Comprehensive Guide to Ford Ranger Frame Parts Diagram

The intricacies of automotive design play a crucial role in ensuring durability and performance. Recognizing the components that make up a vehicle’s skeletal system is essential for both enthusiasts and those seeking to maintain their machinery. A comprehensive understanding of these elements can significantly enhance the overall experience of ownership and repair.

Within this section, we delve into the essential elements that contribute to the integrity and functionality of a vehicle. Each component serves a specific purpose, and knowing how they interrelate is vital for anyone interested in automotive maintenance or upgrades. This knowledge can empower owners to make informed decisions when it comes to repairs or modifications.

By exploring the layout and organization of these critical components, readers will gain valuable insights into the engineering behind their vehicles. This exploration not only aids in understanding potential issues but also fosters a deeper appreciation for the craftsmanship involved in vehicle production. Prepare to uncover the essential building blocks that keep your automobile on the road and performing at its best.

Understanding the Ford Ranger Frame

Grasping the structure that underpins a vehicle is essential for anyone interested in its performance and longevity. This skeletal framework plays a crucial role in supporting various components while providing stability and safety during operation. A comprehensive look at this foundation reveals its importance in both design and function.

Structure is vital to any automobile, as it determines how weight is distributed and impacts handling. The configuration of this essential component influences everything from ride quality to the vehicle’s ability to withstand external forces. Understanding how different sections interact can illuminate maintenance needs and potential upgrades.

Maintenance is another key aspect of this discussion. Regular inspection and timely repairs can prevent larger issues and ensure the vehicle remains in optimal condition. Recognizing common wear points allows owners to be proactive rather than reactive, ultimately extending the lifespan of the entire machine.

In summary, a deep understanding of this integral system is indispensable for enthusiasts and owners alike. Knowledge in this area not only enhances appreciation for engineering but also informs better care and enhancement of the vehicle’s overall performance.

