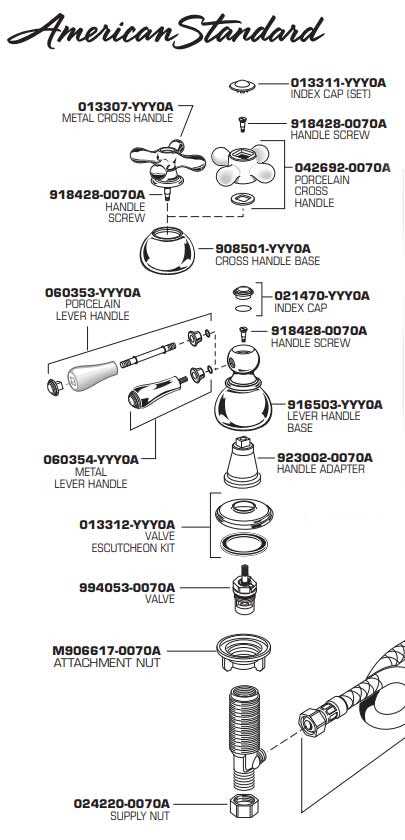

Understanding the American Standard Kitchen Faucet Parts Diagram

When it comes to keeping water flowing smoothly in any environment, having a clear view of the internal mechanisms is essential. The layout of the various elements involved in water distribution can sometimes appear complex, but breaking it down helps to reveal the core functions of each piece. By focusing on the individual components, one can better appreciate the system that ensures a consistent and reliable stream of water.

Each piece within this system serves a unique role, from managing water pressure to controlling the direction of the flow. These elements are carefully designed to work together seamlessly, and understanding their placement and purpose can make troubleshooting or maintenance far more manageable. A well-organized overview allows for a more straightforward approach to handling adjustments or replacements.

Whether you are dealing with minor repairs or looking to enhance the performance of your water supply mechanism, knowing the specific functions of each part is invaluable. By exploring the layout and identifying the critical connections, maintaining smooth water flow becomes an achievable task for any user.

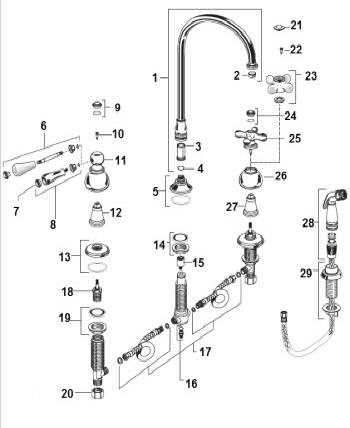

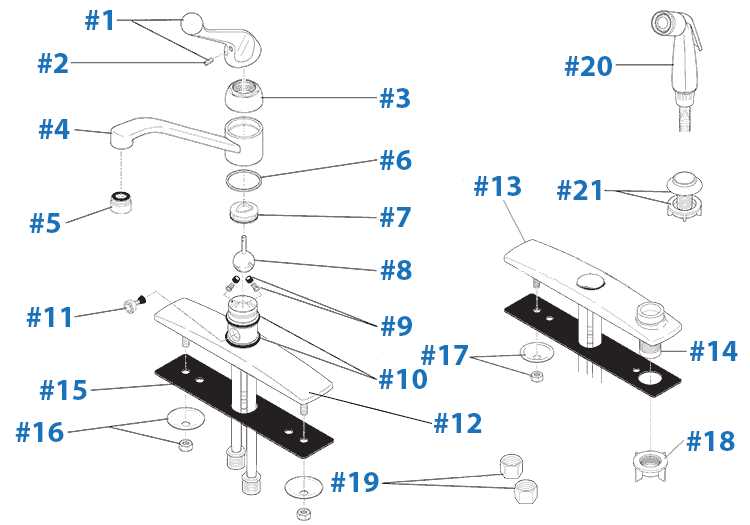

Overview of Kitchen Faucet Components

Understanding the various elements involved in this household fixture is essential for ensuring its smooth operation and maintenance. Each component plays a crucial role in providing functionality and efficiency.

- Handles: These allow control over water temperature and flow. Depending on the model, there may be one or two handles designed for this purpose.

- Spout: This directs the flow of water. Various shapes and sizes offer flexibility and style, from high arches to more compact designs.

