Understanding Ford Select-O-Speed Components

When delving into the intricacies of automotive systems, one finds that a clear representation of mechanical elements is essential for effective maintenance and repair. An accurate schematic provides valuable insights into the arrangement and function of various components within a transmission system.

This section aims to illuminate the critical elements involved in the operation of specific transmission systems, highlighting how each part contributes to overall performance. By grasping the layout and interaction of these elements, enthusiasts and technicians alike can enhance their understanding and efficiency in handling such systems.

Moreover, familiarizing oneself with the configuration of components allows for more informed decisions regarding upgrades, replacements, and repairs. Whether one is a seasoned mechanic or a dedicated hobbyist, knowledge of the underlying structure will undoubtedly lead to improved outcomes in vehicle functionality and longevity.

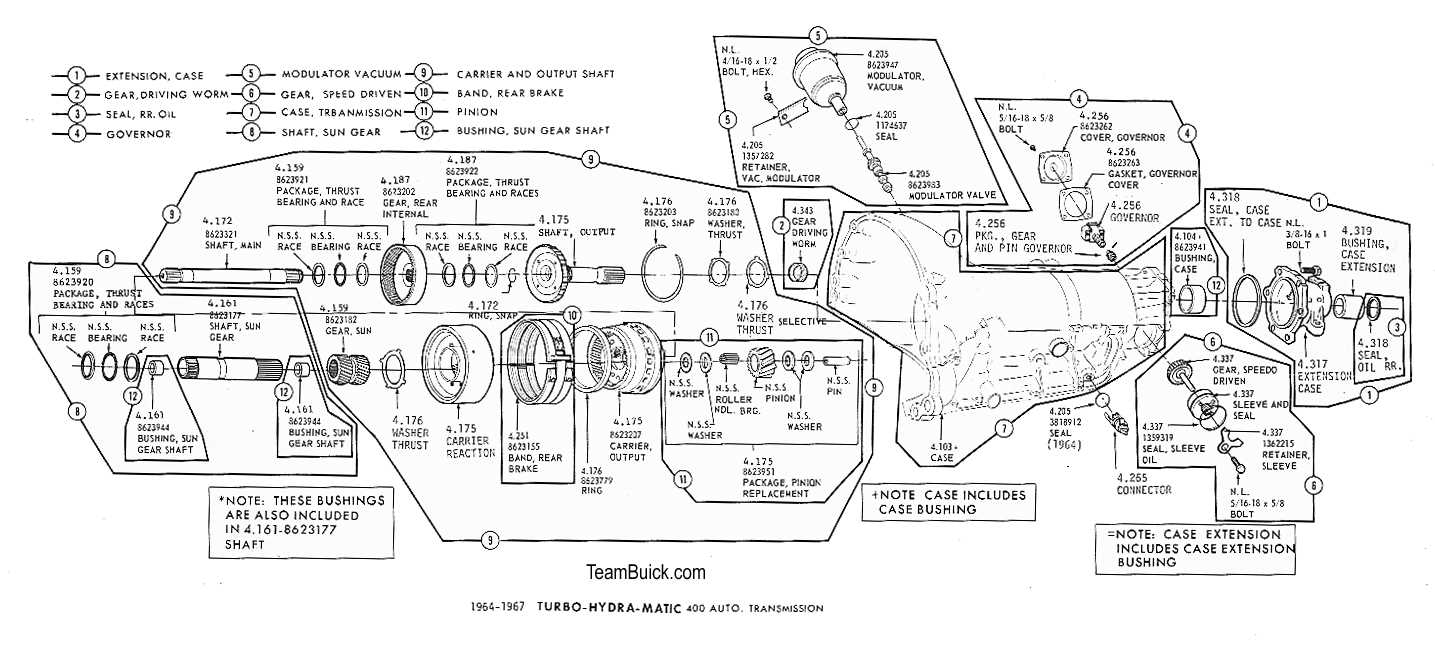

This section delves into the essential elements that contribute to the overall functionality of the transmission mechanism. Understanding these key components is vital for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Torque Converter | A hydraulic device that transfers power from the engine to the transmission, allowing for smooth gear shifts. |

| Control Valve Body | This unit directs hydraulic fluid to the appropriate clutches and bands, determining the transmission’s operational state. |

| Clutch Pack | Sets of friction discs that engage and disengage to allow for shifting between gears. |

| Planetary Gear Set | A system of gears that provides different gear ratios, essential for vehicle speed and power management. |

| Hydraulic Pump | This pump generates hydraulic pressure, enabling the movement of fluid within the transmission system. |

Common Issues with Select-O-Speed

Owners of vehicles equipped with a specific automatic transmission system often encounter various challenges that can affect performance and drivability. Understanding these typical problems is essential for effective maintenance and timely repairs.