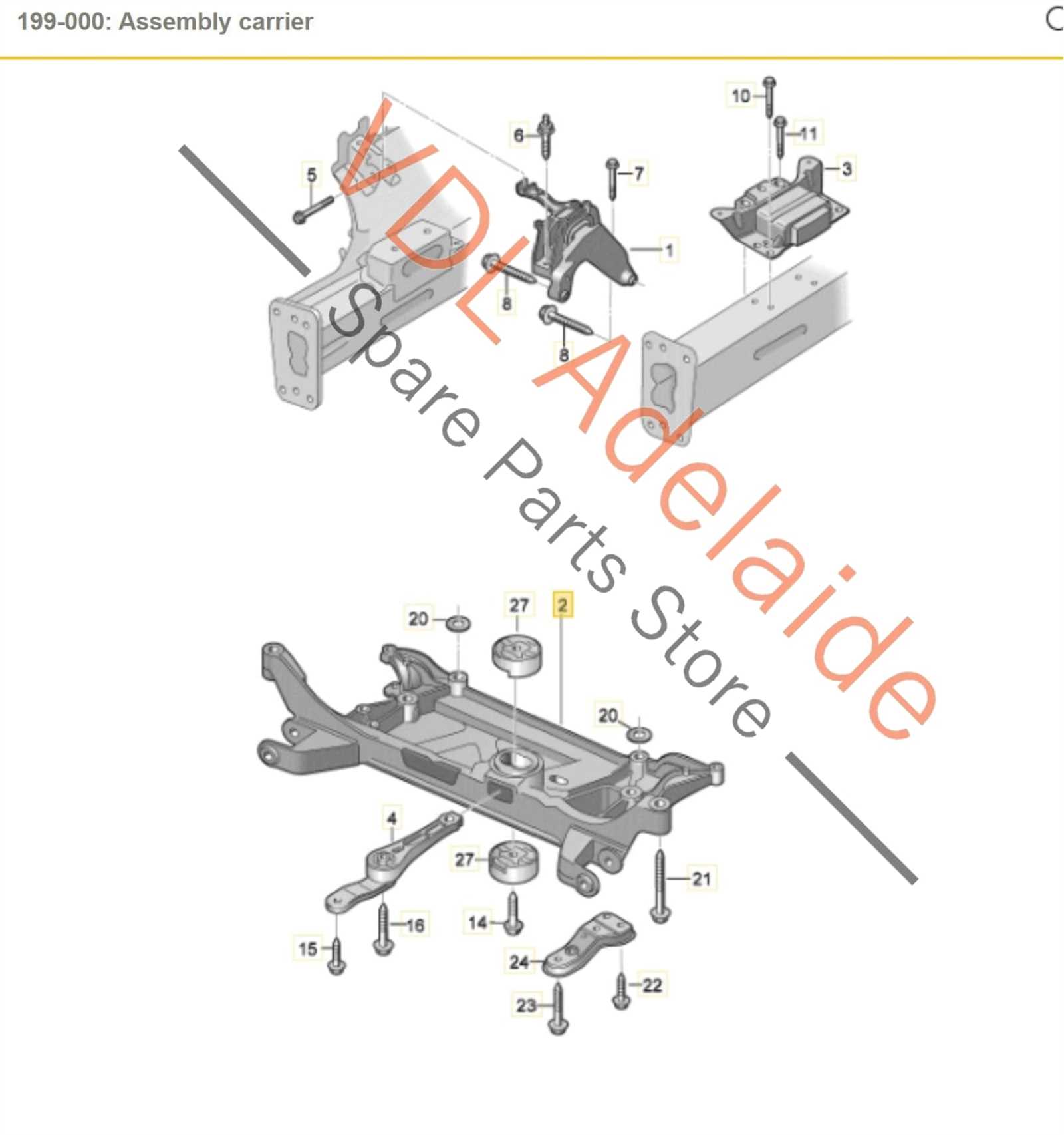

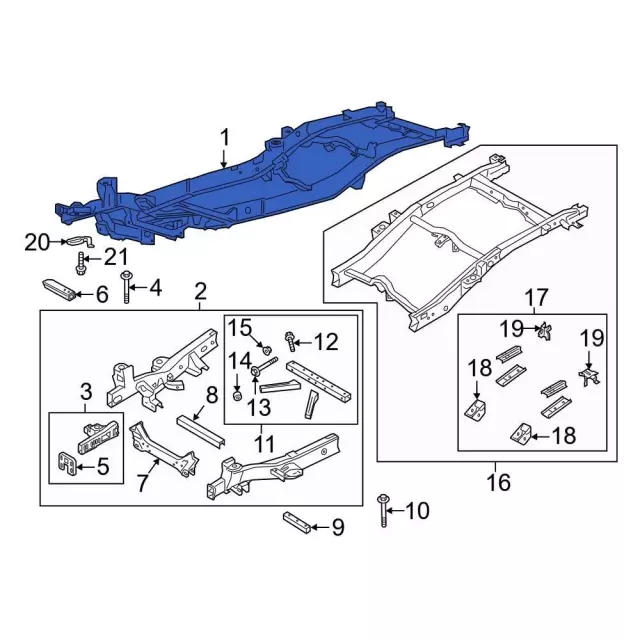

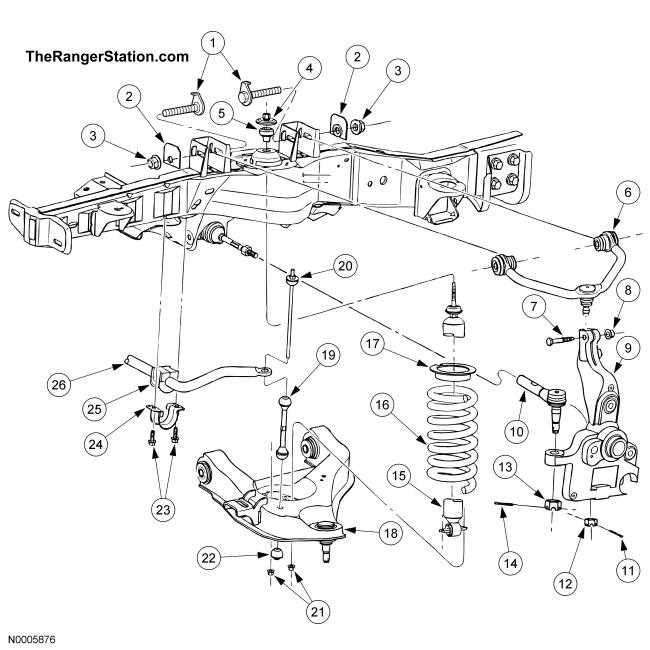

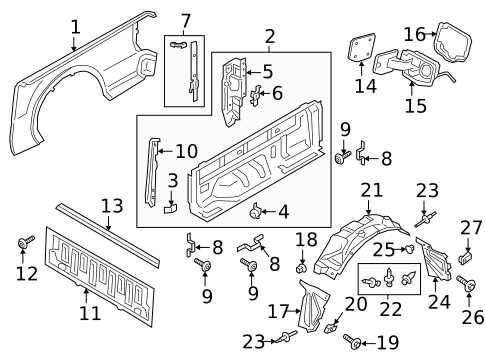

Key Components of the Frame

The structural integrity of any vehicle relies heavily on its foundational elements. These components play a crucial role in supporting the overall architecture, ensuring stability, and enhancing safety. Understanding these vital elements can provide insight into how a vehicle withstands various stresses and strains during operation.

Crossmembers serve as horizontal supports, connecting the vertical structures and distributing loads evenly. They are essential for maintaining rigidity and preventing flex during movement.

Rails form the primary longitudinal support, running along the sides. Their robust design is crucial for absorbing impacts and providing a solid base for mounting various assemblies.

Suspension Mounts are critical attachment points for the vehicle’s suspension system. They must be engineered to withstand dynamic forces and ensure a smooth ride.

Reinforcements are strategically placed to enhance strength in high-stress areas. These additions help to improve durability and resistance to deformation over time.

Understanding these fundamental elements enhances appreciation for the engineering involved in vehicle design, ultimately contributing to performance and safety.

Importance of Frame Parts

The structural components of a vehicle play a crucial role in ensuring safety, stability, and overall performance. These elements serve as the backbone, providing necessary support and integrity to the entire system. Without robust construction, a vehicle may suffer from reduced efficiency and increased vulnerability to external forces.

Durability is one of the primary reasons why these structural components are vital. They are engineered to withstand various stresses and strains encountered during operation. High-quality materials enhance longevity, making sure that the vehicle can endure harsh conditions over time.

