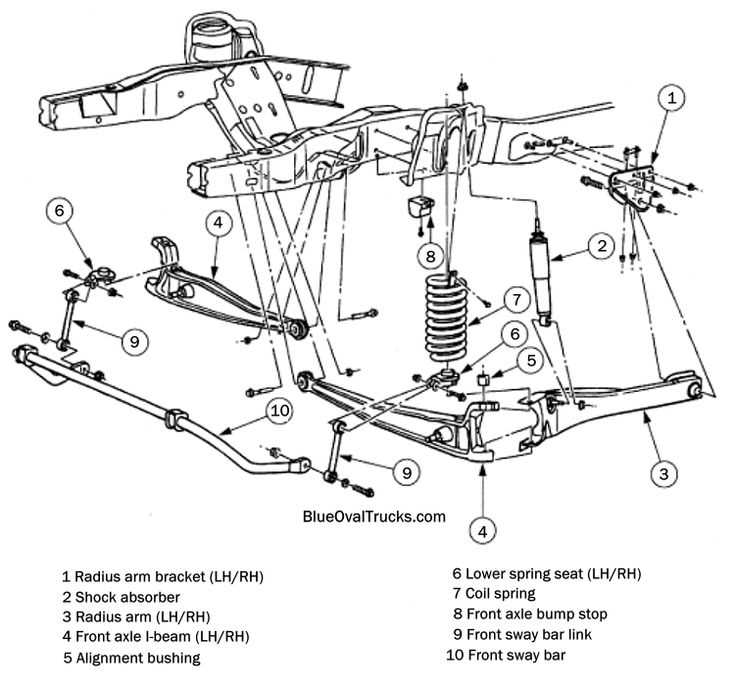

2005 Ford F250 Front Axle Parts Overview

Exploring the intricate elements that contribute to the functionality of robust trucks can provide valuable insights for both enthusiasts and mechanics. These vehicles are designed to withstand significant stress and perform efficiently under demanding conditions. A thorough comprehension of the various assemblies involved in their structure is essential for proper maintenance and repair.

In this section, we will delve into a comprehensive overview of the crucial components that support the vehicle’s suspension and steering systems. Each element plays a pivotal role in ensuring stability and control while driving, particularly when handling heavy loads. By familiarizing yourself with these integral parts, you can enhance your knowledge of vehicle dynamics and improve your ability to troubleshoot any issues that may arise.

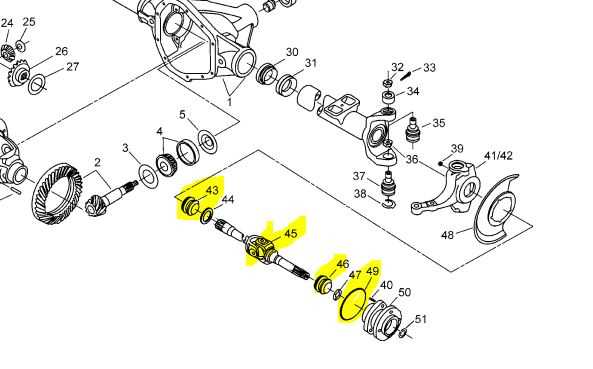

We will provide an illustrative representation to help visualize the arrangement and interrelation of these components. Understanding their function not only aids in effective repairs but also promotes informed decision-making when it comes to upgrades or replacements. Let’s embark on this journey to uncover the vital elements that make heavy-duty trucks reliable companions on the road.