One frequent issue is hesitation during gear shifts, which can result in a sluggish driving experience. This can be attributed to factors such as low fluid levels or worn components within the transmission. Additionally, unexpected slipping of gears may occur, causing a loss of power when accelerating. This condition often indicates the need for inspection of the clutch or internal mechanisms.

Another common concern is overheating, which can lead to severe damage if not addressed promptly. Ensuring the cooling system is functioning properly is vital to prevent this situation. Furthermore, unusual noises, such as grinding or whining, may signal internal wear or misalignment, necessitating a closer examination by a qualified technician.

Finally, erratic shifting patterns can lead to discomfort while driving. This may stem from electrical issues, such as faulty sensors or wiring problems. Regular diagnostics and preventive maintenance can help mitigate these issues and prolong the lifespan of the transmission system.

Maintenance Tips for Longevity

Ensuring the extended life of your vehicle’s transmission system requires regular attention and care. Implementing a few straightforward practices can significantly enhance performance and reduce the likelihood of unexpected failures.

Regular Fluid Checks: Consistently monitor the transmission fluid levels and quality. Clean, adequately filled fluid is crucial for optimal operation. Replace fluid at recommended intervals to prevent overheating and wear.

Routine Inspections: Conduct periodic assessments of the transmission components. Look for signs of leaks, unusual noises, or shifting issues. Early detection of potential problems can save time and expense in the long run.

Proper Driving Habits: Avoid aggressive driving, including rapid acceleration and abrupt stops. Smooth driving reduces strain on the transmission, promoting better longevity. Use appropriate gear selections, especially in varying terrain conditions.

Cooling System Maintenance: Ensure that the cooling system is functioning effectively. Overheating can cause severe damage, so regular checks and timely maintenance of the radiator and cooling lines are essential.

Professional Servicing: Schedule periodic inspections with a qualified technician. Professional assessments can identify issues that may not be apparent during routine checks, ensuring that any necessary repairs are addressed promptly.

Understanding the Wiring Layout

The arrangement of electrical connections is essential for the proper functioning of mechanical systems. A clear comprehension of the wiring structure allows for efficient troubleshooting and maintenance. In this section, we will explore the essential components and their interconnections to enhance understanding of the overall configuration.

Key Components

- Power Supply: Provides the necessary energy for operation.

- Control Switches: Manage the activation of various functions.

- Connectors: Facilitate the joining of different wiring sections.

- Sensors: Monitor system performance and provide feedback.

Wiring Connections

To ensure reliable operation, it is crucial to recognize how these components are interconnected. The following points illustrate typical wiring arrangements:

- Identify the main power lines and their routes throughout the system.

- Trace control lines from switches to respective components.

- Examine the grounding connections to prevent electrical faults.

- Verify sensor connections for accurate readings and responses.

Understanding these elements can significantly aid in diagnosing issues and ensuring optimal performance.

Parts Replacement Procedures Explained

Replacing components within a mechanical system is a vital process that ensures optimal functionality and longevity. Understanding the steps involved in this procedure can greatly enhance efficiency and reduce the likelihood of errors. The following guidelines provide a comprehensive approach to executing replacements effectively.

Preparation for Component Replacement

Prior to beginning the replacement process, it is essential to gather all necessary tools and materials. This includes a suitable workspace, appropriate instruments, and the specific items needed for the task. Additionally, reviewing any available manuals or documentation can offer valuable insights into the specific requirements of the replacement.

