Comprehensive Guide to Ford 6600 Parts Diagram

The world of heavy equipment is intricate, filled with a variety of essential elements that work in harmony to ensure optimal performance. Knowing how these components interact and function together is crucial for anyone involved in maintenance or operation. A clear representation of each element can significantly enhance the understanding of machinery design and efficiency.

In this exploration, we delve into a detailed representation that serves as a valuable resource for identifying and managing individual elements within a specific model. This resource not only aids in repairs and replacements but also promotes a deeper appreciation of the engineering behind these powerful machines. Recognizing each component’s role allows for more informed decisions when it comes to upkeep and enhancement.

For enthusiasts and professionals alike, mastering the layout of these vital pieces is an indispensable skill. It empowers users to troubleshoot effectively, ensuring that the machinery operates smoothly and reliably. The intricacies of these systems reveal a fascinating interplay between design and function, highlighting the importance of each part in achieving overall efficiency.

Understanding the Ford 6600 Parts Diagram

When working with complex machinery, having a clear visual representation of its components is essential. This overview provides insight into how various elements interconnect and function together, allowing for better maintenance and repairs. A comprehensive visual guide can significantly enhance your understanding of the equipment’s structure and mechanics.

Components and Their Functions

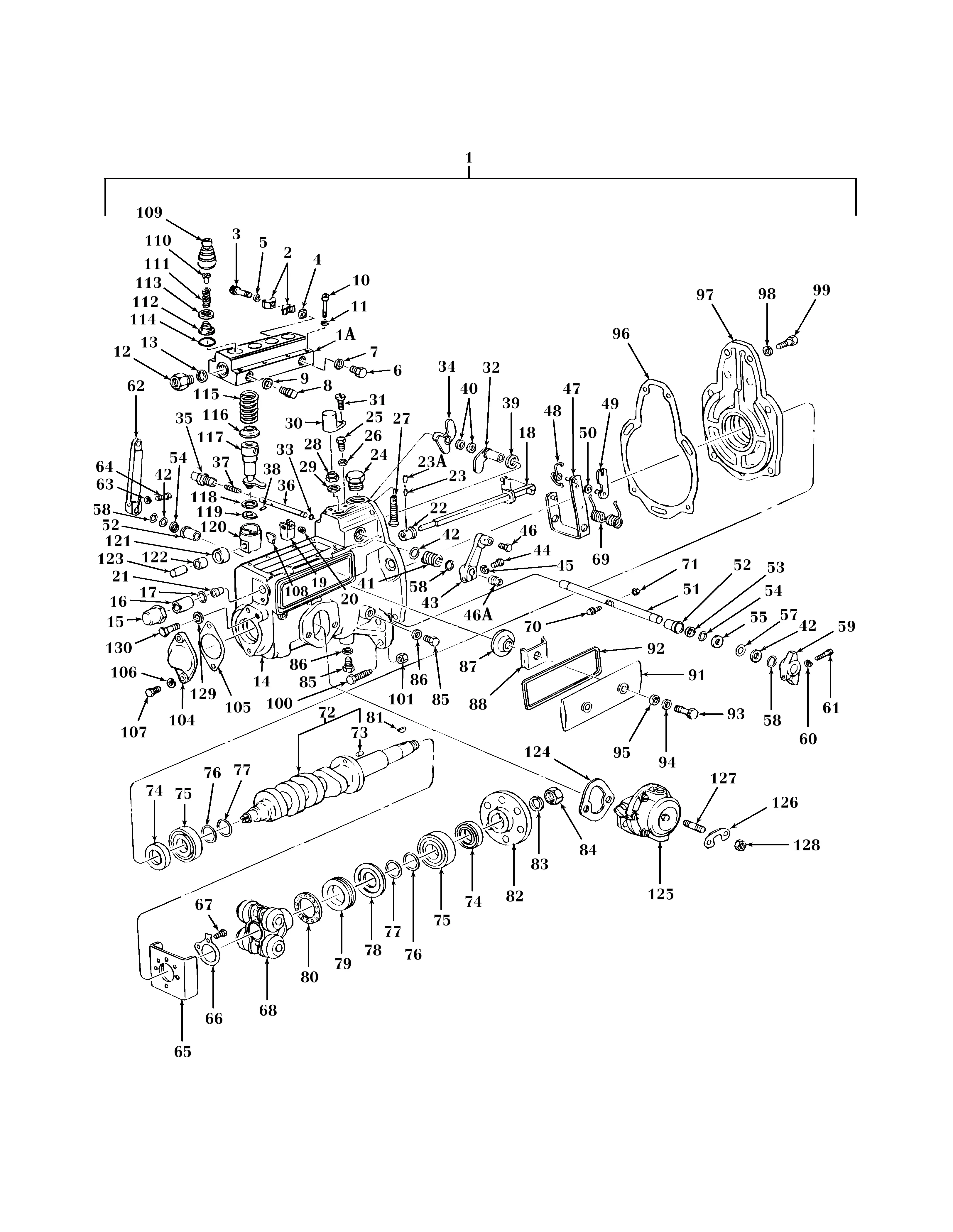

Every element within the machinery serves a specific purpose, from the engine assembly to the hydraulic systems. Familiarizing yourself with each section helps in diagnosing issues and performing effective upkeep. Recognizing these roles ensures that any repairs or replacements can be executed with confidence and precision.

Navigation and Identification

Utilizing a visual reference allows for easy identification of parts, streamlining the repair process. By following the schematic, operators can quickly locate components, understand their arrangement, and assess any required actions. This clarity not only saves time but also reduces the risk of errors during maintenance tasks.

