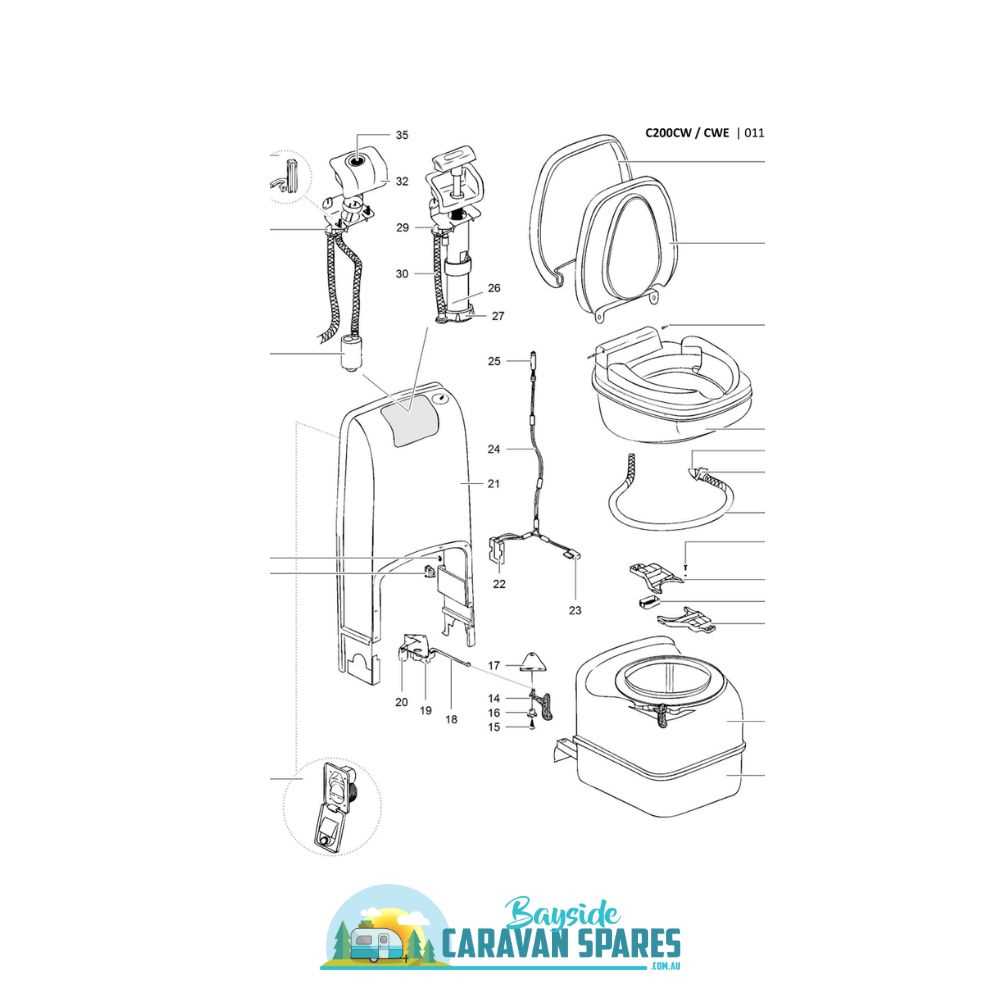

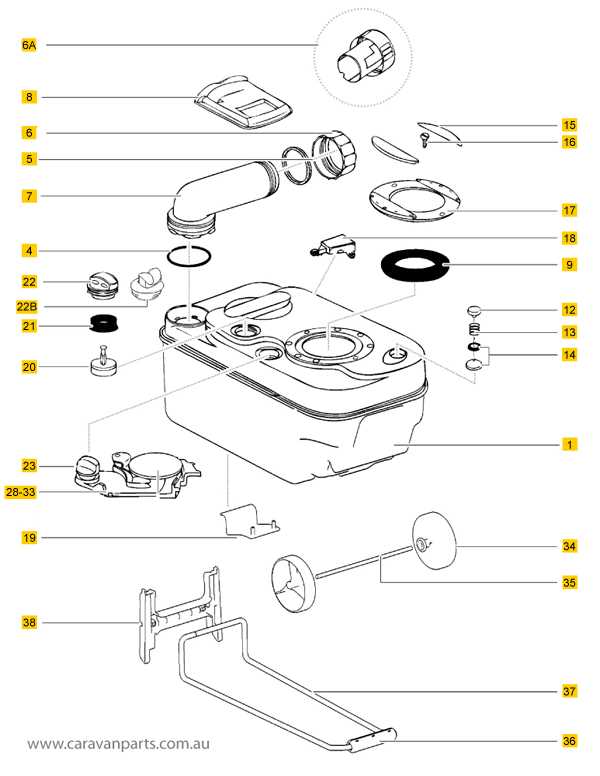

Thetford C402 Parts Diagram Overview

When maintaining and servicing any mechanical unit, understanding the layout and function of each element is crucial. This overview provides valuable insight into the various elements that ensure smooth operation and long-term reliability. Whether you’re performing regular maintenance or addressing a specific issue, having a clear understanding of the system’s structure can make all the difference.

