Understanding the Components of a Sunflower Disc Parts Diagram

The functionality of modern farming machinery relies heavily on a well-designed assembly of various elements. Each of these components plays a crucial role in ensuring optimal performance and efficiency during cultivation tasks. A clear grasp of how these pieces interrelate can significantly enhance operational effectiveness.

In this section, we will explore the intricate relationships among different segments of an agricultural tool. By examining their configuration, users can appreciate how these elements contribute to the overall mechanics. This knowledge is essential for anyone looking to maximize their equipment’s capabilities.

Through a focused analysis, readers will delve into the specific functions of each segment, uncovering their ultimate importance in the agricultural process. Whether for maintenance or enhancement, understanding these components fosters a deeper connection to farming technology.

Understanding Sunflower Disc Components

This section explores the essential elements that contribute to the functionality and efficiency of agricultural equipment. Each component plays a vital role in achieving optimal performance and ensuring the effectiveness of soil management practices.

Main Elements

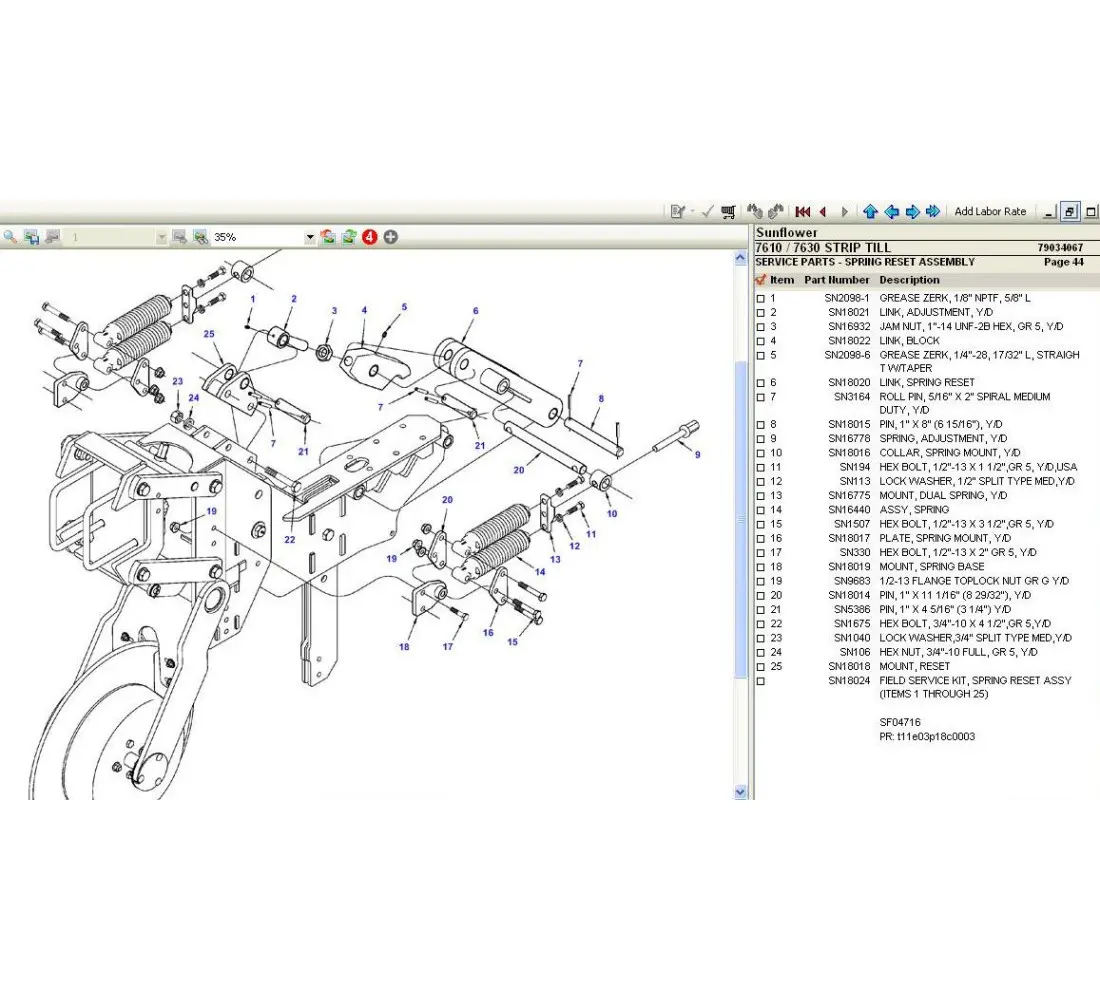

Various components work together to enhance the overall operation. Understanding their individual functions helps in troubleshooting and maintenance.

