Essential Components of a Walk-In Freezer

In the realm of temperature-controlled storage, comprehending the various elements that contribute to efficiency and functionality is essential. Each component plays a vital role in maintaining optimal conditions, ensuring that perishable goods remain fresh and safe. An overview of these components not only enhances operational knowledge but also aids in effective troubleshooting and maintenance.

Familiarity with the individual elements within the refrigeration system allows for a deeper appreciation of how they interact to create a stable environment. From the chilling mechanisms to the insulation materials, each aspect is intricately designed to work in harmony. Recognizing these relationships can lead to improved performance and longevity of the entire setup.

Ultimately, gaining insight into the configuration of these essential elements empowers users to make informed decisions regarding installation, repairs, and upgrades. This understanding is crucial for those who rely on efficient temperature regulation for their storage needs, whether in commercial or residential settings.

Essential Components of Walk-in Freezers

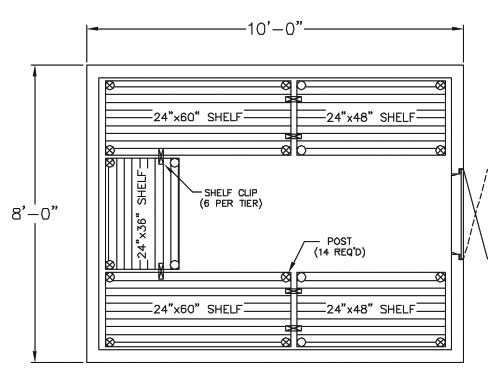

Understanding the fundamental elements of large-scale cold storage units is crucial for maintaining their efficiency and longevity. Each component plays a vital role in ensuring optimal performance, from regulating temperature to facilitating easy access. Below are the key elements that contribute to the functionality of these refrigeration systems.

- Insulation: Quality insulation is essential for energy efficiency, helping to maintain a consistent internal temperature.

- Cooling Unit: This component is responsible for generating and circulating cold air throughout the space.

- Doors: Specialized access points designed to minimize temperature fluctuations when opened.

