Complete Guide to the 2006 Ford F350 Parts Diagram

In the realm of robust machinery, knowing the intricacies of individual elements is essential for optimal performance and maintenance. A thorough grasp of how each segment interacts within a larger framework can greatly enhance both functionality and reliability.

Whether you’re a seasoned mechanic or an enthusiastic DIYer, having access to comprehensive layouts can significantly streamline repair and upgrade processes. These visual representations serve as a roadmap, guiding you through the various assemblies and systems that comprise these powerful machines.

By exploring the specifics of these components, one can delve into the ultimate understanding of maintenance best practices, ensuring that your vehicle operates at peak efficiency. This knowledge not only facilitates repairs but also empowers users to make informed decisions regarding enhancements and modifications.

Understanding the 2006 Ford F350

This section provides an overview of a robust vehicle known for its durability and performance in various driving conditions. This model is celebrated for its ability to handle heavy loads, making it a popular choice among those who require a reliable workhorse.

Equipped with a powerful engine and advanced technology, this vehicle offers impressive towing capabilities and a comfortable ride. Owners often appreciate the balance between strength and user-friendly features, which enhance both utility and driving experience.

Maintenance is essential for ensuring longevity and optimal performance. Regular checks and replacements of key components can prevent issues and maintain efficiency. Understanding the various mechanical systems is crucial for anyone looking to keep this vehicle in prime condition.

Additionally, familiarity with the assembly of different elements can aid in identifying potential problems before they escalate. Whether for personal use or as part of a fleet, this model’s versatility makes it an attractive option.

Key Features of the F350 Model

This vehicle is renowned for its exceptional performance and robust capabilities, making it a top choice for heavy-duty tasks. Its design emphasizes strength and reliability, catering to both work and leisure needs.

- Powerful Engine Options: Multiple engine choices ensure optimal performance for various applications.

- High Towing Capacity: Engineered to handle substantial loads with ease, ideal for hauling trailers and equipment.

- Advanced Safety Features: Equipped with cutting-edge technology to enhance driver and passenger protection.

- Spacious Interior: A roomy cabin that provides comfort for long journeys, featuring quality materials and user-friendly layouts.

- Durable Build: Constructed with high-quality materials to withstand harsh conditions and demanding tasks.

These attributes combined create a vehicle that meets the demands of both commercial and personal use, delivering a dependable experience.

Importance of a Parts Diagram

A schematic representation of components plays a crucial role in the maintenance and repair of vehicles. It serves as a visual guide, enhancing understanding and efficiency when addressing mechanical issues. With such a resource, both professionals and enthusiasts can navigate complex systems with greater ease.

Utilizing this type of reference can lead to several benefits:

| Benefit | Description |

|---|---|

| Enhanced Clarity | Provides a clear view of each element, reducing confusion during repairs. |

| Efficient Troubleshooting | Helps identify problems quickly by showing the relationship between components. |

| Accurate Replacements | Ensures correct selection of replacements, minimizing the risk of errors. |

| Time-Saving | Streamlines the repair process, allowing for quicker resolutions. |

Overall, a well-crafted representation is an ultimate tool for effective vehicle upkeep, fostering better understanding and more precise work.

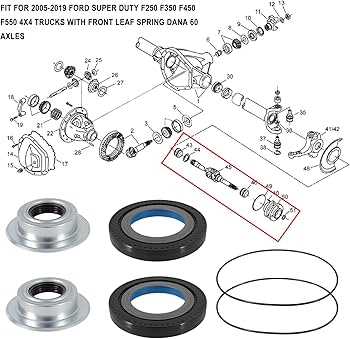

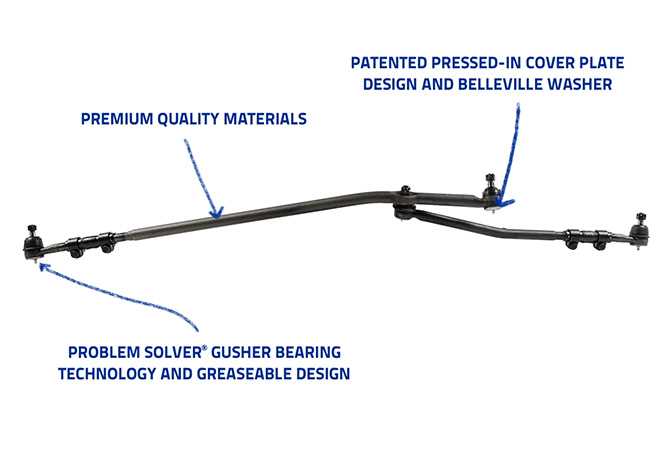

Common Replacement Parts for F350

Maintaining a heavy-duty truck involves understanding which components may need to be replaced over time. Commonly, certain items experience wear and tear due to heavy use, environmental factors, and age. Recognizing these essential elements can enhance vehicle longevity and performance.