In this section, we will delve into the essential elements of the system, examining their functions and how they interconnect. A clear outline of these key elements will help you identify, troubleshoot, and replace components as needed, ensuring optimal performance and functionality. Proper maintenance, combined with an understanding of each element, will help extend the lifespan of the entire unit.

By gaining familiarity with these critical aspects, you can make more informed decisions during repairs, upgrades, or general upkeep. This guide is designed to offer a comprehensive look at the inner workings of the unit, empowering you to keep everything running smoothly and efficiently.

Understanding the Components of Thetford C402

The system in question includes various key elements that work together to ensure smooth operation. Understanding how these components function is essential for proper maintenance and repair. In this section, we will explore the main elements involved in this system, their purpose, and how they interact with each other.

Key Structural Components

- Reservoir Unit: This part holds the necessary fluids and is designed to be easily accessible for refills and maintenance.

- Pumping Mechanism: Ensures the fluid moves through the system efficiently, providing consistent operation.

- Sealing Unit: Prevents leaks and ensures the system remains closed off when not in use, maintaining hygiene and performance.

Operational Elements

- Control Panel: Offers the user easy management of the system’s functions, from activation to monitoring.

- Flush Valve: Regulates the flow of fluid, ensuring proper use with each operation.

- Discharge System: Ensures waste is removed efficiently, reducing

Key Features of the Thetford C402 Model

This model is designed to provide convenience and efficiency for users seeking a reliable sanitation solution. Its user-friendly design and high functionality make it a preferred choice for various settings, offering a range of essential features that enhance its practicality.

Efficient Waste Management

- Easy-to-use waste disposal system that minimizes maintenance efforts.

- Secure and leak-proof construction ensures cleanliness and hygiene.

- Quick-release mechanisms for fast and hassle-free handling.

User-Friendly Operation

- Compact design that maximizes space while maintaining full functionality.

- Intuitive controls and simple operation for ease of use.

- Durable build for long-lasting use in various environments.

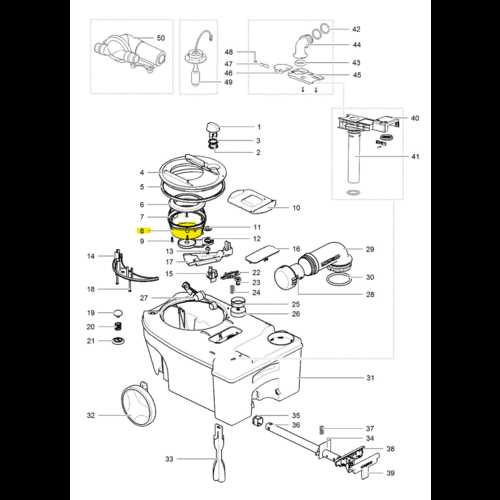

Exploring the Waste Tank Structure

Understanding the layout of a waste container is essential for proper maintenance and long-term use. This section provides a detailed look into the internal features and design of the container, highlighting key components that contribute to its functionality. The aim is to help users recognize the main elements and their roles in the efficient operation of the system.

Main Components

The waste container is built around several primary elements, each serving a specific purpose in managing and processing waste. These components work together to ensure the system functions smoothly. Here is a breakdown of the critical sections:

Component Description Storage Chamber The main compartment where waste is held until disposal. It is designed to store waste securely, preventing leaks and odors. Sealing Mechanism A feature that ensures the container remains closed when not in use, effectively containing the waste and preventing contamination. Emptying Valve A valve located at the bottom of the container that allows for efficient waste removal when the tank is full. Detailed View of the Water Supply System

Understanding the water supply mechanism is essential for maintaining efficient operation. This system ensures proper flow and distribution, allowing smooth function of all components that rely on water. A well-organized structure is vital for consistent performance, as it directs water through various channels, connecting multiple key areas.

Main Components of the System

The system consists of several integral parts working in unison to regulate water flow. Each section has a specific role in guiding and managing the supply from the source to the areas where it is required. This coordination ensures a seamless delivery of water, avoiding any interruptions in the process.

