Understanding the Frigidaire Ice Maker Parts Diagram

Every household relies on a variety of cooling devices that enhance our daily lives, especially during warm months. These essential tools often require a deep understanding of their individual components for optimal performance and longevity. This section will explore the intricate elements that contribute to the efficient operation of these appliances.

By gaining insight into each section of your device, users can identify potential issues and ensure their cooling equipment functions smoothly. A comprehensive grasp of these mechanisms not only aids in troubleshooting but also empowers users to undertake basic maintenance.

In this exploration, we will delve into the structure and functionality of each crucial element, providing clarity on how they work together to deliver the ultimate experience. Whether you are a seasoned technician or a curious homeowner, understanding these components will enhance your interaction with your cooling appliance.

Understanding Frigidaire Ice Maker Components

Gaining insight into the various elements involved in the freezing appliance is essential for efficient operation and maintenance. Each component plays a crucial role in the overall functionality, ensuring that the device performs optimally.

Key Components

- Water Supply System

- Heating Element

- Control Module

- Storage Bin

- Thermostat

Functionality Overview

- The water supply system delivers necessary fluid for freezing.

- The heating element assists in the release of frozen cubes.

- The control module regulates the entire process, ensuring efficiency.

- The storage bin collects the finished product for use.

- The thermostat monitors temperature, maintaining optimal conditions.

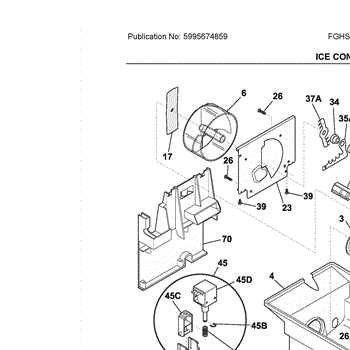

How to Read Ice Maker Diagrams

Understanding technical schematics is essential for troubleshooting and maintenance of any appliance. These visual representations provide crucial insights into the components and their functions, allowing users to effectively diagnose issues and facilitate repairs.

Key Elements to Identify

- Symbols: Familiarize yourself with common icons used to represent various components.

- Connections: Note how elements are linked, as this reveals their interactions.

- Labels: Pay attention to text annotations that clarify the function of each part.

Steps for Interpretation

- Start by reviewing the entire schematic to grasp its layout.

- Identify major sections and components based on the symbols.

- Trace connections to understand how parts communicate with one another.

- Refer to the legend or key if available for additional context.

Common Issues with Ice Maker Parts

Various components within a cooling unit designed for freezing water can encounter issues that hinder their performance. Understanding these common problems can aid in troubleshooting and maintenance, ensuring optimal functionality.

Frequent Problems Encountered

- Blockages: Obstructions can prevent the flow of water, leading to inadequate freezing.

- Faulty Sensors: Malfunctioning detection mechanisms may cause erratic operation or complete failure.

- Water Supply Issues: Insufficient or disrupted water supply can impact the ability to create frozen products.

- Electrical Failures: Wiring issues or power supply problems may interrupt normal functioning.

Troubleshooting Tips

- Check for blockages in the water line and ensure proper flow.

- Inspect sensors for damage or misalignment and replace if necessary.

- Verify the water supply connection for leaks or kinks.

- Examine wiring and connections for any signs of wear or disconnection.

Maintenance Tips for Ice Makers

Regular upkeep is essential for ensuring optimal performance and longevity of your cooling appliances. By following some straightforward guidelines, you can enhance efficiency and minimize potential issues, providing a steady supply of frozen refreshment.

Routine Cleaning

Cleaning the interior and components frequently helps prevent buildup of debris and minerals. Use a soft cloth and a gentle cleaner, focusing on areas that come into direct contact with water and freezing elements.

Check Water Supply

Ensure the water source is free from blockages and delivers a steady flow. Inspect hoses and connections for leaks or kinks that could disrupt functionality, addressing any concerns promptly.

