Understanding the Ford 8.8 Parts Diagram for Enhanced Performance

The intricacies of automotive mechanics often lie within the unseen elements that contribute to a vehicle’s performance. A crucial aspect of this system is the assembly responsible for transferring power from the driveshaft to the wheels. Recognizing the individual elements of this assembly can greatly enhance both maintenance and performance tuning efforts.

In this section, we will explore the essential components that make up this vital assembly. By delving into the specifics of each part, enthusiasts and professionals alike can gain insights into optimal operation and potential upgrades. Understanding the relationships between these elements can lead to improved efficiency and handling.

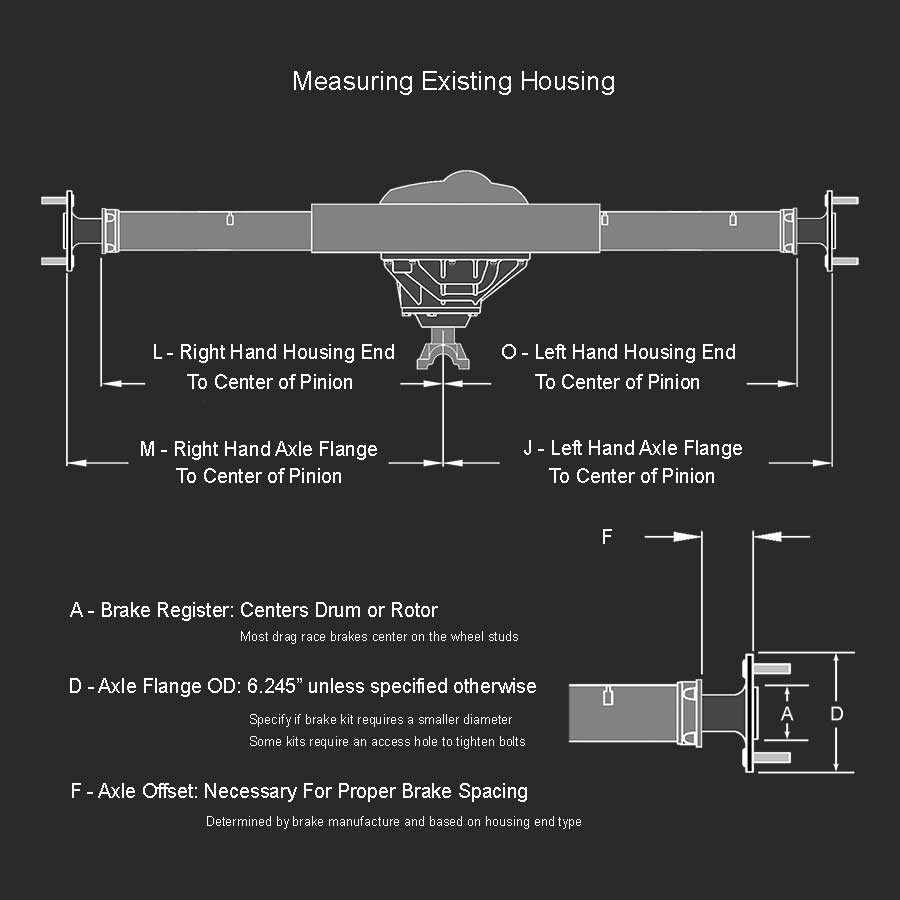

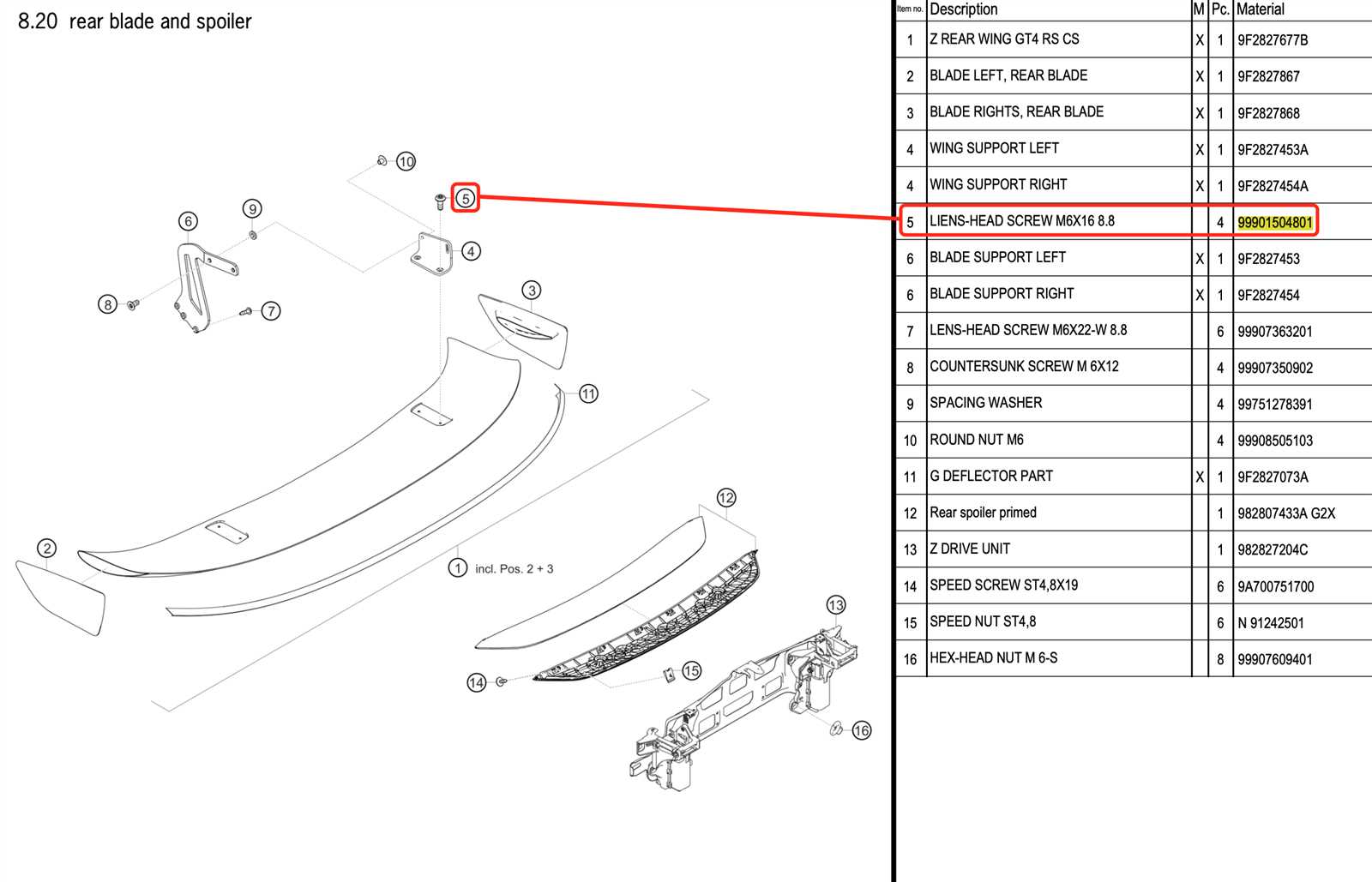

With detailed visual representations, one can easily identify and comprehend the functionality of various components. This knowledge is invaluable for anyone looking to undertake repairs or modifications, ensuring that each piece works harmoniously within the overall framework. Whether you are a seasoned mechanic or a budding hobbyist, familiarity with these components will empower your automotive endeavors.

Understanding the Ford 8.8 Differential

The differential is a crucial component in a vehicle’s drivetrain, playing a vital role in ensuring smooth operation during turns and varying speeds. This system allows wheels to rotate at different speeds, enhancing handling and stability while providing necessary power to the axles. An in-depth comprehension of this mechanism can aid in maintenance and performance tuning, making it essential for enthusiasts and technicians alike.

Key Features of the Differential

- Gear Set: The arrangement of gears that transmits power to the wheels, enabling smooth turns.

- Housing: The casing that protects internal components and maintains fluid integrity.

- Pinion and Ring Gear: Vital elements that transfer power from the driveshaft to the axle assembly.

- Limited Slip Options: Variations that improve traction by distributing torque more effectively between wheels.

Maintenance Considerations

- Regular fluid checks to ensure optimal lubrication and cooling.

