Comprehensive Guide to Ford 655A Backhoe Parts Diagram PDF

When working with heavy machinery, having a clear understanding of its components is essential for effective maintenance and repair. Familiarity with each element allows operators and technicians to identify issues quickly and ensure optimal performance. This knowledge is crucial for both seasoned professionals and those new to the field.

Visual aids, such as comprehensive visual representations, serve as invaluable resources in this context. They not only illustrate the intricate relationships between different parts but also highlight the specific functions each plays in the overall operation. By referring to these guides, users can enhance their comprehension and troubleshoot problems more efficiently.

Moreover, access to detailed documentation facilitates smoother repairs and replacements. Whether it’s a matter of routine upkeep or addressing unexpected malfunctions, having reliable reference material at hand can save time and reduce frustration. This article will explore the best ways to utilize these resources for effective machinery management.

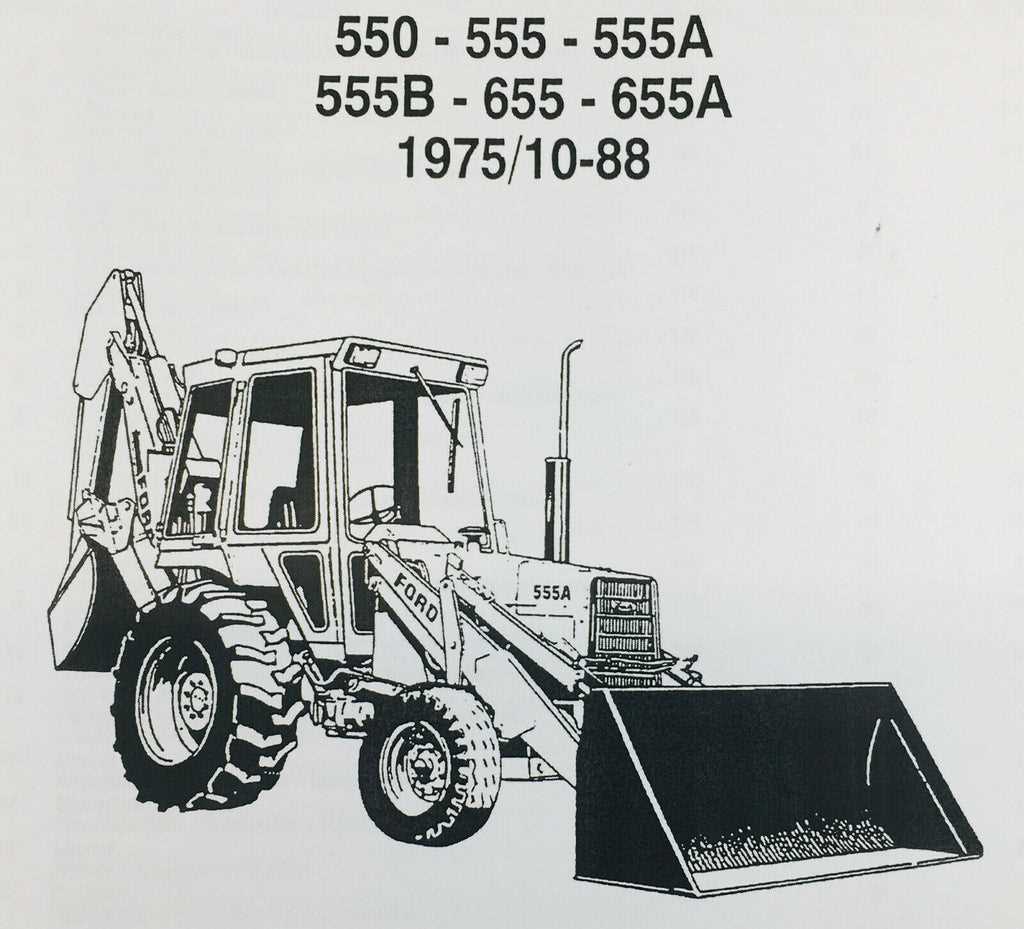

Overview of Ford 655A Backhoe

This section provides a comprehensive look at a versatile piece of machinery designed for digging and excavation tasks. Known for its reliability and efficiency, this equipment has become a staple in construction and landscaping projects. With its robust design and powerful performance, it offers operators the ultimate advantage in various applications.

The unit is equipped with features that enhance maneuverability and functionality, making it suitable for both small and large-scale operations. Its hydraulic system plays a crucial role in ensuring smooth operation and effective handling of various attachments, adding to its adaptability in the field.