Flow Control and Distribution

Water is managed through a series of valves and connections, which help control pressure and direction. These control points ensure the system remains balanced, and that water reaches the correct areas without loss or overflow.

Component Function Inlet Valve Allows water to enter the How the Flush Mechanism Works

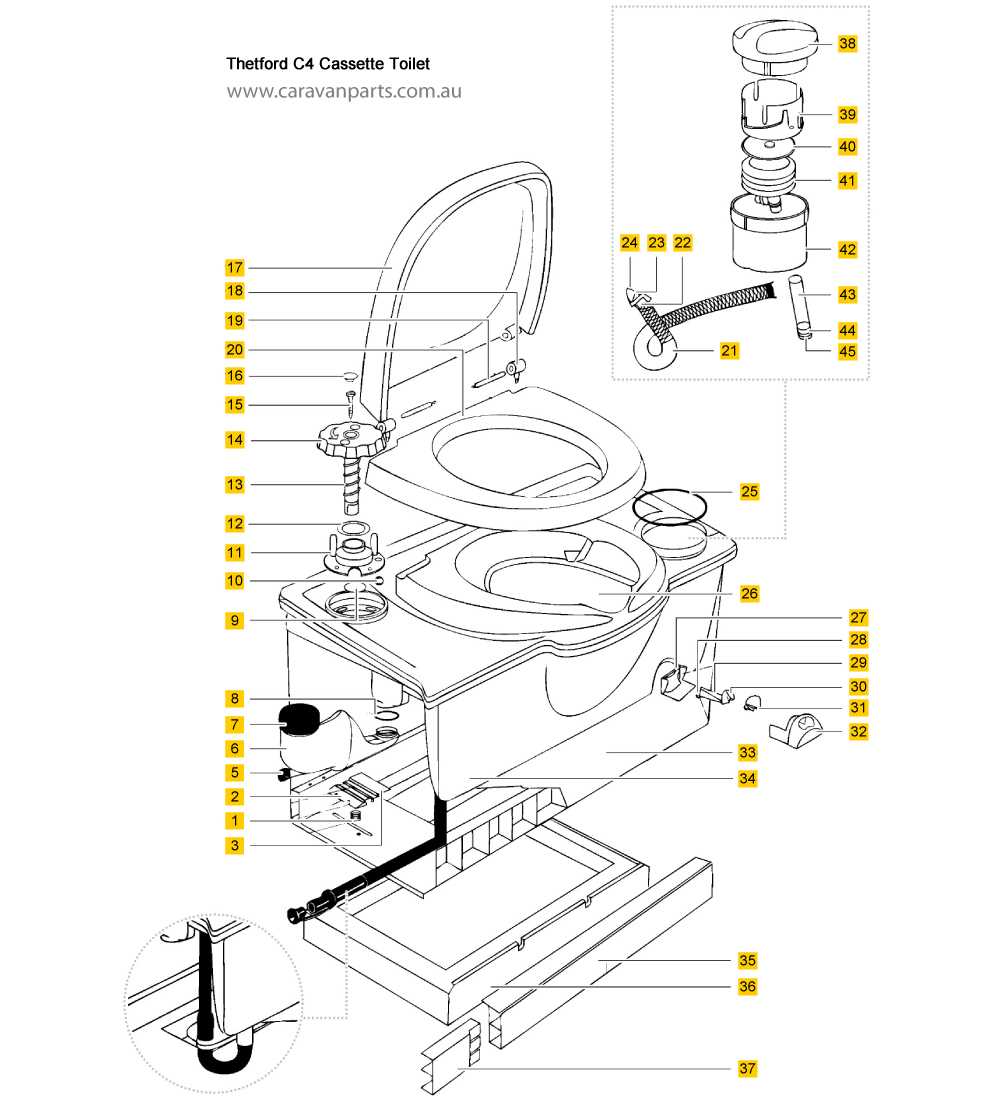

The flush system is designed to ensure efficient cleaning by channeling water through a dedicated pathway. This process removes waste and leaves the bowl ready for the next use. The mechanism relies on a balance between water flow and pressure to achieve a thorough rinse.

Water Flow Control

At the core of the system is a control element that regulates how much water is released during each activation. When engaged, this component opens the valve, allowing water to move from the reservoir into the bowl. The timing and quantity of water released are crucial for optimal cleaning.