- Cartridge: The mechanism inside that controls water flow and mixing, typically found beneath the handles, ensuring smooth operation.

- Mounting hardware: These parts secure the fixture to the sink or countertop, ensuring stability and preventing leaks.

- Seals and washers: These small but vital elements prevent water from leaking by providing tight seals between different components.

By familiarizing yourself with these components, you can easily troubleshoot common issues and understand how to enhance the overall performance of your fixture.

Key Features of Faucet Systems

Modern water delivery systems incorporate a variety of elements designed to ensure both functionality and user convenience. These systems combine mechanical components that control the flow and temperature of water, creating an efficient and easy-to-use interface. Understanding these key features is essential for selecting the right setup for any home or commercial space.

Durability plays a crucial role in the longevity of any water control unit. Materials used in the construction are often designed to withstand pressure, corrosion, and wear over time. The components that handle water flow must be built with precision to ensure consistent performance.

Another vital element is ergonomics, which influences how users interact with the system. Handles and levers are designed for ease of use, while ensuring that adjustments to water flow or temperature can be made comfortably and with minimal effort.

Efficiency is a key consideration in modern systems. Innovations in water flow technology ensure that the right amount of water is dispensed, reducing waste and promoting sustainability. These systems often include features like temperature regulation to enhance comfort and safety.