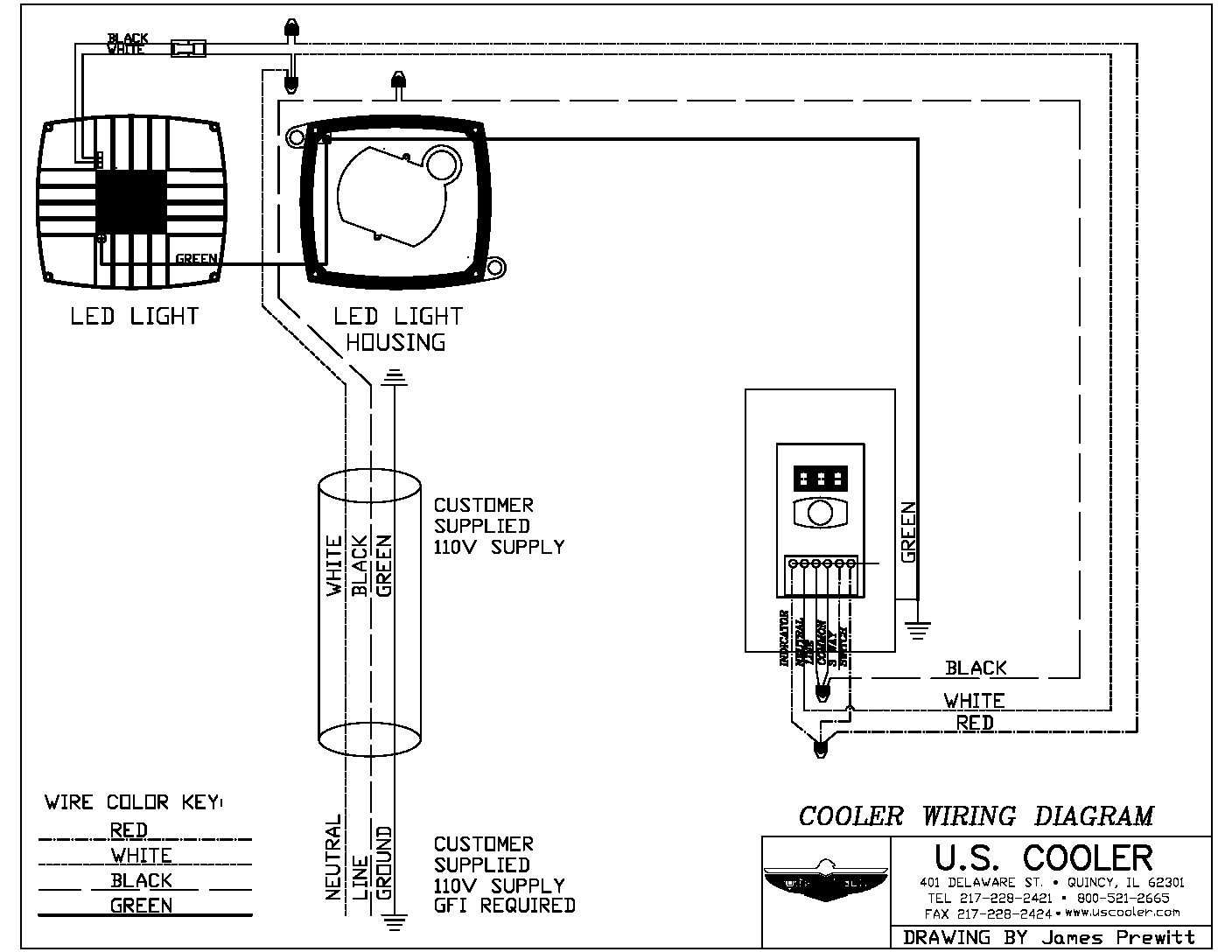

- Lighting: Energy-efficient lighting solutions ensure visibility inside the storage area without generating excessive heat.

- Temperature Control System: A crucial feature that monitors and adjusts the internal environment based on set parameters.

- Flooring: Durable flooring materials that can withstand low temperatures and heavy loads while providing safety.

By familiarizing oneself with these essential components, users can better appreciate the intricacies involved in the operation of large refrigeration systems.