- Inspection of seals and gaskets to prevent leaks.

- Monitoring gear wear for signs of damage or deterioration.

- Upgrading components for enhanced performance, especially in high-demand scenarios.

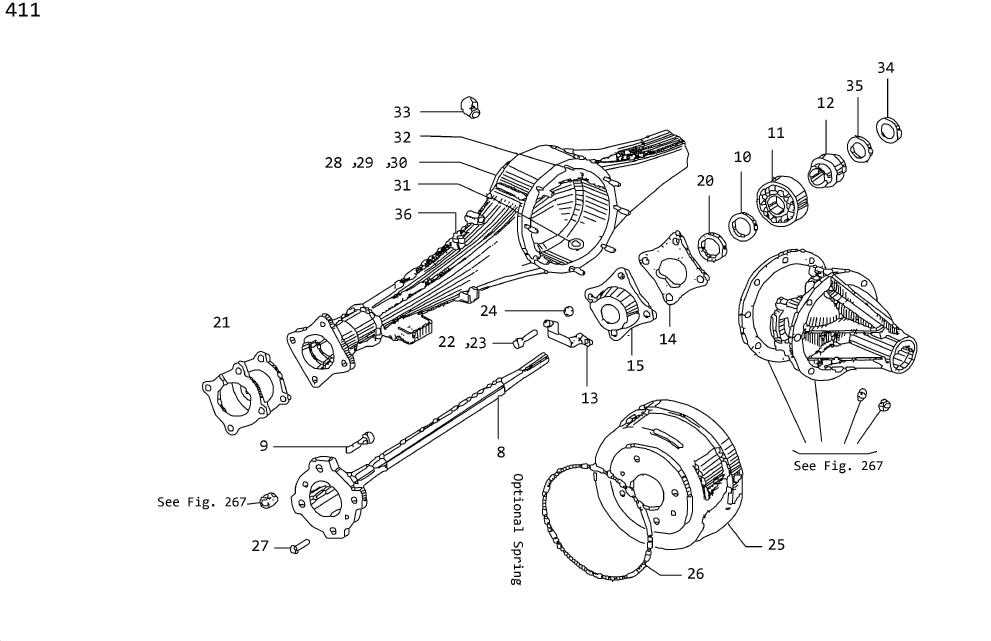

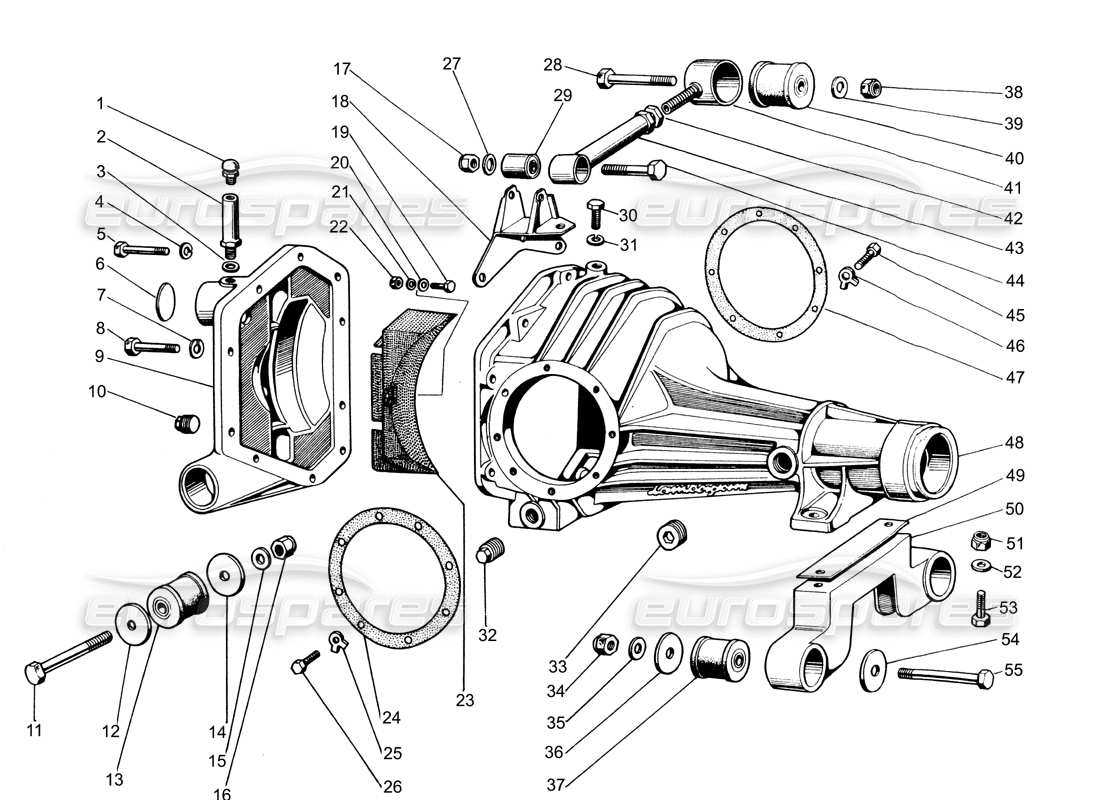

Components of the 8.8 Rear End

The assembly of a vehicle’s rear differential plays a crucial role in ensuring optimal performance and handling. Each element within this system is designed to work in harmony, contributing to the overall efficiency and reliability of the drivetrain.

Center Section: This is the heart of the assembly, housing the gears and the differential. It facilitates power transfer from the driveshaft to the axles, allowing for smooth acceleration and handling.

Ring Gear: This large gear engages with the pinion gear, converting rotational force from the driveshaft into the differential. Its size and tooth configuration are vital for torque distribution.

Pinion Gear: Mounted on the driveshaft, this smaller gear meshes with the ring gear. Its rotational speed is crucial for the overall gear ratio, affecting both acceleration and top speed.

Carrier Assembly: The carrier houses the differential gears, which enable wheel speed differentiation during turns. This component is essential for maintaining traction and stability.

