Understanding the Front Axle Parts Diagram for Super Duty Ford F250

In the realm of heavy-duty vehicles, a comprehensive grasp of the critical components that ensure optimal performance is essential. This section delves into the intricate assembly responsible for providing stability and support under extreme conditions. Gaining insight into these elements not only enhances maintenance practices but also contributes to overall vehicle safety and efficiency.

Each component plays a pivotal role in the functioning of the vehicle’s undercarriage, impacting everything from maneuverability to load-bearing capacity. By familiarizing oneself with the layout and interconnections of these essential units, operators can make informed decisions regarding repairs and upgrades. The following breakdown serves as a valuable resource for those seeking to enhance their understanding of this vital system.

Whether you’re a seasoned mechanic or a vehicle enthusiast, comprehending the intricacies of these assemblies is key to ensuring longevity and reliability. As we explore the individual elements, we will highlight their functions and significance, providing a clearer picture of how they work together to deliver exceptional performance.

Understanding the F250 Front Axle

The assembly that supports the weight of the vehicle and facilitates steering is crucial for performance and handling. A clear grasp of its components is essential for maintenance and upgrades. This section delves into the significance of each element, providing insights into their functions and interconnections.

| Component | Description |

|---|---|

| Knuckles | Connects the steering mechanism to the wheels, allowing for rotation and stability. |

| Hubs | Enable wheel attachment and facilitate smooth rotation, crucial for traction. |

| Bearings | Support the spinning motion of the hubs, ensuring minimal friction and wear. |

| Spindle | The central shaft that connects the wheel to the suspension, pivotal for load distribution. |

| Control Arms | Link the vehicle’s body to the wheels, aiding in suspension movement and stability. |

Each element plays a vital role in overall vehicle dynamics, impacting handling and safety. Understanding these components can lead to better decision-making during repairs or enhancements.

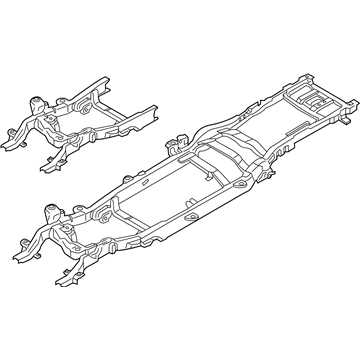

Overview of Specifications

This section provides a comprehensive understanding of the technical characteristics and performance features that define a robust vehicle, focusing on its structural integrity, powertrain capabilities, and overall utility. These specifications serve as a benchmark for assessing durability and functionality in challenging conditions.

Engine Performance

The powertrain is a critical component, offering various configurations to meet diverse needs. Key aspects include:

- Engine options: V8 configurations with varying horsepower ratings.

- Torque output: Designed to enhance towing and hauling capacity.

- Fuel efficiency: Balancing power and consumption for practical use.

Chassis and Suspension

The vehicle’s framework and suspension system are engineered for optimal handling and stability. Important features include:

- Heavy-duty suspension components for improved load management.

- High ground clearance to navigate rough terrains.

- All-wheel drive capabilities for enhanced traction in various environments.

Understanding these specifications helps in evaluating the vehicle’s suitability for specific tasks, whether for commercial use or personal adventures.

Importance of Front Axle Components

The significance of essential components in the steering and suspension system cannot be overstated. These elements play a crucial role in maintaining vehicle stability, enhancing control, and ensuring overall safety. Understanding their function helps in appreciating their contribution to optimal performance and longevity.

Role in Vehicle Dynamics

Key components in the assembly directly affect handling characteristics. They facilitate smooth navigation over various terrains, minimizing vibrations and disturbances. Proper functioning of these elements ensures that the vehicle responds effectively to driver inputs, leading to a more enjoyable driving experience.

Impact on Safety and Maintenance

Regular inspection and maintenance of these critical components are essential for preventing accidents and prolonging vehicle life. Worn or damaged pieces can lead to serious handling issues, making it vital to address any signs of wear promptly. Investing in quality replacements not only enhances performance but also safeguards the well-being of all occupants.

Common Issues with F250 Axles

Vehicles in the heavy-duty category often face specific challenges related to their suspension and drive systems. These concerns can affect performance, handling, and overall safety. Understanding these issues can help owners identify potential problems early and maintain their vehicles more effectively.

- Wear and Tear: Components may experience significant wear over time due to heavy loads and rough terrain.