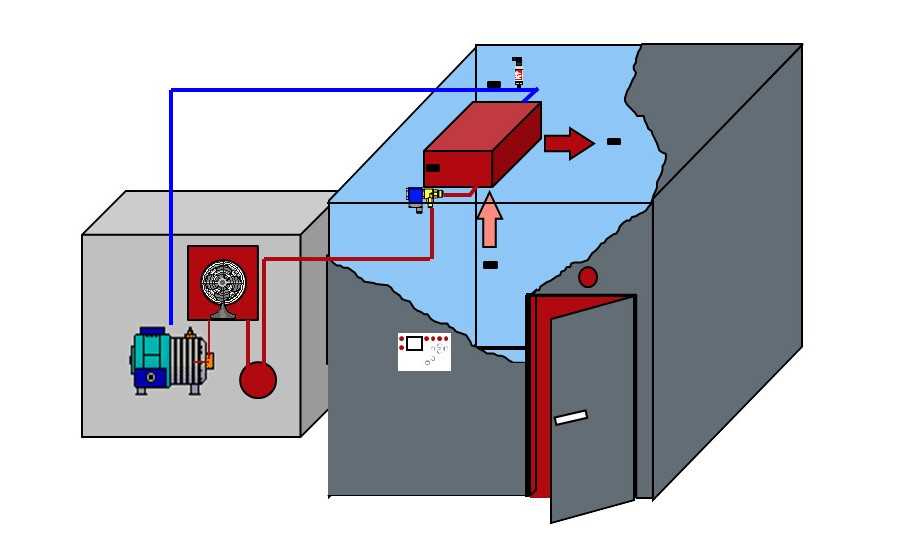

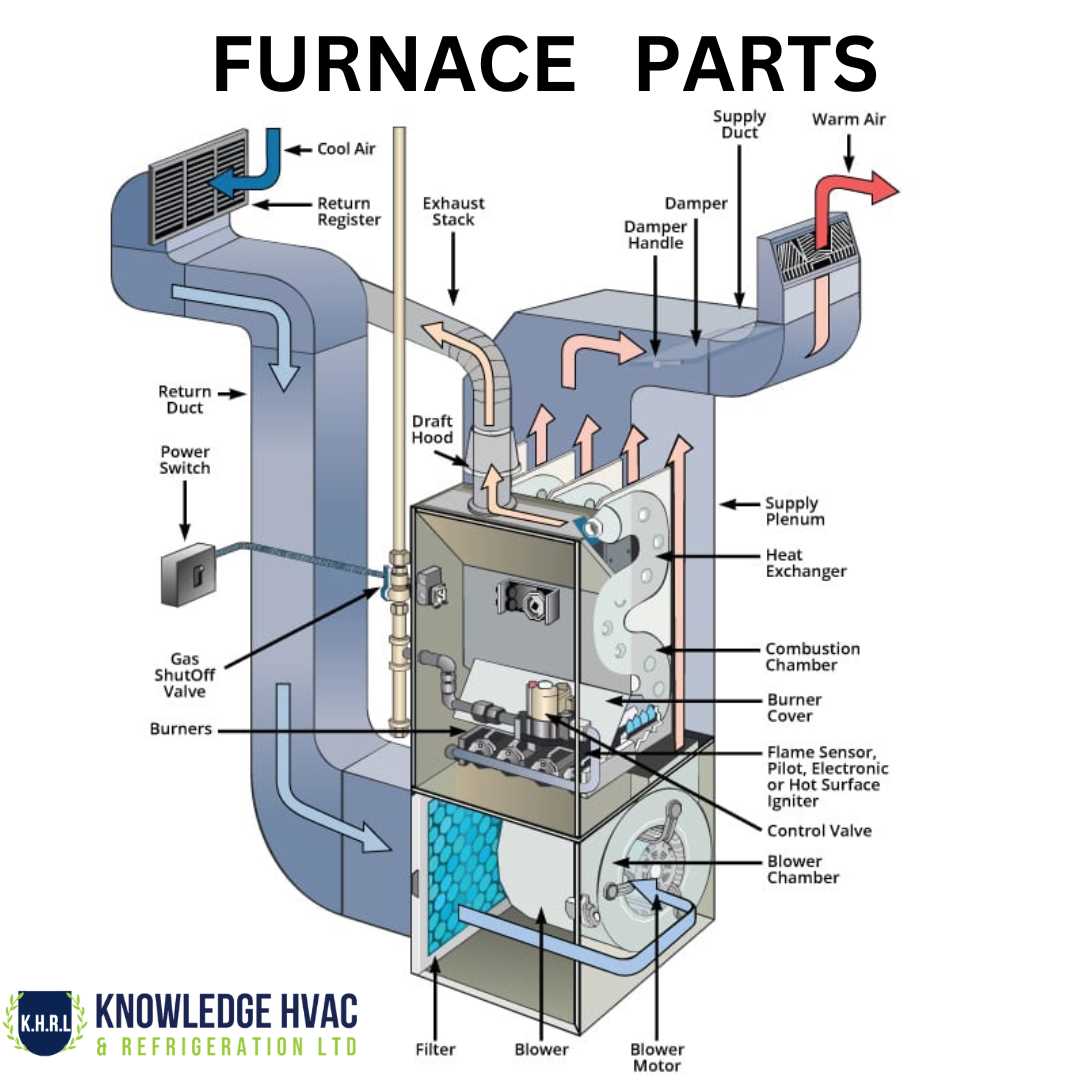

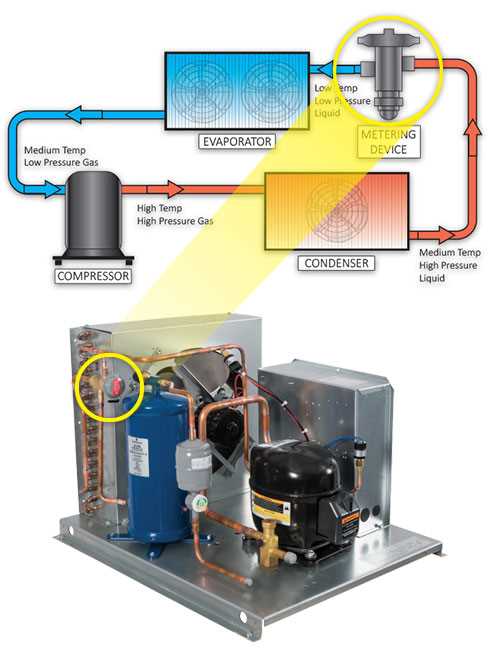

Understanding Cooling Systems in Freezers

The efficiency of refrigeration units relies heavily on their cooling mechanisms. These systems are designed to maintain low temperatures by transferring heat from the interior to the outside environment. By grasping how these systems function, one can appreciate their role in preserving perishable goods and ensuring optimal conditions for storage.

