Understanding the 2015 Ford F250 Front End Parts Diagram

When it comes to maintaining and enhancing the performance of heavy-duty trucks, having a clear understanding of the arrangement of essential components is crucial. This knowledge not only aids in effective repairs but also facilitates upgrades that can significantly improve the vehicle’s functionality.

Each truck model features a unique configuration of various elements that contribute to its overall operation. Familiarizing oneself with these components is essential for both DIY enthusiasts and professional mechanics alike. By examining these layouts, one can identify potential issues and streamline the repair process.

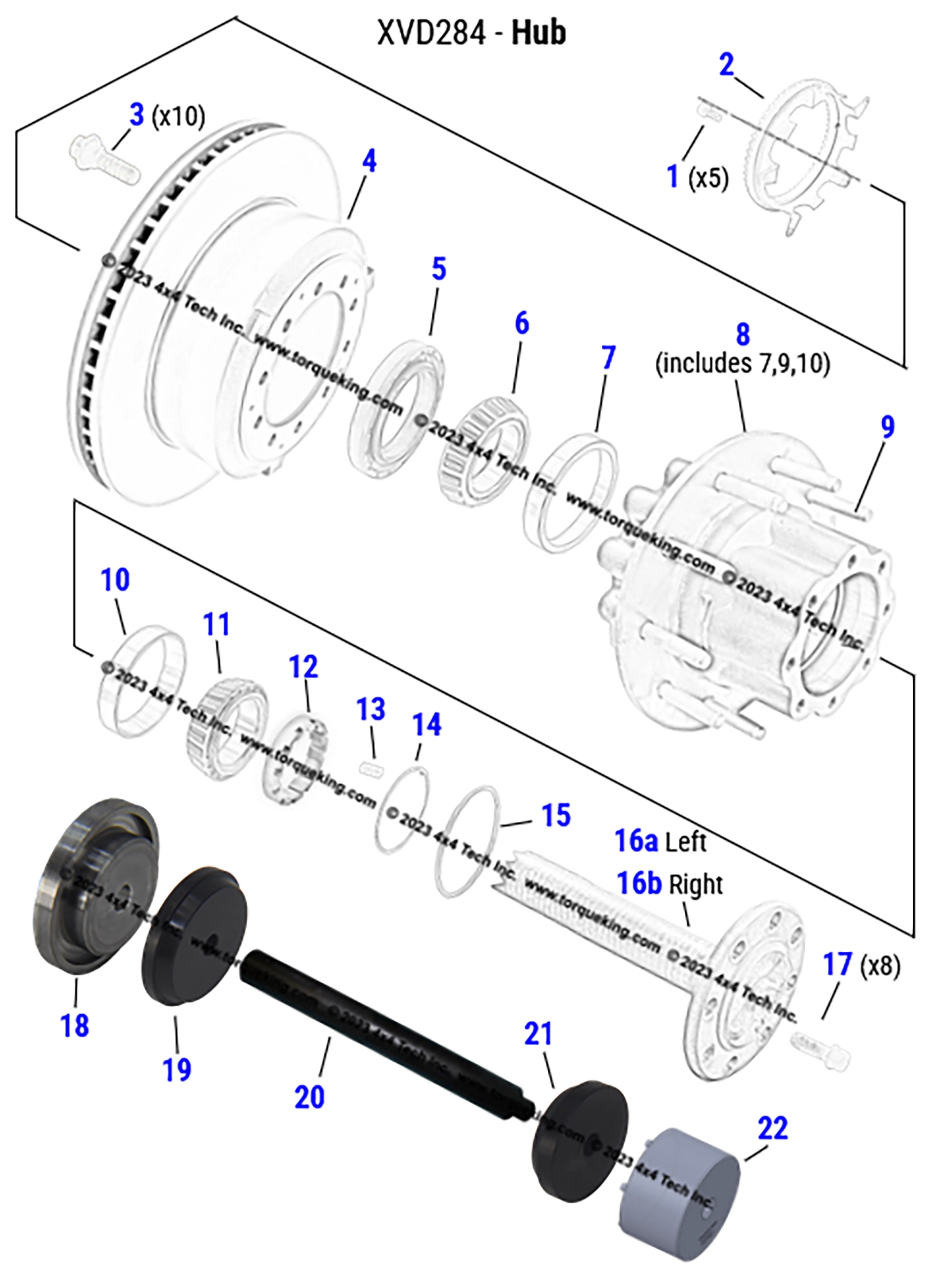

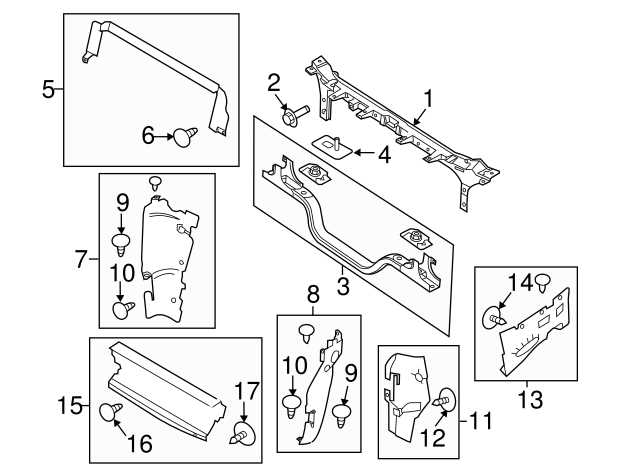

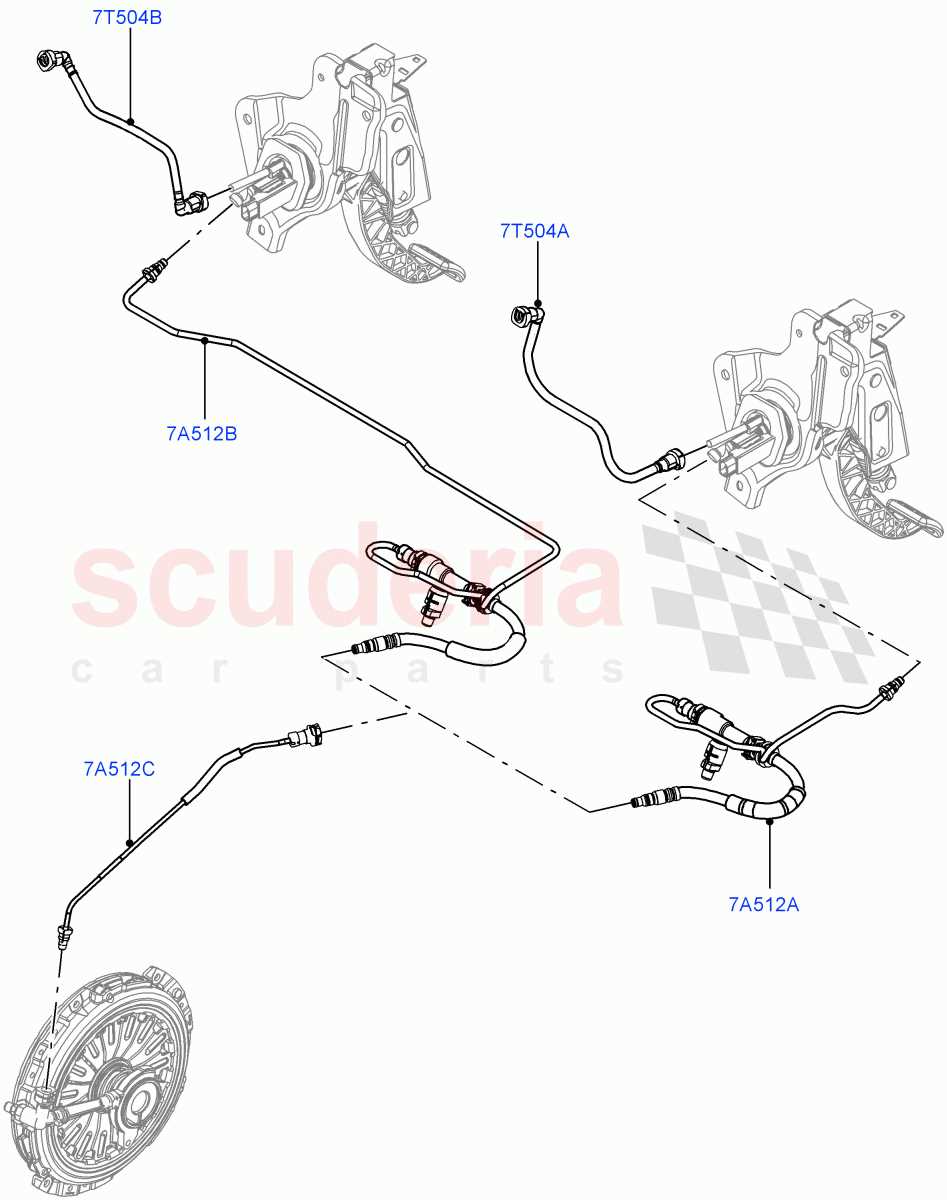