Axles: These components transfer power from the differential to the wheels. Their design influences both strength and performance, particularly in high-torque situations.

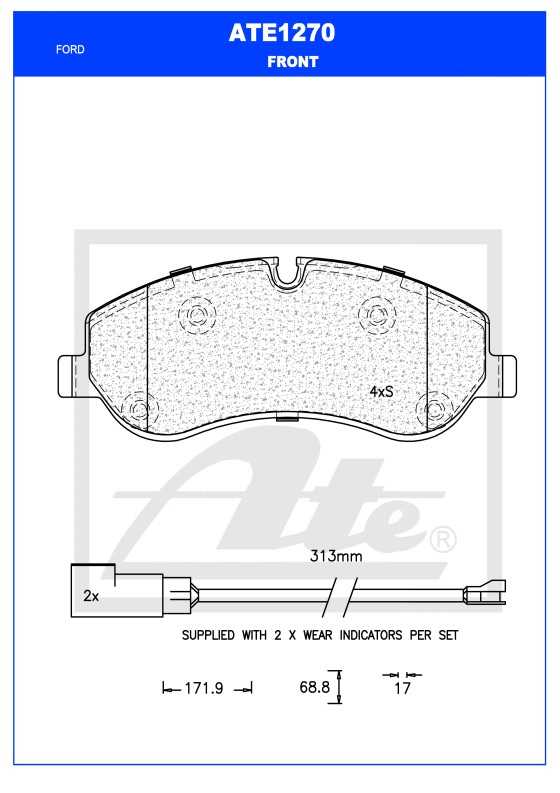

Wheel Bearings: Supporting the axle, these bearings reduce friction and wear, ensuring a smooth and stable ride. Proper maintenance of these components is key to longevity.

Seals and Gaskets: Essential for preventing fluid leaks, these components help maintain the integrity of the system. They are often overlooked but are critical for optimal operation.

Understanding the intricate relationships between these components is essential for any enthusiast or technician looking to enhance performance or carry out maintenance effectively.

Common Issues with the 8.8 System

When it comes to the rear axle assembly, various challenges can arise that affect performance and reliability. Understanding these common problems is crucial for any enthusiast or technician looking to maintain or upgrade their vehicle’s drivetrain.

Noise and Vibration: One prevalent issue is excessive noise or vibration during operation. This can stem from worn bearings or inadequate lubrication, leading to premature wear of critical components. Regular inspection and timely maintenance are essential to prevent escalation.