At the heart of these systems lies a compressor, which compresses refrigerant gas, raising its pressure and temperature. This hot gas then travels through a series of coils located outside the storage space, where it dissipates heat and transforms into a liquid state. As the liquid refrigerant re-enters the cooling compartment, it evaporates, absorbing heat from the interior, thereby cooling the surrounding air.

Moreover, evaporator coils play a crucial role in this process. Positioned within the storage area, these coils facilitate the absorption of warmth as the refrigerant evaporates. Proper airflow, generated by fans, is essential to circulate the chilled air throughout the environment, ensuring consistent temperatures across all areas.

Finally, a thermostat monitors and regulates the temperature, activating the compressor as needed to maintain the desired conditions. Understanding these components and their interactions provides valuable insights into the effectiveness of refrigeration systems in maintaining freshness and safety for various products.

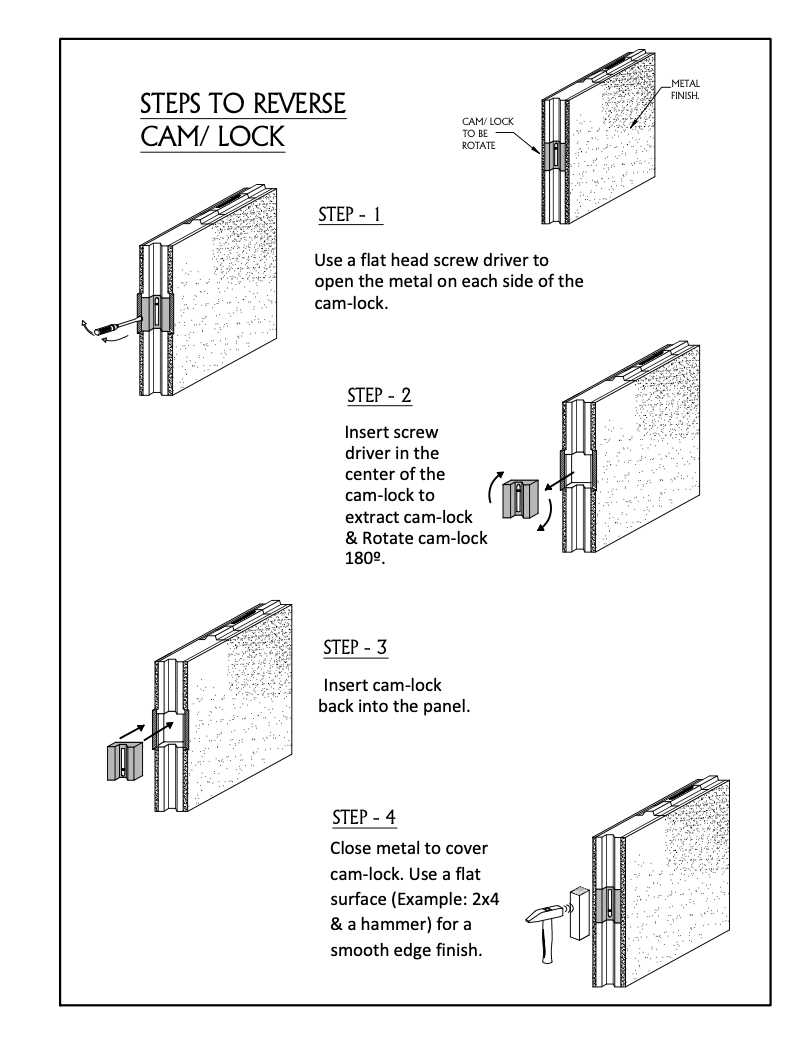

Key Features of Insulated Panels

Insulated panels are essential components designed to enhance thermal efficiency in various applications. They play a crucial role in maintaining a stable internal environment, making them invaluable in settings where temperature control is critical. Understanding the distinctive attributes of these panels can significantly impact their effectiveness and longevity.