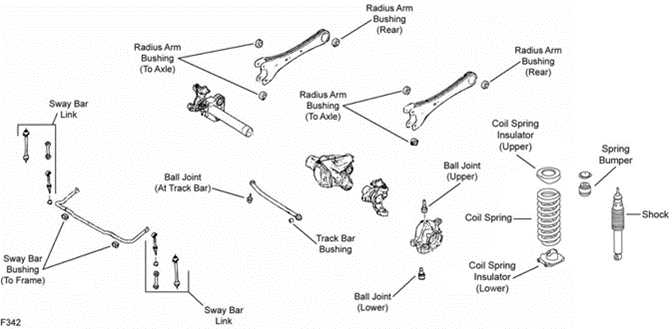

Visual aids play a vital role in this understanding. Detailed illustrations provide a comprehensive overview, allowing for quick identification of individual parts and their interrelations. This can be especially helpful when troubleshooting or when seeking to replace specific components efficiently.

In summary, grasping the structural details of vehicle assemblies enhances not only repair capabilities but also empowers owners to make informed decisions regarding modifications and maintenance, ensuring optimal performance on the road.

Understanding the 2015 Ford F250 Front End

This section explores the key components of the vehicle’s frontal structure, focusing on their functionality and significance in overall performance. The assembly plays a crucial role in vehicle dynamics, safety, and aesthetic appeal.

Structural Integrity: The architecture provides essential support and stability, ensuring that the vehicle can handle various driving conditions. The integration of robust materials enhances durability.

Suspension System: This aspect greatly influences ride quality and handling. An efficient system absorbs shocks and maintains tire contact with the road, contributing to a smoother experience.

Lighting Features: Effective illumination is vital for visibility during night driving. Advanced lighting technology enhances safety by providing clearer sightlines.

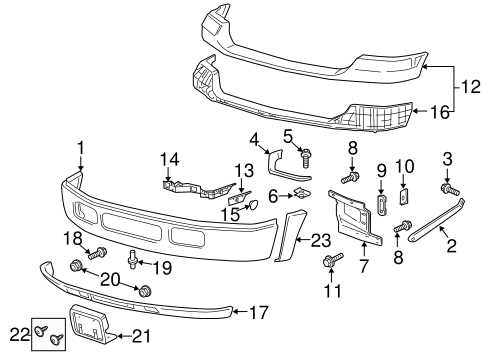

Grille and Bumper Design: These elements are not only functional but also contribute to the overall aesthetic. They serve to protect critical components while enhancing the vehicle’s visual presence.

