Understanding the Ford 1320 Parts Diagram for Effective Maintenance

In the realm of agricultural equipment, grasping the intricate relationships between various elements is essential for optimal performance. Each component plays a crucial role in ensuring seamless operation, which can ultimately enhance productivity and efficiency.

Whether you’re a seasoned professional or a novice in the field, having access to a comprehensive visual reference can significantly aid in identifying and understanding the functionality of each part. This insight not only facilitates repairs but also fosters a deeper appreciation for the engineering behind these robust machines.

As you explore the interconnectedness of these mechanical elements, you will uncover the ultimate advantages of being informed. A thorough comprehension empowers users to make informed decisions, leading to better maintenance practices and prolonged lifespan of the equipment.

Understanding Ford 1320 Components

Comprehending the individual elements of a machinery unit is essential for effective maintenance and operation. Each component plays a vital role in the overall functionality, and recognizing how they interact can significantly enhance performance. This section delves into the key elements that make up this specific model, providing insights into their purposes and interrelations.

Key Elements and Their Functions

Among the primary constituents are the engine, transmission, and hydraulic systems. The engine serves as the powerhouse, converting fuel into mechanical energy. The transmission facilitates the transfer of this energy to the wheels, allowing for efficient movement. Meanwhile, the hydraulic system enables various functions, such as lifting and steering, by utilizing fluid pressure to exert force on the necessary components.

Maintenance and Care

Regular inspection and upkeep of these elements are crucial for longevity and optimal performance. Understanding the signs of wear or malfunction in each part can prevent larger issues and reduce downtime. Adopting a proactive approach to maintenance ensures that the machinery operates smoothly and reliably, maximizing productivity in any application.

Overview of Ford 1320 Tractor

This section provides a comprehensive look at a popular agricultural vehicle known for its durability and efficiency. Designed to meet the needs of farmers and landowners, this machine combines advanced engineering with user-friendly features, making it a favored choice in various farming tasks.

Power and Performance: The vehicle is equipped with a robust engine that delivers impressive horsepower, ensuring it can handle demanding workloads with ease. Its design promotes fuel efficiency, allowing users to maximize productivity while minimizing operational costs.

Versatility: This model is known for its adaptability, capable of performing a range of functions from plowing to transporting materials. Its compatibility with various implements enhances its utility on the farm.

Maintenance and Support: Regular upkeep is crucial for optimal performance. The availability of replacement components and technical assistance ensures that owners can maintain their equipment effectively, extending its lifespan and reliability.

In summary, this agricultural powerhouse exemplifies a blend of strength, versatility, and efficiency, making it an ultimate asset in modern farming.

