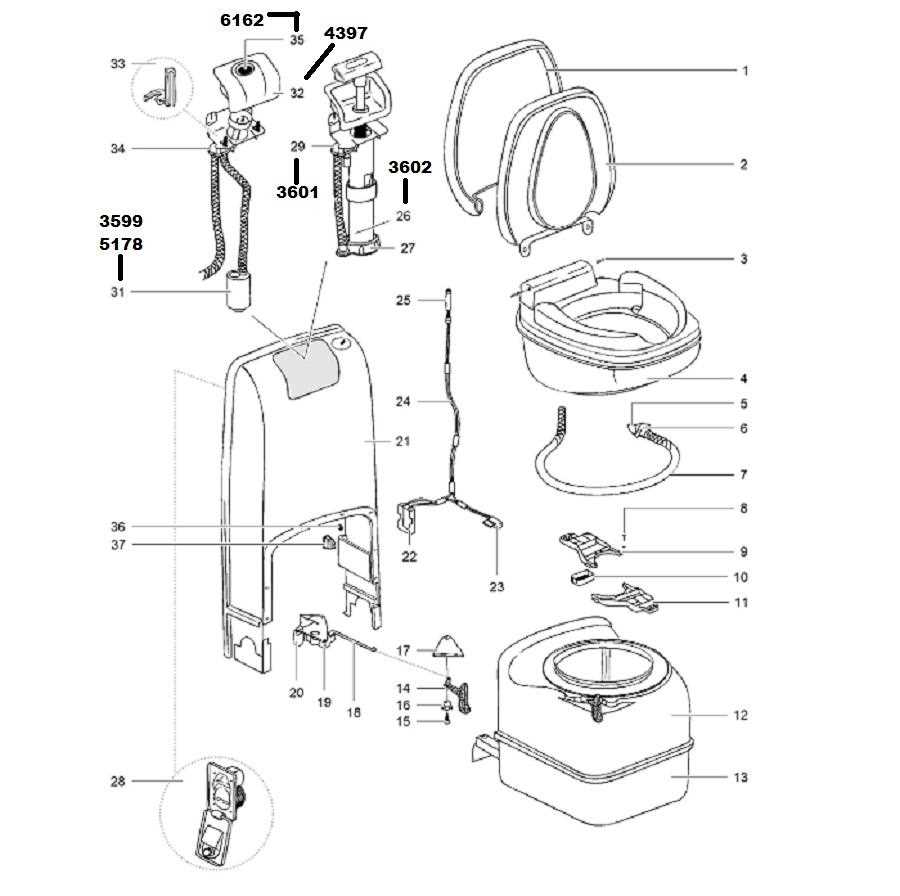

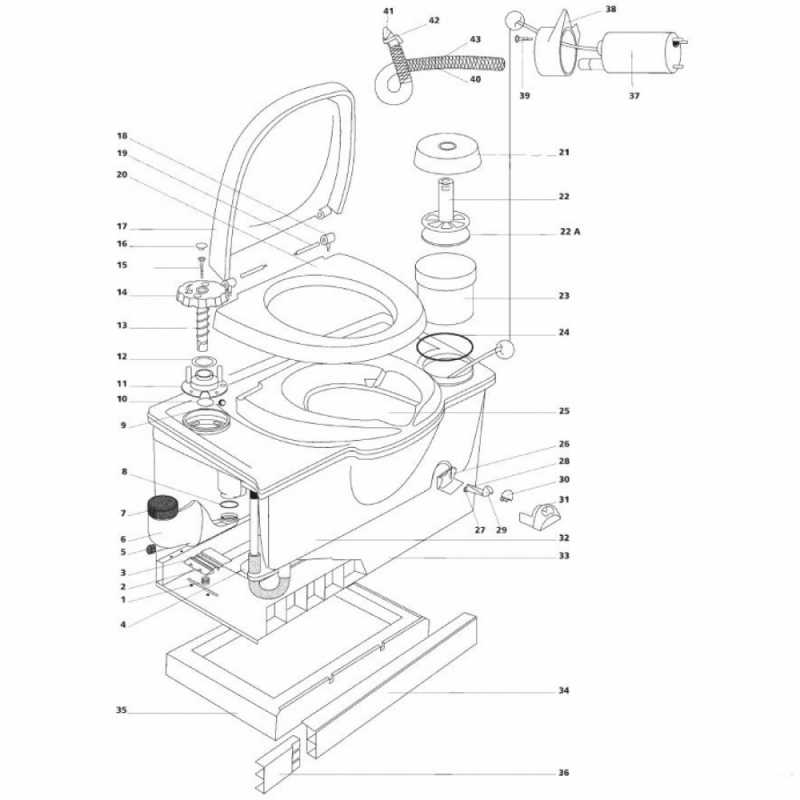

Thetford 31688 Parts Diagram Overview

In the world of recreational vehicles, having a comprehensive understanding of various elements is essential for optimal performance and maintenance. Knowing how each component fits into the overall structure can significantly enhance your experience on the road.

Visual aids play a crucial role in helping owners navigate the intricate network of features within their vehicles. By exploring these illustrations, users can easily identify the specific sections and ensure that everything is in working order.

Moreover, familiarity with these visual representations allows for informed decision-making when it comes to repairs and upgrades. This knowledge empowers enthusiasts to delve deeper into their vehicle’s mechanics and ultimately achieve the best functionality possible.

Understanding Thetford 31688 Components

Grasping the intricacies of specific components is essential for effective maintenance and repair. A clear comprehension of how each element functions within the system allows for better troubleshooting and enhanced longevity. This section will break down the key elements, providing insights into their roles and interconnections.

| Component Name | Description |

|---|---|

| Base Assembly | The foundation that supports the entire structure, ensuring stability. |

| Flush Mechanism | Facilitates the removal of waste, critical for operational efficiency. |

| Water Supply Unit | Controls the flow of water, essential for effective cleansing. |

| Seal System | Prevents leaks and maintains pressure, vital for hygiene. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functioning of complex systems. These illustrations serve as essential tools for both technicians and enthusiasts, facilitating easier identification and replacement of individual elements. By providing clarity, they enhance the overall maintenance experience and ensure that every piece is correctly situated.

Moreover, these schematics streamline troubleshooting processes. When issues arise, having a clear layout of each constituent enables users to pinpoint malfunctions quickly. This efficiency can save time and resources, ultimately leading to more effective repairs.