Pressure and Rinse

The role of water pressure is vital for the rinsing action. As water enters the bowl, it circulates with sufficient force to remove waste effectively. The mechanism ensures that the water pressure is high enough to perform a complete rinse, yet controlled to prevent overuse of

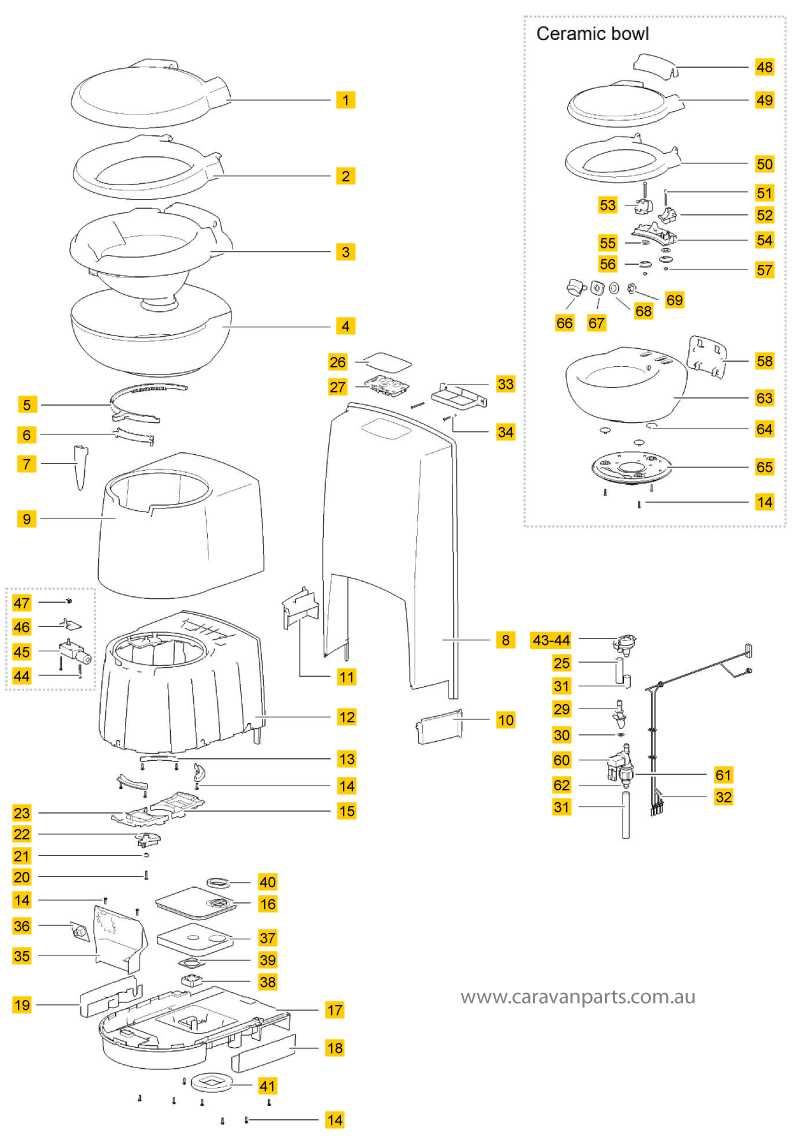

Replacement Parts for the C402 Toilet

When it comes to maintaining your sanitation unit, ensuring the availability of essential components is crucial. Various elements may need to be substituted over time to keep your restroom equipment functioning smoothly. This section outlines the key components that may require attention and offers guidance on how to find suitable replacements.

Common Components That May Need Replacement

Several parts within your sanitation system can wear out or become damaged. Common items include seals, valves, and levers. Regular inspections can help identify issues early, preventing more significant problems down the line. For instance, replacing worn seals can prevent leaks and maintain optimal performance.

Where to Find Quality Components

Numerous suppliers offer high-quality alternatives for your restroom unit. Online retailers, local hardware stores, and specialty shops often stock a wide selection of necessary items. When sourcing replacements, ensure that the components meet compatibility standards for your model to guarantee seamless functionality.

Commonly Replaced Seals and Gaskets

In various mechanical systems, seals and gaskets play a crucial role in preventing leaks and maintaining efficiency. Over time, these components can wear out or become damaged, leading to the necessity for replacement. Understanding which seals and gaskets are most commonly replaced can help users maintain their systems effectively.

Here are some frequently replaced components:

- Rubber Seals: Often found in doors and lids, these flexible components provide a tight fit to prevent leaks.

- O-Rings: Circular rings that seal connections and joints, preventing fluids from escaping.

- Flat Gaskets: Used between two surfaces to create a seal, preventing leakage of liquids or gases.