Key Components of the Front End

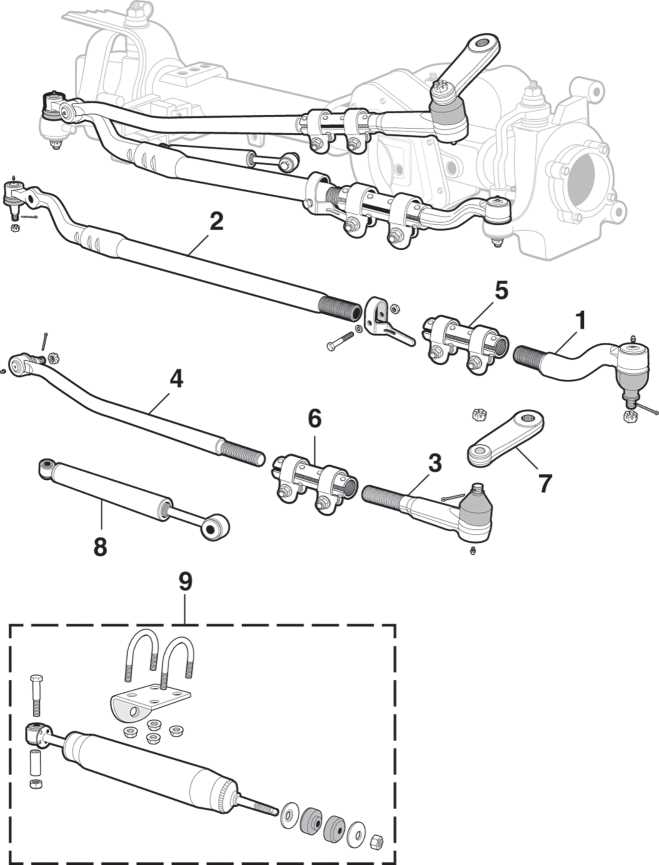

The assembly at the front of a vehicle plays a crucial role in its overall performance and safety. Understanding the various elements within this area can enhance your knowledge of how they work together to provide stability, control, and comfort during driving.

One of the primary elements is the suspension system, which includes components that absorb shocks and support the weight of the vehicle. This system helps maintain tire contact with the road, ensuring a smooth ride.

Another essential part is the , which allows the driver to guide the vehicle accurately. This component connects the steering wheel to the wheels, translating the driver’s intentions into directional movement.

Additionally, braking systems are integrated into this assembly, providing the necessary stopping power. These systems are designed to work effectively under various conditions, ensuring safety during operation.

Finally, the frame serves as the backbone of the assembly, supporting other components and maintaining structural integrity. A robust frame contributes significantly to the vehicle’s durability and performance.

Importance of Regular Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of any vehicle. Neglecting this vital aspect can lead to significant issues, affecting both safety and functionality.

Here are key reasons why consistent maintenance is crucial:

- Enhanced Safety: Routine checks can identify potential hazards before they escalate.

- Improved Efficiency: Well-maintained systems operate more effectively, saving on fuel costs.

- Cost Savings: Addressing minor problems early prevents costly repairs down the line.

- Increased Resale Value: A well-documented maintenance history boosts market appeal.

Ultimately, investing time in regular maintenance not only preserves your vehicle’s condition but also enhances the overall driving experience.

Common Issues with Front End Components

When it comes to vehicle maintenance, certain challenges often arise with the components located at the front of the chassis. These elements play a crucial role in steering and suspension, and their degradation can lead to a range of performance problems. Understanding typical issues can help in identifying symptoms early and addressing them effectively.

Frequent Problems

Several common concerns may affect the functionality and safety of the front components. Drivers should be vigilant for signs of wear and tear, which can manifest in various ways.

| Issue | Description |

|---|---|

| Alignment Issues | Improper alignment can cause uneven tire wear and affect handling. |

| Worn Bushings | Deteriorated bushings may lead to vibrations and noise during driving. |

| Leaking Shocks | Fluid loss from shocks can compromise ride quality and stability. |

| Ball Joint Failure | Worn ball joints can result in poor steering response and potential accidents. |

Preventive Measures

Regular inspections and maintenance can significantly reduce the likelihood of these issues. Keeping components properly lubricated and checking for damage can prolong their lifespan and ensure safe driving conditions.

How to Identify Worn Components

Recognizing degraded elements in a vehicle’s assembly is crucial for maintaining optimal performance and safety. Regular inspections can reveal signs of wear and tear, enabling timely interventions before more severe issues arise.

Visual Inspection

Start by conducting a thorough visual assessment. Look for cracks, rust, or corrosion on visible components. Pay attention to any unusual discoloration or deformation, which often indicates deterioration.

Functional Tests

Next, perform functional checks. Listen for any unusual noises during operation, as they may suggest internal issues. Additionally, observe any vibrations or shaking while driving, which can point to misalignment or wear.

Replacement Options for Front End Parts

When it comes to maintaining and enhancing the performance of your vehicle’s front components, understanding the available choices is essential. This ensures longevity and optimal functionality.

