Comprehensive Guide to 2012 Ford F250 4×4 Front End Parts Diagram

In the realm of robust transportation, understanding the intricate makeup of vehicle systems is paramount. A comprehensive grasp of these crucial elements not only enhances maintenance practices but also contributes to improved performance and longevity. This section delves into the various segments responsible for the functionality and reliability of these powerful machines.

Whether you’re an enthusiast or a professional, familiarizing yourself with the configuration and interrelation of these key components is essential. Recognizing how each element interacts can prevent costly repairs and ensure optimal operation. Here, we will dissect the foundational aspects that support these formidable vehicles, providing insights into their structure and design.

As we navigate through the intricate layout of these systems, we aim to shed light on the significance of each component. This knowledge empowers owners and mechanics alike to make informed decisions, ultimately fostering a deeper appreciation for the engineering prowess behind heavy-duty transport. Join us as we uncover the essential features that contribute to the strength and resilience of these automotive giants.

Understanding the 2012 Ford F250 4×4

This section delves into the robust characteristics and mechanical components of a heavy-duty vehicle designed for versatility and durability. By examining its construction and essential features, we can gain insights into its performance capabilities and maintenance requirements.

Key Features

- Powerful engine options for enhanced towing capacity

- Advanced suspension system for improved off-road handling

- Spacious interior designed for comfort and utility

- Innovative technology for safety and connectivity

Maintenance Tips

- Regularly check fluid levels to ensure optimal performance.

- Inspect tires for wear and maintain proper inflation.

- Schedule routine inspections of the braking system.

- Keep the vehicle clean to prevent rust and corrosion.

Understanding these aspects will help you appreciate the capabilities and upkeep needed for this impressive machine.

Key Features of the Front End

The architecture at the forefront of a vehicle plays a crucial role in both performance and safety. Understanding its distinctive characteristics can enhance the overall driving experience and vehicle durability.

Structural Integrity

Robust construction ensures that the assembly can withstand various stresses during operation. The materials used contribute to both strength and weight optimization, which is essential for maintaining balance.

Suspension Components

Effective suspension elements are vital for handling and ride comfort. These components work together to absorb shocks and provide stability, ensuring that the vehicle can navigate diverse terrains with ease.

Common Issues with Front End Components

The components that connect the wheels to the vehicle body are crucial for handling and stability. Over time, various problems can arise due to wear, environmental factors, or manufacturing defects. Understanding these issues can help in maintaining optimal performance and safety.

Wear and Tear: Regular usage leads to natural degradation of elements such as bushings and ball joints. These parts are susceptible to friction and stress, resulting in reduced effectiveness and eventual failure.

Alignment Problems: Misalignment can occur due to hitting potholes or curbs. This not only affects steering precision but also leads to uneven tire wear, compromising overall driving safety.

Noise and Vibration: Unusual sounds or vibrations while driving can indicate issues with suspension components. These symptoms often point to loose or damaged fittings that require immediate attention to prevent further damage.

Corrosion: Exposure to moisture and road salts can lead to rust and corrosion, particularly in metal components. This can weaken the structure and function of essential parts, necessitating prompt inspection and potential replacement.

Fluid Leaks: Components such as shock absorbers or steering racks may develop leaks over time. This can impair their functionality, leading to diminished ride quality and handling capabilities.

Addressing these common challenges promptly can enhance vehicle longevity and ensure a safer driving experience. Regular maintenance and inspections are key to preventing significant issues from arising.

Components of the Suspension System

The suspension system plays a crucial role in vehicle performance and comfort, acting as the interface between the chassis and the wheels. It is designed to absorb shocks from the road, maintain tire contact, and ensure stability during various driving conditions. Understanding the key elements of this system can enhance vehicle maintenance and improve driving experience.

Key Components

- Springs: These are essential for absorbing energy from bumps and irregularities in the road, maintaining a smooth ride.

- Dampers: Also known as shock absorbers, they control the spring motion and help reduce bouncing.

- Control Arms: These link the chassis to the wheels, allowing for controlled movement while maintaining alignment.

- Stabilizer Bar: This component minimizes body roll during turns, enhancing vehicle stability.

- Ball Joints: These facilitate movement between the suspension components and the steering system, ensuring flexibility and control.

Importance of Maintenance

Regular inspection and maintenance of suspension components are vital for safety and performance. Worn parts can lead to decreased handling, increased tire wear, and compromised comfort. Timely replacements and adjustments ensure optimal functionality and longevity of the vehicle.