Additionally, such visuals promote learning and knowledge sharing. They allow individuals to familiarize themselves with intricate designs, deepening their comprehension of how various elements interact. This educational aspect is invaluable, particularly for those looking to enhance their skills in repair and maintenance.

In summary, visual representations are indispensable for effective service and understanding, serving as guides that promote efficiency, accuracy, and continuous learning in the maintenance of equipment.

Common Issues with Thetford Toilets

Toilets designed for mobile living can encounter several frequent problems that affect their functionality and user experience. Understanding these common challenges can help users maintain their units effectively and ensure a smooth operation.

| Issue | Description |

|---|---|

| Clogging | Blocked drains can lead to backups, requiring immediate attention. |

| Leaking Seals | Wear and tear can cause seals to fail, resulting in unwanted water leakage. |

| Flushing Problems | Insufficient flushing can occur due to low water pressure or faulty components. |

| Odor Issues | Unpleasant smells may arise from waste buildup or inadequate ventilation. |

| Tank Indicator Failures | Malfunctioning indicators can lead to confusion about tank levels, causing overflows. |

How to Interpret Diagrams Effectively

Understanding visual representations can greatly enhance your ability to troubleshoot and assemble various components. By breaking down complex images into manageable sections, you can uncover essential information that aids in clarity and comprehension.

Start with the Basics: Familiarize yourself with common symbols and notations used in visuals. Each icon often carries specific meaning that can guide you in the right direction.

Break It Down: Analyze each segment individually. Identify relationships and connections between elements to grasp the overall structure.

Refer to Annotations: Pay attention to accompanying labels and notes. They provide crucial insights and context that enhance your understanding.

Practice Makes Perfect: Regularly engage with different visuals to improve your interpretative skills. The more you practice, the more intuitive it becomes.

Seek Clarification: If something is unclear, don’t hesitate to consult additional resources or ask for help. Gaining different perspectives can provide the ultimate clarity.