This section aims to provide a comprehensive overview of the key components that constitute the assembly responsible for steering and support in heavy-duty vehicles. Understanding these elements is crucial for both maintenance and repair, as they play a vital role in ensuring optimal performance and safety.

| Component | Description | Function | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Housing | The main structure that encases various components. | Provides support and protection to internal parts. | |||||||||

| Knuckles | Pivot points that connect the wheels to the steering mechanism. | Facilitates wheel movement and steering response. | |||||||||

| Spindle | The shaft on which the wheel rotates. | Connects the wheel to the vehicle and allows for rotation. | |||||||||

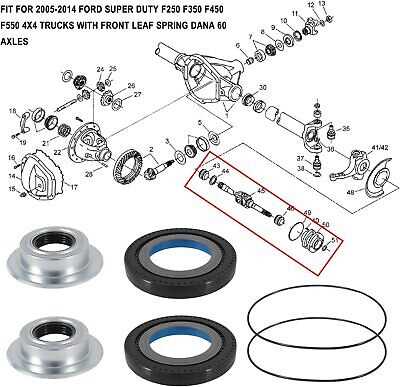

| Bearings | Components that allow smooth rotation of the spindle. | Reduces friction and wear between moving parts. | |||||||||

| Control Arms | Links that connect the wheels to the vehicle’s frame. | Allows for vertical movement and helps in absorbing road shocks. | |||||||||

| Shocks | Dampers that absorb impacts from the road. | Enhances ride quality and vehicle stability. | |||||||||

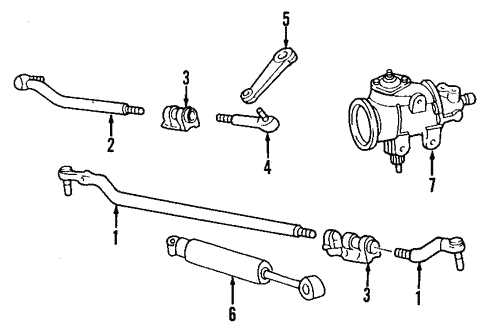

| Steering Linkage | Connections that transmit steering input from the wheel. | Enables directional control of the vehicle. | |||||||||

| Brakes | Components responsible for slowing down or stopping the vehicle. | Ensures safety by allowing the driver to control speed. | |||||||||