| Component | Description |

|---|---|

| Blade | Designed for cutting through soil and vegetation, ensuring a clean and precise operation. |

| Frame | Provides structural support, maintaining the integrity and durability of the system. |

| Bearing | Allows smooth rotation of moving parts, reducing friction and wear. |

A thorough knowledge of these elements enables operators to make informed decisions regarding repairs and enhancements, ultimately leading to improved productivity in agricultural tasks.

Essential Parts of Sunflower Discs

This section explores the critical components involved in agricultural equipment designed for effective soil management and seed planting. Understanding these elements is vital for optimizing performance and enhancing productivity in farming practices.

The foremost element is the cutting edge, which plays a pivotal role in penetrating the soil. Next, the support frame provides stability, ensuring durability during operation. Additionally, the concave structure facilitates efficient soil turnover, promoting healthy crop growth. Lastly, the mounting system ensures proper alignment and ease of attachment to machinery.

Functionality of Each Disc Element

This section explores the various components of an agricultural implement designed for soil preparation. Each element plays a crucial role in ensuring effective performance and optimal results during the cultivation process.

Cutting Edge: The sharp leading edge of the tool is responsible for penetrating the soil, facilitating the initial breakdown of compacted layers and enabling deeper tillage.

Body: The main structure provides strength and stability, allowing the implement to withstand rigorous conditions while maintaining its shape during operation.

Attachment Points: These locations enable secure connections to other machinery, ensuring seamless integration and enhancing overall functionality.

Weight Distribution: Properly balanced components ensure even pressure across the working surface, promoting consistent tilling depth and reducing soil disturbance.

Shape: The curvature of each element influences the movement through the soil, affecting how effectively it mixes, aerates, and prepares the ground for planting.

Material Composition: The choice of materials directly impacts durability and resistance to wear, ensuring longevity and efficiency during extensive use.

Benefits of Proper Component Alignment

Ensuring the precise arrangement of components is crucial for optimal performance and longevity of machinery. This meticulous alignment not only enhances efficiency but also minimizes wear and tear, leading to significant cost savings in maintenance and operation.

Enhanced Performance: Proper alignment allows for smoother operation, reducing friction and energy consumption. This ultimately translates to improved productivity.

Increased Durability: When components are correctly positioned, the risk of unexpected failures diminishes. This results in extended lifespan and reliability of the equipment.

Cost Efficiency: Regular alignment checks can prevent costly repairs and downtime, making it a financially sound practice for any operation.

In summary, investing time in accurate component alignment yields substantial benefits that contribute to the overall effectiveness and sustainability of machinery.

Common Issues in Disc Mechanisms

Various challenges can arise in the functionality of rotational tools, impacting their performance and efficiency. Understanding these issues is crucial for ensuring optimal operation and longevity.

| Issue | Description |

|---|---|

| Wear and Tear | Over time, components may degrade due to constant friction and pressure, leading to reduced efficiency. |

| Misalignment | Improper alignment can cause uneven wear and affect the overall performance of the mechanism. |

| Blockages | Debris accumulation can hinder movement, leading to potential failures and inefficiencies. |

| Hydraulic Issues | Malfunctions in hydraulic systems can impact the responsiveness and effectiveness of the tools. |

| Corrosion | Exposure to moisture and chemicals can lead to rust, compromising the integrity of the components. |

Maintenance Tips for Disc Longevity

Proper care and regular upkeep are essential for ensuring the durability and efficiency of your agricultural equipment. By implementing effective maintenance practices, you can enhance performance and extend the lifespan of these vital tools.

Regular Inspection: Routinely check components for signs of wear and tear. Early detection of issues can prevent more significant problems later on.

Cleaning: After each use, clean the equipment to remove dirt, debris, and residue. This helps to avoid corrosion and ensures optimal functionality.

Lubrication: Apply appropriate lubricants to moving parts to minimize friction and reduce wear. This simple step can significantly prolong the life of your machinery.

Storage: When not in use, store your equipment in a dry, sheltered area. Protecting it from harsh weather conditions can prevent damage and deterioration.

Professional Servicing: Schedule regular professional maintenance to address any complex issues. Experts can provide comprehensive checks and necessary repairs, ensuring everything operates at peak performance.