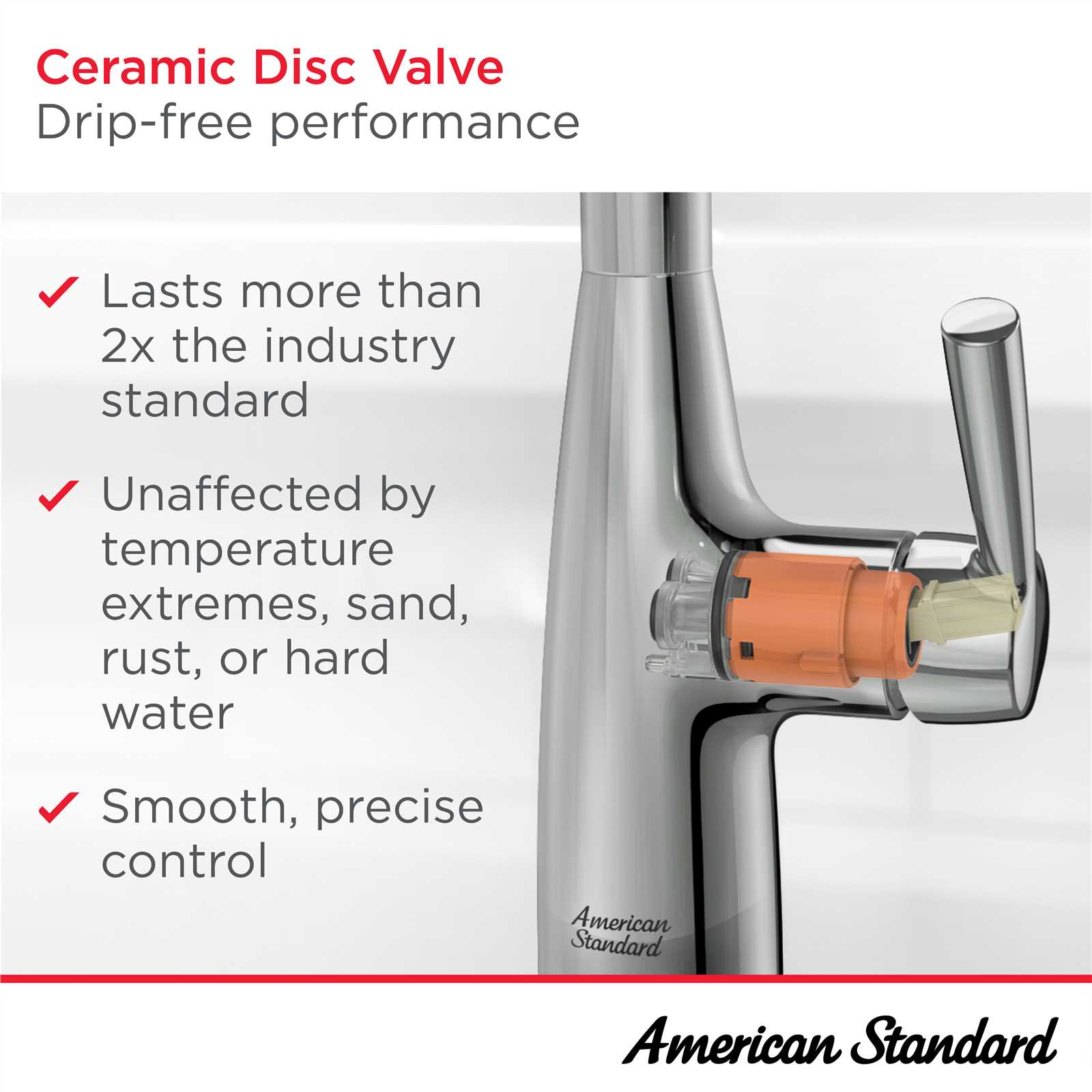

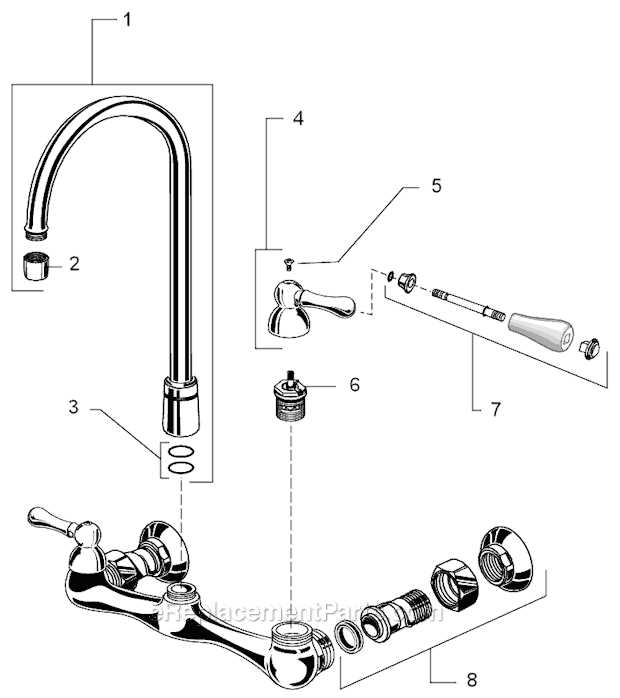

Understanding Valve Cartridge Mechanisms

In modern plumbing systems, the valve cartridge plays a critical role in regulating the flow and temperature of water. This component controls the movement of water through the system, adjusting to user input for both volume and heat. By leveraging a precise mechanism, it allows for seamless operation, ensuring reliability and durability in everyday use.

The Role of the Cartridge in Water Flow Control

The valve cartridge is responsible for managing water distribution, directing the flow through various channels. It contains a series of moving parts that respond to user adjustments, whether for cold or hot water. The precision with which these components move directly impacts the smoothness and consistency of the water stream.

Why Proper Maintenance is Essential

Maintaining the valve cartridge ensures the longevity and functionality of the entire system. Over time, wear and tear can affect its efficiency, potentially causing leaks or difficulty in adjusting water temperatures. Regular checks and timely replacements of worn parts help maintain optimal performance and prevent costly repairs.

