assembly:

- Attach the barrel securely

- Install the handguard

- Mount the sights

-

Combine Upper and Lower Assemblies:

- Align the two sections

- Secure with the necessary pins

- Double-check alignment for accuracy

-

Final Adjustments and Safety Checks:

- Inspect all connections

- Ensure proper functioning of all components

- Conduct a safety test before use

By following these detailed steps, you will achieve a successful assembly. Always prioritize safety and consult professional resources if needed.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves a consistent and thorough approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of your gear, safeguarding your investment.

1. Clean Regularly: Keeping your equipment free of debris and residues is essential. Use appropriate cleaning solutions and tools to remove dirt and grime after each use.

2. Inspect Components: Periodically check all elements for signs of wear or damage. Addressing issues early can prevent more significant problems down the line.

3. Lubricate Properly: Applying the right lubricants reduces friction and wear. Follow manufacturer recommendations for the best results.

4. Store Correctly: Proper storage conditions can protect your gear from environmental factors. Choose a dry, cool place and use protective cases if necessary.

5. Follow Manufacturer Guidelines: Adhering to the specific maintenance recommendations provided by the manufacturer ensures optimal functionality and longevity.

By integrating these practices into your routine, you can effectively prolong the life of your equipment and maintain its ultimate performance.

Tools Needed for Repairs

When it comes to maintaining and fixing firearms, having the right equipment is essential for ensuring safety and functionality. A well-prepared toolkit can make the repair process efficient and effective, allowing enthusiasts to address any issues with confidence.

Here’s a list of essential tools you’ll need for successful repairs:

- Wrenches: Various sizes for loosening and tightening components.

- Screwdrivers: A set of both flat-head and Phillips for different screw types.

- Pliers: Needle-nose and regular pliers for gripping and manipulation.

- Torque Wrench: To apply the correct amount of force when fastening screws.

- Cleaning Kit: Brushes and patches to maintain cleanliness and prevent corrosion.

- Bench Vise: To hold parts securely while you work.

- Calipers: For precise measurements of components.

- Safety Gear: Goggles and gloves to protect yourself during repairs.

Having these tools on hand will not only facilitate smoother repairs but also help in maintaining the integrity of your equipment over time.

Identifying Faulty Components

Recognizing when a specific part is malfunctioning is crucial for maintaining the reliability and safety of any mechanical system. Being able to spot early signs of wear or damage can prevent more significant issues and ensure optimal performance. Understanding how to identify these faulty elements allows for timely repairs or replacements, which is essential for long-term functionality.

Common Indicators of Wear

Over time, components can exhibit certain signs that indicate the need for attention. These signs might include unusual sounds, increased friction, or visible wear marks. Regular inspections and a keen awareness of these early warning signals are key to keeping everything running smoothly.

Inspecting for Damage

Performing a thorough visual check is the first step in determining if any parts have been compromised. Look for cracks, bending, or deformation that could indicate stress or impact damage. Any irregularities in the shape or functi

Safety Considerations During Disassembly

Proper safety measures are essential when taking apart any mechanical device. Being cautious and following the right procedures helps prevent accidents and protects both the user and the tool. Before starting, ensure you are familiar with the mechanics and that the area is prepared for safe work.

Key Precautions to Follow

- Always ensure the device is unloaded and in a safe state before handling.

- Work in a well-lit, clean environment free of distractions or obstacles.

- Use appropriate tools for each step to avoid damage or injury.

- Handle springs and small components with care to prevent them from flying out unexpectedly.

Personal Protection

Wear appropriate safety gear, including eye protection and gloves, to shield yourself from potential hazards. Avoid applying excessive force to components, as this can cause damage or personal injury.

Upgrades for Enhanced Performance

Optimizing your firearm for better efficiency and precision can be achieved through a variety of modifications. These upgrades are designed to improve overall functionality, providing smoother handling, increased accuracy, and enhanced durability. By focusing on key components, shooters can experience a noticeable improvement in performance during different scenarios, from sport shooting to self-defense.

Barrel improvements are a common starting point for enhancing accuracy and consistency. Choosing a high-quality barrel made from durable materials ensures longevity and precision, making it a critical upgrade for any enthusiast aiming to enhance their setup.

Trigger systems play a significant role in improving control and response time. A smoother, more responsive trigger allows for faster, more accurate shots, giving the user greater control during operation.

For enhanced stability, upgrading the stock can make a significant difference. A more ergonomic design offers better comfort and balance, allowing for improved control and aim

Legal Considerations for Modifications

When considering adjustments or upgrades to any firearm, it is crucial to understand the legal implications that may arise. Different jurisdictions have varying regulations governing the customization of weapons, and failure to comply with these laws can result in serious penalties.

Compliance with Local and Federal Laws

Firearm modifications are often subject to both local and federal regulations. It is essential to research the specific laws in your region regarding allowable changes, as some modifications may be restricted or require special permits. Ignoring these legal requirements can lead to significant legal consequences.

Modifications That May Affect Legality

Certain alterations, such as changes to the firing mechanism or structural components, could shift a firearm into a category requiring additional regulation. Before making any significant changes, it is advisable to consult with a legal

Historical Development of the AR-15

The origins of this popular rifle design trace back to the mid-20th century, when firearm innovation was advancing at a rapid pace. This period saw a growing demand for lightweight, modular firearms that could adapt to different operational environments and combat scenarios. Engineers and military officials worked together to create a model that could meet these needs while also incorporating modern materials and technology.

Early Innovations

During the initial development phase, the concept of a versatile, semi-automatic firearm began to take shape. Key improvements focused on reducing weight without sacrificing durability, while also ensuring compatibility with newly developed ammunition types. Advances in metallurgy and manufacturing techniques played a critical role in refining the weapon’s overall performance.

Military Adoption

After several prototypes and field tests, the design was eventually adopted by the military due to its effectiveness in varied conditions. The introduction of this rifle into service marked a significant shift in milita

Comparing AR Variants and Models

There are numerous versions and models of this popular rifle platform, each catering to different user needs and preferences. The variations typically reflect differences in build quality, intended use, and additional features that can enhance performance, accuracy, or handling. While all share a common design, the differences between models are worth examining for those looking to optimize their shooting experience.

- Military vs Civilian Models: Military versions often have specific performance enhancements and features, such as select-fire capability, that are restricted in civilian variants. Civilian models, however, offer extensive customization options.

- Barrel Length and Caliber: Different models offer a variety of barrel lengths and calibers, affecting range, accuracy, and power. Shorter barrels are preferred for close-quarters use, while longer ones are chosen for long-range accuracy.