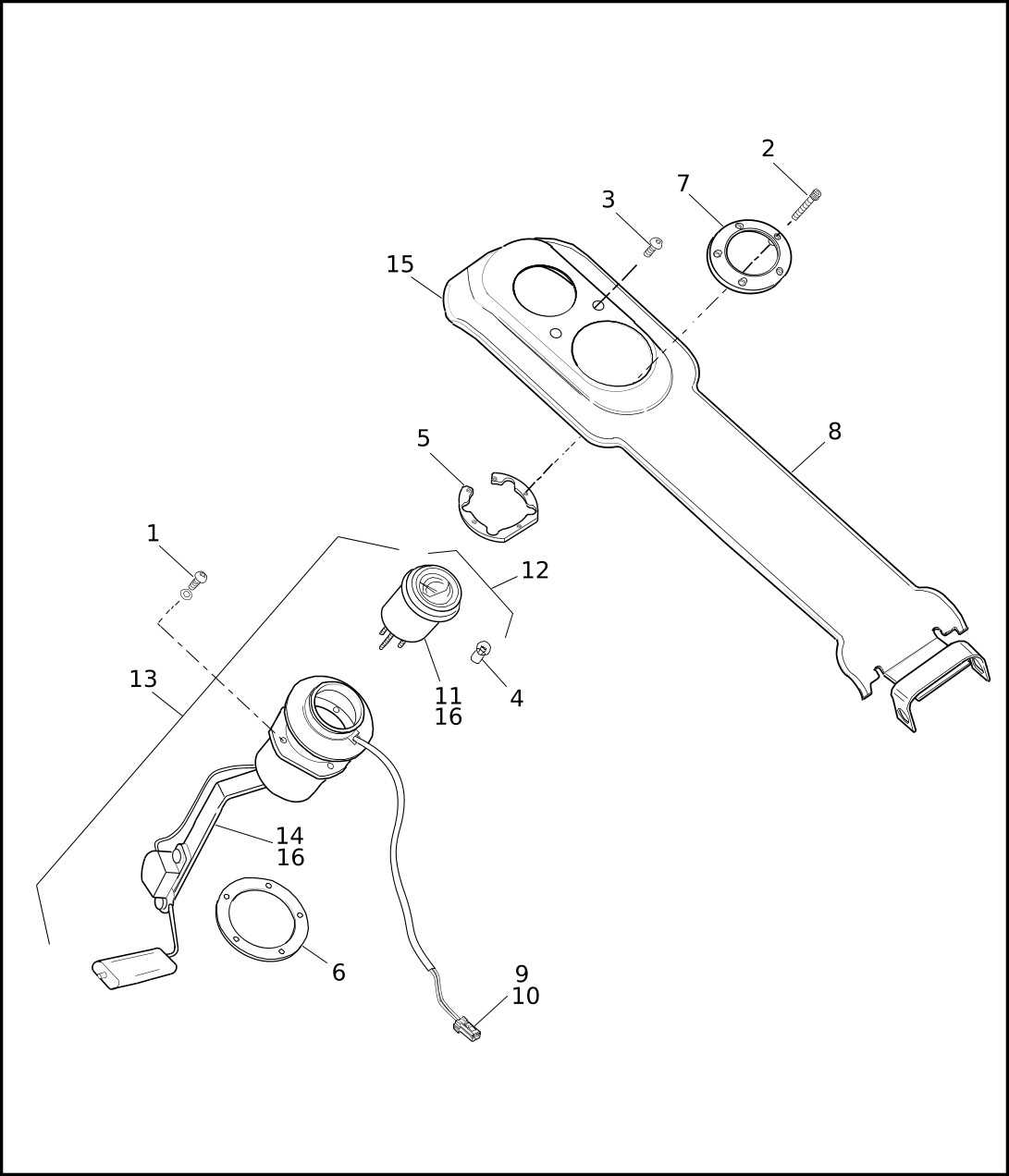

Essential Replacement Parts Overview

Understanding the critical components necessary for maintenance and repair is vital for ensuring optimal performance. These elements play a significant role in the functionality and longevity of equipment, providing seamless operation and preventing unexpected failures.

| Component | Description | Importance |

|---|---|---|

| Seal | Prevents leaks and maintains pressure. | Essential for avoiding fluid loss and maintaining system integrity. |

| Valve | Controls the flow of liquids. | Crucial for regulating operation and ensuring efficiency. |

| Filter | Removes impurities from liquids. | Important for protecting sensitive components and enhancing performance. |

| Hose | Transports fluids between parts. | Vital for maintaining connection and function across the system. |

Maintenance Tips for Longevity

Proper upkeep of your equipment ensures it functions efficiently over time, preventing unexpected breakdowns and extending its service life. Consistent attention to detail and a proactive approach will save you both time and money by avoiding costly repairs or replacements.