- Noise Issues: Unusual sounds, such as grinding or clunking, can indicate problems with the joints or bearings.

- Alignment Problems: Misalignment can lead to uneven tire wear and compromised handling.

- Fluid Leaks: Seals and gaskets may deteriorate, causing fluid leaks that can affect lubrication.

- Corrosion: Exposure to moisture and road salt can lead to rust, weakening structural integrity.

Addressing these common issues promptly can help ensure a longer lifespan and better performance for your vehicle. Regular inspections and maintenance are key to preventing more serious problems down the line.

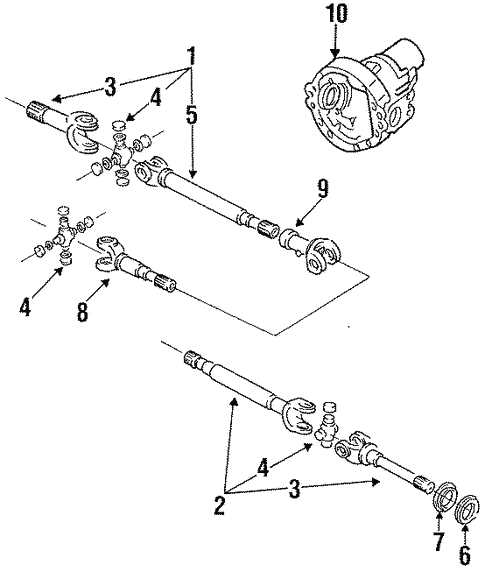

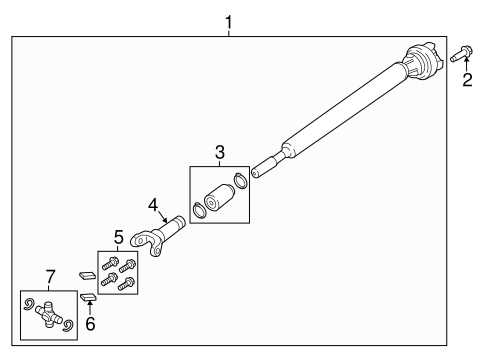

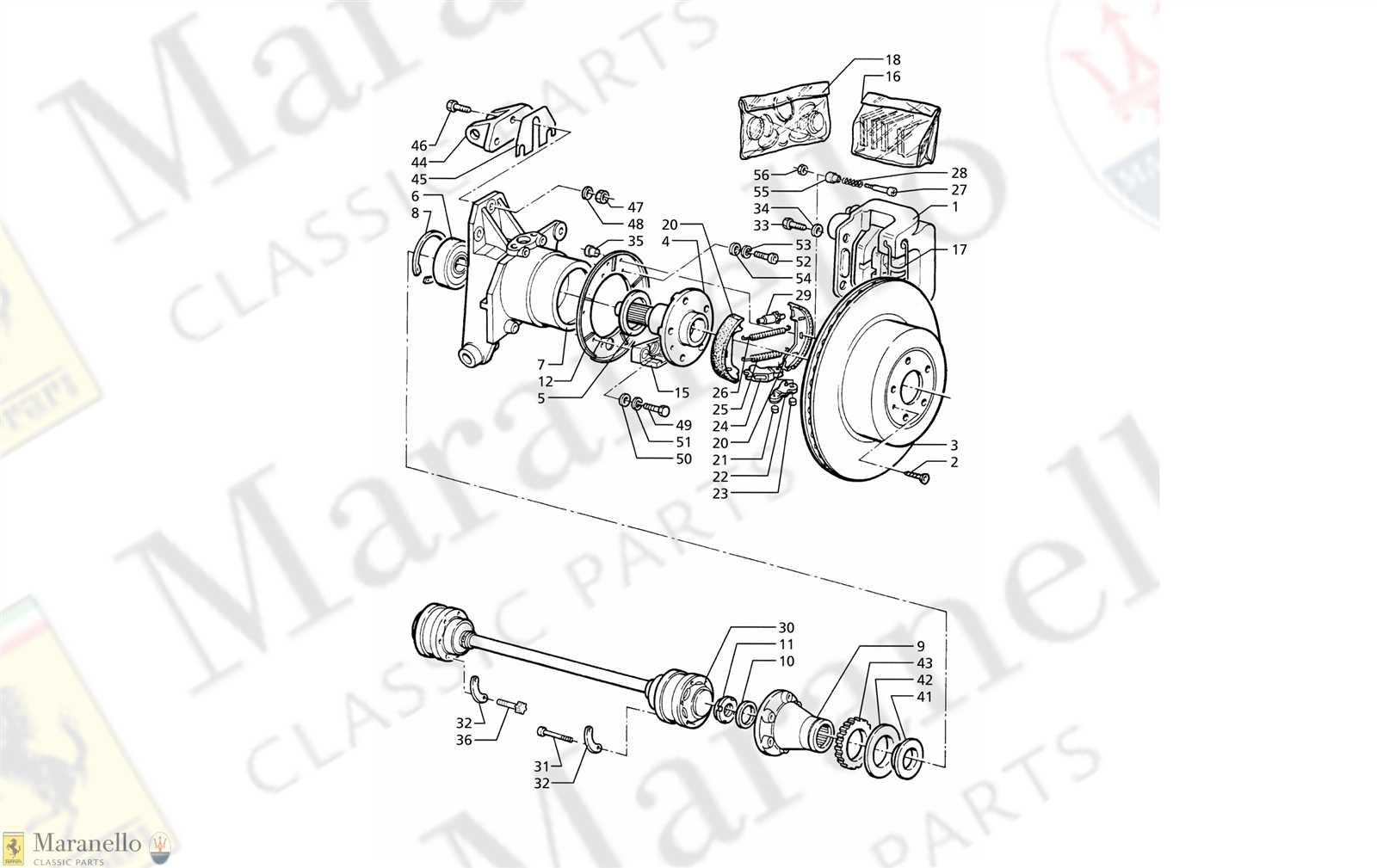

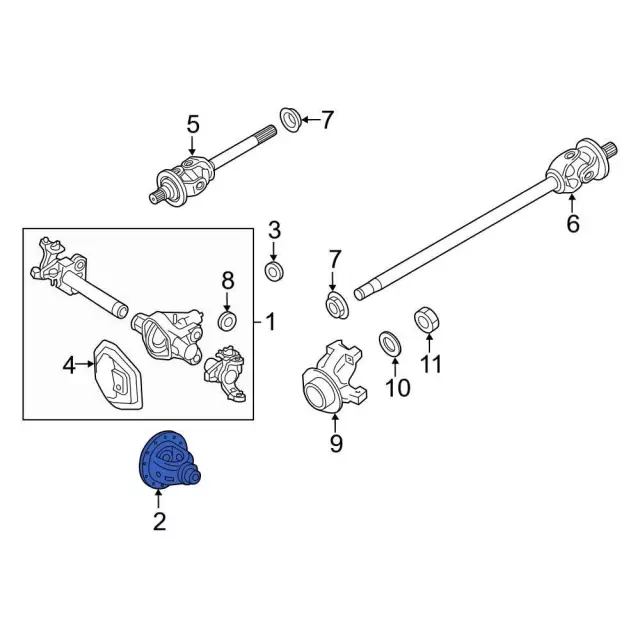

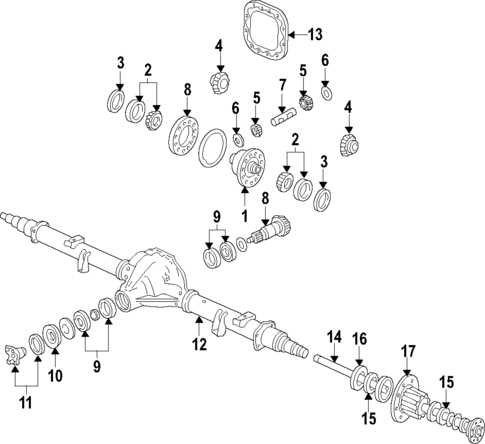