- OEM Components: Original equipment manufacturer items guarantee a perfect fit and quality.

- Aftermarket Alternatives: These options often provide cost-effective solutions with varied performance enhancements.

- Rebuilt Units: Reconditioned items can be a sustainable choice, combining quality with affordability.

- Custom Solutions: Tailored parts may be available for specific needs, offering unique performance characteristics.

Exploring these alternatives can help you make informed decisions that align with your vehicle’s requirements and your budget.

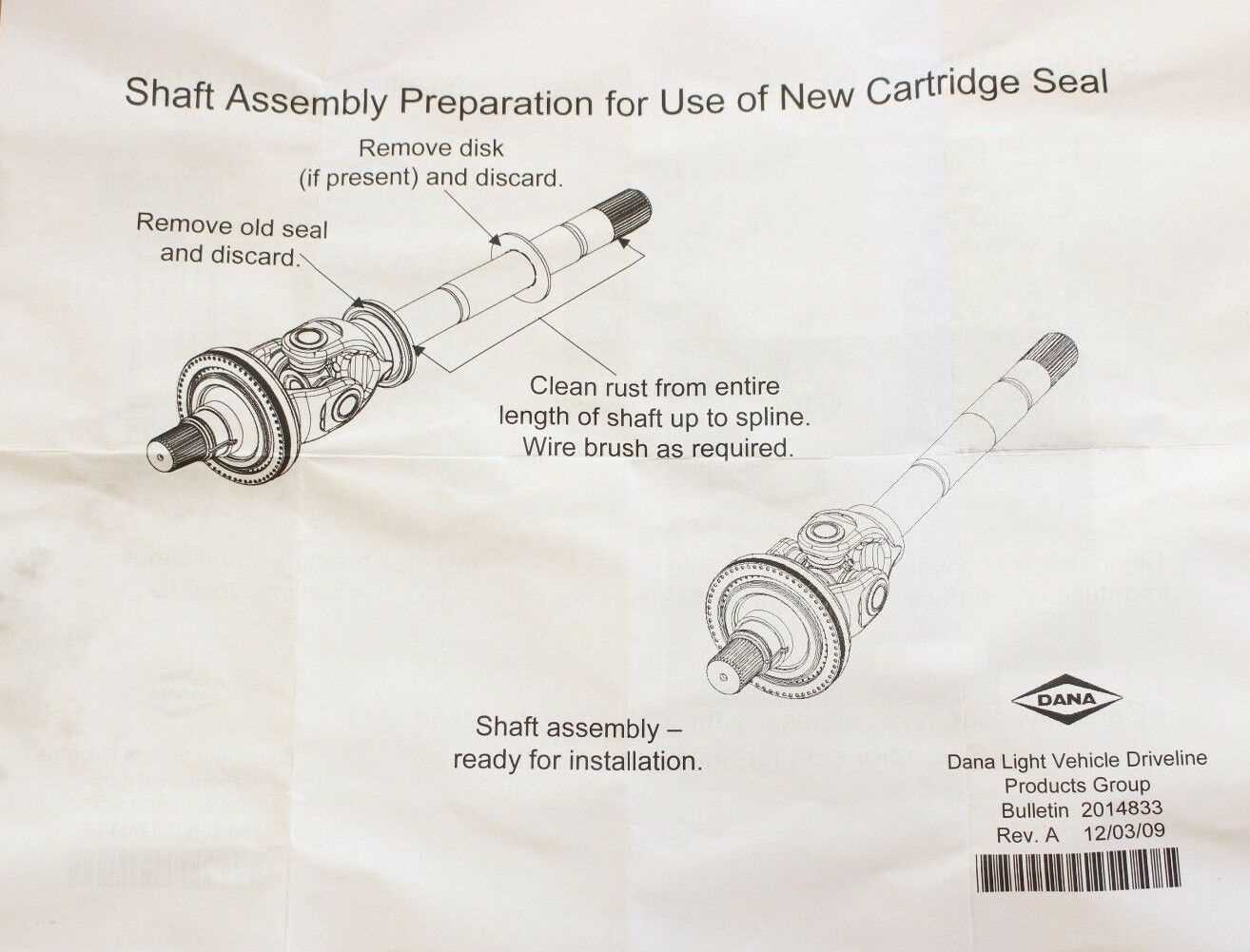

Step-by-Step Installation Guide

This section provides a comprehensive guide for the installation process of essential components in your vehicle’s front section. Following these detailed steps will help ensure a smooth and efficient procedure, minimizing the risk of errors and enhancing overall performance.