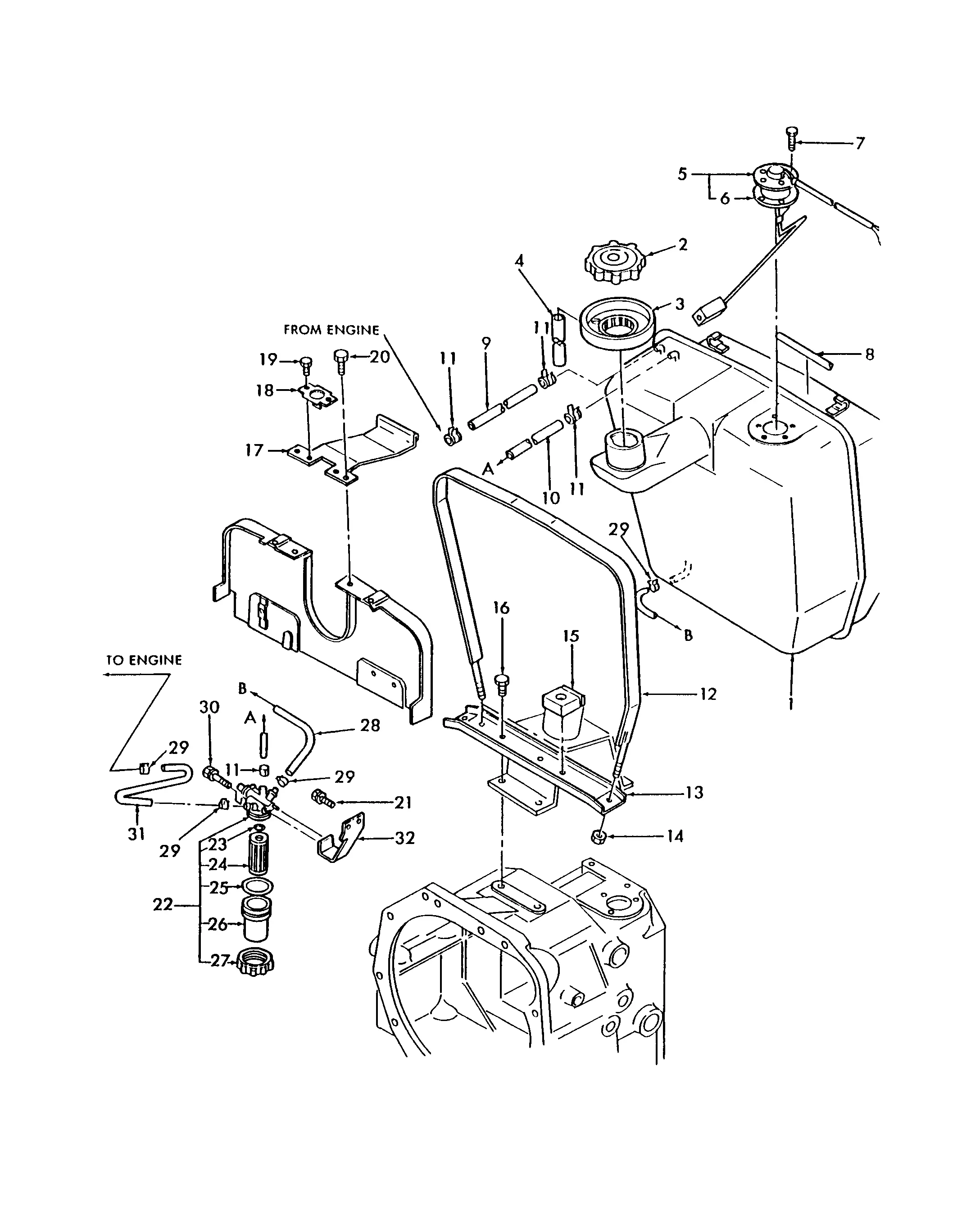

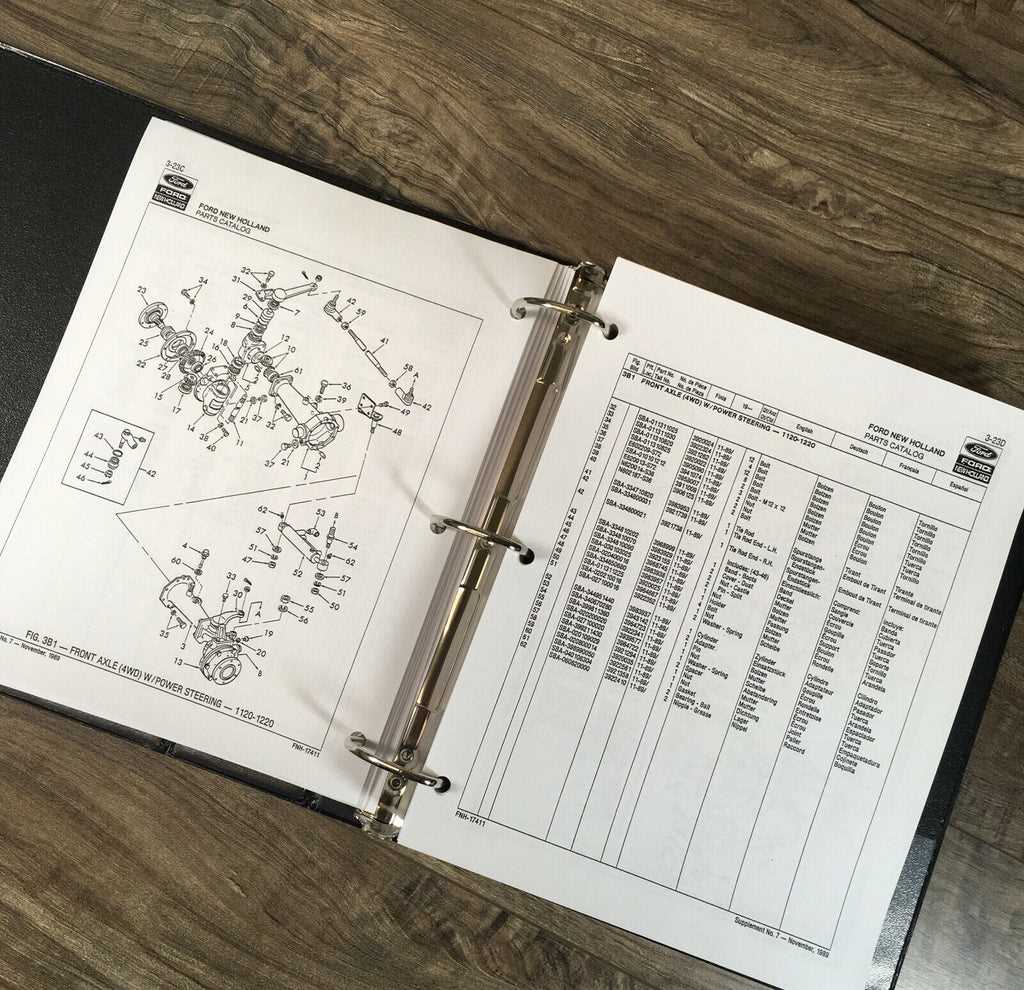

Importance of Parts Diagrams

Understanding the intricate layout of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, allowing users to identify components, their functions, and interrelations. This clarity aids not only in troubleshooting but also in enhancing overall efficiency.

First and foremost, having access to detailed illustrations minimizes errors during assembly or disassembly. It provides a reference point that can prevent costly mistakes and ensure that each element is correctly installed. Moreover, these visuals can streamline the ordering process for replacements, making it easier to procure the exact items needed.

Additionally, familiarity with these schematics promotes a deeper understanding of the equipment’s functionality. This knowledge empowers operators to address minor issues independently, fostering a sense of confidence and competence. Ultimately, clear visuals contribute significantly to the longevity and reliability of the machinery.

Common Issues with Ford 1320

Many users of compact utility tractors encounter several recurring challenges that can affect performance and reliability. Understanding these common issues can help in identifying problems early and ensuring proper maintenance, thereby prolonging the lifespan of the machine.

One prevalent concern involves the hydraulic system, where leaks or low fluid levels may lead to diminished lifting capabilities or sluggish operation. Regular inspection of hoses and connections can prevent more significant problems.

Engine performance can also be compromised by fuel system issues, such as clogged filters or air leaks, which may cause hard starting or reduced power. Maintaining a clean fuel system is crucial for optimal operation.

Transmission troubles often arise, particularly with shifting difficulties or unexpected slippage. This can often be attributed to low fluid levels or worn components that require timely replacement to maintain smooth operation.

Electrical problems, including faulty wiring or weak batteries, can result in starting issues or malfunctioning lights. Regular checks can help in identifying potential electrical failures before they escalate.

By being aware of these frequent issues and performing routine maintenance, operators can significantly enhance the reliability and efficiency of their machinery, ensuring it remains in good working order for years to come.

Key Components of the Tractor

Understanding the essential elements of a farming machine is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the vehicle performs optimally, enhancing productivity and efficiency in agricultural tasks. Below are some of the fundamental parts that contribute to the functionality of such machinery.