- Compression Seals: Designed to compress under pressure, ensuring a leak-proof connection in various applications.

- Wave Washers: Help maintain a constant pressure on seals, often used in conjunction with other sealing components.

Regularly inspecting and replacing these items can enhance performance and extend the lifespan of the equipment. Ensuring a proper fit and material compatibility is essential for effective sealing.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires regular care and attention. By implementing effective maintenance practices, you can significantly extend its lifespan and improve overall performance. Here are some essential tips to help you keep your device in top shape.

Regular Cleaning

Frequent cleaning is crucial in preventing the buildup of dirt and grime, which can lead to malfunctions. Make sure to use suitable cleaning agents that are safe for the materials involved. A soft cloth or sponge is often effective for routine maintenance.

Inspection and Replacement

Periodic inspections allow you to identify wear and tear before they escalate into serious issues. Pay attention to seals and connectors, as these components may require replacement after extensive use. Keeping a log of your maintenance activities can help track when parts were last checked or replaced.

Task Frequency Notes Clean exterior surfaces Weekly Use non-abrasive cleaners Inspect seals Monthly Look for cracks or damage Replace worn parts As needed Keep spare components handy Lubricate moving parts Every 6 months Use appropriate lubricant Diagram of the Control Panel Layout

The control panel serves as the central interface for user interaction, providing essential functionalities and information at a glance. Understanding the arrangement of various components can enhance the operational experience and facilitate troubleshooting.

Component Description Power Button Initiates and terminates the operation of the system. Display Screen Shows current settings, alerts, and operational status. Control Knob Adjusts settings such as temperature and fan speed. Indicator Lights Provide visual feedback on system status (e.g., ready, error). Function Buttons Allow quick access to specific features like reset or mode selection. Understanding the Cassette Handling System

The cassette handling system is a crucial component of portable sanitation solutions, ensuring efficient waste management. This system is designed to facilitate the easy removal and installation of waste containers, enhancing user convenience and hygiene. Understanding how this mechanism operates is essential for effective maintenance and optimal performance.

Key Features of the Handling System

- Ease of Use: The system allows users to quickly access the waste container, making the disposal process straightforward and efficient.

- Secure Locking Mechanism: A reliable locking system ensures that the cassette remains securely in place during transportation.

- Durability: Made from high-quality materials, the components of the system are designed to withstand the rigors of outdoor usage.

Maintenance Tips

- Regularly inspect the locking mechanism for any signs of wear or damage.

- Clean the system periodically to prevent the buildup of waste residues.

- Ensure that all moving parts are well-lubricated for smooth operation.

By understanding the cassette handling system, users can ensure that their portable sanitation solutions operate efficiently and effectively, providing a clean and hygienic experience.

Troubleshooting Issues with the C402 Parts

When dealing with common challenges related to a specific model of portable sanitation equipment, it’s essential to understand potential malfunction points. Identifying issues effectively can save time and ensure smooth operation. This section outlines typical problems users may encounter and offers practical solutions to enhance functionality.

Common Problems and Solutions

One frequent issue involves leaks, which can arise from various components. Inspect seals and joints for any signs of wear or damage. Replacing worn-out seals often resolves the issue. Additionally, if the unit exhibits poor flushing performance, check for blockages in the internal mechanisms. Clearing any obstructions typically restores functionality.

Maintenance Tips

Regular maintenance is crucial to prolonging the lifespan of your equipment. Clean components frequently to prevent buildup that could lead to malfunctions. Additionally, ensure that all connections are secure and free from corrosion. By adopting a proactive maintenance routine, users can minimize potential problems and enjoy a more reliable experience.

Where to Find Spare Parts for C402

Locating replacement components for your equipment can be straightforward if you know where to look. Various options are available, ranging from specialized retailers to online marketplaces. Understanding these avenues will help ensure you find what you need efficiently.

Online Retailers

Many websites offer a wide selection of replacement components. Online retailers often have extensive inventories and competitive pricing. It’s advisable to check the specifications to ensure compatibility with your model.

Local Suppliers

Local stores specializing in outdoor or recreational equipment may carry the components you need. Visiting these shops allows you to speak with knowledgeable staff who can assist you in identifying the correct items.

Source Type Description Online Stores Convenient access to a variety of items, often with detailed descriptions and user reviews. Local Shops Personalized assistance and the opportunity to inspect items before purchasing. Manufacturer’s Website Official source for genuine components and additional resources. Second-Hand Markets Potential savings by finding used or refurbished items, though caution is advised regarding quality.