Importance of Proper Alignment

Achieving the correct positioning of wheels is essential for ensuring optimal vehicle performance. Misalignment can lead to uneven tire wear, compromised handling, and increased fuel consumption. Understanding the significance of maintaining accurate alignment is crucial for both safety and longevity of the vehicle.

| Benefits | Consequences of Poor Alignment |

|---|---|

| Improved tire lifespan | Uneven tire wear |

| Better fuel efficiency | Higher fuel costs |

| Enhanced vehicle stability | Poor handling |

| Smoother ride | Increased stress on suspension components |

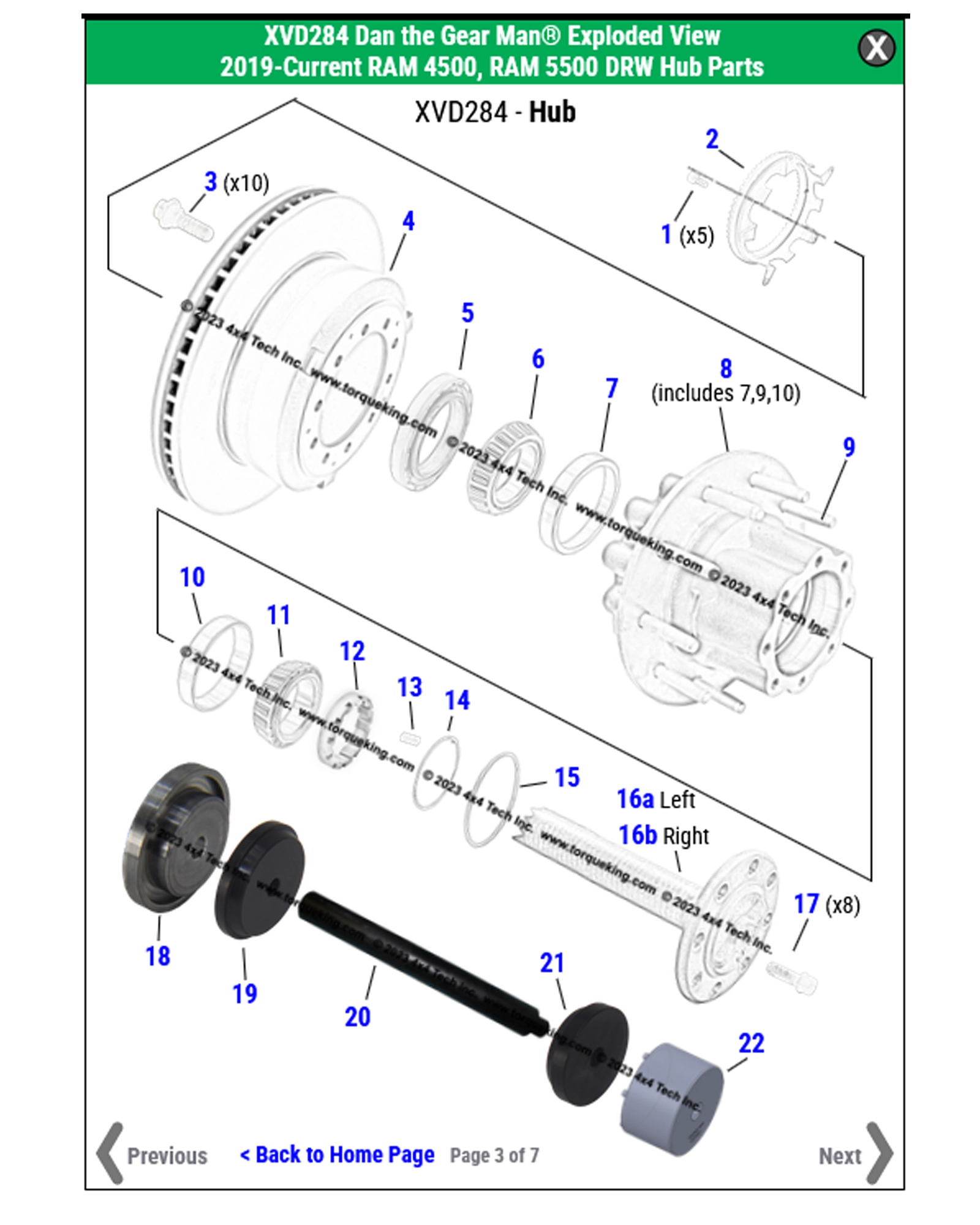

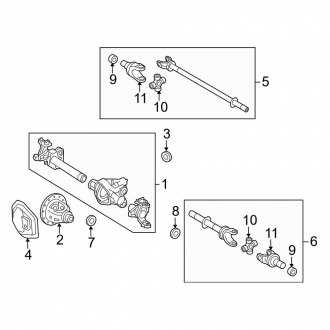

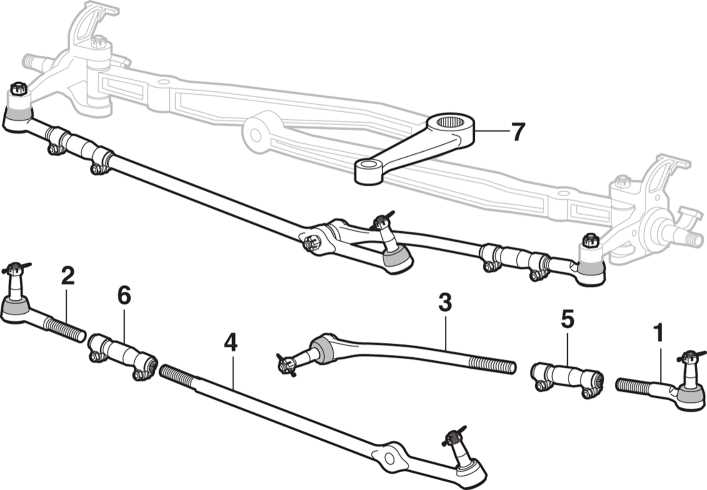

Diagram Overview for Mechanics

This section provides a comprehensive look at the components that comprise the front suspension system, essential for understanding vehicle dynamics and maintenance. Mechanics can benefit greatly from visual representations, allowing for quicker diagnosis and effective repairs.

Key Components

Among the crucial elements are the steering knuckles, control arms, and various bushings. Each component plays a vital role in the overall performance and safety of the vehicle. Understanding their arrangement and function is imperative for any mechanic aiming to ensure optimal handling and ride quality.

Importance of Visual References

Utilizing visual references helps in identifying wear and tear, facilitating timely interventions. An accurate illustration serves as an ultimate tool for both novice and experienced mechanics, streamlining the repair process and enhancing efficiency.

Replacing Worn Out Components

Over time, various elements of your vehicle can experience wear and tear, leading to decreased performance and safety. Regular maintenance and timely replacement of these components are crucial for optimal functionality. Identifying the signs of deterioration early can save you from more significant issues down the road.

Identifying Signs of Wear

Look for common indicators that suggest a need for replacement. Unusual noises, decreased handling, or vibrations can all point to aging components. Performing routine inspections can help catch these issues before they escalate.

Replacement Process

Once you have identified the components that need replacing, follow a systematic approach to ensure proper installation. Always refer to your vehicle’s service manual for specific guidelines and torque specifications.

| Component | Symptoms of Wear | Replacement Tips |