Importance of Accurate Parts Identification

Precise identification of components is crucial for the efficient functioning of machinery. When individuals or technicians can accurately recognize each element, it leads to better maintenance, reduced downtime, and increased overall productivity. Misidentification can result in incorrect replacements, leading to further complications and costly repairs.

Moreover, understanding the specific attributes of each component ensures compatibility and enhances performance. It allows users to make informed decisions when sourcing replacements, ensuring they acquire the correct items for their needs.

| Benefits of Accurate Identification | Consequences of Misidentification |

|---|---|

| Enhanced operational efficiency | Increased downtime |

| Cost-effective maintenance | Higher repair costs |

| Improved safety | Potential hazards |

| Longer lifespan of equipment | Premature failure |

In conclusion, meticulous attention to detail in component identification not only fosters better maintenance practices but also contributes to the longevity and safety of the machinery. Investing time in understanding each element pays off significantly in the long run.

Common Issues with Ford 6600 Components

When it comes to machinery maintenance, understanding frequent problems associated with various elements is crucial for optimal performance. Identifying these issues early can prevent significant downtime and costly repairs. Below are some of the typical challenges faced by users of this particular model’s components.

| Component | Common Issues | Potential Solutions |

|---|---|---|

| Engine | Overheating, oil leaks | Regular oil changes, checking coolant levels |

| Transmission | Shifting difficulties, fluid leaks | Inspecting seals, ensuring proper fluid levels |

| Hydraulic System | Slow response, fluid contamination | Frequent filter changes, using clean fluid |

| Electrical System | Battery drainage, faulty wiring | Regular battery checks, inspecting connections |

Addressing these issues promptly not only extends the lifespan of machinery but also enhances overall efficiency. Regular maintenance and inspections can greatly mitigate many of these common challenges.