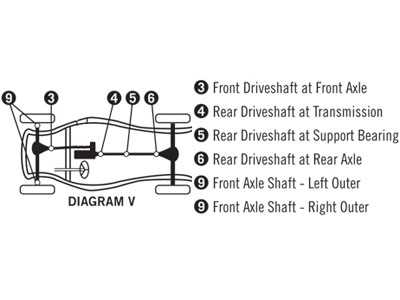

| Drive Shafts | Components that transmit power from the en

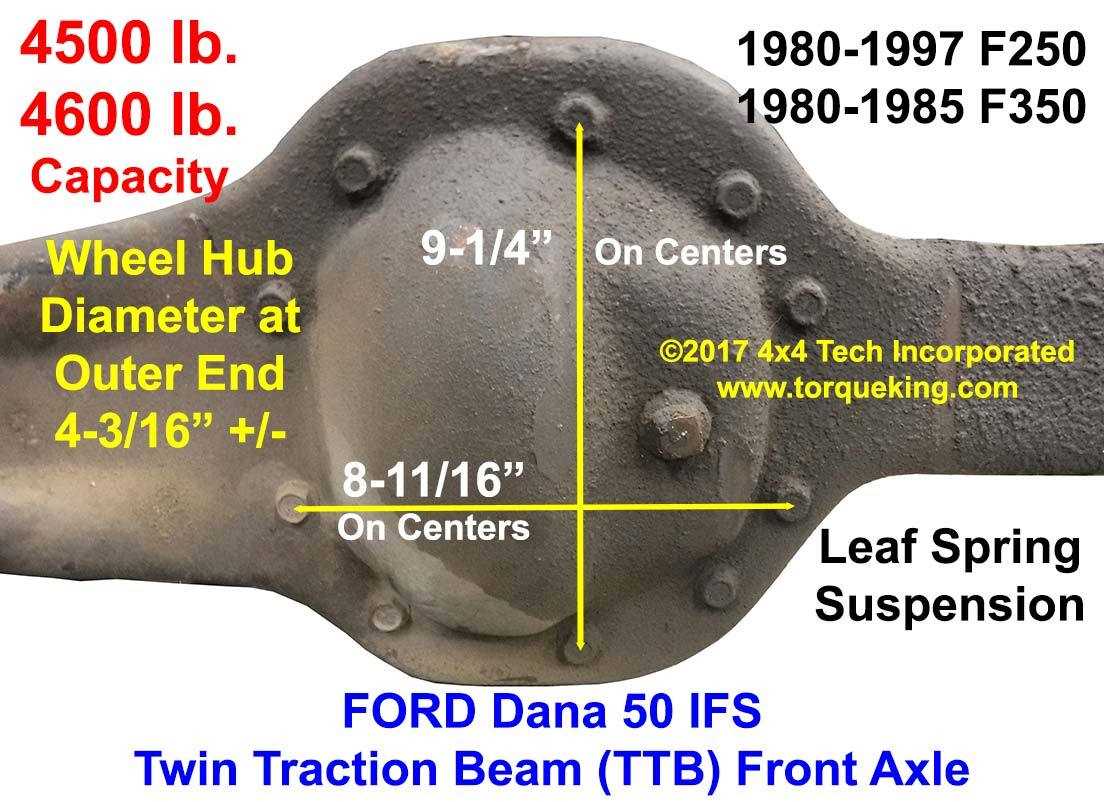

Key Components of the AxleThe fundamental elements of a vehicle’s undercarriage play a critical role in ensuring efficient performance and stability. Understanding these components is essential for maintaining and repairing the vehicle, as they directly affect handling, safety, and overall functionality. 1. Differential: This component allows for the distribution of torque between the wheels, enabling them to rotate at different speeds, especially during turns. It plays a vital role in maintaining traction and stability. 2. Hub Assembly: The hub assembly connects the wheels to the suspension system. It houses the bearings, allowing smooth rotation while supporting the weight of the vehicle. Proper maintenance of this part is crucial for wheel alignment and performance. 3. Spindle: This is the part that connects the wheel hub to the suspension system. The spindle enables the wheels to pivot for steering and supports the weight of the vehicle during operation. 4. Knuckles: These components serve as the connection points for the suspension and steering mechanisms. They provide the necessary pivot points for the wheels, allowing for smooth maneuvering and handling. 5. Control Arms: Control arms link the chassis to the suspension, allowing for vertical movement of the wheels. They help maintain the correct wheel alignment and absorb impacts from the road. Familiarity with these essential components enhances the understanding of a vehicle’s performance dynamics and helps identify potential issues during maintenance. Understanding Axle FunctionalityThe functionality of a vehicle’s wheel assembly is crucial for ensuring smooth operation and stability on the road. This component serves as the central point that supports the weight of the vehicle and enables efficient power transfer from the engine to the wheels. By understanding how this assembly operates, one can better appreciate its significance in overall vehicle performance. Key Roles of the Wheel Assembly

Components of the Wheel Assembly

Understanding the roles and components of this assembly is essential for diagnosing issues and performing maintenance effectively. Regular inspections and knowledge of its functionality can greatly contribute to the vehicle’s reliability and performance. Common Issues with Front Axles

Problems with the steering system can lead to a variety of complications, affecting the vehicle’s handling and safety. Understanding these issues is crucial for maintaining optimal performance and longevity. Regular inspections can help identify potential failures before they escalate into more significant problems. Signs of Wear and TearOne of the most prevalent concerns involves unusual noises, such as clunking or grinding sounds while turning or accelerating. These symptoms may indicate that components are deteriorating. Additionally, vibrations felt through the steering wheel can suggest misalignment or damage, requiring immediate attention. Fluid Leaks and Contamination

