Comprehensive Guide to Ford 1720 Parts Diagram

The intricate machinery that powers our everyday tasks relies heavily on a well-organized system of elements. Each component plays a vital role in ensuring optimal performance and reliability. Recognizing the layout of these components can significantly enhance maintenance efforts and troubleshooting processes.

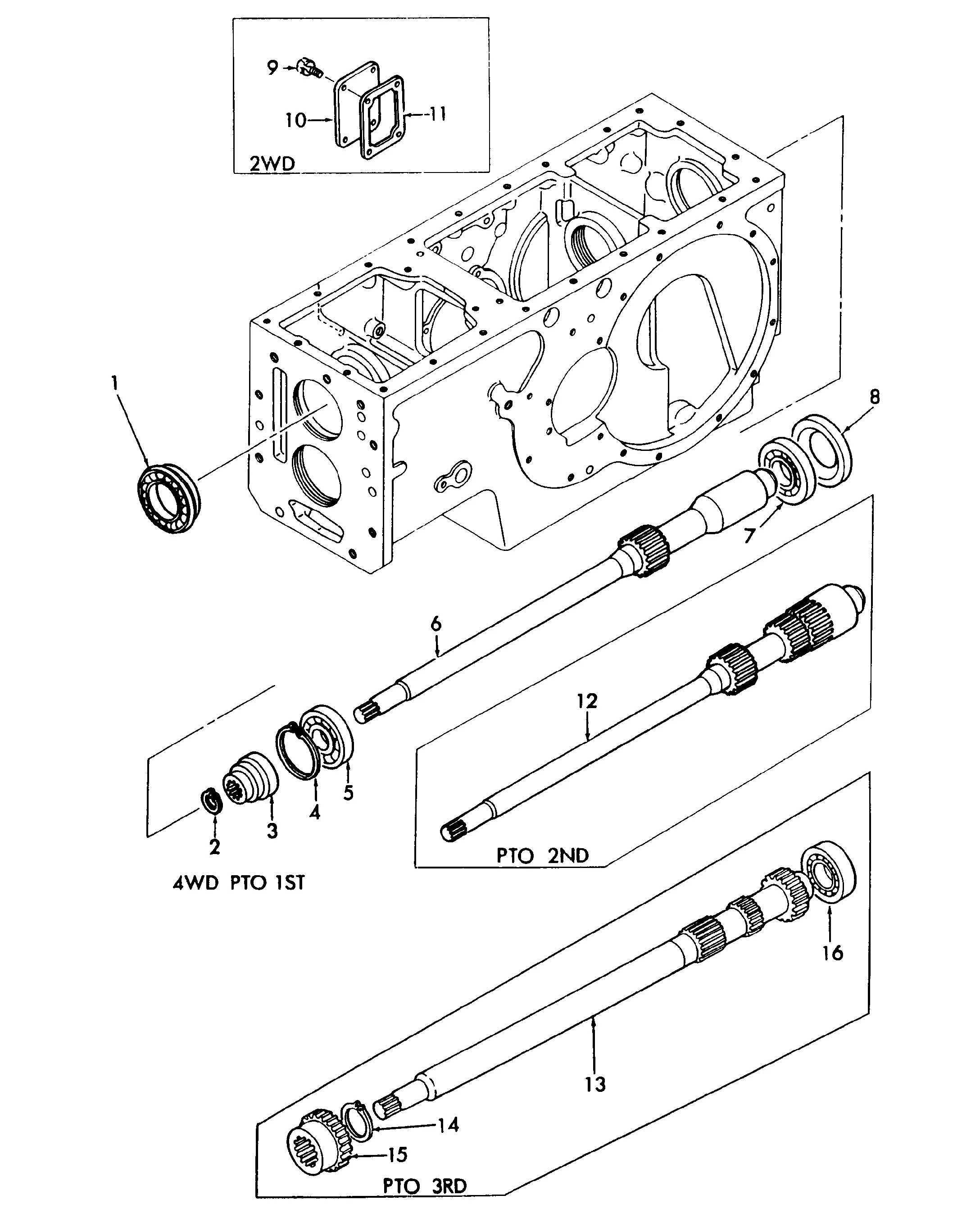

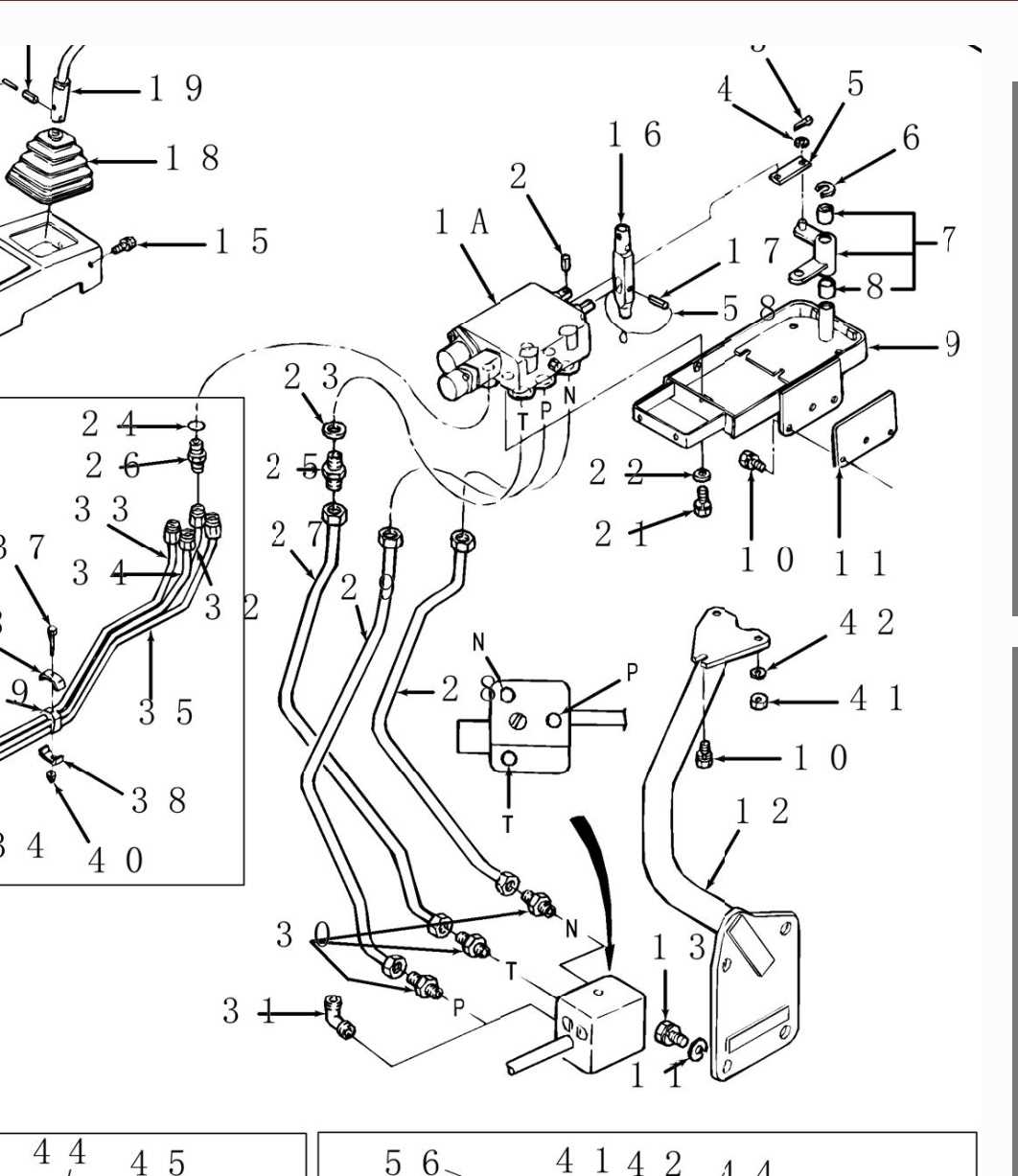

Visual representations of mechanical assemblies serve as essential tools for operators and technicians alike. By breaking down complex systems into understandable segments, these illustrations facilitate better comprehension of how each piece interacts with others. This knowledge is invaluable for anyone looking to ensure longevity and efficiency in their machinery.

In the realm of heavy equipment, access to detailed visual guides is crucial. These references not only assist in identifying specific elements but also aid in planning repairs and upgrades. By familiarizing oneself with the configuration of essential components, one can approach maintenance with greater confidence and skill.

Understanding the Ford 1720 Parts Diagram

Interpreting the components layout of machinery is essential for effective maintenance and repair. Familiarity with these visual aids enables users to identify each element and understand their functions within the overall system. Such diagrams serve as a valuable reference, simplifying the process of locating specific parts and understanding their interactions.