Users appreciate the ease of maintenance and availability of support, which contributes to the longevity of the machinery. Overall, this excavator exemplifies engineering excellence, providing the ideal solution for diverse digging needs.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations serve as valuable tools for technicians and operators, providing clarity and facilitating troubleshooting processes. The significance of these illustrations cannot be overstated.

Here are some key benefits of utilizing such visual aids:

- Enhanced Understanding: Diagrams break down complex systems into manageable sections, making it easier to identify parts and their functions.

- Improved Communication: These visuals provide a common reference point, enabling better collaboration among team members and clearer instructions from manufacturers.

- Efficiency in Repairs: Knowing the exact location and function of components allows for quicker diagnostics and repairs, minimizing downtime.

- Preventative Maintenance: Regular reference to these illustrations helps in identifying wear and tear before issues escalate, promoting proactive care.

- Training Resources: New personnel can learn faster by studying these visual guides, accelerating their familiarity with the equipment.

In conclusion, the use of visual representations in understanding machinery plays a critical role in effective operation, maintenance, and education, ensuring longevity and reliability of equipment.

Where to Find PDF Resources

Accessing high-quality documentation can significantly enhance your understanding and maintenance of machinery. Numerous online platforms and resources provide essential manuals and schematics, making it easier for users to locate the information they need.

Here are some effective avenues to explore when searching for technical documents:

| Resource Type | Description | Examples |

|---|---|---|

| Manufacturer Websites | Official pages often host a repository of documents related to their products. | Company manuals, service guides |

| Online Forums | Community-driven sites where users share resources and tips. | Discussion threads, shared links |

| Specialized Retailers | Sites that focus on equipment sales may also offer downloadable resources. | Product listings, downloadable manuals |

| Library Databases | Many libraries provide access to technical documents through their online catalogs. | Academic journals, technical reports |

Utilizing these resources can streamline your search for valuable documentation, ensuring you have the necessary information at your fingertips.

Understanding Backhoe Components

Grasping the elements of excavation machinery is crucial for effective operation and maintenance. Each segment plays a vital role in overall performance, and comprehending their functions can enhance productivity and longevity.

- Loader Arm: The primary component for lifting and moving materials.

- Bucket: Used for digging and transporting soil or debris.

- Stabilizers: Ensure the machine remains stable during operation.

- Hydraulic System: Powers various functions and enhances efficiency.

- Transmission: Transfers power from the engine to the wheels or tracks.

Familiarity with these components allows operators to optimize their use, troubleshoot issues, and make informed decisions during repairs.

Common Issues with Ford 655A

When operating heavy machinery, various challenges can arise that affect performance and reliability. Identifying and addressing these problems promptly can ensure smoother operation and prolong the lifespan of the equipment.

Hydraulic System Failures

One prevalent issue involves the hydraulic system, which can experience leaks or decreased pressure. This may lead to inefficient operation and difficulty in maneuvering.

Engine Performance Problems

Engine-related concerns often manifest as stalling or reduced power output. Regular maintenance and inspections are crucial for diagnosing these issues before they escalate.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Hydraulic Leaks | Decreased lifting capability | Inspect hoses and seals; replace damaged components |

| Engine Stalling | Loss of power during operation | Check fuel filters; inspect ignition system |

Benefits of Using Original Parts

Utilizing genuine components in machinery and equipment provides numerous advantages that enhance performance and longevity. These authentic elements are designed to meet specific engineering standards, ensuring optimal functionality and reliability.

Quality Assurance

- Manufactured to precise specifications, ensuring compatibility and seamless integration.

- Undergo rigorous testing to meet safety and durability benchmarks.

- Crafted from high-grade materials that withstand wear and tear.

Enhanced Performance

- Improved efficiency, leading to better fuel consumption.

- Reduction in unexpected breakdowns and maintenance costs.

- Consistent operation, allowing for increased productivity on job sites.

Choosing authentic components not only safeguards your investment but also contributes to the overall effectiveness of your machinery, making it a wise choice for any operator.

Repair vs. Replacement Considerations

When assessing equipment functionality, a crucial decision arises between mending existing components and opting for new replacements. Each choice carries its own set of implications, impacting both performance and budget. An informed approach is necessary to determine the most effective solution based on various factors.

Cost Analysis

Financial considerations play a significant role in the decision-making process. Repairs may initially appear more economical, yet frequent maintenance can accumulate costs over time. In contrast, investing in new components might provide long-term savings and improved reliability.

Performance and Longevity

Evaluating the operational efficiency of repaired items versus new ones is essential. While repairs can restore functionality, new components often enhance overall performance and extend the lifespan of the machinery. Weighing these aspects helps in making the ultimate choice.