Executing the Replacement

Once preparation is complete, the next phase involves carefully removing the existing component. Take caution to note the positioning and connections of the original part to ensure accurate reinstallation. After removal, inspect the area for any signs of wear or damage. Proceed to install the new component, ensuring all connections are secure and properly aligned. After installation, conduct a thorough check to confirm that everything is functioning correctly.

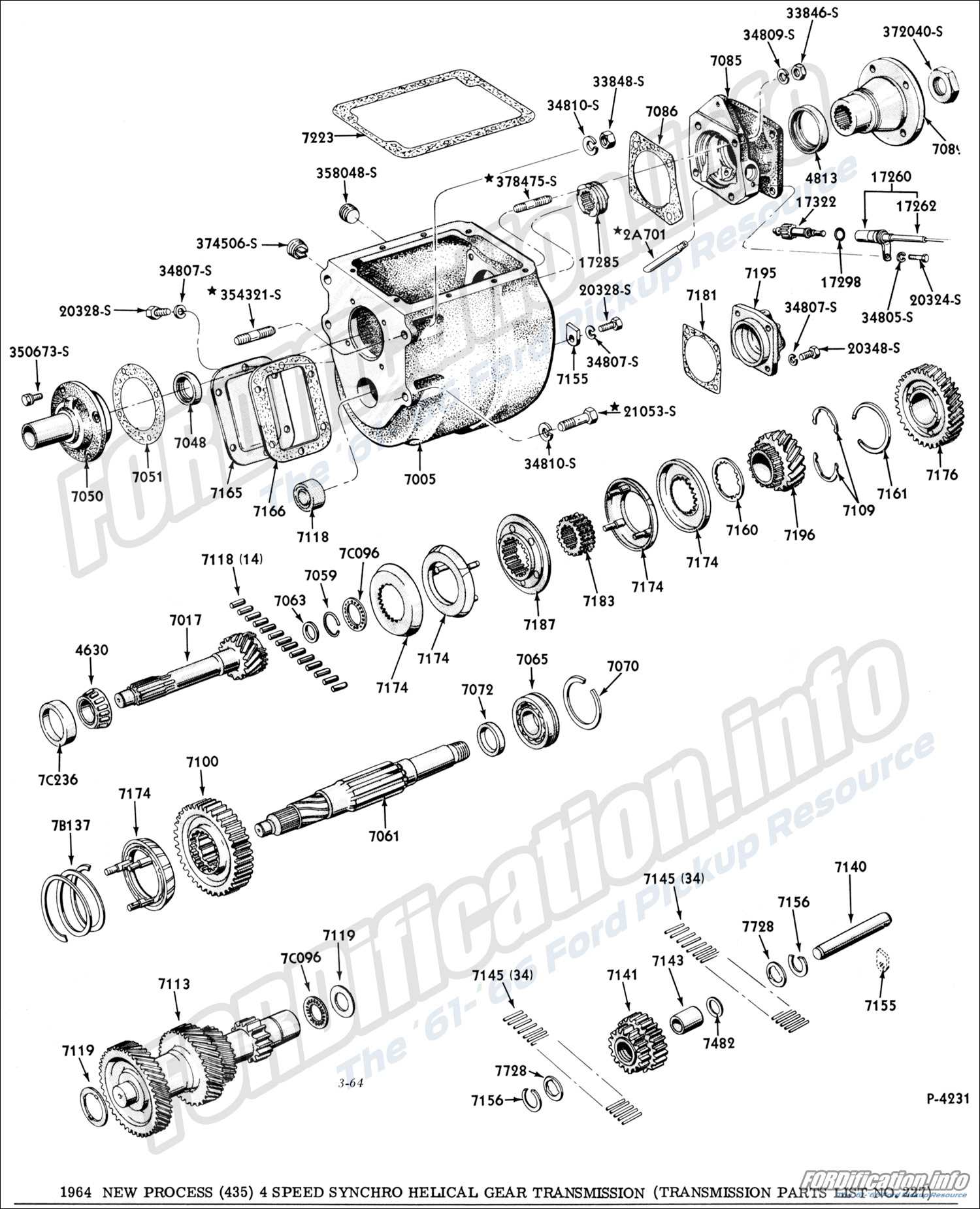

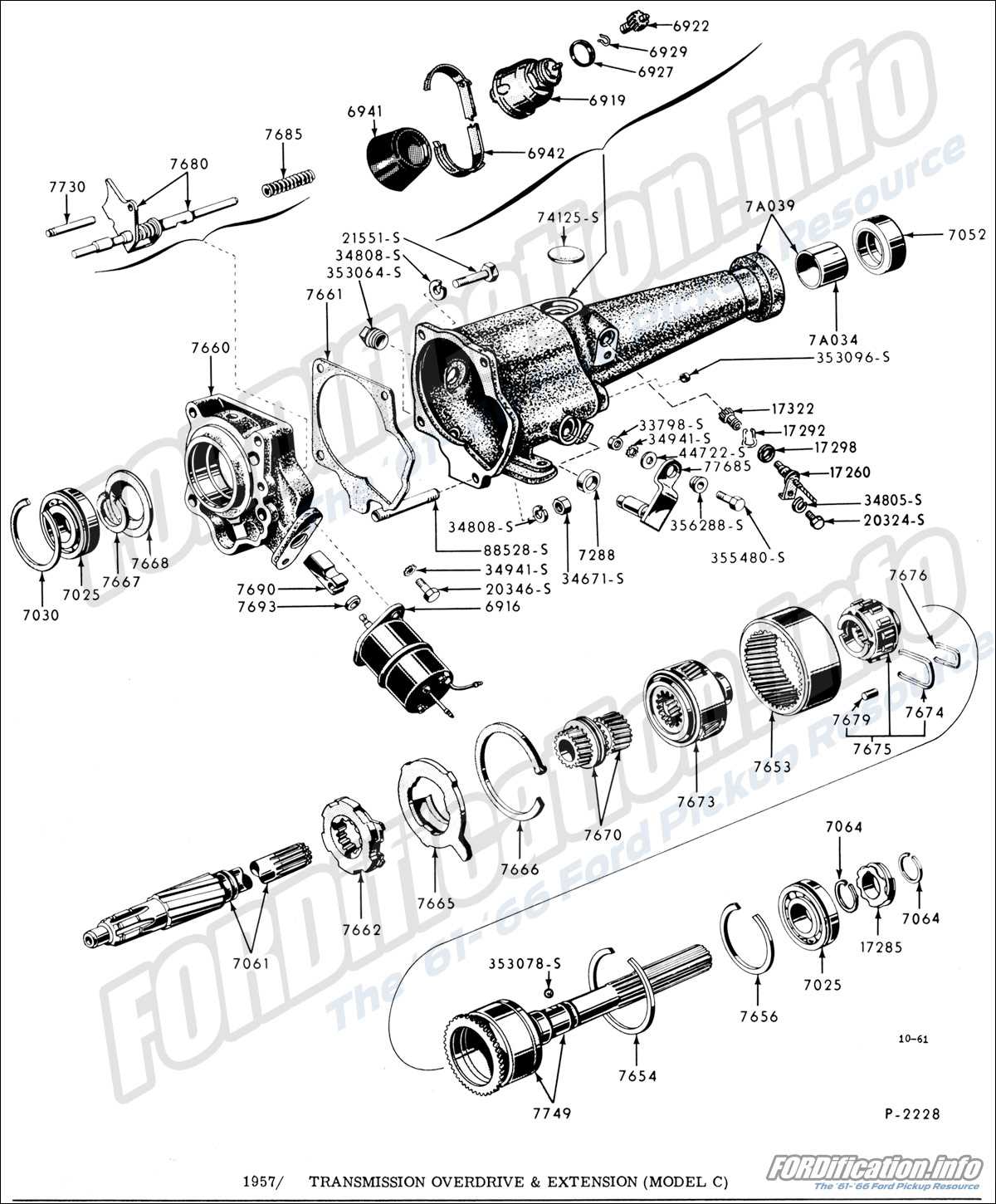

Importance of Accurate Diagrams

Precise illustrations are crucial in understanding complex mechanical systems. They provide essential insights into the arrangement and interconnection of various components, facilitating effective maintenance and repair. By presenting clear visual representations, these illustrations enable users to identify parts and understand their functions more effectively.