These visual representations typically break down complex machinery into easily understandable sections, highlighting various components and their respective connections. By studying the layout, users can gain insights into how each piece contributes to the machine’s performance. Moreover, it facilitates troubleshooting by allowing users to pinpoint issues more efficiently.

When engaging with these illustrations, it is important to pay attention to the labels and notations provided. Recognizing the differences between similar components can prevent mistakes during assembly or repairs. Additionally, understanding the orientation and placement of parts enhances the ability to perform tasks accurately and safely.

Overall, mastering the interpretation of these visual tools not only boosts confidence in handling machinery but also fosters a deeper appreciation for its engineering and design. Knowledge of the components and their arrangement empowers users to maintain their equipment effectively.

Importance of Accurate Diagrams

Precise illustrations serve as essential tools in the realm of machinery maintenance and repair. They provide a visual reference that simplifies complex assembly processes and enhances understanding of component relationships. By leveraging these visuals, technicians can reduce errors and improve efficiency in their work.

Enhancing Efficiency

Having access to well-constructed visuals can significantly streamline repair tasks. When a technician can quickly identify the location and function of each element, it minimizes the time spent searching for parts and understanding their placements. This efficiency translates into faster turnaround times for repairs and maintenance.

Reducing Errors

Inaccurate representations can lead to costly mistakes. A clear and detailed illustration ensures that each component is handled correctly, decreasing the likelihood of incorrect installations or replacements. This not only preserves the integrity of the machinery but also enhances safety for those working on it.

| Benefits | Details |

|---|---|

| Time-saving | Quick identification of components speeds up the repair process. |

| Error reduction | Clear visuals decrease the risk of incorrect installations. |

| Enhanced safety | Accurate information helps prevent accidents during repairs. |

| Improved understanding | Visual aids facilitate better comprehension of complex systems. |

Key Components of Ford 1720

The machinery in question is built on a foundation of essential elements that work harmoniously to ensure optimal performance and reliability. Each component plays a significant role in the overall functionality, contributing to the efficiency and longevity of the equipment.

Engine: At the heart of the system lies the power unit, designed to deliver robust performance while maintaining fuel efficiency. This unit is vital for providing the necessary torque and horsepower for various tasks.

Transmission: The transmission system allows for smooth power transfer from the engine to the wheels. It is engineered to provide different gear ratios, enabling operators to handle diverse terrains and loads effectively.

Hydraulic System: A sophisticated hydraulic assembly powers various attachments and implements. This system is crucial for lifting, pushing, and digging operations, enhancing the versatility of the machinery.

Chassis: The sturdy framework supports all other components, ensuring durability and stability during operation. Its design is crucial for handling heavy loads and providing a solid base for attachments.

Steering Mechanism: Precision steering allows for agile maneuverability, making it easier for operators to navigate tight spaces and perform intricate tasks. This component is essential for ensuring control and safety.

Understanding these core elements is essential for maintenance and troubleshooting, allowing users to maximize the functionality and lifespan of their equipment.

Common Replacement Parts Explained

In the world of machinery, understanding essential components is crucial for maintaining optimal performance. This section delves into frequently replaced elements that ensure smooth operation and longevity of equipment. Recognizing when these items require attention can significantly enhance reliability and efficiency.

Filters are among the most vital components, designed to keep contaminants out of critical systems. Regular replacement helps maintain fluid cleanliness, preventing damage to internal parts. Air, oil, and fuel filters are common examples that require periodic checks to ensure proper function.

Batteries also play a significant role, providing the necessary power for starting engines and operating electrical systems. Over time, batteries can lose their charge capacity, making regular inspection and timely replacement essential for avoiding unexpected breakdowns.

Belts and hoses are other key elements that wear out due to constant use and exposure to heat. These components are crucial for transferring power and fluids throughout the machinery. Signs of wear, such as cracks or leaks, should prompt immediate attention to prevent more extensive damage.

Seals and gaskets are essential for maintaining system integrity. They prevent leaks and ensure that fluids remain contained within their respective systems. Regular checks and replacements can help avoid costly repairs due to fluid loss and system failure.

By staying proactive about these common replacements, operators can ensure their machinery remains in peak condition, minimizing downtime and maximizing productivity.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual tool allows users to identify individual elements, their functions, and how they interconnect within a larger system. By familiarizing yourself with the layout and symbols used, you can navigate the intricacies of any mechanical assembly with confidence.