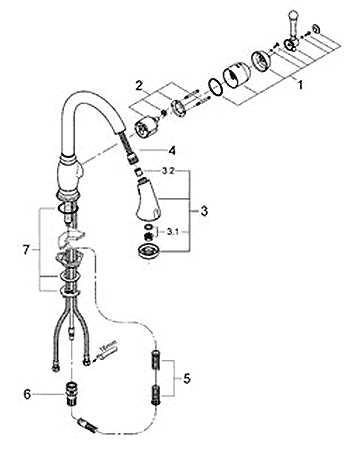

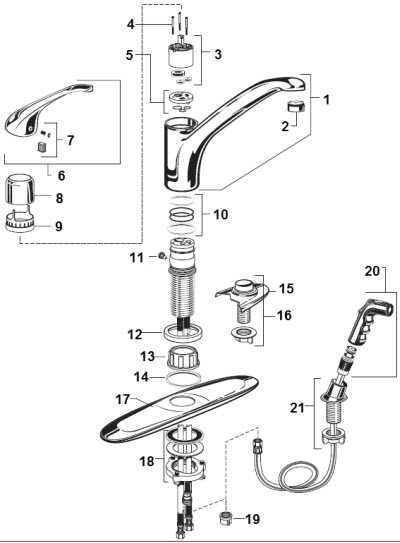

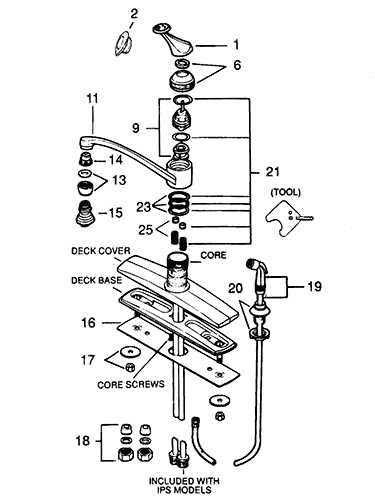

Sprayer Hose and Mounting Guide

Understanding the correct installation and setup of the sprayer hose and its mounting system is essential for a functional and efficient water delivery solution. Proper positioning and securing of the hose ensure smooth operation, preventing leaks and wear over time. This guide covers essential steps to correctly handle and mount the sprayer hose for optimal performance.

Positioning the Hose: Begin by ensuring the hose is positioned for easy reach and maximum flexibility. Avoid kinks or sharp bends that could restrict water flow. The hose should be able to retract smoothly without resistance and be long enough to cover all necessary areas.

Securing the Hose: Once the hose is positioned, it’s important to secure it properly using the appropriate mounts or clips. These mounts should hold the hose in place, keeping it accessible while preventing unnecessary strain. A secure attachment prevents the hose from tangling or slipping out of place during use.

Checking for Leaks: After mounting, it’s essential to test the system for leaks. Ensure all connections are tightened correctly. A well-mounted hose will not only function effectively but also prevent water damage due to leaks.

By following these guidelines, you’ll ensure the sprayer hose is set up for durability and convenience, offering reliable performance whenever needed.

Handle Assembly and Its Role

The handle mechanism is a critical component of any water control system, providing users with the ability to regulate the flow and temperature of water. This assembly consists of various elements that work together seamlessly to ensure smooth operation. Understanding its structure and function is essential for proper maintenance and troubleshooting.

Key Components of the Handle Mechanism

The assembly typically includes the handle, internal cartridge, and connection parts that facilitate smooth movement. Each part serves a specific function, contributing to the efficiency of the system. Proper installation and maintenance of these components ensure optimal performance and longevity.

| Component | Function |

|---|---|

| Handle | Provides the user with control over water flow and temperature adjustments. |

| Cartridge | Regulates the water temperature and flow by controlling the mixing of hot and cold water. |

| Connection Parts | Connects the handle to the internal components, allowing smooth movement and effective control. |

Importance of Proper Maintenance

Regular inspection and maintenance of the handle assembly are vital to prevent wear and tear, leaks, and malfunctions. Lubricating moving parts and replacing worn components can extend the life of the system and ensure reliable performance for daily use.

Water Supply Line Connections

Properly connecting the water supply to your sink is essential for ensuring a reliable and secure flow of water. This process involves establishing solid connections between the water lines and the fixtures to maintain optimal functionality. The correct setup prevents leaks and ensures that water flows freely when needed.

Types of Connections

- Compression Fittings: These are used to tightly seal connections and prevent water leakage. They are a common choice for many setups.

- Threaded Connections: These fittings have threads that screw onto the pipes, creating a secure connection. They are commonly found in residential plumbing.

- Push-Fit Connections: These provide a quick, tool-free connection by simply pushing the pipe into the fitting. Ideal for ease of installation.

Installation Tips

- Ensure all connections are tightened properly to avoid any leaks.

- Use plumber’s tape on threaded connections to enhance the seal.

- Check for leaks after installation to confirm that everything is connected correctly.