Fluid Leaks: Another concern is fluid leakage, which can occur due to degraded seals or gaskets. This not only affects the efficiency of the system but can also lead to more significant damage if not addressed promptly. Keeping an eye on fluid levels and addressing leaks early is key to ensuring longevity.

Gear Wear: Gear wear is also common, particularly in high-torque applications. Improper gear setup or poor-quality components can accelerate this issue, resulting in a loss of power transfer and potential failure. Regular checks and using quality parts can mitigate these risks.

Overheating: Overheating of the assembly is a serious problem that can arise from heavy use or insufficient cooling. This can lead to fluid breakdown and ultimately, component failure. Ensuring proper ventilation and using the correct type of lubricant are critical in preventing overheating.

By being aware of these typical issues, owners can take proactive steps to maintain their axle system, enhancing performance and extending its lifespan.

Upgrading Your 8.8 for Performance

Enhancing the capabilities of your rear axle can significantly improve your vehicle’s overall performance. By selecting the right components and modifications, you can achieve better power delivery, increased traction, and improved handling characteristics. This section explores essential upgrades that can elevate your setup to new heights.

Gear Ratios: One of the most impactful modifications involves adjusting the gear ratios. Opting for a lower numerical value can enhance acceleration, while a higher value can improve top speed. It’s essential to find the right balance based on your driving style and intended use.