Preparation

Before beginning the installation, gather all necessary tools and components. Ensure that the work area is clean and well-lit. It is advisable to consult the user manual specific to your vehicle model for any additional instructions or safety precautions.

Installation Steps

1. Remove Old Components: Start by disconnecting the battery to ensure safety. Carefully remove the existing parts by loosening bolts and fasteners. Keep track of all hardware for reinstallation.

2. Install New Parts: Position the new components in place. Align them properly and secure with the provided fasteners. Make sure each part is tightened to the manufacturer’s specifications to avoid future issues.

3. Reconnect Battery: Once everything is securely in place, reconnect the battery. Check all connections and ensure that there are no loose wires.

Following these steps carefully will help you successfully complete the installation process and enjoy the improved functionality of your vehicle.

Tools Needed for Repairs

When undertaking maintenance on your vehicle, having the right instruments at your disposal is crucial for achieving efficient and effective results. Each component requires specific tools to ensure that repairs are performed safely and accurately.

Essential Tools

Begin with basic hand tools, such as wrenches and screwdrivers, which are fundamental for loosening and tightening various fittings. A sturdy jack and jack stands are also necessary for safely lifting the vehicle.

Advanced Equipment

For more intricate repairs, consider investing in a torque wrench to apply the correct amount of force on bolts. Diagnostic tools can also help identify issues swiftly, making the repair process smoother and more precise.

Cost Factors for Replacement Parts

When considering the expense of replacing components in a heavy-duty vehicle, various elements come into play that influence pricing. Understanding these factors can help vehicle owners make informed decisions, ensuring they choose the best options for their needs without compromising quality or performance.

Key Influences on Pricing

Several factors can affect the cost of replacement components, including brand reputation, material quality, and sourcing location. It is essential to weigh these aspects when selecting the right item for your vehicle.

| Factor | Description |

|---|---|

| Brand | Reputable brands often charge more due to their established quality and reliability. |

| Material | Higher-quality materials may lead to increased longevity and performance, justifying a higher price. |

| Sourcing | Components sourced from different regions can vary in price due to shipping costs and local market conditions. |

Long-Term Considerations

While upfront costs are important, it’s also vital to consider the long-term implications of your choices. Investing in higher-quality components may reduce the need for frequent replacements, ultimately saving money over time.

Comparing OEM and Aftermarket Options

When it comes to selecting components for vehicle repair or enhancement, the choice often narrows down to original equipment manufacturer (OEM) items versus aftermarket alternatives. Each category has its unique advantages and potential drawbacks, influencing the decision based on individual needs and preferences.

Benefits of OEM Components

- Designed specifically for the vehicle, ensuring perfect fit and compatibility.

- Often backed by warranties that guarantee performance and durability.

- Typically manufactured with high-quality materials, maintaining the vehicle’s integrity.

Advantages of Aftermarket Options

- Usually more affordable, making them budget-friendly choices.

- Offer a wider variety of styles and features, catering to personal preferences.

- Some options may provide enhanced performance compared to factory alternatives.

Ultimately, the choice between these two categories hinges on factors such as cost, desired quality, and specific vehicle requirements.

Resources for Technical Diagrams

Understanding complex machinery requires access to detailed visual aids. These illustrations serve as essential tools for both professionals and enthusiasts, providing clarity on components and their arrangements.

Online Platforms: Numerous websites offer comprehensive repositories of technical visuals. These platforms allow users to explore various models and configurations, making it easier to find specific information.

Manufacturer Manuals: Official manuals are invaluable resources. They typically contain accurate schematics tailored to particular models, ensuring that users have access to precise data.

Forums and Communities: Engaging with online forums can yield a wealth of shared knowledge. Community members often post diagrams and insights, creating a collaborative environment for troubleshooting and learning.

Utilizing these resources can enhance understanding and facilitate effective maintenance or repair tasks.