|---|---|---|

| Shock Absorbers | Excessive bouncing, poor handling | Replace in pairs for balanced performance |

| Ball Joints | Clunking noises, uneven tire wear | Check alignment after replacement |

| Control Arms | Steering issues, misalignment | Inspect bushings for damage |

Tools Required for Front End Repairs

Proper maintenance of the vehicle’s suspension and steering components necessitates a selection of essential tools. Having the right equipment on hand ensures efficient repairs and enhances safety while working on the chassis.

To begin, a comprehensive set of sockets and wrenches is crucial for loosening and tightening bolts. Pliers and screwdrivers are also needed for various fasteners and adjustments. A floor jack and jack stands are necessary for safely elevating the vehicle, providing ample access to the undercarriage.

Specialized tools such as a torque wrench ensure that components are secured to the manufacturer’s specifications. A ball joint separator can aid in removing and installing joints without damaging surrounding parts. Lastly, an alignment tool is vital for ensuring that the wheels are positioned correctly after repairs.

Upgrades for Enhanced Performance

Improving your vehicle’s capabilities can significantly elevate its driving experience and efficiency. By focusing on key components and systems, you can achieve greater handling, power, and durability. Whether for towing, off-roading, or daily driving, strategic enhancements will provide noticeable benefits.

Suspension Enhancements

Upgrading your suspension system is crucial for improved stability and comfort. High-performance shock absorbers and coil springs can enhance responsiveness and reduce body roll during cornering. Consider adjustable setups for tailored performance based on your driving style.

Powertrain Modifications

Boosting the powertrain will yield impressive gains in torque and horsepower. Installing a high-flow air intake and performance exhaust system can optimize airflow, while a reprogrammed engine control unit (ECU) can unlock your vehicle’s full potential. These modifications ensure a robust driving experience tailored to your needs.

Routine Maintenance Tips for Longevity

Maintaining your vehicle is essential for ensuring its reliability and extending its lifespan. Regular attention to various components can prevent costly repairs and enhance performance. By following a few straightforward practices, you can keep your machine in optimal condition and ready for any adventure.