Thermal Performance

One of the primary advantages of insulated panels is their exceptional thermal performance. These panels are constructed with materials that minimize heat transfer, ensuring that the internal temperature remains consistent regardless of external conditions. Key characteristics include:

- Low thermal conductivity, which reduces energy consumption.

- Resistance to temperature fluctuations, providing a stable environment.

- Improved insulation values, contributing to overall energy efficiency.

Durability and Strength

In addition to thermal efficiency, insulated panels are known for their durability and structural integrity. Their robust construction helps withstand external pressures and environmental challenges. Notable features include:

- High resistance to impact and wear, ensuring long-term use.

- Moisture and corrosion resistance, which prolongs lifespan.

- Lightweight design, facilitating easy installation and transportation.

Importance of Door Seals and Gaskets

The effectiveness of temperature-controlled storage units greatly depends on the integrity of their entryways. Properly functioning seals and gaskets play a crucial role in maintaining optimal conditions within these environments. They prevent the escape of cold air and the infiltration of warm air, thereby ensuring that the desired internal climate is preserved efficiently.

Energy Efficiency

Well-maintained door seals contribute significantly to energy conservation. When seals are compromised, the cooling system has to work harder to compensate for the lost air, leading to increased energy consumption. By ensuring that these components are in good condition, operators can achieve substantial savings on energy costs while also reducing their environmental impact.

Product Quality Preservation

In addition to energy savings, effective seals and gaskets protect the quality of stored items. Maintaining a stable temperature is essential for preserving perishable goods, preventing spoilage, and ensuring compliance with safety standards. Regular inspections and timely replacements of these components are essential for safeguarding the integrity of stored products.