Here are some key steps to effectively interpret such a representation:

- Familiarize with Symbols:

- Learn the common symbols used to represent various components.

- Refer to the legend or key, which typically explains what each symbol signifies.

- Identify Components:

- Locate each part based on its designated symbol.

- Pay attention to numbers or letters that may indicate specific models or versions.

- Understand Connections:

- Observe how parts are linked together through lines or arrows.

- Note the types of connections, such as bolts, screws, or electrical links.

- Refer to Additional Resources:

- Use manuals or online guides for more detailed explanations of complex components.

- Consult forums or communities for insights from experienced users.

By following these steps, you can enhance your understanding and proficiency in working with mechanical systems. This skill is invaluable for troubleshooting and performing repairs effectively.

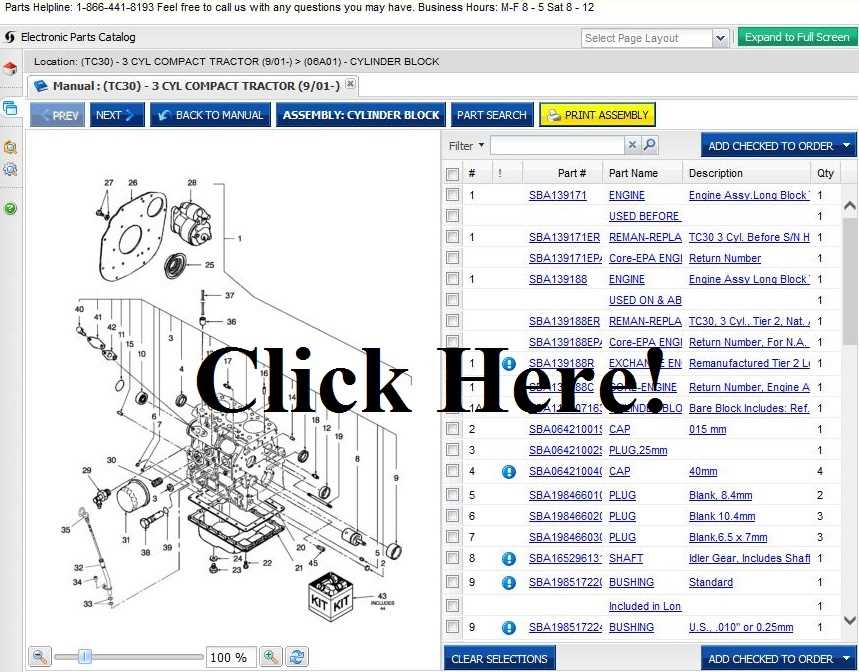

Where to Find Quality Diagrams

Finding high-quality illustrations for machinery components can significantly enhance your understanding and maintenance capabilities. Various resources are available, ranging from online databases to specialized publications, which can provide detailed visuals and explanations. Utilizing the right sources not only aids in repairs but also helps in the identification of parts and their functions.

Online Resources

The internet is a treasure trove for technical visuals. Websites dedicated to machinery often host a wealth of information, including comprehensive manuals and detailed schematics. Online forums and community groups can also be valuable, as enthusiasts frequently share their insights and resources, including useful links and scanned documents. Make sure to check reputable sites to ensure the accuracy of the information.

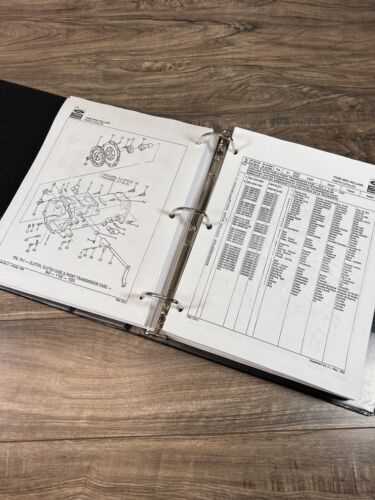

Printed Manuals and Books

For those who prefer traditional methods, printed manuals and reference books remain indispensable. Many publishers specialize in technical literature that covers machinery specifications, including well-organized illustrations. Local libraries and bookstores often have these resources available, providing a tangible reference that can be easily annotated for personal use.

Tips for Maintaining Your Ford 1720

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular maintenance not only helps in identifying potential issues before they escalate but also enhances efficiency and reliability. Here are some practical suggestions to keep your machine in top condition.

Firstly, always refer to the manufacturer’s guidelines for scheduled maintenance tasks. This includes oil changes, filter replacements, and fluid checks. Staying on top of these routines will prevent wear and tear.