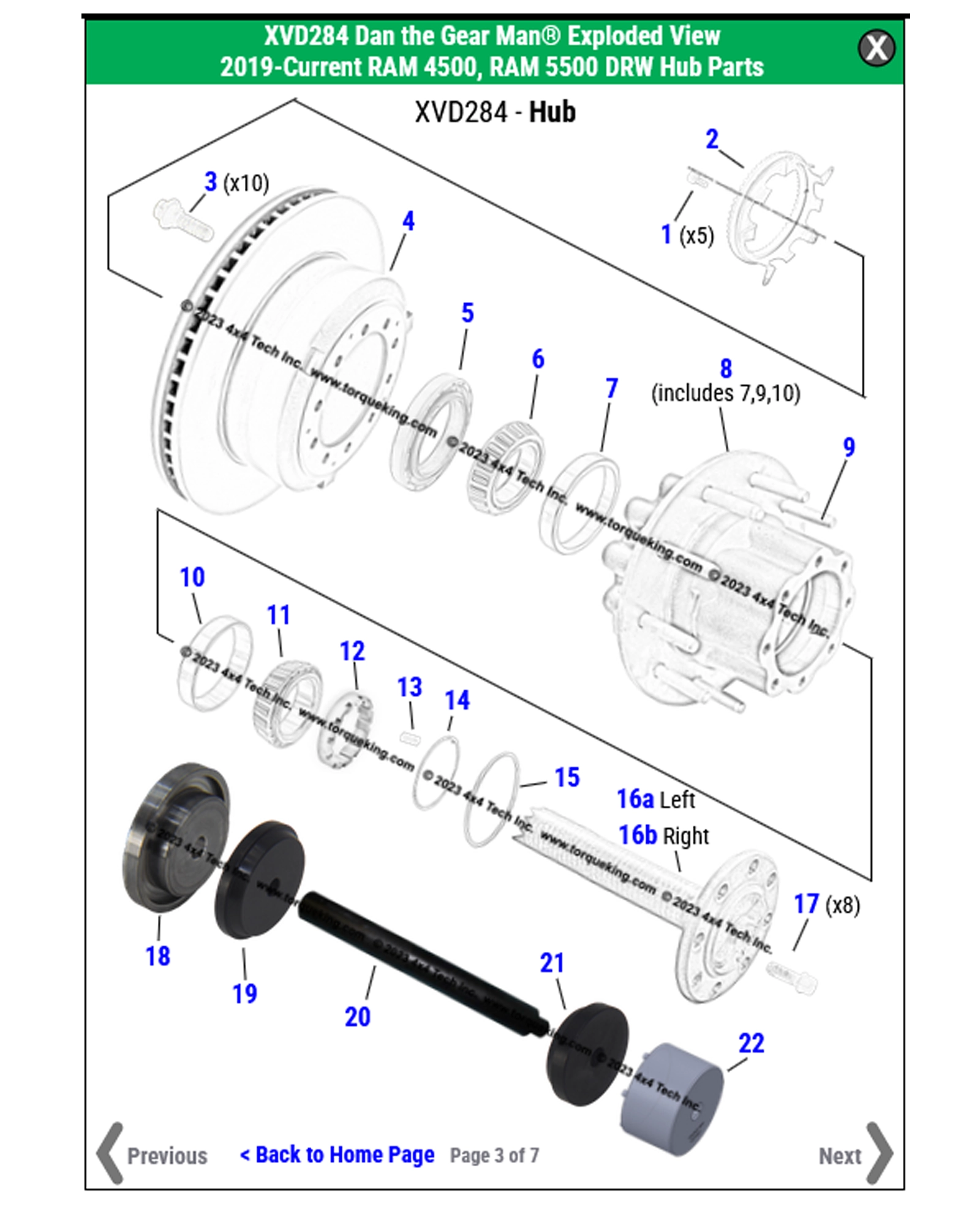

Detailed Parts Diagram Explanation

This section aims to provide a comprehensive understanding of the components illustrated in the visual representation. Each element plays a vital role in the overall functionality and performance of the vehicle’s suspension and steering systems. Recognizing these components enhances the ability to troubleshoot issues and perform necessary maintenance effectively.

At the core of this illustration are critical elements such as the housing, bearings, and various linkages. The housing serves as a protective shell, while bearings facilitate smooth movement, reducing friction. Linkages connect different parts, ensuring synchronized operation and stability during driving.

Additionally, attention is given to the mounting brackets and supports that secure these components in place. These structural elements are essential for maintaining alignment and integrity, contributing to the vehicle’s durability under various driving conditions.

Understanding the configuration and relationships between these components is crucial for both novice and experienced technicians. This knowledge not only aids in repairs but also promotes better performance and longevity of the vehicle.

How to Read Axle Diagrams

Understanding technical illustrations can be crucial for effective maintenance and repairs. These visuals provide a comprehensive overview of various components, helping enthusiasts and professionals alike grasp the intricate relationships between different elements. Knowing how to interpret these images allows for better decision-making when working on vehicles.