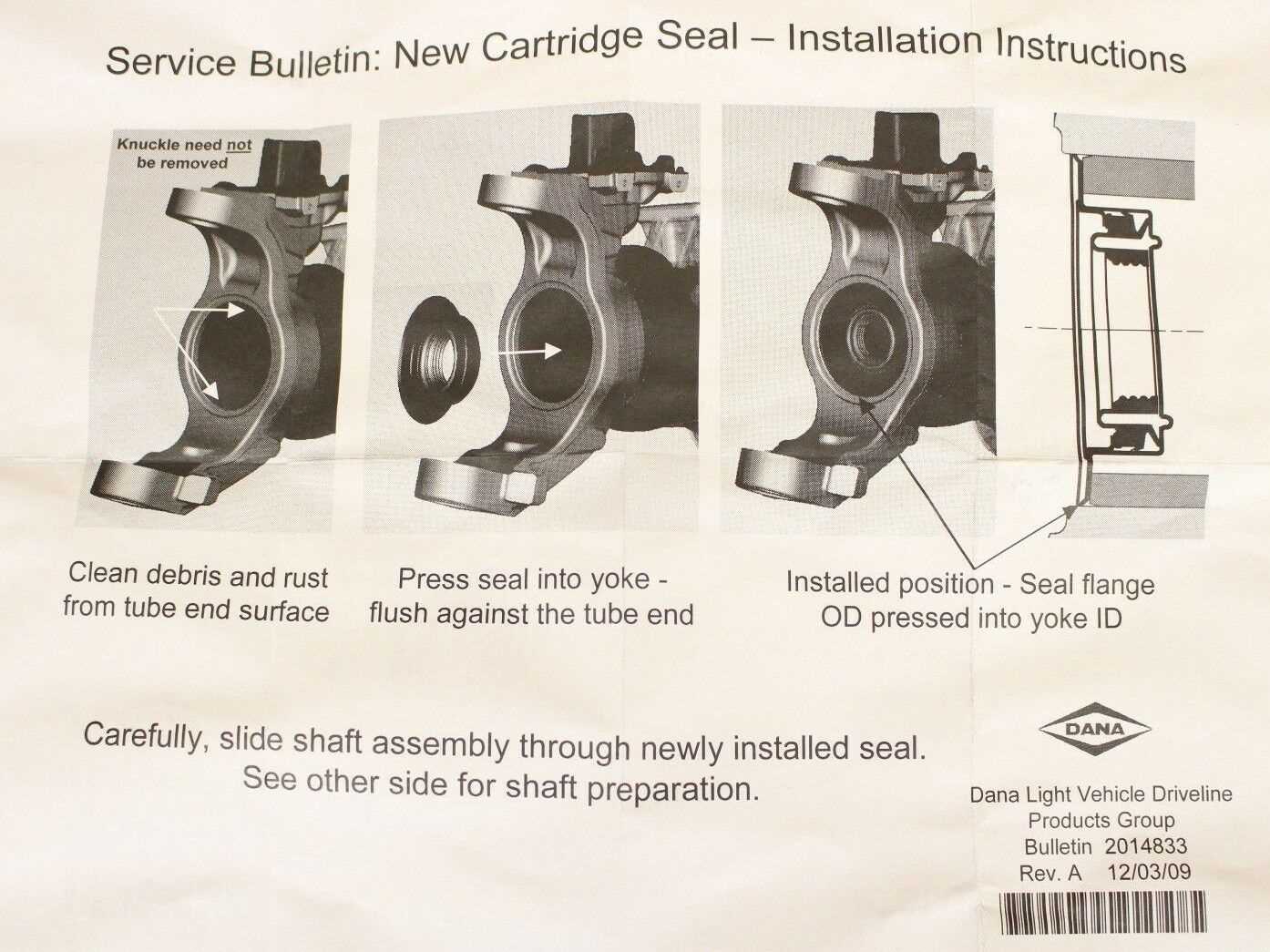

Fluid leaks around the assembly can signify failing seals or gaskets, leading to reduced lubrication and overheating. It’s essential to address any signs of leakage promptly. Contaminated fluids can also contribute to wear, as debris can compromise the functionality of critical components. Maintenance Tips for LongevityProper upkeep is essential for ensuring the durability and efficiency of your vehicle’s components. Regular maintenance not only extends the lifespan of various elements but also enhances performance and safety. By following a few key practices, you can significantly reduce wear and tear and keep your vehicle running smoothly for years to come. Regular InspectionsConducting routine inspections is vital for identifying potential issues before they escalate. Check for any signs of leaks, unusual noises, or wear in critical areas. Make it a habit to examine components during oil changes or every few thousand miles to ensure everything is functioning optimally. Quality Lubrication