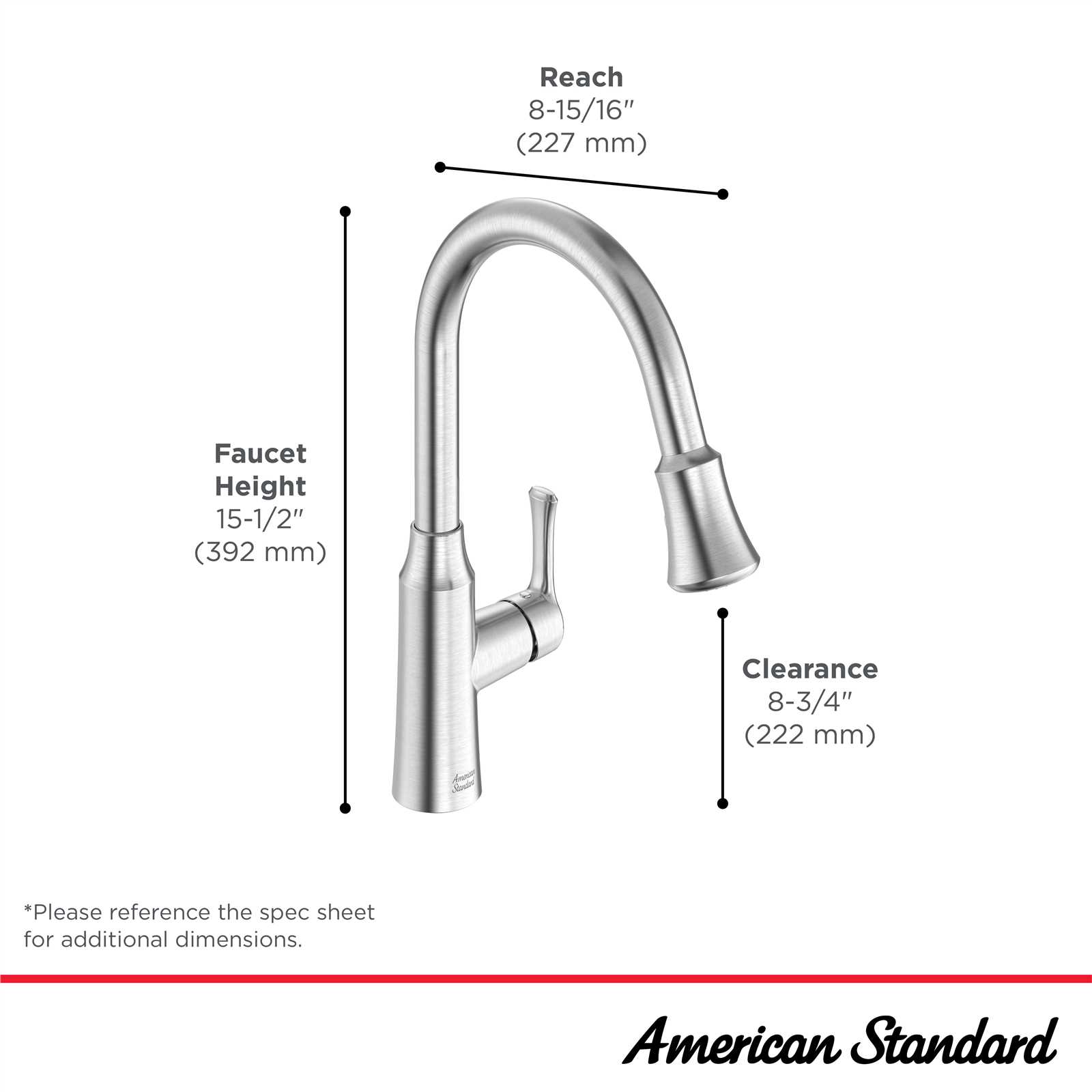

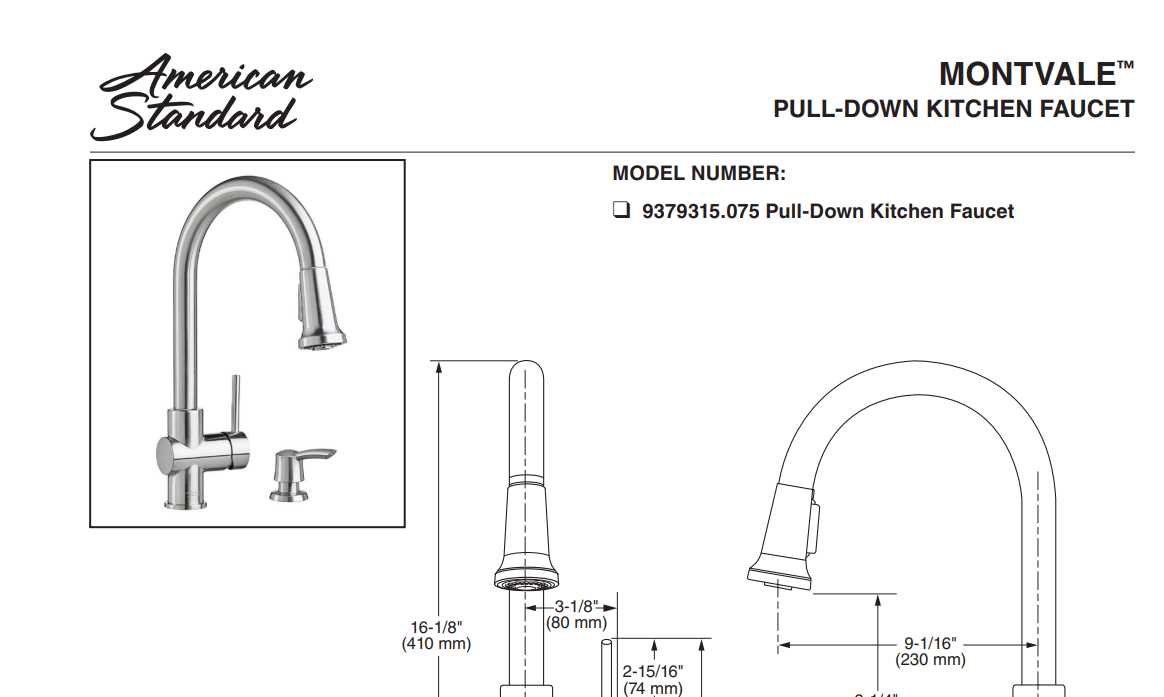

Spout Design and Flow Control

The structure of the spout and its regulation mechanism play a crucial role in managing the water output and user experience. These components work together to provide smooth, controlled water flow, ensuring both efficiency and ease of use. The design features vary, influencing how water is dispensed and controlled, making it essential to understand their functionality for optimal performance.

Various spout types and flow control mechanisms are designed to accommodate different needs. From simple to advanced designs, each system offers unique benefits in terms of water direction, speed, and pressure adjustment. Understanding these designs is key to choosing the right system for different usage scenarios.

| Spout Design | Flow Control Features |

|---|---|

| Traditional | Manual handle for water volume adjustment |

| Pull-down | Integrated sprayer for adjustable spray patterns |

| Gooseneck | High arc for greater clearance and reach |

| Touchless | Sensor activation with automatic flow regulation |

Importance of O-Rings in Faucets

Seals play a crucial role in ensuring the smooth operation of various plumbing fixtures. Among these, one of the most essential components is a rubber ring, which helps maintain proper function and prevent leakage. These small yet vital elements are integral to the longevity and reliability of a wide range of water-handling systems.

Here are the key reasons why rubber rings are so important:

- Leak Prevention: Rubber rings provide a tight seal, preventing water from leaking out around joints and connections.

- Durability: High-quality seals are designed to withstand frequent movement and wear, ensuring long-lasting performance.

- Easy Maintenance: These rings are simple to replace, making repairs quicker and more cost-effective.

- Improved Efficiency: By maintaining a secure seal, they help optimize the overall functionality of the system.

Without these seals, the risk of water damage and inefficient performance increases, making them a fundamental part of any water-controlling mechanism.

Exploring Aerator Functions and Maintenance

A key element in optimizing water flow and ensuring efficient usage is a small yet essential component found in many water outlets. This device blends air with water, improving the stream’s consistency while reducing water consumption. It plays a significant role in enhancing performance and promoting sustainability. Understanding its purpose and the necessary upkeep can extend its lifespan and maintain optimal operation.

The aerator functions by mixing air with water as it flows through, creating a smooth, controlled stream that helps conserve water without compromising the pressure. It reduces splashing and ensures even distribution, making it crucial for both comfort and efficiency in daily tasks.