Safety is another critical aspect linked to these structural elements. In the event of an impact, the way a vehicle is constructed can significantly affect the outcome for its occupants. Well-designed supports absorb shock effectively, minimizing potential injuries and ensuring passenger protection.

Furthermore, the performance of the vehicle can be directly influenced by the integrity of these components. A well-constructed framework allows for better handling, stability, and alignment, leading to a smoother driving experience. Regular maintenance and inspections of these structural elements can prevent issues that might compromise performance.

In summary, the significance of these foundational elements cannot be overstated. They contribute to a vehicle’s durability, safety, and overall functionality, making them essential for anyone seeking reliability on the road.

How to Identify Frame Damage

Recognizing structural impairment in a vehicle is crucial for ensuring safety and performance. Damage to the chassis can lead to serious issues, affecting handling and stability. Understanding the signs of such impairment can save both time and money in repairs.

Visual Inspection

Start with a thorough visual examination. Look for cracks, bends, or any signs of deformation. Pay attention to the welds and joints; any irregularities may indicate underlying problems. Additionally, inspect for rust or corrosion, which can weaken the structure over time.

Alignment and Handling Tests

After conducting a visual check, assess how the vehicle behaves on the road. Uneven tire wear or difficulty in steering can be indicators of structural issues. If the vehicle pulls to one side or has a noticeable vibration, these could be signs of serious alignment problems. Consider consulting a professional for a comprehensive evaluation if any abnormalities are detected.