Engine and Transmission

The engine is the heart of the machine, providing the necessary power for various operations. It converts fuel into mechanical energy, enabling the vehicle to perform tasks such as plowing, tilling, and hauling. Coupled with the engine, the transmission system allows for smooth gear shifts, optimizing the torque and speed based on the task at hand. Together, these components form the backbone of the machine’s performance.

Hydraulic System

The hydraulic system is vital for operating attachments and implements. It uses fluid pressure to power devices such as loaders and backhoes, making it possible to lift heavy loads and perform intricate tasks with precision. The efficiency of this system significantly impacts the overall versatility and capability of the equipment, enabling farmers to adapt to various challenges on the field.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visual representations provide a clear overview of components and their arrangement, allowing for easier identification and troubleshooting.

To begin, familiarize yourself with the legend or key often included with the illustration. This section typically outlines symbols and color codes used to represent different elements. Paying attention to these details will enhance your comprehension.

Next, examine the overall layout. Components are usually organized in a logical manner, often reflecting their actual positioning within the machinery. Identifying major sections can help you navigate the illustration more efficiently.

Focus on the numbers or labels associated with each element. These identifiers are essential for cross-referencing with inventory or ordering new items. Make sure to take note of any specific details such as sizes or specifications.

It can also be beneficial to compare the illustration with the physical unit. This hands-on approach reinforces your understanding of how each piece fits together and functions within the system.

Lastly, don’t hesitate to consult additional resources if you’re uncertain about a particular part or its role. Manufacturer manuals or online forums can provide valuable insights that enhance your overall understanding.

Finding Replacement Parts Easily

Locating the right components for machinery can often feel daunting. However, with the right approach, this process can become seamless and efficient. Understanding where to search and how to assess available options is essential for maintaining your equipment’s functionality.

Utilize Online Resources: The internet offers a wealth of platforms where you can find information on the required components. Websites dedicated to machinery often feature comprehensive catalogs and user reviews, making it easier to gauge quality and compatibility.

Consult Community Forums: Engaging with fellow enthusiasts or professionals in online communities can yield invaluable insights. Many experienced users share their recommendations and tips for sourcing components, helping you navigate your choices more effectively.

Consider Local Suppliers: While online searches are convenient, local distributors can provide immediate access to the needed items. Building relationships with these suppliers may also lead to better pricing and personalized assistance.

Stay Organized: Keeping a detailed record of your machinery’s specifications and previous purchases can simplify future searches. Having this information at hand will help you quickly identify suitable replacements when needed.

Maintaining Your Ford 1320

Regular upkeep of your machinery is essential for optimal performance and longevity. A proactive approach to maintenance can prevent breakdowns and enhance efficiency.

Key areas to focus on include:

- Fluid Levels: Regularly check and replace oils, coolant, and hydraulic fluids.

- Filters: Ensure air and fuel filters are clean and replace them as needed.

- Tires: Inspect tire pressure and tread for safe operation.

To establish a routine:

- Develop a maintenance schedule based on usage and manufacturer recommendations.

- Keep a log of all maintenance activities to track performance over time.

- Consult the manual for specific maintenance tips and guidelines.

Implementing these practices will help you maintain peak functionality and extend the life of your equipment.

Upgrading Parts for Better Performance

Enhancing the components of machinery can lead to significant improvements in efficiency and capability. By focusing on key areas of the system, enthusiasts can unlock the full potential of their equipment, ensuring a smoother and more powerful operation.

Choosing Quality Components: Selecting high-quality replacements is crucial. Opt for durable materials that can withstand rigorous use while providing superior performance.

Tuning for Optimal Efficiency: Adjusting specific elements can enhance overall functionality. Whether it’s the engine, transmission, or hydraulic systems, fine-tuning allows for increased responsiveness and power.

Regular Maintenance: Upgrading isn’t solely about new parts. Routine checks and maintenance ensure that all components work harmoniously, preventing wear and tear that could diminish performance over time.

Research and Development: Staying informed about the latest advancements in technology can provide valuable insights. Delving into innovative solutions may reveal new upgrades that can elevate your machine to its ultimate potential.