To effectively analyze these illustrations, follow these key steps:

| Step | Description |

|---|---|

| 1 | Identify the Legend: Look for a legend or key that explains the symbols used in the illustration. This will help you understand the various components and their functions. |

| 2 | Examine the Layout: Notice the arrangement of elements. Components are usually grouped by function or location, which can provide insights into how they interact. |

| 3 | Look for Annotations: Pay attention to any notes or arrows that indicate movement, orientation, or specific details. These can clarify complex relationships between parts. |

| 4 | Cross-reference with Manuals: Use service manuals or repair guides to supplement your understanding. These documents often provide additional context or specific instructions related to the components. |

| 5 | Practice: The more you engage with these illustrations, the more comfortable you will become. Regular practice will enhance your ability to quickly identify and understand essential parts. |

By following these steps, you will improve your skills in interpreting technical visuals, allowing for more effective troubleshooting and repairs.

Replacement Parts for F250 Front Axle

When it comes to maintaining your vehicle’s suspension and steering components, selecting high-quality replacements is crucial. This section explores essential components necessary for optimal performance and longevity, ensuring your ride remains smooth and reliable.

1. Bearings: These small but vital components reduce friction and enable smooth rotation. Regular inspection and timely replacement can prevent further damage.

2. Seals: These elements help to keep contaminants out and lubricants in, preserving the integrity of the assembly. Choosing durable seals will enhance longevity.

3. U-Joints: Universal joints are critical for transferring torque between different parts of the drivetrain. Ensuring these are in good condition is key to maintaining functionality.

4. Hubs: The hub assemblies support the wheels and provide the necessary attachment points. Upgrading to quality hubs can improve handling and safety.

5. Knuckles: These components allow for steering motion and bear significant loads. Regular checks can prevent issues related to steering responsiveness.

6. Spindles: They play a vital role in connecting the wheels to the suspension system. Proper maintenance and timely replacement are essential for vehicle stability.

Investing in reliable replacements for these components will not only enhance the performance of your vehicle but also ensure safety and comfort on the road.

Tools Needed for Axle Maintenance

Maintaining the essential components of your vehicle’s suspension system is crucial for optimal performance and safety. A well-equipped toolkit will make the process efficient and ensure that you can address any issues that arise during inspections or repairs. Below is a list of essential instruments and equipment you will need for effective upkeep.

Essential Tools

- Socket Set: A comprehensive socket set allows for the removal and tightening of bolts with precision.

- Wrenches: Both standard and adjustable wrenches are necessary for various sizes of nuts and bolts.

- Torque Wrench: This tool is critical for ensuring that all fasteners are tightened to the manufacturer’s specifications.

- Jack and Jack Stands: Safe lifting equipment is vital for accessing the undercarriage of the vehicle.

- Pry Bar: Useful for separating components and providing leverage when needed.

Additional Supplies

- Grease Gun: For applying lubricant to moving parts, which helps reduce friction and wear.

- Brake Cleaner: Essential for cleaning surfaces before reassembly to ensure optimal adhesion and function.

- Safety Gear: Protective gloves and goggles to keep you safe during maintenance tasks.

- Measuring Tools: Calipers and micrometers for checking tolerances and ensuring proper fitment.

Having the right tools and supplies on hand not only streamlines maintenance processes but also enhances safety and efficiency. Regular upkeep will prolong the life of your vehicle’s systems and improve overall driving experience.

Step-by-Step Maintenance Guide

Ensuring the longevity and performance of your vehicle’s suspension system requires regular upkeep and attention. This guide outlines essential procedures to help you maintain key components effectively, preventing costly repairs and enhancing overall safety.

1. Gather Necessary Tools

Before starting, collect all required tools, including a jack, jack stands, wrenches, and a torque wrench. Having everything on hand will streamline the process.

2. Raise the Vehicle

Use the jack to lift the vehicle and secure it with jack stands. This step is crucial for safety and accessibility during the maintenance tasks.

3. Inspect Components

Carefully examine the suspension elements for wear or damage. Look for signs such as cracks, rust, or excessive play. Identifying issues early can prevent further complications.

4. Clean the Area

Use a degreaser to clean any dirt and debris from the components. A clean work area allows for better inspection and maintenance of parts.

5. Lubricate Moving Parts

Apply appropriate lubricant to all moving components. This step helps to reduce friction and prolong the life of your system.

6. Tighten Bolts and Fasteners

Using a torque wrench, ensure all bolts and fasteners are tightened to the manufacturer’s specifications. Proper torque is vital for safety and performance.