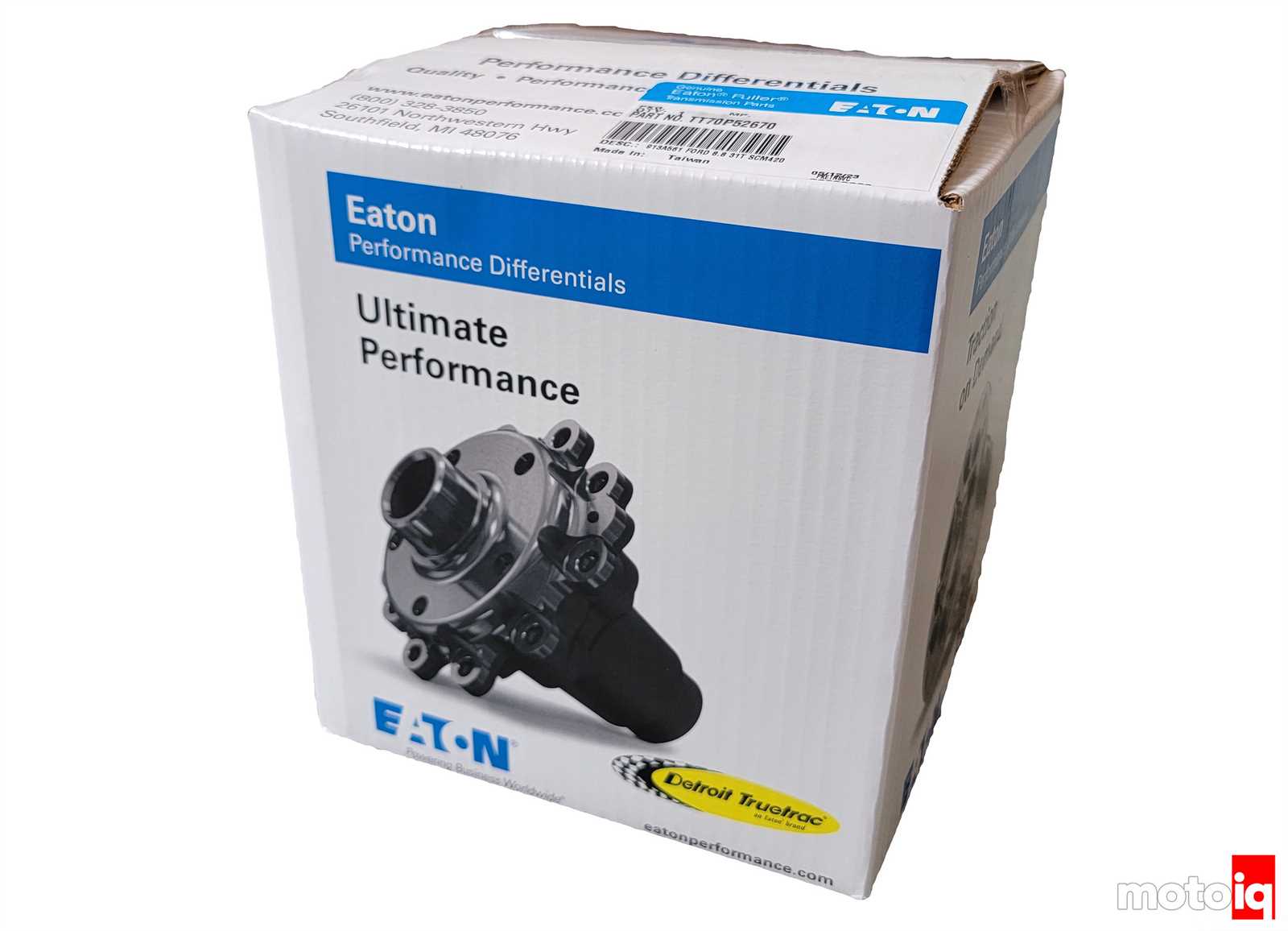

Limited Slip Differentials: Upgrading to a limited slip differential can dramatically increase traction, especially in high-performance scenarios. This modification allows for better power distribution to both wheels, reducing wheel spin during acceleration and improving cornering stability.

Strengthening Components: Reinforcing your setup with high-strength axles and housing can prevent failures during demanding conditions. Upgraded bearings and seals can also enhance durability, ensuring longevity even under stress.

Suspension Compatibility: Consider how your enhancements interact with the suspension system. Upgraded control arms and bushings can optimize alignment and handling, making your overall performance package more cohesive.

By focusing on these areas, you can transform your axle into a performance powerhouse, unlocking the potential for exhilarating driving experiences.