Where to Buy Authentic Parts

Finding genuine components for machinery is crucial for maintaining performance and longevity. Several reputable sources can ensure that you receive high-quality items that meet industry standards.

- Authorized Dealers: These outlets specialize in genuine merchandise and often provide warranties.

- Online Marketplaces: Websites dedicated to industrial equipment offer a vast selection and user reviews to guide purchases.

- Local Repair Shops: Many service centers sell authentic components directly or can order them for you.

- Manufacturer Websites: Direct purchases from official sites guarantee authenticity and may provide customer support.

Researching each option can help you make the ultimate choice for your needs.

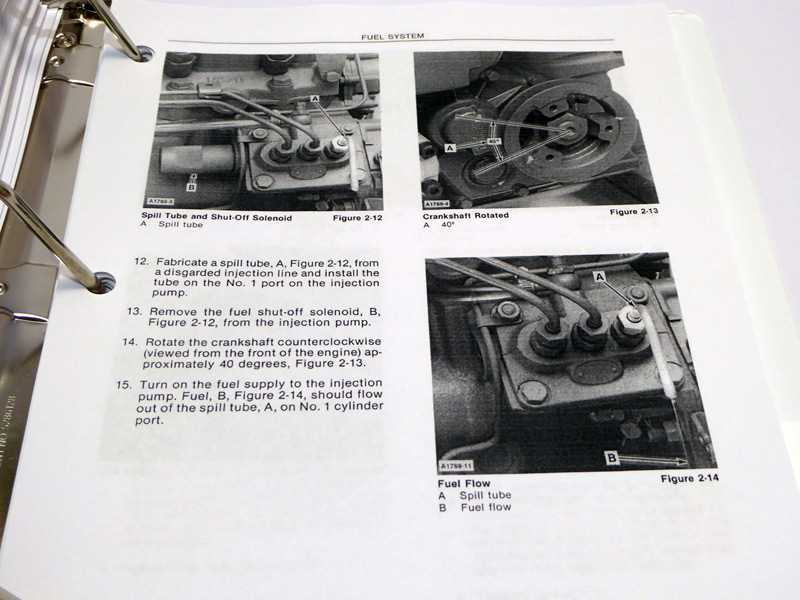

DIY Repairs Using Diagrams

Engaging in self-repair can be a rewarding experience, especially when you have clear visual aids to guide you. Such illustrations provide a detailed representation of components, making it easier to understand the structure and functionality of various systems. This approach not only saves time but also enhances your confidence in tackling mechanical challenges independently.

Understanding Visual Aids

Visual aids serve as a roadmap for your repair journey. They break down complex assemblies into manageable parts, allowing you to identify and locate each element with ease. By referencing these images, you can ensure that you’re making the correct modifications or replacements, minimizing the risk of errors. Moreover, having a clear picture can significantly reduce frustration during the process.

Step-by-Step Process

To effectively use these resources, start by familiarizing yourself with the layout presented. Carefully examine each section and note any specific tools or techniques required for each task. Once you have a good understanding, gather the necessary supplies and follow the illustrated steps methodically. This structured approach not only enhances efficiency but also allows for a smoother repair experience, ultimately leading to successful outcomes.

Consulting Experts for Assistance

When navigating the complexities of machinery maintenance, seeking advice from seasoned professionals can be invaluable. Experts possess a wealth of knowledge and experience, enabling them to provide insights that enhance understanding and efficiency. Engaging with these specialists not only streamlines the troubleshooting process but also fosters a deeper appreciation of the equipment’s intricacies.

Benefits of Expert Consultation

Consulting knowledgeable individuals can uncover solutions that may not be immediately apparent. Their guidance often leads to cost-effective repairs and optimizations, ultimately extending the lifespan of your machinery. Additionally, their ability to delve into specific issues allows for targeted interventions that can prevent future complications.

Finding the Right Professional

Identifying the appropriate expert involves researching credentials and experience in relevant fields. Look for those who have a proven track record in dealing with similar equipment and can offer personalized advice. This careful selection ensures that you receive the ultimate support for your maintenance needs.