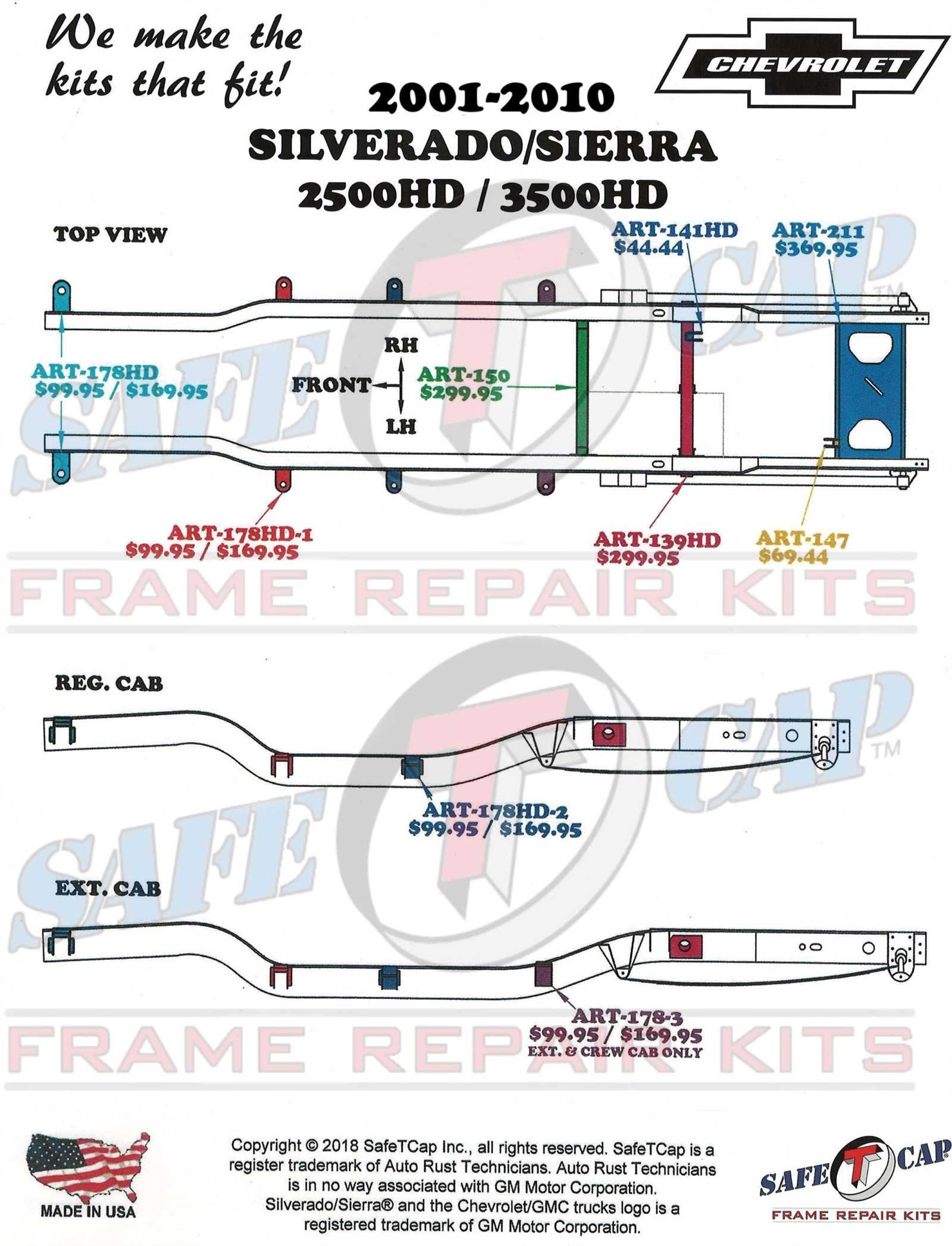

Common Frame Repair Techniques

Repairing structural components is essential for maintaining vehicle integrity and safety. Various methods can be employed to address damage, ensuring that the foundation remains strong and reliable. Understanding these techniques can help in selecting the most appropriate solution for specific issues.

One of the most common methods is straightening, which involves the use of specialized equipment to restore bent sections to their original alignment. This process typically requires precise measurements and adjustments to ensure that all dimensions meet manufacturer specifications.

Welding is another prevalent technique, often used to fix cracks or breaks in the structure. Skilled technicians can apply different types of welding depending on the materials involved, ensuring a robust bond that can withstand the stresses of daily use.

Reinforcement may be necessary in cases where structural integrity is compromised. This can involve adding additional material to strengthen weakened areas, providing extra support where needed to enhance overall durability.