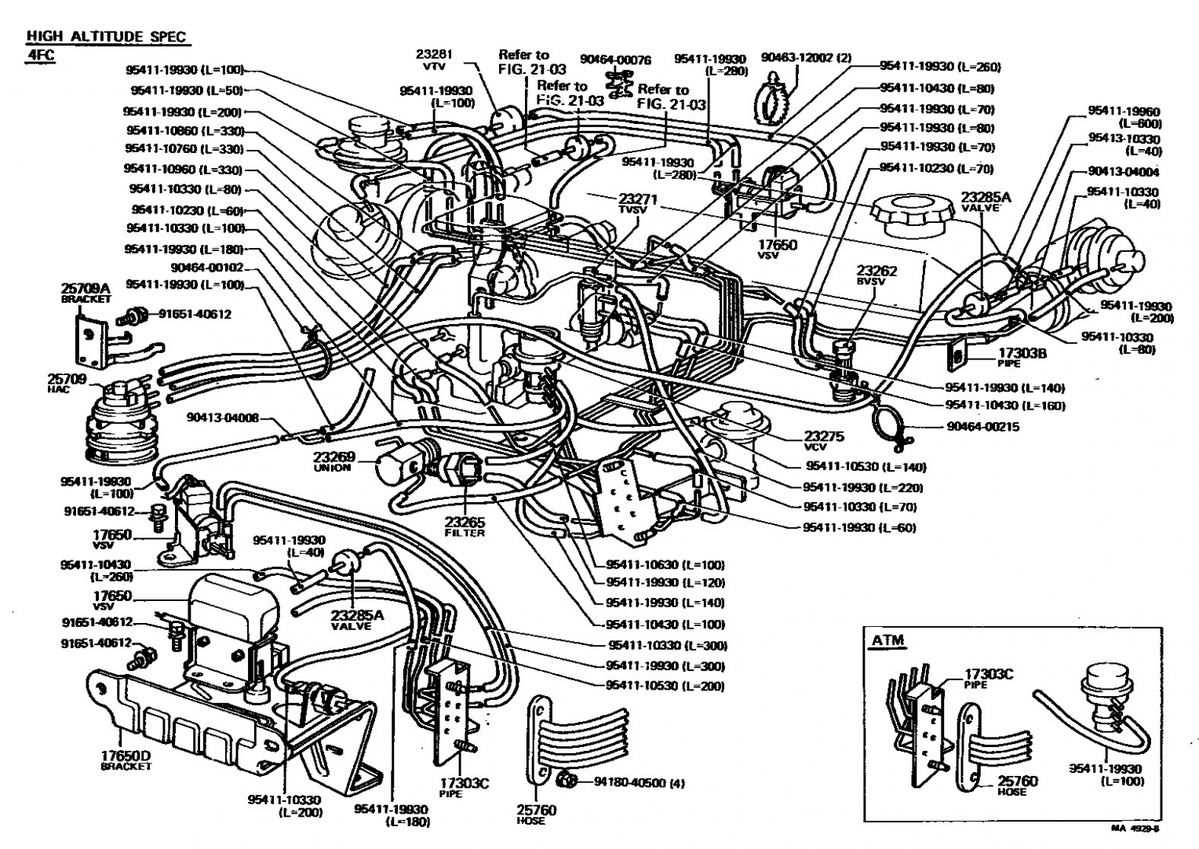

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to identify and locate components in a mechanical system. These visuals serve as guides, providing an organized representation of various elements and their relationships. By familiarizing yourself with the structure and notation used in these illustrations, you can simplify the process of maintenance and repairs.

When approaching these visuals, it’s essential to grasp the key components involved. The following table outlines common symbols and their meanings to help you navigate effectively:

| Symbol | Description |

|---|---|

| ⬤ | Represents a component or assembly |

| → | Indicates direction of movement or flow |

| Denotes a fastening element | |

| ⚙️ | Symbolizes a rotating part |

| Indicates measurement specifications |

By recognizing these symbols and understanding their context, you’ll be better equipped to interpret the information presented. This skill not only aids in identifying necessary elements but also enhances your overall comprehension of the system as a whole.

Essential Tools for 8.8 Maintenance

Maintaining a reliable rear axle system requires a set of specialized tools designed to ensure precision and efficiency. Proper equipment not only simplifies the maintenance process but also enhances the longevity and performance of the assembly. Below is a compilation of essential tools that every enthusiast should consider when working on this type of drivetrain component.

Basic Hand Tools

- Socket Wrench Set: For loosening and tightening bolts with ease.

- Torque Wrench: To ensure proper tightening according to manufacturer specifications.

- Adjustable Wrench: Useful for various sizes of nuts and bolts.

- Screwdrivers: Both flathead and Phillips for removing cover plates and other components.

Specialized Equipment

- Diff Cover Gasket Tool: For ensuring a proper seal when replacing the differential cover.

- Pinion Depth Gauge: To measure and adjust the pinion depth accurately.

- Bearing Puller: For removing bearings without causing damage.

- Magnetic Oil Drain Plug: Helps catch metal particles during oil changes, aiding in diagnosis.

Equipping yourself with the right tools can make a significant difference in the effectiveness of maintenance tasks, leading to a smoother and more reliable driving experience.

Comparing the 8.8 to Other Models

The analysis of various rear axle configurations reveals significant differences in performance, strength, and versatility. Each design serves specific purposes and caters to distinct vehicle requirements, making it essential for enthusiasts and builders to understand these variations.

Furthermore, aftermarket support plays a vital role in the popularity of certain designs. Some configurations have a wide array of enhancements available, allowing for greater customization and tuning options. In contrast, others may lack the same level of aftermarket parts, limiting modification potential.

Ultimately, the choice between these axle types often depends on the intended use of the vehicle, whether for daily driving, racing, or off-road adventures. Understanding these distinctions ensures that enthusiasts select the most suitable assembly for their specific needs.

Aftermarket Parts for Enhanced Durability

Upgrading your vehicle’s components can significantly improve its longevity and performance. The market offers a wide array of alternatives designed to withstand extreme conditions and provide reliable service. By investing in superior-quality replacements, enthusiasts can enhance their ride’s resilience and reliability.

When considering enhancements, it’s crucial to focus on specific areas that typically experience wear and tear. Here are some popular aftermarket options that can boost durability:

- Heavy-Duty Bearings: Reinforced bearings can handle greater loads, reducing friction and extending lifespan.

- Performance Differentials: Upgraded differentials provide better traction and stability, especially in demanding situations.