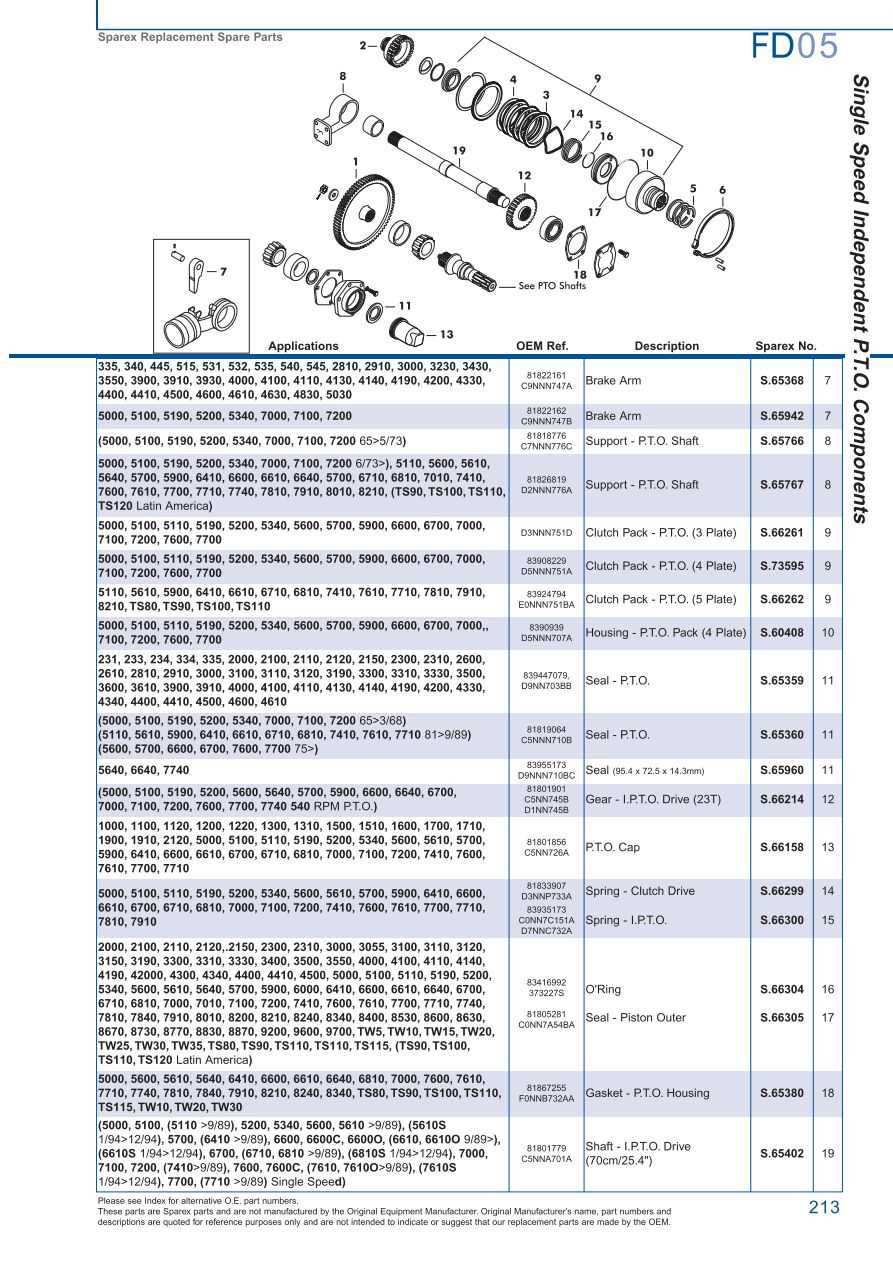

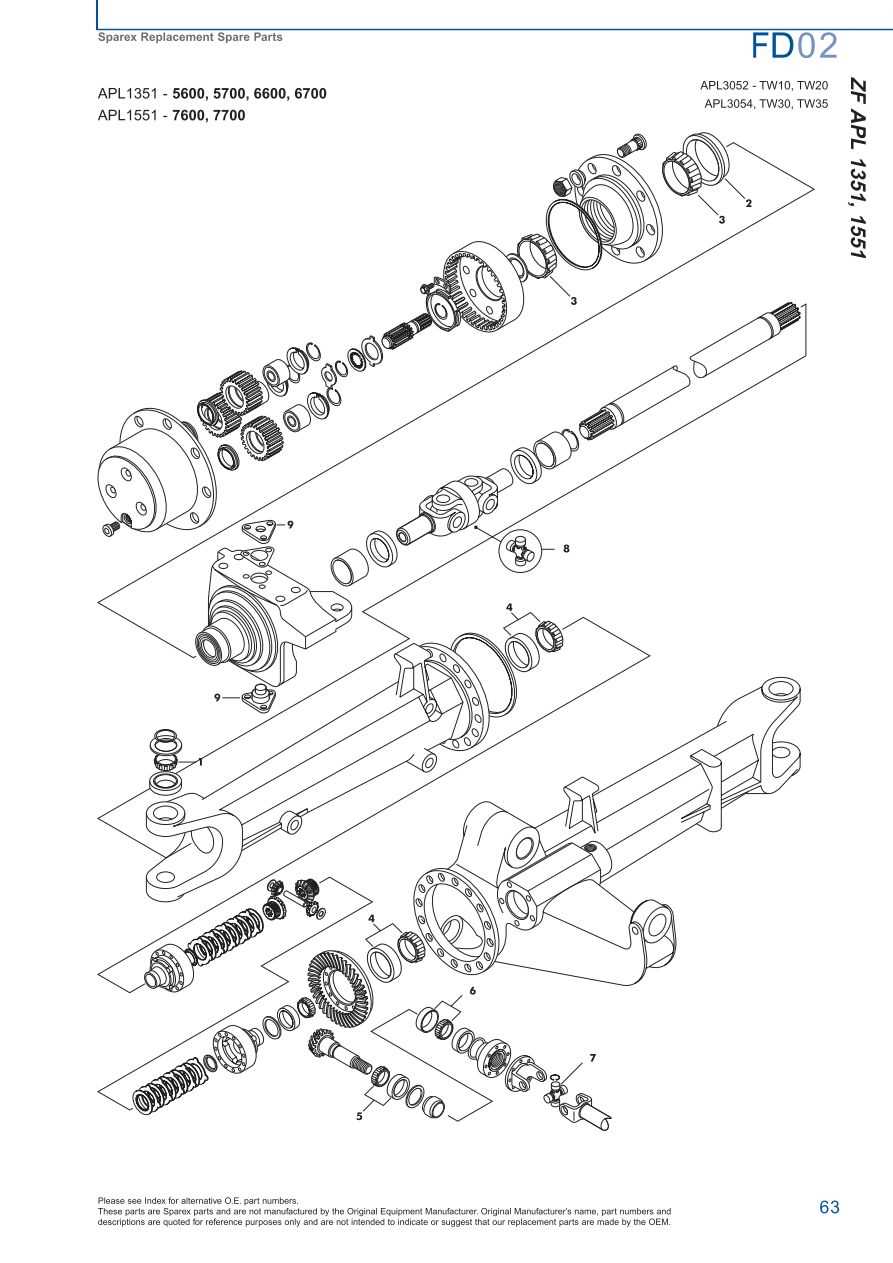

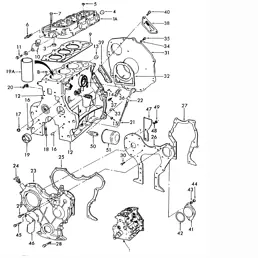

How to Read the Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and replace specific elements. This guide will help you navigate these illustrations effectively, ensuring you grasp the relationships and functions of various parts.

Start by examining the layout: Each section typically groups related items, which simplifies locating what you need. Look for numbers or letters that correspond to the list provided, as these will lead you to the exact components.

Pay attention to annotations: Descriptive notes often accompany the illustrations, providing additional context or specifications. This information can be crucial for understanding compatibility and installation requirements.

Familiarize yourself with symbols: Many diagrams employ standardized icons to represent different types of components. Learning these symbols can save you time and help prevent confusion during your search.

Cross-reference with manuals: For a deeper understanding, consult maintenance or repair guides that elaborate on the components shown. This can offer insight into the functionality and maintenance of the parts depicted.

Essential Tools for Parts Replacement

When it comes to swapping out components in machinery, having the right equipment is crucial for efficiency and safety. Whether you’re performing maintenance or upgrades, a well-prepared toolkit can make all the difference.

- Wrenches: Different sizes and types are necessary for loosening and tightening bolts.

- Screwdrivers: A variety of Phillips and flathead options will cover most fasteners.

- Pliers: Ideal for gripping and manipulating small parts.

- Jack Stands: Essential for safely elevating equipment.

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

Investing in high-quality tools not only improves the ease of replacement tasks but also enhances overall durability and performance of the equipment.

Where to Find Genuine Ford Parts

Finding authentic components for your machinery is crucial for maintaining its performance and longevity. Whether you’re a professional or a hobbyist, knowing the right places to source these items can save you time and money.

- Authorized Dealers: Visiting certified retailers ensures you receive high-quality products.

- Manufacturer Websites: Official online platforms often have extensive catalogs of available items.

- Online Marketplaces: Reputable sites provide a wide selection, but verify seller ratings.

- Local Shops: Small, specialized stores may have what you need and offer personalized service.

- Forums and Communities: Engage with fellow enthusiasts for recommendations and possible leads.

By exploring these avenues, you can confidently acquire the best options for your needs.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures superior quality and reliability. These items are designed specifically for compatibility with your machinery, leading to enhanced performance and longevity. By choosing these authentic replacements, you minimize the risk of malfunction and costly repairs.

Quality Assurance

Original components undergo rigorous testing and adhere to strict standards, providing peace of mind. This assurance translates into better overall performance, contributing to the efficient operation of your equipment.