Maintaining Your Backhoe Effectively

Proper upkeep of heavy machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns, saving time and money in the long run. Understanding the key aspects of maintenance can greatly contribute to the reliability of your equipment.

Key Maintenance Practices

To keep your machinery in top shape, consider implementing the following practices:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Inspect hydraulic, oil, and coolant levels to ensure proper functioning. |

| Filter Replacement | Monthly | Change air and fuel filters to prevent clogs and maintain performance. |

| Greasing | Every 50 hours | Lubricate all moving parts to reduce wear and tear. |

| Inspection of Tires | Monthly | Check for wear and proper inflation to ensure safety and efficiency. |

| Overall Inspection | Every 200 hours | Conduct a comprehensive review of all systems to identify potential issues. |

Benefits of Regular Maintenance

Investing time in routine care leads to improved operational efficiency, enhanced safety, and extended equipment lifespan. By staying proactive in maintenance, you can avoid costly repairs and ensure that your machinery remains a reliable asset on the job site.

Identifying Compatible Aftermarket Parts

When maintaining heavy machinery, ensuring the availability of suitable replacements is crucial for optimal performance and longevity. Aftermarket components can provide a viable alternative to original equipment, often at a reduced cost. However, selecting the right items requires careful consideration of compatibility to avoid operational issues.

To identify appropriate aftermarket components, begin by researching specifications and dimensions that align with the original models. Cross-referencing manufacturer catalogs can reveal options that meet or exceed the required standards. Additionally, consulting with trusted suppliers and industry forums can yield valuable insights and recommendations.

It is also important to evaluate the reputation of the aftermarket provider. Look for companies that offer warranties and have a history of reliability. User reviews and feedback can further guide the decision-making process, ensuring that the chosen alternatives deliver quality performance without compromising the integrity of the machinery.

Tips for Accurate Diagram Interpretation

Understanding technical illustrations is essential for effective maintenance and repair tasks. Accurate interpretation can significantly streamline your workflow and enhance the quality of your projects.

- Familiarize Yourself with Symbols: Different illustrations use unique symbols. Make sure to learn what each one represents.

- Identify Sections Clearly: Break down the illustration into manageable sections to avoid confusion.

- Use Reference Materials: Cross-check with manuals or other resources for context and additional information.

- Take Notes: Jot down key points as you study the illustration to reinforce your understanding.

- Ask for Help: If uncertain, consult experts or online forums for clarification on complex elements.

Applying these strategies will ensure you can delve into the details with confidence and achieve the ultimate accuracy in your tasks.

Historical Significance of Ford Equipment

The legacy of a renowned manufacturer in the machinery sector illustrates the profound impact of innovative engineering and design on various industries. Their equipment has played a pivotal role in transforming construction and agriculture, facilitating tasks that were once labor-intensive and time-consuming.

Over the decades, this company has not only enhanced productivity but also influenced the development of modern machinery through advancements in technology. Their commitment to quality and reliability has made their machines a staple in job sites worldwide.

| Era | Impact |

|---|---|

| 1920s-1930s | Introduction of versatile machines for agriculture |

| 1940s-1950s | Innovations in construction equipment |

| 1960s-1970s | Focus on operator comfort and safety |

| 1980s-Present | Integration of advanced technology and automation |

Customer Reviews on Parts Quality

This section explores feedback from users regarding the durability and performance of various components. Insights from customers provide a valuable perspective on reliability and overall satisfaction, helping potential buyers make informed decisions.

Overall Satisfaction

Many users express high levels of satisfaction with the longevity of their acquired components. Reviews often highlight that these items perform exceptionally well, exceeding expectations in demanding conditions.

Common Issues

While most feedback is positive, some customers note occasional discrepancies in fit and finish. These experiences underline the importance of careful selection and research prior to purchase, ensuring the best possible outcome.

Future of Backhoe Design Technology

The evolution of excavation machinery is poised for significant transformation, driven by advancements in technology and changing industry demands. Future innovations aim to enhance efficiency, safety, and sustainability, reshaping how these machines operate and integrate into various projects.

Technological Innovations

- Automation: Integration of AI to improve operational precision.

- Electric Power: Shift towards environmentally friendly energy sources.

- Smart Connectivity: Enhanced data analytics for real-time performance monitoring.

Sustainable Practices

- Use of recyclable materials in construction.

- Design improvements for reduced fuel consumption.

- Implementation of noise-reduction technologies.

These trends indicate a future where machinery not only meets the demands of productivity but also aligns with environmental goals, ultimately redefining the industry landscape.