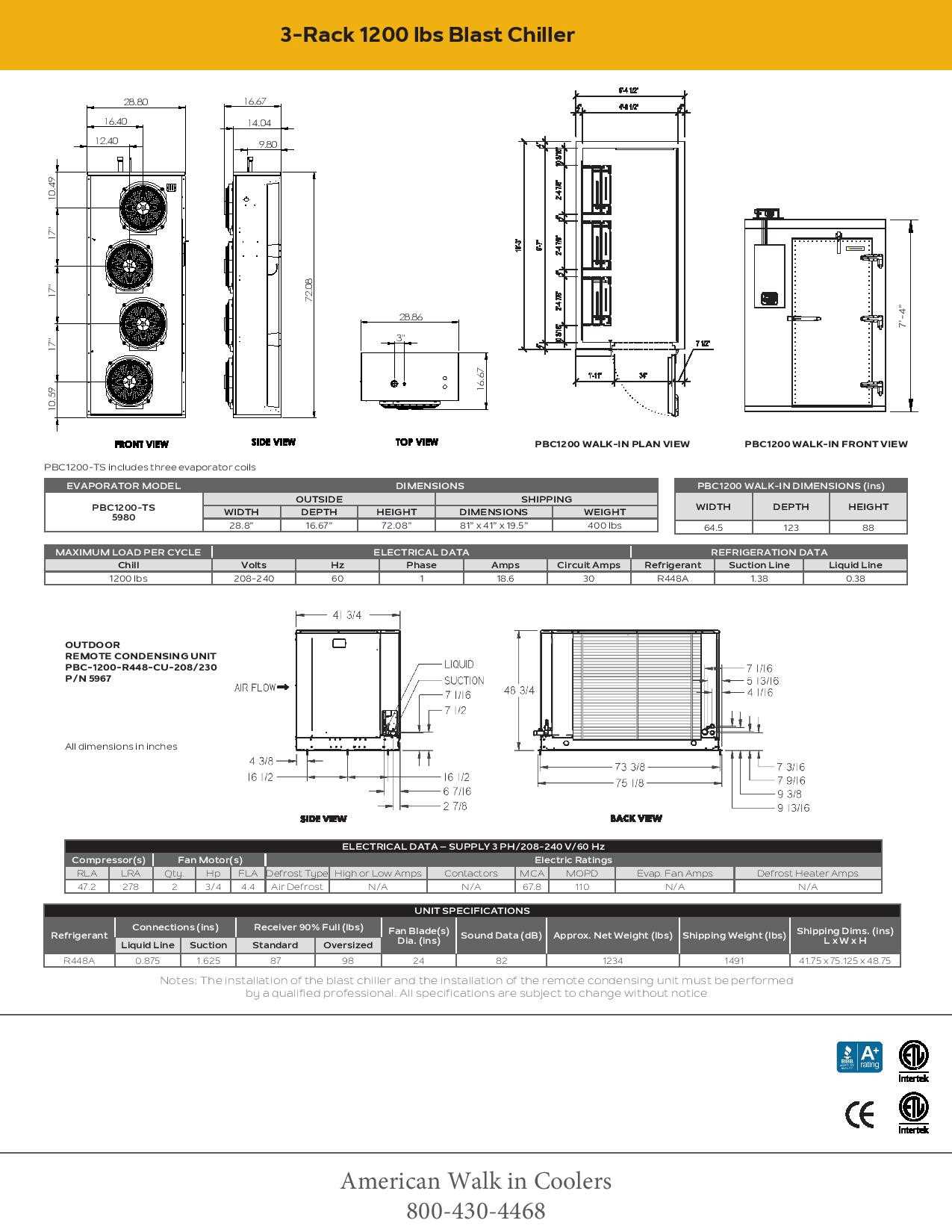

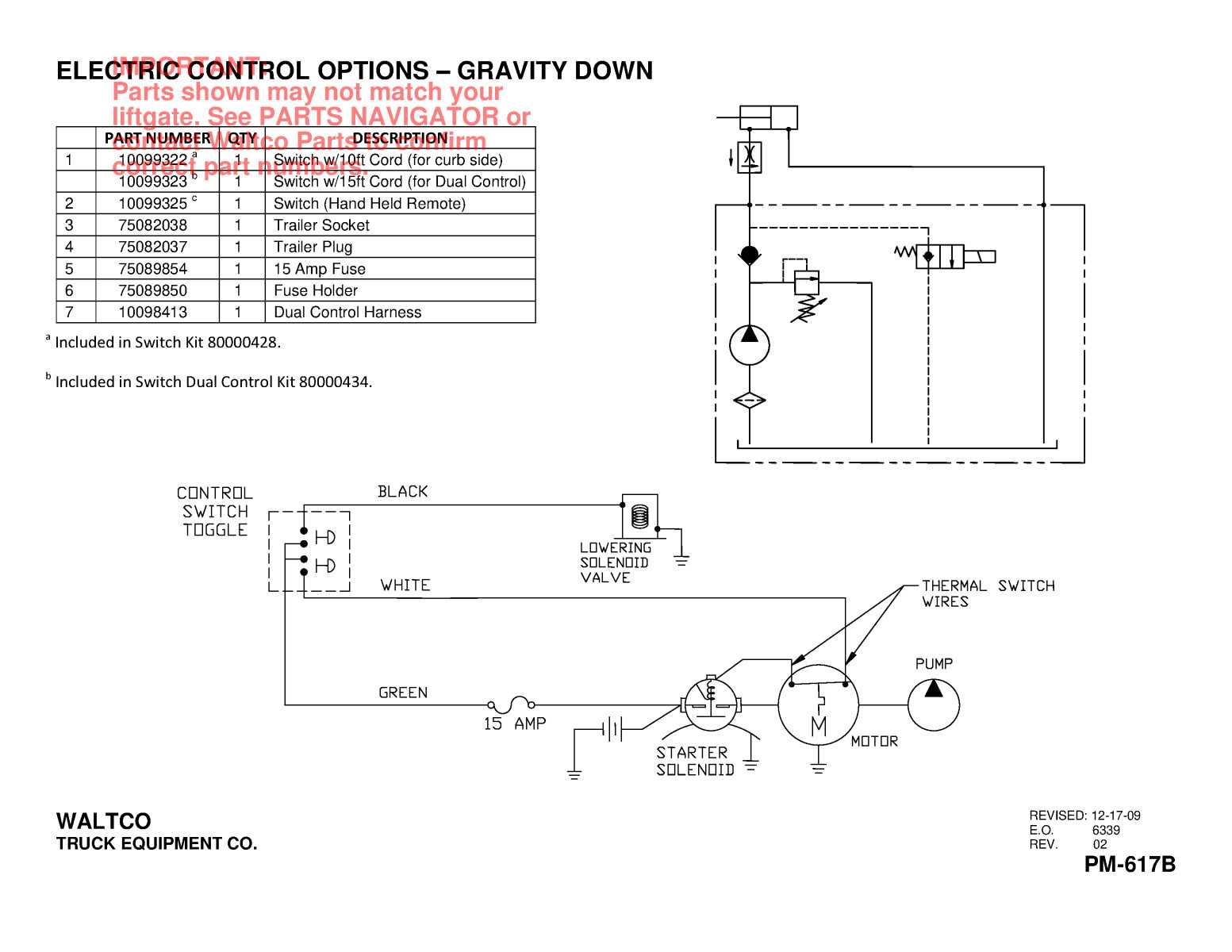

Exploring Refrigeration Units and Compressors

Understanding the components that facilitate temperature control is essential for efficient operation. These systems play a critical role in preserving perishable items by maintaining optimal conditions. Among the key elements are refrigeration mechanisms and compressors, which work in tandem to ensure effective cooling and energy conservation.

Refrigeration units consist of various components that contribute to their overall functionality:

- Compressor: Acts as the heart of the system, compressing refrigerant gas to initiate the cooling cycle.

- Evaporator: Absorbs heat from the interior space, converting the refrigerant from liquid to gas.

- Condenser: Releases the absorbed heat to the external environment, allowing the refrigerant to condense back into a liquid state.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, maintaining the system’s pressure balance.

Each of these components plays a vital role in ensuring that the entire cooling system operates smoothly. Understanding their functions and interactions can help in troubleshooting and maintaining these essential units.

When selecting compressors, consider factors such as:

- Size and capacity suitable for the specific cooling requirements.

- Energy efficiency ratings to minimize operational costs.

- Noise levels, particularly in environments where sound control is important.

- Durability and reliability, ensuring long-term performance under demanding conditions.

By delving into the intricacies of refrigeration units and compressors, one can appreciate their importance in preserving quality and extending the lifespan of stored items.

Functionality of Evaporator Coils Explained

Evaporator coils play a crucial role in the refrigeration cycle, facilitating the transfer of heat to maintain a controlled environment. These components are essential for ensuring optimal performance in cooling systems, contributing to energy efficiency and product preservation.