Regular Inspections

Conducting routine checks on your vehicle is crucial. Inspect fluid levels, tire pressure, and brakes frequently. Addressing minor issues promptly can prevent them from escalating into major problems. Additionally, looking out for unusual noises or changes in handling can alert you to potential concerns before they require significant repairs.

Scheduled Service Intervals

Adhering to a maintenance schedule based on the manufacturer’s recommendations is vital. This includes oil changes, filter replacements, and other essential services. Keeping up with these intervals not only enhances performance but also promotes efficiency, leading to better fuel economy and smoother operation.

Safety Considerations During Repairs

When undertaking maintenance on vehicles, it is crucial to prioritize safety throughout the entire process. Proper precautions not only protect the individual performing the repairs but also ensure that the vehicle operates effectively afterward. By adhering to safety guidelines, one can significantly reduce the risk of accidents and injuries.

Personal protective equipment (PPE) is essential. Always wear gloves, goggles, and appropriate footwear to shield against potential hazards. Additionally, working in a well-ventilated area minimizes exposure to harmful fumes and allows for better visibility.

Another important aspect is tool safety. Regularly inspect tools for damage or wear, and ensure they are used according to the manufacturer’s instructions. This practice not only prolongs the lifespan of the tools but also enhances personal safety.

Additionally, it is vital to maintain a clean and organized workspace. Clutter can lead to slips, trips, and falls, which are common causes of injury. Keeping tools and materials neatly arranged allows for efficient workflow and minimizes distractions.

Lastly, always consult the vehicle’s manual for specific safety recommendations related to the repair task at hand. Understanding the vehicle’s systems and following best practices is key to ensuring a successful and safe repair experience.

Resources for Further Information

For individuals seeking a deeper understanding of vehicle components and their configurations, a variety of resources are available. These tools can provide valuable insights into assembly, maintenance, and troubleshooting, enhancing both knowledge and practical skills.

Below is a list of useful references that can aid in exploring vehicle architecture and related subjects:

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Communities of enthusiasts sharing experiences and advice on various automotive topics. | AutoTrader |

| Repair Manuals | Detailed guides that outline repair procedures and specifications for various models. | Chilton DIY |

| Video Tutorials | Step-by-step visual guides available on platforms to assist in hands-on tasks. | YouTube |

| Parts Retailers | Websites that sell components and often provide detailed descriptions and diagrams. | AutoZone |

| Manufacturer Websites | Official pages offering technical specifications, service bulletins, and support. | NHTSA |

Utilizing these resources can significantly enhance one’s proficiency in understanding and working on automotive systems, leading to more informed decisions and effective maintenance practices.

Comparing F250 Parts with Other Models

This section explores the differences and similarities between components of a specific heavy-duty vehicle and those found in other similar models. Understanding these variations can aid in making informed decisions regarding repairs and upgrades.

- Compatibility: Assessing how certain elements from other vehicles can fit into the discussed model.

- Durability: Evaluating the robustness of components across different brands and models.

- Performance: Comparing how various parts influence the overall efficiency and handling of the vehicle.

- Suspension Systems:

- Examining differences in shock absorbers and leaf springs.

- Evaluating lift kits compatibility.

- Braking Components:

- Assessing brake pad materials and their longevity.

- Comparing caliper designs and effectiveness.

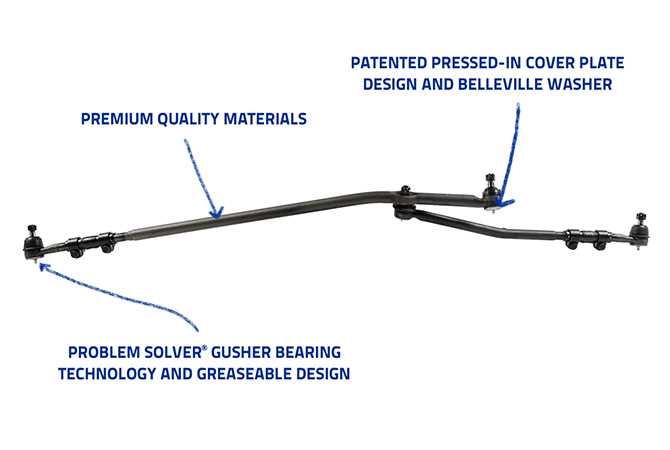

- Steering Mechanisms:

- Identifying variations in steering racks and linkages.

- Looking into power steering options available in other models.

By delving into these comparisons, enthusiasts can find the ultimate solutions for their vehicular needs.