- High-Strength Axles: Stronger axles can endure more power and torque, minimizing the risk of breakage.

- Reinforced Housings: Enhanced housings help prevent distortion and failure under pressure.

- Premium Seals and Gaskets: Better sealing components reduce the risk of leaks and contamination, ensuring optimal performance.

Incorporating these modifications can lead to a significant increase in the overall durability of your vehicle. It is essential to choose reputable manufacturers and products to ensure compatibility and effectiveness. Proper installation and regular maintenance will further enhance the benefits of these upgrades, providing peace of mind on the road.

Step-by-Step Rebuild Process

Rebuilding a differential can significantly enhance your vehicle’s performance and longevity. This process involves a series of meticulous steps to ensure everything functions optimally. Below is a detailed guide to walk you through the rebuilding procedure.

- Preparation

- Gather necessary tools: wrenches, sockets, screwdrivers, and a torque wrench.

- Secure a clean workspace with ample lighting.

- Acquire a rebuild kit specific to your model.

- Disassembly

- Remove the differential cover by unbolting it carefully.

- Drain the fluid and discard it properly.

- Take out the ring gear and carrier assembly.

- Inspect components for wear and damage.

- Cleaning

- Use solvent to clean all metal parts thoroughly.

- Inspect and clean the housing to eliminate any debris.

- Replacement of Components

- Replace bearings, seals, and gaskets with new ones from your kit.

- Install new ring and pinion gears if necessary.

- Reassembly

- Reassemble the carrier and ring gear, ensuring proper alignment.

- Carefully reinstall the differential cover and tighten bolts to specifications.

- Fluid Replacement

- Fill with appropriate gear oil as recommended.

- Check for leaks around seals and gaskets.

- Final Inspection

- Spin the wheels to check for smooth operation.

- Test drive to ensure everything functions correctly.

cssCopy code

Following these steps carefully will help you achieve a successful rebuild, ensuring that your differential operates smoothly and efficiently for years to come.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and performance of any mechanical component. By following a structured maintenance routine, you can significantly extend the lifespan of your equipment and enhance its reliability.

- Regular Inspections: Schedule frequent checks to identify any signs of wear or damage. Look for leaks, cracks, or unusual noises that may indicate issues.

- Fluid Changes: Maintain optimal performance by regularly replacing lubricants and fluids. Follow the recommended intervals for changes to prevent overheating and friction.

- Cleaning: Keep all surfaces free of debris and contaminants. Regular cleaning helps prevent corrosion and other damage that can compromise function.

- Torque Specifications: Ensure all fasteners are tightened to the manufacturer’s specifications. Proper torque helps maintain structural integrity and prevents components from loosening over time.

- Use Quality Parts: When replacements are necessary, opt for high-quality components. Inferior materials can lead to premature failure and may negate any maintenance efforts.

By implementing these practices, you can enhance the reliability of your mechanical systems, ensuring they perform optimally for years to come.

Resources for 8.8 Owners

For enthusiasts and owners of specific automotive components, having access to reliable resources is essential. Whether you’re looking for maintenance tips, upgrades, or troubleshooting assistance, a variety of tools and information are available to enhance your experience and ensure your vehicle performs optimally.

Online Forums: Engaging with fellow owners through dedicated online communities can provide invaluable insights. These forums often feature discussions on common issues, modification ideas, and solutions that can help you navigate any challenges you may encounter.

Repair Manuals: Comprehensive manuals are crucial for understanding the intricacies of your equipment. They typically include detailed instructions, specifications, and troubleshooting guides, making them indispensable for DIY repairs and upgrades.

Manufacturer Websites: Official sites often provide resources such as technical specifications, recalls, and service bulletins. These documents can keep you informed about the latest developments and ensure that your vehicle adheres to safety standards.

Video Tutorials: Platforms like YouTube offer a plethora of instructional videos, ranging from basic maintenance to advanced modifications. Visual aids can make complex procedures more approachable and easier to follow.

Local Shops and Specialists: Building relationships with local mechanics or specialists who have experience with your type of equipment can lead to personalized advice and service. They can also recommend quality aftermarket products tailored to your needs.

Utilizing these resources will not only enhance your knowledge but also contribute to a more enjoyable ownership experience, ensuring that you get the most out of your investment.