Regular Cleaning

Routine cleaning is essential to maintain optimal performance. Dirt, dust, and debris can accumulate and hinder the overall efficiency of your unit. Make sure to regularly clean all accessible components using appropriate cleaning agents. This not only enhances performance but also helps identify any potential issues early.

Scheduled Inspections

Periodic inspections are crucial for spotting wear and tear before it becomes a problem. Check moving parts, seals, and other critical areas for any signs of damage or fatigue. Timely replacements of worn components can prevent larger malfunctions and ensure uninterrupted operation.

| Maintenance Task | Frequency |

|---|---|

| General cleaning | Monthly |

| Seal inspection | Quarterly |

| Lubrication of moving parts | Every 6 months |

Following these guidelines will not only keep your system running smoothly but also maximize its lifespan, ensuring reliable performance for years to come.

Where to Find Quality Parts

Finding reliable components for your equipment is essential to ensuring longevity and optimal performance. It’s crucial to select trusted sources that offer durable and compatible items. This section explores the best places and methods to locate high-grade products for your needs.

- Authorized Dealers: Always check for certified retailers, as they provide genuine and approved items directly from manufacturers.

- Specialty Stores: Many stores specialize in specific categories of equipment, offering a wide range of compatible items with expert advice.

- Online Marketplaces: Reputable e-commerce platforms often provide various options, but make sure to verify the seller’s reputation and reviews.

When looking for suitable replacements, prioritize quality over price. The right supplier will offer a warranty, clear specifications, and customer support, ensuring you get exactly what you need for your machinery.

Step-by-Step Repair Instructions

In this guide, we will walk you through the process of fixing and maintaining your equipment, ensuring its longevity and efficient operation. By following these instructions, you can address common issues and restore functionality without the need for professional assistance. Let’s begin by preparing the necessary tools and workspace.

1. Preparing for the Repair

Before starting any repair, make sure you have all required tools at hand. Lay out everything on a clean surface, ensuring there is enough space to work. Disconnect the power supply and double-check that the area is safe for handling the equipment.

2. Disassembly and Inspection

Start by carefully removing the outer casing of the unit. Use a screwdriver or other appropriate tool to loosen screws or clips. Once the outer layer is off, inspect the interior components for visible damage or signs of wear. Be cautious not to damage any fragile parts during this process.

With the internal structure exposed, identify the problematic area that needs attention. Whether it’s a loose connection or a worn-out part, take note of the issue before proceeding with the repair.

Once you’ve identified the cause of the malfunction, you can move forward with replacing or adjusting the necessary components. Reassemble the unit by following the reverse steps, ensuring all parts are securely in place.

After reassembly, power the unit back on and test its functionality to confirm that the repair was successful.