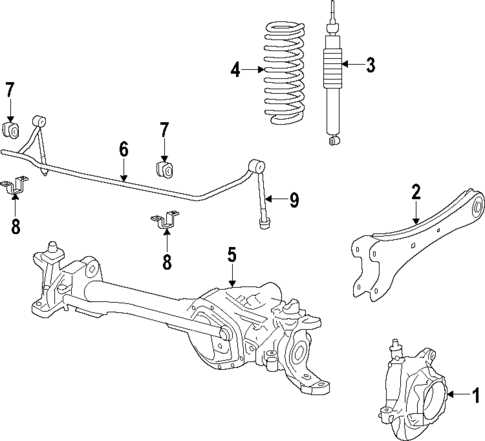

One frequently replaced component is the brake system, including pads and rotors, which ensure safe stopping capabilities. Additionally, the suspension system often requires new shocks or struts to maintain ride quality. Another critical area is the engine, where gaskets and filters play vital roles in efficiency and functionality.

Transmission parts, such as fluid and filters, are essential for smooth shifting and overall vehicle performance. Finally, battery replacements are common as they age, impacting starting and electrical systems. Understanding these common replacements can help truck owners keep their vehicles in peak condition.

Locating the Parts Diagram Online

Finding the necessary visuals for vehicle components can greatly assist in maintenance and repair tasks. The internet offers a variety of resources where one can easily access detailed illustrations and schematics. This guide will help you navigate through the options available online to ensure you get the most accurate and useful information.

Utilizing Manufacturer Websites

One of the most reliable sources for component visuals is the official website of the vehicle manufacturer. These sites often have dedicated sections for service and repair information, where you can find comprehensive resources, including detailed charts and layouts. Always ensure you are visiting the correct site to avoid misinformation.

Online Forums and Communities

Automotive enthusiast forums and online communities can be treasure troves of information. Users frequently share their experiences, including links to helpful resources and even personal diagrams. Engaging with these communities can also provide insights from seasoned mechanics and other vehicle owners, enhancing your understanding of the components.

Tools Needed for Maintenance

Proper upkeep of a vehicle requires a selection of essential implements to ensure efficiency and longevity. Having the right tools not only simplifies tasks but also enhances safety during maintenance activities. Below is a comprehensive list of tools that are indispensable for regular servicing.

| Tool | Description |

|---|---|

| Wrench Set | A variety of sizes for tightening and loosening bolts and nuts. |

| Screwdriver Set | Includes flathead and Phillips screwdrivers for different fasteners. |

| Jack and Jack Stands | Used for lifting the vehicle safely for undercarriage access. |

| Oil Filter Wrench | Specialized tool for removing oil filters during changes. |

| Multimeter | For diagnosing electrical issues and testing battery voltage. |

| Tire Pressure Gauge | Measures tire pressure to ensure proper inflation. |

| Diagnostic Scanner | Reads error codes and provides information about system malfunctions. |

| Fluid Transfer Pump | Facilitates easy transfer of fluids like oil and coolant. |

Equipping yourself with these tools can make maintenance tasks more manageable and effective, ultimately contributing to the vehicle’s performance and reliability.

Comparing OEM and Aftermarket Parts

When it comes to vehicle maintenance and repair, the choice between original equipment and alternative components can significantly impact performance and longevity. Understanding the differences between these options is crucial for making informed decisions that align with your vehicle’s needs and your budget.

| Criteria | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Manufactured to exact specifications | Varies widely, some high-quality options available |

| Price | Generally higher | Often more affordable |

| Warranty | Usually includes a warranty | Warranties vary by manufacturer |

| Availability | Typically available through dealerships | Widely available from various retailers |

| Fitment | Exact fit guaranteed | May require modifications for proper fit |

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues found in heavy-duty vehicles. Following a structured process ensures effective troubleshooting and repair, enabling you to maintain optimal performance.

Preparation

- Gather necessary tools and equipment.

- Obtain a repair manual specific to your model.

- Ensure a clean, organized workspace.

- Disconnect the battery to avoid electrical hazards.

Troubleshooting Steps

- Identify the symptoms of the problem.

- Perform visual inspections for wear and damage.

- Use diagnostic tools to retrieve error codes if applicable.

- Research common issues associated with your vehicle type.

- Prioritize repairs based on severity and urgency.

Following these steps will streamline the repair process, helping you efficiently restore functionality and reliability.