Comparison of Disc Types and Features

Understanding the various varieties of cutting tools used in agricultural equipment is crucial for optimizing soil management practices. Each type possesses distinct characteristics that cater to specific agricultural needs, impacting efficiency and effectiveness in different conditions.

Types of Cutting Tools

- Chisel: Designed for deeper tillage, these tools are effective in breaking up compacted soil layers.

- Offset: Ideal for heavy-duty tasks, they can cut through tough soil with ease.

- Winged: These models enhance soil mixing and aeration, making them suitable for certain crops.

- Notched: Equipped with specialized edges, they excel in cutting through tough vegetation and residue.

Key Features to Consider

- Material: The durability and lifespan of a tool largely depend on the materials used in its construction.

- Size and Shape: Variations in size and design affect penetration depth and soil coverage.

- Adjustability: Tools that allow for adjustments can better adapt to changing soil conditions.

- Weight: Heavier models often provide better stability and performance in challenging terrains.

Choosing the right implement involves evaluating these types and features, ensuring that farmers can achieve optimal results in their fields.

Impact of Soil Conditions on Discs

The characteristics of the ground play a crucial role in determining the efficiency and performance of agricultural tools. Variations in texture, moisture, and nutrient content can significantly influence the interaction between equipment and the soil, ultimately affecting crop yield and soil health.

Key Factors

- Soil Texture: The composition of soil particles impacts how implements penetrate and interact with the earth.

- Moisture Levels: Adequate hydration can facilitate smoother operation, while overly dry or saturated conditions may hinder performance.

- Nutrient Availability: The presence of essential nutrients affects soil structure and overall health, which in turn influences equipment effectiveness.

Recommendations for Optimal Use

- Regularly test soil to understand its properties and make necessary adjustments.

- Choose equipment based on specific soil conditions to maximize efficiency.

- Implement practices that enhance soil structure, such as crop rotation and cover cropping.

How to Optimize Disc Performance

Enhancing the efficiency of agricultural implements requires a strategic approach. By understanding key factors and implementing best practices, one can achieve optimal functionality and longevity.

Regular Maintenance: Consistent upkeep is crucial. Inspecting and cleaning components regularly can prevent wear and tear, ensuring smooth operation.

Adjusting Operating Depth: Proper depth settings are essential. This allows for effective soil engagement and minimizes unnecessary strain on the machinery.

Choosing the Right Speed: Operating at the correct speed can significantly influence performance. Experimenting within recommended ranges can yield the best results.

Utilizing Quality Components: Investing in high-quality materials enhances durability. Premium components can withstand harsher conditions and reduce the frequency of replacements.

In conclusion, focusing on these strategies will ultimately lead to improved performance, maximizing productivity and efficiency in the field.

Latest Innovations in Disc Design

Recent advancements in agricultural technology have transformed the engineering of circular tools, enhancing their efficiency and functionality. These innovations focus on improving performance, reducing wear, and increasing precision in various applications.

Materials and Durability

New composite materials are being employed to boost the longevity and strength of circular implements. These advancements lead to reduced maintenance and increased productivity in the field.

Precision Engineering

With the advent of computer-aided design, the accuracy of these tools has reached new heights. This precision allows for better soil penetration and improved crop yields.

| Innovation | Description |

|---|---|

| Advanced Materials | Utilization of composites for enhanced durability. |

| CAD Technology | Precision design for optimal performance. |

| Ergonomic Shapes | Redesigned geometry for improved handling. |

Resources for Sunflower Disc Maintenance

Effective upkeep of agricultural equipment is crucial for optimal performance and longevity. Accessing the right tools and information can significantly enhance the maintenance process, ensuring that machinery operates efficiently throughout its lifespan. Below are various resources that can assist in the care of your farming implements.

Manuals and Guides

- Owner’s Manual: Always refer to the manufacturer’s manual for specific maintenance instructions and recommended practices.

- Online Resources: Many manufacturers offer downloadable guides and maintenance tips on their websites.

- YouTube Tutorials: Search for instructional videos that demonstrate proper care techniques and troubleshooting methods.

Tools and Equipment

- Basic Tool Set: Ensure you have a comprehensive set of wrenches, pliers, and screwdrivers for general maintenance tasks.

- Lubrication Supplies: Use high-quality oils and greases to keep moving parts functioning smoothly.

- Diagnostic Tools: Invest in diagnostic equipment to identify issues early and prevent costly repairs.