In more severe situations, component replacement might be the only viable option. Identifying and sourcing the correct replacements ensures that the vehicle maintains its performance and safety standards after repairs.

Finally, thorough inspections following any repair work are crucial. Regular assessments help identify potential issues early, allowing for timely interventions that can prevent further damage and extend the lifespan of the vehicle.

Tools Needed for Frame Work

When engaging in structural modifications or repairs, having the right set of tools is crucial for achieving precision and safety. Various implements are required to ensure that every task is executed effectively, minimizing the risk of errors and enhancing the overall quality of the work.

Essential Hand Tools

Basic hand tools play a vital role in any construction or repair project. These tools provide the necessary leverage and control for intricate tasks.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts and nuts. |

| Screwdrivers | To drive screws into various surfaces. |

| Pliers | For gripping and twisting components. |

| Jack | To lift heavy parts safely off the ground. |

Power Tools for Efficiency

In addition to hand tools, power tools can significantly expedite the process and provide enhanced capabilities for more demanding tasks.

| Tool | Function |

|---|---|

| Impact Wrench | To quickly remove or fasten bolts with minimal effort. |

| Circular Saw | For cutting through metal and other materials with precision. |

| Grinder | To smooth and shape surfaces effectively. |

| Drill | For creating holes in various materials for fasteners. |

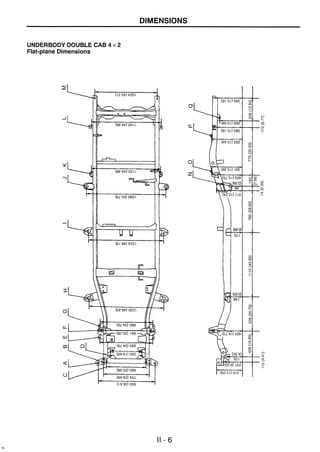

Step-by-Step Frame Inspection Guide

Conducting a thorough evaluation of your vehicle’s structural integrity is essential for safety and performance. This guide outlines a systematic approach to identifying potential issues, ensuring your automobile remains reliable and secure on the road.

Preparation and Tools

Before starting the inspection, gather the necessary tools, including a flashlight, measuring tape, and a comprehensive checklist. Ensure the vehicle is parked on a flat surface and is securely elevated using jack stands to allow for safe access to the underside.

Inspection Steps

Begin by visually assessing the entire structure for any signs of damage, such as bends, cracks, or corrosion. Pay close attention to critical areas, including junction points and welds. Next, measure specific sections to verify alignment and ensure that they meet manufacturer specifications. Document any findings for further evaluation or repair, and consult a professional if significant issues are detected.

Comparing Different Ranger Models

This section delves into the various iterations of a popular utility vehicle, highlighting their unique features, performance capabilities, and design elements. Understanding the distinctions among these models can aid potential buyers in making an informed choice that best suits their needs and preferences.

Engine Options and Performance

Diverse models offer a range of engine specifications, from economical four-cylinder units to robust V6 options. Each variant provides different power outputs and fuel efficiency levels, catering to both daily commuting and heavy-duty tasks. Enthusiasts often appreciate the balance between torque and handling, which enhances the overall driving experience.

Interior Features and Comfort

The cabin design varies significantly across the lineup, with certain editions emphasizing luxury and advanced technology, while others focus on practicality and durability. Features such as infotainment systems, seating materials, and cargo space play crucial roles in determining the comfort and usability of each model, making it essential to consider personal preferences when evaluating options.

Aftermarket Frame Parts Overview

The market for replacement components has expanded significantly, providing enthusiasts and professionals with a wide array of choices. These enhancements not only improve the performance and durability of vehicles but also allow for personalization. Understanding the options available is crucial for making informed decisions when upgrading or repairing essential structural elements.

Types of Aftermarket Components

Various aftermarket options cater to different needs and preferences. Below are some common types of components available:

| Component Type | Description |

|---|---|

| Crossmembers | Structural supports that enhance rigidity and stability. |

| Brackets | Attachments that secure various elements, providing added strength. |

| Reinforcements | Additional materials designed to bolster weak areas for improved durability. |

| Mounting Kits | Assemblies that facilitate the secure installation of various components. |

Benefits of Aftermarket Options

Choosing replacement components can yield numerous advantages. Enhanced performance, improved longevity, and customization opportunities are just a few benefits. Additionally, aftermarket solutions often come with better pricing and availability compared to original equipment options, making them an appealing choice for many vehicle owners.