Secondly, clean the exterior and components regularly. Debris and dirt can accumulate and affect performance. A thorough cleaning after each use can help maintain functionality and prevent corrosion.

Additionally, inspect belts and hoses for any signs of wear or damage. Replace them promptly to avoid breakdowns. Regular checks will help in catching any issues early on.

Lastly, ensure that all bolts and fasteners are tight. Vibrations during operation can loosen these components, leading to potential failures. A simple visual inspection can save you from future complications.

Understanding Part Numbers and Codes

In the realm of machinery and equipment, identification of components is crucial for maintenance and repair. Each element is assigned a unique code or identifier, which simplifies the process of sourcing and replacing items. These identifiers not only help in finding the correct components but also provide insights into compatibility and specifications.

The Structure of Identification Codes

Typically, these codes are composed of a series of letters and numbers, each segment representing different attributes of the component. For instance, the initial letters may indicate the category of the item, while the subsequent numbers can reflect size, model, or manufacturing details. Understanding this structure is essential for anyone involved in repairs or restorations.

Interpreting Codes for Efficient Maintenance

Deciphering these identifiers allows users to quickly locate the necessary components, reducing downtime during repairs. Familiarity with these codes also assists in verifying the authenticity of items, ensuring that replacements meet the required standards. Thus, mastering the interpretation of these codes enhances the overall efficiency of maintenance tasks.

DIY Repairs Using the Diagram

When it comes to maintaining machinery, having a clear reference can make all the difference. A well-organized visual guide enables enthusiasts and professionals alike to tackle repairs with confidence. This approach not only simplifies the process but also enhances understanding of how various components interact within the system.

By utilizing a visual representation of the machine’s assembly, you can identify specific sections that require attention. Begin by isolating the area needing repair, ensuring you have all necessary tools and replacement parts on hand. This proactive step can save time and prevent unnecessary frustration.

Once you’ve located the relevant components, carefully follow the outlined steps for disassembly and reassembly. Documenting each stage can further assist in keeping track of your progress. Moreover, consulting supplementary resources like manuals or online tutorials can provide additional insights, ensuring a thorough and efficient repair process.

After completing the repairs, conducting a thorough test will confirm that everything functions as intended. Regular maintenance, guided by clear visuals, can significantly extend the life of your equipment and enhance its performance, making DIY repairs a rewarding endeavor.

Consulting Professionals for Complex Issues

When faced with intricate challenges, seeking the expertise of qualified individuals can make a significant difference in resolving problems effectively. These specialists possess a wealth of knowledge and experience that can lead to innovative solutions and informed decisions. Their insights can streamline processes and prevent costly mistakes, ultimately saving time and resources.

In many situations, attempting to navigate complexities alone can lead to confusion and suboptimal outcomes. Professionals offer a fresh perspective, enabling a deeper understanding of the nuances involved. Collaboration with experts not only enhances problem-solving capabilities but also fosters a sense of confidence in the decision-making process.

| Benefit | Description |

|---|---|

| Expert Knowledge | Access to specialized skills and insights that are not readily available. |

| Efficiency | Streamlined processes that save time and reduce resource expenditure. |

| Risk Mitigation | Identification and management of potential pitfalls and challenges. |

| Innovative Solutions | Creative approaches to complex issues that may not be apparent from a singular viewpoint. |

Ultimately, consulting professionals is not just about addressing immediate concerns; it is also about building a foundation for future success. By leveraging their expertise, individuals and organizations can navigate complexities with greater assurance and clarity.

Benefits of Regular Maintenance Checks

Routine inspections and upkeep are essential for the longevity and efficiency of any machinery. By prioritizing regular maintenance, operators can ensure that their equipment runs smoothly and minimizes the risk of unexpected breakdowns.

Improved Performance

Consistent maintenance plays a critical role in optimizing the performance of machines. Key advantages include:

- Enhanced efficiency: Regular servicing helps keep components in top condition.

- Better fuel consumption: Well-maintained equipment typically consumes less energy.

- Smoother operation: Preventative measures reduce wear and tear, leading to a more seamless experience.

Cost Savings

Investing time and resources in routine checks can lead to significant financial benefits. These include:

- Reduced repair costs: Early detection of issues often prevents costly repairs later.

- Extended lifespan: Proper care can prolong the operational life of machinery.

- Minimized downtime: Preventative maintenance decreases the likelihood of unexpected failures.