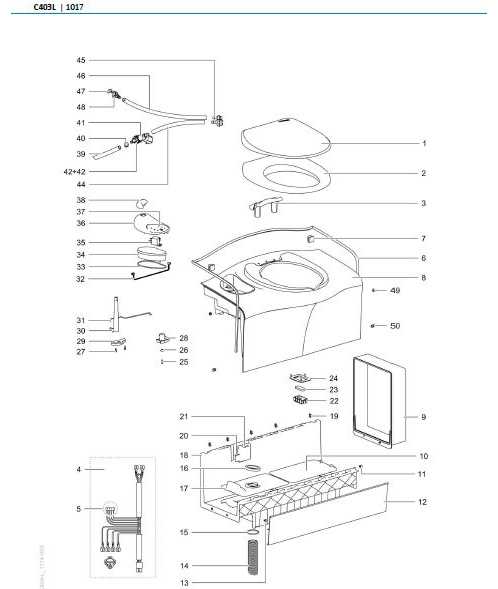

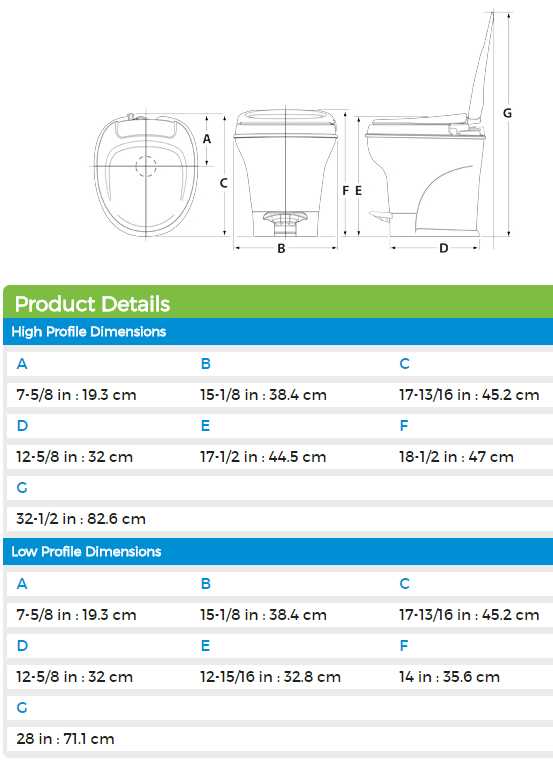

Comparing Thetford Models and Parts

When choosing between different models of mobile sanitation systems, it’s essential to understand their unique features and variations in components. Each model offers specific advantages, making them suitable for various needs. In this section, we will break down key differences, highlighting how certain features influence performance and usability.

Key Features Across Different Models

Understanding the strengths of each system begins with looking at their most distinctive attributes. Here are some critical features to consider when comparing options:

- Capacity: Different models are designed to hold varying amounts of waste, catering to both small and large usage needs.

- Flush Mechanisms: There are variations in how the flushing systems operate, which can affect convenience and water efficiency.

- Portability: The ease of transport differs between models, depending on size, weight, and handle design.

Component Variations

The internal and external components of these systems can differ significantly. These variations impact both durability and ease of maintenance.

- Valves: Some models are equipped with more robust valve mechanisms, offering enhanced sealing and preventing leaks.

- Tanks: The shape, material, and capacity of the waste and water tanks vary, influencing their longevity and user experience.

- Handles and Wheels: Certain designs feature more ergonomic handles and larger wheels for smoother mobility.

Cost Considerations for Repairs

When addressing the financial aspect of maintenance and restoration, it’s important to weigh both immediate and long-term expenses. Evaluating the total investment required for repairs can help prevent unexpected financial strain and ensure the longevity of the equipment. Careful budgeting and planning will allow for more strategic decision-making when handling complex repair tasks.

Initial Costs vs. Long-Term Savings: Some repairs may seem costly upfront, but they can lead to significant savings over time by preventing more serious issues. Prioritizing essential fixes and investing in quality components often proves more economical in the long run, reducing the need for frequent interventions.

Labor and Expertise: In addition to material costs, labor expenses can vary based on the complexity of the work required. Choosing skilled professionals may come at a higher rate, but their experience can minimize the risk of further damage, ensuring the job is done efficiently and accurately.

Budgeting for Future Maintenance: Proactive maintenance planning is key to managing repair expenses. Setting aside a portion of your budget for routine inspections and minor fixes can mitigate larger, more costly repairs down the line, helping to maintain optimal performance.

FAQs About Thetford 31688 Parts

Understanding the components and their role in the overall functionality can be essential for maintaining performance and longevity. Below are answers to the most common questions related to these essential items, providing clarity and helping users avoid common issues.

What is the primary function of each component?

Each individual element plays a crucial role in ensuring smooth operation. These mechanisms work together, balancing both efficiency and reliability to meet user needs.

How often should these components be replaced or maintained?

Regular upkeep is key to extending their lifespan. Recommendations suggest periodic checks, depending on usage frequency, to avoid potential breakdowns and ensure optimal performance.

What are the signs that a part needs to be replaced?

Early indicators may include decreased efficiency, unusual sounds, or visible wear. Timely attention to these signs can prevent larger issues from arising.

Are there any specific tools required for maintenance or replacement?

Basic tools are often sufficient for most maintenance tasks. However, some situations may require specialized equipment to ensure proper installation or adjustment.

Can I install new components on