OEM vs. Aftermarket Options

When it comes to choosing components for your vehicle, the decision often lies between original equipment manufacturer (OEM) and alternative solutions. Each option has its own set of advantages and considerations that can impact performance, longevity, and budget.

Advantages of OEM Components

- Designed to meet specific manufacturer standards.

- Typically offer a warranty that covers defects and issues.

- Ensures compatibility with your vehicle’s existing systems.

- Often made from high-quality materials, enhancing durability.

Benefits of Aftermarket Solutions

- Generally more cost-effective, providing savings for the consumer.

- Wide variety of options, allowing for customization and upgrades.

- Potential for improved performance and innovative features.

- Availability from multiple retailers, increasing accessibility.

Ultimately, the choice between OEM and aftermarket options depends on your specific needs, budget, and performance goals. Assessing the pros and cons of each can help you make an informed decision that best suits your vehicle’s requirements.

Maintenance Tips for Frame Longevity

Ensuring the durability of your vehicle’s structure is essential for optimal performance and safety. Regular care and attention can significantly extend the lifespan of these crucial components, preventing costly repairs and maintaining overall integrity.

Here are some effective maintenance strategies:

- Regular Inspections: Schedule routine checks to identify signs of wear or damage. Look for rust, cracks, or misalignments.

- Rust Prevention: Apply protective coatings to shield against moisture and corrosive elements. Consider using sealants in vulnerable areas.

- Keep It Clean: Regularly wash the underside of your vehicle to remove dirt, salt, and debris that can lead to corrosion.

- Check for Tightness: Ensure that all connections and bolts are secure, as loose components can cause additional stress.

- Professional Servicing: Seek assistance from professionals for comprehensive inspections and maintenance services.

By following these guidelines, you can significantly enhance the durability of your vehicle’s supporting structure and ensure a safer driving experience.

Frame Modifications for Off-Roading

Enhancing the structural components of a vehicle is essential for those who venture into rugged terrains. These upgrades not only improve durability but also significantly boost performance in challenging conditions. By reinforcing and modifying key elements, off-road enthusiasts can ensure their vehicles handle obstacles with greater stability and resilience.

Strengthening the Chassis is one of the primary focuses for off-road modifications. Adding additional cross-members or utilizing heavier materials can enhance rigidity, allowing the vehicle to better withstand the stress of uneven surfaces and harsh impacts.

Upgrading Suspension Systems is another critical aspect. Incorporating long-travel suspension kits enables better articulation, improving ground clearance and allowing for larger tires. This modification is vital for tackling rocky paths and deep ruts without damaging the vehicle.

Reinforcing Attachment Points for bumpers and skid plates can provide additional protection against debris and potential collisions. Stronger mounting options prevent failure during high-impact situations, ensuring essential components remain secure.

In summary, strategic enhancements to a vehicle’s structural integrity can make a substantial difference in off-road capabilities. Investing in quality modifications not only prolongs the lifespan of the vehicle but also elevates the overall driving experience in the great outdoors.

Resources for Frame Parts Diagrams

This section provides valuable tools and references for understanding the structure and components of vehicle underpinnings. Accessing accurate illustrations and schematics is essential for repairs and modifications, ensuring that users can identify and source necessary elements effectively.

Below is a table highlighting various resources available for locating detailed visual references and guides:

| Resource Type | Description | Link |

|---|---|---|

| OEM Manuals | Original Equipment Manufacturer manuals provide comprehensive guides including diagrams and specifications. | OEM Manuals |

| Online Forums | Community-driven platforms where enthusiasts share insights, images, and repair tips. | Online Forums |

| Repair Websites | Dedicated sites offering detailed schematics and instructional content for various vehicle models. | Repair Websites |

| Automotive Publications | Books and magazines that include guides and illustrations for DIY repairs. | Automotive Publications |

Utilizing these resources will enhance your understanding and facilitate better decision-making when it comes to vehicle maintenance and upgrades.