The primary function of these coils is to absorb heat from the surrounding air. As the refrigerant circulates through the coils, it evaporates, transitioning from a liquid to a gas state. This phase change effectively removes warmth from the area, allowing the temperature to drop.

Moreover, evaporator coils are designed to distribute cool air evenly, preventing temperature fluctuations that could compromise the quality of stored items. By facilitating consistent airflow, these coils ensure that every corner of the space remains at the desired temperature, enhancing the overall effectiveness of the refrigeration system.

In summary, the significance of evaporator coils lies in their ability to absorb heat, promote even cooling, and support the efficiency of the entire cooling apparatus. Understanding their functionality is vital for maintaining a stable and reliable cooling environment.

Role of Condenser Units in Freezing

Condenser units play a pivotal role in maintaining low temperatures within refrigeration systems. They are essential components that facilitate the removal of heat from the refrigerant, allowing the system to operate efficiently. By condensing gas back into a liquid state, these units ensure that the cooling cycle continues effectively, thus preserving the integrity of stored items.

Functionality and Importance

The primary function of condenser units is to convert vaporized refrigerant into a liquid by dissipating heat. This process involves the circulation of air or water, which absorbs the heat and transfers it away from the refrigerant. The effectiveness of this heat exchange directly impacts the overall efficiency of the refrigeration system, making these units crucial for optimal performance.

Impact on Energy Efficiency

Energy efficiency is significantly influenced by the design and maintenance of condenser units. Well-maintained units operate more efficiently, consuming less energy and reducing operational costs. Proper airflow and regular cleaning of coils are essential practices that enhance their effectiveness, ultimately contributing to a sustainable refrigeration environment.