Using high-quality lubricants is crucial for minimizing friction and preventing premature wear. Ensure that all moving parts are adequately lubricated, and replace fluids as recommended by the manufacturer. Proper lubrication not only protects components but also improves overall efficiency. How to Identify Parts on Diagram

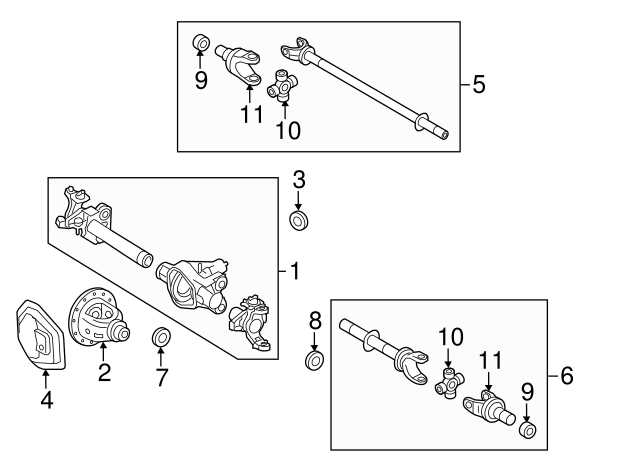

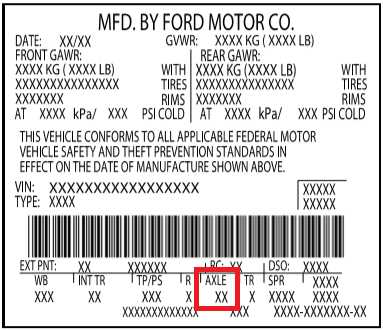

Understanding the components of a vehicle can be a daunting task, especially when looking at a visual representation. Recognizing the elements in such illustrations is crucial for effective maintenance and repairs. Familiarity with the layout and terminology will enhance your ability to navigate and interpret the information accurately. Familiarizing Yourself with the Layout

The first step in grasping the elements depicted in the visual guide is to familiarize yourself with its overall layout. Each section typically represents a specific area of the vehicle, and knowing how these sections relate to one another can provide valuable context. Look for labeled areas that indicate where each component fits within the assembly. Identifying Components Through LabelsMost visual guides include labels that point to various elements. Pay close attention to these annotations, as they often include alphanumeric codes or descriptive names. Taking notes on these identifiers can assist you in cross-referencing with parts catalogs or manuals, ensuring you have a complete understanding of each piece’s function and placement. Additionally, utilizing online resources or forums can provide further clarification and insights. Step-by-Step Disassembly GuideThis section aims to provide a comprehensive procedure for carefully taking apart the suspension mechanism of your vehicle. Whether for maintenance, repair, or upgrades, following these steps will ensure a systematic approach, minimizing the risk of damage to components. Preparation for DisassemblyBefore starting the disassembly process, gather the necessary tools and safety equipment. Ensuring a well-organized workspace will enhance efficiency and safety. Here are some essential preparations:

Disassembly Steps

Following these steps methodically will aid in successfully disassembling the vehicle’s suspension mechanism, allowing for further inspection or maintenance. Always refer to the specific service manual for detailed instructions and torque specifications when reassembling the components. Tools Required for Front Axle WorkWhen engaging in maintenance or repairs related to the suspension system of a heavy-duty vehicle, having the right tools at your disposal is crucial. The correct equipment not only ensures efficiency but also enhances safety during the procedure. This section outlines essential tools that facilitate various tasks involved in this type of work. Essential Hand Tools