Long-Term Value

Investing in genuine items can lead to significant savings over time. While the initial cost may be higher, the durability and reliability of these components often reduce maintenance needs and extend the lifespan of your machinery.

Comparing Aftermarket vs. Original Components

When it comes to machinery maintenance, the choice between replacement items can significantly impact performance and longevity. Understanding the differences between generic and manufacturer-specific components is essential for making informed decisions that align with your needs and budget.

Quality and Performance

Original components often come with a guarantee of quality, crafted to fit precisely and function optimally with the equipment. In contrast, aftermarket alternatives can vary widely in quality, with some providing excellent performance while others may fall short. Evaluating reviews and specifications is crucial when opting for non-original options.

Cost Considerations

Price differences are a key factor in this comparison. Aftermarket items are typically more affordable, which can be tempting for budget-conscious operators. However, it’s important to weigh the potential for increased wear or shorter lifespan against initial savings, as this may lead to higher costs in the long run.

Maintenance Tips for Ford 6600

Proper upkeep of your agricultural machinery is essential for longevity and optimal performance. Regular maintenance not only ensures efficient operation but also helps prevent costly repairs. By adopting a systematic approach to care, you can enhance productivity and reliability in your daily tasks.

Routine Inspections

Conduct regular checks on all components to identify wear and tear early. Focus on the engine, hydraulic system, and transmission. Keep an eye on fluid levels and replace filters as needed to maintain peak functionality.

Lubrication and Cleaning

Ensure all moving parts are well-lubricated to minimize friction and wear. Regularly clean the exterior and undercarriage to prevent the buildup of dirt and debris, which can lead to corrosion and damage over time.

Step-by-Step Replacement Process

This section outlines a clear procedure for successfully substituting components in agricultural machinery. Following these steps ensures both efficiency and safety during the replacement process.

Preparation

- Gather all necessary tools and new components.

- Consult the manual for specific instructions and safety precautions.

- Ensure the machinery is powered down and secured.

Replacement Steps

- Carefully remove the old component, taking note of its attachment points.

- Clean the area where the new part will be installed.

- Align the new component with the mounting brackets.

- Secure the new part using appropriate fasteners.

- Test the installation by running the machinery at low speed.

By adhering to this structured approach, you can effectively complete the replacement task with confidence.

How to Troubleshoot Common Problems

When dealing with machinery issues, it’s essential to adopt a systematic approach. Identifying and resolving common malfunctions can save time and enhance performance. This guide will outline typical challenges and offer solutions to help restore functionality.

Identifying Symptoms

Start by observing the machine’s behavior. Common indicators include unusual noises, lack of power, or unexpected shutdowns. Keep a checklist of symptoms to track patterns and potential causes.

Basic Troubleshooting Steps

| Issue | Possible Cause | Solution |

|---|---|---|

| No Start | Dead battery or fuel issue | Check battery connections and fuel levels |

| Overheating | Coolant leak or blocked radiator | Inspect for leaks and clean radiator |

| Poor Performance | Clogged filters | Replace air and fuel filters |

| Excessive Noise | Loose parts | Tighten or replace any loose components |

By following these steps and referring to your notes, you can effectively address common issues and enhance your equipment’s longevity.

Upgrading Your Ford 6600 Performance

Enhancing the capabilities of your agricultural machinery can lead to significant improvements in efficiency and productivity. Whether you’re looking to increase power, optimize fuel consumption, or improve overall handling, several strategies can be employed to elevate performance.

Engine Modifications play a crucial role in boosting power output. Consider upgrading to a high-performance air filter and exhaust system, which can enhance airflow and reduce back pressure. Additionally, tuning the engine control unit can optimize fuel delivery and ignition timing, resulting in better throttle response and increased horsepower.

Transmission Improvements can also make a notable difference. Installing a more efficient transmission system can lead to smoother gear shifts and improved torque management, allowing for better handling of heavy loads and varied terrains.

Suspension and Tires are vital for maintaining stability and traction. Upgrading to heavy-duty shock absorbers and quality tires designed for specific conditions can enhance ride quality and grip, contributing to safer and more efficient operation.

Finally, regular maintenance is essential for sustaining performance. Ensure that all components are in optimal condition by adhering to a consistent service schedule, addressing wear and tear promptly, and utilizing high-quality lubricants and fluids.