Maintenance Tips for Walk-in Freezers

Ensuring the longevity and efficiency of your cold storage unit requires regular upkeep. A well-maintained unit not only operates effectively but also reduces energy costs and extends the lifespan of its components. Implementing routine checks and preventive measures can lead to significant benefits.

Routine Inspections

- Conduct frequent visual inspections to identify any signs of wear or damage.

- Check door seals to ensure they are airtight and functioning properly.

- Inspect the flooring for any leaks or pooling water that may indicate drainage issues.

Cleaning and Maintenance

- Regularly clean the evaporator and condenser coils to maintain optimal performance.

- Ensure that drainage lines are clear of debris to prevent clogs.

- Schedule professional maintenance at least once a year to address any underlying issues.

By following these maintenance guidelines, you can help ensure that your cold storage environment remains efficient and reliable, safeguarding the quality of stored goods.

Common Issues and Troubleshooting Steps

Understanding typical challenges in large refrigeration units is essential for maintaining optimal functionality. Regularly encountering specific problems can affect performance and efficiency. Identifying these issues promptly ensures smooth operations and extends the lifespan of the equipment.

Frequent Problems

Several common difficulties can arise, such as temperature fluctuations, unusual noises, and inadequate airflow. These issues often stem from faulty components, improper settings, or blocked vents. Regular inspections can help detect these problems early, minimizing downtime and costly repairs.

Troubleshooting Techniques

To address these challenges, start by checking the temperature settings and ensuring they align with operational standards. Inspect components for any signs of wear or damage, and clean vents and filters to enhance airflow. If noises persist, examine the motor and fan for loose parts or obstructions. Implementing these steps can significantly improve performance and prevent further complications.

Energy Efficiency in Freezer Operations

Maximizing energy efficiency in refrigerated storage environments is essential for reducing operational costs and minimizing environmental impact. Understanding the factors that influence energy consumption can lead to significant savings and improved performance. By implementing best practices and utilizing advanced technologies, facilities can optimize their cooling systems for better energy management.

- Regular Maintenance: Routine checks and servicing can prevent energy waste caused by equipment malfunctions.

- Insulation Quality: High-quality insulation materials help maintain internal temperatures, reducing the workload on cooling systems.

- Energy-Efficient Equipment: Upgrading to modern, energy-efficient units can lead to lower electricity usage and increased reliability.

Additionally, proper airflow and temperature management are crucial for maintaining efficiency. Ensuring that air circulation is unobstructed allows for uniform temperature distribution, reducing the need for excessive energy input. Moreover, implementing smart technology for monitoring and controlling conditions can provide real-time insights, leading to more informed operational decisions.

- Use of LED Lighting: Switching to LED lighting reduces energy consumption while providing adequate illumination.

- Optimized Door Seals: Ensuring that entry points are sealed properly prevents cold air from escaping, enhancing overall performance.

- Temperature Set Points: Adjusting temperature set points based on the load can lead to substantial energy savings.

In conclusion, focusing on energy efficiency not only lowers operational costs but also supports sustainability efforts. By adopting a holistic approach that includes regular maintenance, equipment upgrades, and smart technologies, organizations can create a more efficient and environmentally friendly refrigerated environment.

Upgrading Walk-in Freezer Components

Enhancing the essential elements of a large cold storage unit can significantly improve its efficiency and performance. Upgrading specific components not only extends the lifespan of the system but also ensures optimal functionality, leading to energy savings and reduced operational costs.

When considering improvements, several key aspects warrant attention:

- Insulation: Replacing outdated insulating materials can drastically reduce energy loss, maintaining a stable internal environment.

- Cooling Systems: Upgrading compressors and evaporators can enhance cooling efficiency, ensuring consistent temperatures throughout the unit.

- Doors and Seals: Installing new doors or seals minimizes air exchange, further protecting the internal climate and saving energy.

- Lighting: Transitioning to LED lighting not only lowers energy consumption but also improves visibility within the space.

- Temperature Control: Implementing advanced temperature monitoring and control systems can provide real-time data, facilitating better management of the storage environment.

Each of these enhancements contributes to a more effective and reliable cold storage solution, addressing the needs of both operators and stored products. Regular assessments and timely upgrades can lead to substantial long-term benefits.