Among the basic necessities are various hand tools, such as wrenches and ratchets. These tools are vital for loosening or tightening components securely. Additionally, a good set of screwdrivers will assist in managing smaller fasteners that may be present. Having pliers and pry bars on hand can also be beneficial for manipulating stubborn parts that require extra leverage. Specialized Equipment

In addition to hand tools, specialized equipment is often required. A jack or lift is essential for raising the vehicle safely, providing adequate access to the suspension area. A torque wrench is also necessary to ensure that all fasteners are tightened to the manufacturer’s specifications, preventing potential damage or failure. Moreover, having a parts cleaner can aid in maintaining the components by removing dirt and debris before reassembly. Comparative Analysis of Axle DesignsThis section delves into the various configurations of vehicular suspension systems, examining their structural differences and operational efficiencies. Different designs serve unique purposes, impacting performance, durability, and maintenance requirements. One of the key distinctions lies in the construction materials used. Some systems incorporate lightweight alloys for improved fuel efficiency, while others utilize robust steel for enhanced strength and longevity. Additionally, the arrangement of components plays a crucial role in load distribution, which can influence ride quality and handling characteristics. Another significant aspect to consider is the adaptability of designs to different driving conditions. Certain configurations are engineered for off-road capabilities, featuring increased articulation and greater ground clearance. In contrast, others prioritize stability on paved surfaces, ensuring superior grip and maneuverability during high-speed travel. Finally, ease of repair and replacement is an essential factor in assessing design efficiency. Some systems are designed for straightforward disassembly, enabling quicker service times and reduced downtime. In contrast, others may require specialized tools or expertise, complicating maintenance efforts. Upgrading Axle Components for Performance

Enhancing the efficiency and durability of your vehicle’s undercarriage can significantly improve its overall performance. This process involves replacing or upgrading various elements that contribute to the robustness and handling capabilities of your ride. Focused improvements can lead to better traction, handling, and longevity of critical components. Key Benefits of Upgrading

Popular Components for Upgrades

Safety Precautions During RepairsWhen undertaking mechanical repairs, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, ensuring a smooth and efficient process. It is essential to create a secure working environment and to use the right tools and protective gear while handling components. Essential Safety GearWearing appropriate protective equipment is crucial during any repair task. Here are some recommended items to consider:

Creating a Safe Workspace

A well-organized and clean workspace is essential for safety. Remove any unnecessary tools or materials from the area to minimize hazards. Ensure proper lighting and ventilation, especially when working with hazardous substances. Keeping the floor clear of spills and debris will help avoid slips and falls. Frequently Asked Questions about Axles

This section aims to address common inquiries related to essential components of a vehicle’s suspension system, focusing on their functions, maintenance, and troubleshooting. Understanding these elements can enhance the overall performance and safety of your vehicle. What are the main functions of axles?Axles serve several crucial roles, including:

How can I tell if my vehicle needs axle repair?

There are several indicators that may suggest the need for attention:

Resources for Further LearningExploring various sources of information can significantly enhance your understanding of automotive systems and components. Engaging with educational materials, online platforms, and community resources will provide valuable insights and foster a deeper knowledge of vehicle mechanics. These resources can aid in troubleshooting, maintenance, and modifications, empowering you to approach your automotive projects with confidence. Online Platforms and ForumsNumerous websites and forums offer extensive discussions and resources related to vehicle components. Engaging with automotive communities can provide real-world insights and practical advice from experienced enthusiasts. Websites such as specialized forums, video tutorials, and instructional blogs are excellent starting points for learning about vehicle mechanics and maintenance. Technical Manuals and GuidesInvesting in technical manuals and repair guides can be invaluable for those looking to delve deeper into automotive systems. These documents typically include detailed diagrams, specifications, and step-by-step instructions, making them essential references for understanding vehicle mechanics. Many manufacturers provide downloadable resources that can enhance your knowledge and skills. |