Common Issues and Solutions

This section explores frequent challenges encountered with heavy-duty vehicles, providing effective solutions to enhance performance and reliability. Understanding these issues can aid owners in maintaining their vehicles efficiently.

Electrical Problems

Electrical faults often lead to starting issues or malfunctioning accessories. These can stem from corroded connections or worn-out components. Regular inspection of wiring and battery condition is crucial.

Transmission Troubles

Transmission complications can result in rough shifting or slipping. Routine fluid changes and monitoring for leaks can significantly mitigate these issues.

| Issue | Possible Cause | Solution |

|---|---|---|

| Starting Failure | Corroded battery terminals | Clean and secure connections |

| Rough Shifting | Low transmission fluid | Check and refill fluid |

| Overheating | Coolant leaks | Inspect hoses and replace as needed |

How to Read a Parts Diagram

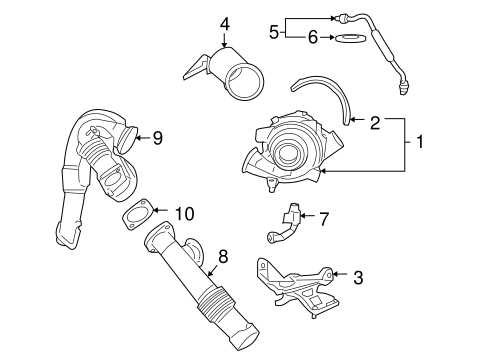

Understanding an illustration of components is essential for effective maintenance and repairs. These visuals provide a clear representation of various elements, helping to identify each piece and its location within a system.

To interpret such an illustration, follow these steps:

| Step | Description |

|---|---|

| 1 | Examine the overall layout to grasp the general structure. |

| 2 | Identify each labeled item, often accompanied by a reference number. |

| 3 | Cross-reference with a list to understand the function of each component. |

| 4 | Note any additional symbols or lines indicating connections or relationships. |

With practice, interpreting these visuals will become intuitive, ultimately enhancing your repair and maintenance skills.

Visual Components of the F350

This section delves into the intricate elements that comprise the vehicle’s design and functionality. Understanding these visual components enhances appreciation for the engineering that drives performance and reliability. Each aspect serves a specific purpose while contributing to the overall aesthetic appeal.

Key Features

Numerous essential features define the exterior and interior of the truck, each carefully crafted to ensure durability and user comfort. From structural elements to finer details, these components work in harmony to create a robust driving experience.

| Component | Description |

|---|---|

| Chassis | The main framework that supports the vehicle’s structure. |

| Cab | The enclosed space for the driver and passengers, designed for comfort and visibility. |

| Bed | The open area at the back, used for transporting cargo. |

| Suspension System | A system that absorbs shocks and provides stability during movement. |

Interior Elements

The internal configuration includes a variety of components that enhance user experience. These elements not only provide functionality but also reflect modern design trends, making the driving experience more enjoyable.

| Interior Component | Functionality |

|---|---|

| Dashboard | Displays crucial information and controls for the driver. |

| Seats | Provide comfort and support for passengers during travel. |

| Infotainment System | Integrates entertainment and navigation features for ease of use. |

Resources for Further Assistance

When seeking help with vehicle components and their configurations, various sources can enhance your understanding and provide valuable insights. Whether you’re looking for detailed illustrations or expert advice, these resources will guide you in your endeavors.

Online Forums and Communities

Engaging with online communities can be incredibly beneficial. Platforms like automotive forums and social media groups allow enthusiasts and experts to share knowledge, troubleshoot issues, and provide recommendations on repairs and upgrades.

Official Manuals and Technical Guides

Consulting official manuals and technical documentation is essential for accurate information. These resources often contain in-depth explanations, wiring schematics, and maintenance tips that can significantly assist you in your projects.

Maintaining Your Ford F350

Ensuring the longevity and performance of your vehicle requires consistent care and attention. Regular maintenance not only enhances safety but also preserves the overall functionality of the machine. This involves a range of tasks, from routine inspections to timely replacements of essential components, all of which contribute to a reliable driving experience.

Regular Inspections

Conducting frequent evaluations of your vehicle’s systems is crucial. Check fluid levels, including oil, coolant, and brake fluid, to prevent potential issues. Inspect tires for wear and proper inflation, and examine brakes for signs of degradation. These proactive measures can help identify problems early, saving both time and money in the long run.

Timely Replacements

Replacing worn-out components is vital for maintaining optimal performance. Pay attention to filters, belts, and hoses, as these elements can significantly impact efficiency. Additionally, staying up to date with scheduled service intervals recommended by the manufacturer will ensure that your vehicle remains in peak condition, ready to handle any challenge.