Regular maintenance of this component is vital for maintaining smooth water flow and preventing issues such as clogging. Over time, mineral deposits, dirt, and other debris can accumulate, obstructing the flow. Cleaning or replacing it periodically ensures optimal performance and prevents long-term damage.

| Maintenance Task | Frequency | Steps |

|---|---|---|

| Cleaning | Every 3-6 months | Unscrew and soak in vinegar, scrub with a brush |

| Replacement | As needed | Remove old part and screw in a new one |

| Check for Leaks | Annually | Inspect for any water leakage or damage |

Escutcheon Plate Placement and Purpose

The escutcheon plate plays a vital role in ensuring both the aesthetic appeal and functionality of plumbing setups. Positioned at the base, this component serves as a decorative cover while also providing necessary support to other essential elements. Its installation helps to secure the system in place, offering a clean and finished look while concealing any gaps or imperfections around the mounting area.

Typically, this piece is placed where the plumbing connections meet the surface, acting as a barrier to water leakage and preventing debris buildup. It also assists in aligning the hardware properly, ensuring stability during regular use. Without this component, the setup may appear incomplete, and the overall durability of the installation could be compromised.

Guide to Faucet Base Seals

When installing or repairing a water fixture, ensuring a proper seal at the base is essential for preventing leaks. The seal serves as a barrier, protecting the surrounding area from water damage and maintaining a secure connection between the fixture and the surface. Understanding how to choose, install, and replace these seals is critical for long-lasting performance.

Types of Base Seals

There are several options available when selecting a base seal, each designed for specific applications. These seals vary in material, shape, and durability to suit different types of installations. Here are the most common types:

| Material | Best For | Durability |

|---|---|---|

| Rubber | Standard Installations | Moderate |

| Silicone | High-Pressure Environments | High |

| Foam | Easy Installation | Low |

Installing a Base Seal

Proper installation is key to achieving an effective seal. Ensure the surface is clean and dry before placing the seal. Carefully align it with the base and the mounting surface, ensuring it is evenly distributed. Tighten the fixture gradually to avoid shifting or damaging the seal. Regular checks and maintenance are recommended to extend the seal’s lifespan.

Diverter Valve Operations and Troubleshooting

The diverter valve plays a crucial role in directing water flow to different outlets, allowing users to switch between various functions, such as spouts and sprayers. Understanding how this component functions can help in diagnosing and resolving common issues that arise over time. This section explores the key aspects of its operation and troubleshooting techniques to maintain a smooth and efficient flow of water in your system.

Proper functioning of the diverter valve is essential for ensuring a seamless transition between different water sources. The valve typically operates by either a lever or a knob that diverts the flow from one output to another. When issues arise, they can often be traced to blockages, wear, or misalignment of internal components. Regular maintenance and quick troubleshooting can prevent many of these issues from escalating into more significant problems.

- Common Problems:

- Water flow not shifting to the desired outlet

- Weak or inconsistent water pressure

- Difficulty in turning the diverter mechanism

- Leakage around the diverter valve area

- Steps to Troubleshoot:

- Check for blockages or debris inside the valve mechanism.

- Inspect the valve seals for wear or damage.

- Ensure the diverter lever or knob moves freely without obstruction.

- If leaks are present, replace worn washers or O-rings around the valve.

- Prevention Tips:

- Regularly clean and inspect the valve area to avoid buildup.

- Lubricate moving parts to reduce friction and wear.

- Ensure the diverter is aligned properly during installation.

Adjusting Temperature Control Levers

Proper regulation of water temperature is essential for ensuring comfort and efficiency when using your water dispensing system. Temperature control levers allow for precise adjustment, giving users the flexibility to set the desired warmth of the water. Understanding how to modify these controls can help avoid discomfort caused by water that is too hot or too cold.

In most systems, the temperature control levers are designed to operate by mixing hot and cold water to reach the perfect temperature. By carefully adjusting these levers, you can maintain a steady and safe water temperature for daily tasks.

| Control Lever Position | Water Temperature Outcome |

|---|---|

| Fully to the left | Cold water |

| Fully to the right | Hot water |

| Middle position | Warm water |

| Small adjustments | Gradual changes in temperature |