Accurate schematics offer several benefits:

- Enhanced Clarity: Well-defined graphics help in grasping intricate designs.

- Improved Efficiency: Quick reference aids in reducing time spent on repairs.

- Minimized Errors: Clear representations lower the likelihood of mistakes during assembly or disassembly.

- Better Training Tools: Effective teaching materials enhance learning for newcomers in the field.

In summary, reliable visual representations are essential for anyone involved in the upkeep of mechanical systems. They not only streamline processes but also contribute to the longevity and functionality of the equipment.

Tools Required for Repairs

Having the right equipment is crucial for successfully performing maintenance and fixing any mechanical issues. Proper tools not only ensure that the job is done efficiently but also minimize the risk of damage to components. Below is a list of essential implements that will facilitate repairs and enhance the overall workflow.

Basic Hand Tools

Starting with fundamental hand tools, a set of wrenches, screwdrivers, and pliers are indispensable. These items allow for loosening or tightening fasteners and manipulating various parts with precision. Additionally, a torque wrench is essential to apply the correct amount of force to bolts, ensuring they are neither too loose nor too tight.

Specialized Equipment

In addition to basic tools, specialized equipment such as a hydraulic jack and jack stands are necessary for lifting the vehicle safely. A transmission jack can also be invaluable when dealing with specific assemblies, providing stability and ease during removal and installation. Furthermore, a multimeter aids in diagnosing electrical issues, ensuring that all systems function correctly.

Consulting the Service Manual

Accessing the official service documentation is crucial for anyone seeking to understand the intricacies of automotive transmission systems. These manuals provide essential insights into maintenance procedures, troubleshooting techniques, and component specifications.

Benefits of Using the Service Documentation

- Comprehensive information on assembly and disassembly.

- Step-by-step troubleshooting guides to identify issues.

- Illustrated diagrams to clarify complex procedures.

- Specifications for various components and their configurations.

How to Effectively Use the Service Manual

- Locate the specific section related to the transmission system.

- Follow the outlined procedures carefully, ensuring all steps are completed.

- Refer to the troubleshooting guide if problems arise during the process.

- Use the diagrams to verify correct assembly of components.

Consulting the official documentation not only enhances understanding but also ensures that all maintenance tasks are performed accurately, contributing to the longevity and efficiency of the vehicle.

FAQs about Select-O-Speed Parts

This section addresses common inquiries regarding components associated with specific transmission systems. Understanding these elements can enhance both functionality and maintenance of vehicles equipped with these mechanisms.

1. What are the common issues encountered with these components?

Frequently reported challenges include fluid leaks, shifting difficulties, and unusual noises during operation. Regular inspection can help identify potential problems early.

2. How can I identify which components need replacement?

Inspecting for signs of wear and damage is crucial. Look for leaks, frayed wires, or any signs of corrosion. Consulting a professional can also provide clarity on necessary replacements.

3. Are there any compatibility concerns with aftermarket options?

Aftermarket options can vary in quality. It is essential to verify compatibility with your specific transmission model to ensure proper function and performance.

4. What maintenance tips can help prolong the lifespan of these elements?

Regular maintenance, including fluid changes and inspections, is vital. Keeping the system clean and addressing issues promptly can significantly extend the life of these components.

5. Where can I find replacement components?

Replacement elements can be sourced from specialized auto parts retailers, online marketplaces, or local dealerships. Ensure you check for quality and compatibility when purchasing.

Upgrades and Modifications Options

Enhancing the functionality and performance of your transmission system can significantly improve your driving experience. There are various approaches to upgrading and modifying components to achieve better efficiency, durability, and responsiveness. This section explores several options available for those looking to optimize their setup.

Performance Enhancements

Investing in performance-enhancing components can yield remarkable improvements. Consider upgrading to high-quality clutches and servo kits designed to deliver better power transfer and quicker shifts. Aftermarket solutions may also offer enhanced durability and heat resistance, making them ideal for high-performance applications.

Custom Modifications

For those seeking a tailored experience, custom modifications can be a viable route. This might include adjusting gear ratios to suit specific driving conditions or personal preferences. Consulting with a specialist can help identify the best modifications for your particular needs, ensuring optimal performance and reliability.