7. Lower the Vehicle

Once all checks and maintenance tasks are complete, carefully lower the vehicle. Make sure everything is in place and secure before taking it for a test drive.

8. Test Drive

After maintenance, take the vehicle for a short drive to ensure everything is functioning correctly. Listen for unusual noises and check for any changes in handling.

Regular maintenance of your vehicle’s suspension system not only enhances performance but also contributes to safety on the road. Follow these steps diligently to keep your ride smooth and reliable.

Upgrades for Improved Axle Performance

Enhancing the functionality and durability of the drivetrain is crucial for maximizing vehicle performance, especially under challenging conditions. Upgrades can significantly improve handling, stability, and overall strength, making them an essential consideration for any enthusiast or operator looking to push their vehicle to the next level.

High-Performance Components

Investing in high-quality components is a foundational step towards boosting overall performance. Upgrading to stronger differentials, reinforced knuckles, and enhanced bearings can provide greater reliability and efficiency. These elements are designed to withstand higher torque loads, reducing the likelihood of failure during demanding applications.

Suspension Enhancements

Integrating advanced suspension systems can also play a vital role in performance improvement. Options such as adjustable shocks and heavy-duty springs allow for better load management and improved handling. These enhancements can result in increased traction and stability, especially when navigating rough terrains or during heavy towing.

Ultimately, selecting the right upgrades tailored to specific needs can lead to remarkable improvements in performance and longevity, ensuring that the vehicle operates at its best, no matter the conditions.

Safety Precautions When Working on Axles

Engaging in maintenance or repairs involving vehicle support components requires a keen awareness of safety protocols. Ensuring a secure environment not only protects the individual but also enhances the overall efficiency of the task at hand.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and steel-toed boots. These items provide essential protection against potential hazards such as sharp edges and heavy materials.

Before beginning any work, ensure that the vehicle is securely lifted and supported. Utilizing proper jacks and jack stands is crucial to prevent accidental drops. Never rely solely on a hydraulic jack, as it may fail under pressure.

Be aware of your surroundings. Clear the workspace of unnecessary tools and debris to minimize the risk of tripping or injury. It’s also important to work in a well-ventilated area, especially if you are using chemicals or lubricants that may produce harmful fumes.

Always consult the manufacturer’s guidelines and follow recommended procedures. Each model may have specific requirements for safe handling and maintenance. Familiarizing yourself with these instructions can prevent accidents and ensure a smooth workflow.

Finally, if you feel uncertain about any aspect of the work, seek assistance from a professional. Prioritizing safety not only protects you but also ensures the longevity and reliability of the vehicle.

Comparison with Other Ford Models

When examining heavy-duty vehicles, it’s essential to recognize the distinctions and similarities across various models in the lineup. Each model caters to specific needs and preferences, showcasing unique characteristics that contribute to performance, durability, and user experience.

In this context, understanding how one model measures up against others helps potential buyers make informed decisions. Key factors such as load capacity, suspension systems, and overall handling can vary significantly between models, providing different advantages based on intended use.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Payload Capacity | 3,300 lbs | 2,800 lbs | 3,000 lbs |

| Towing Capability | 12,000 lbs | 10,500 lbs | 11,000 lbs |

| Engine Options | V8 Diesel | V6 Gasoline | V8 Gasoline |

| Suspension Type | Leaf Spring | Coil Spring | Leaf Spring |

Ultimately, each model’s design choices reflect different engineering priorities, shaping how they perform in various conditions. Buyers should consider these differences carefully to select a vehicle that best fits their requirements.

Frequently Asked Questions About Axles

This section addresses common inquiries regarding the essential components responsible for transferring power from the engine to the wheels. Understanding these elements is crucial for maintaining vehicle performance and ensuring safety on the road.

What is the role of an axle in a vehicle?

An axle plays a vital role in supporting the weight of the vehicle and facilitating the movement of wheels. It connects the two wheels on either side, allowing them to rotate together and transmit engine power efficiently.

How do I know if my axle needs replacement?

Signs of a failing component may include unusual noises while driving, vibrations, or difficulty steering. If you notice any of these issues, it’s advisable to have the component inspected by a professional.

| Symptoms | Possible Causes |

|---|---|

| Unusual noises | Worn bearings or joints |

| Vibrations | Imbalance or damage |

| Steering issues | Misalignment or wear |