Replacing Frigidaire Ice Maker Parts

Maintaining your appliance’s functionality often requires the replacement of certain components. Understanding the key elements involved in this process can enhance efficiency and extend the lifespan of your unit. Whether you’re dealing with a malfunction or routine upkeep, knowing how to navigate the replacement can save time and resources.

Identifying the Components

Before proceeding with the replacement, it’s crucial to identify which components need attention. Here are some common elements to consider:

- Water supply valve

- Heating element

- Control module

- Reservoir

- Auger motor

Replacement Process

Once you’ve identified the necessary components, follow these steps for effective replacement:

- Disconnect the appliance from the power source.

- Access the compartment housing the components.

- Carefully remove the faulty part, taking note of its connections.

- Install the new component, ensuring all connections are secure.

- Reassemble the compartment and reconnect the power.

Regular maintenance and timely replacement of these essential elements can lead to improved performance and reliability of your appliance.

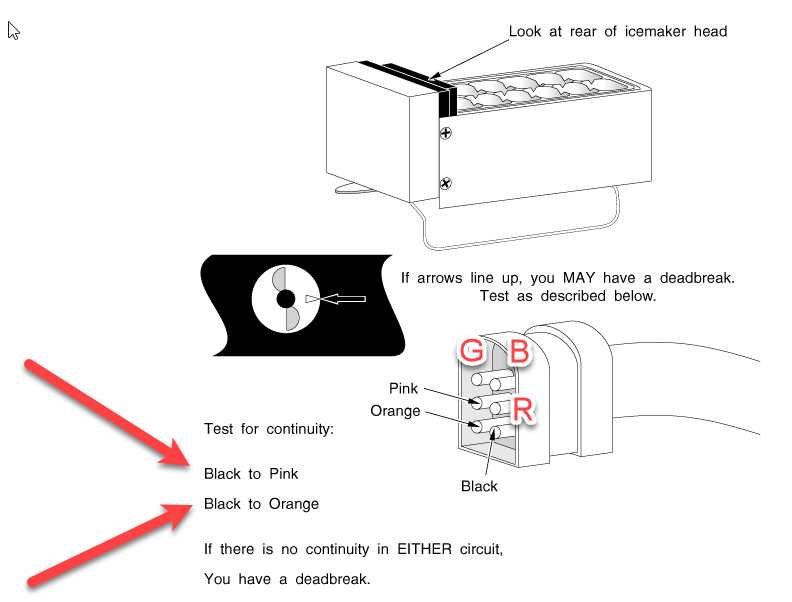

Identifying Faulty Components Easily

Recognizing malfunctioning elements in your appliance can save time and money. By understanding the various components and their functions, you can quickly pinpoint issues. This process involves visual inspections and basic troubleshooting techniques to determine which parts may be underperforming or completely nonfunctional.

Start by checking for common symptoms, such as unusual noises or a lack of performance. Use a systematic approach: examine connections, look for signs of wear, and verify that all components are properly aligned. A methodical inspection not only helps identify faults but also enhances your understanding of the device’s operation.

Documentation, including diagrams or manuals, can serve as a valuable reference during this evaluation. They provide insights into the layout and interrelationships of different parts, enabling a more efficient diagnosis. By familiarizing yourself with these resources, you empower yourself to tackle issues proactively.

Essential Tools for Repairing Ice Makers

Having the right instruments is crucial for effectively resolving issues with your freezing appliances. A well-equipped toolkit not only streamlines the repair process but also enhances your ability to tackle various challenges that may arise.

- Screwdrivers: A set of Phillips and flathead screwdrivers is essential for removing covers and accessing internal components.

- Wrench Set: Adjustable wrenches are useful for loosening and tightening fittings.

- Multimeter: This tool helps diagnose electrical problems by measuring voltage and resistance.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small parts.

- Utility Knife: Handy for cutting through insulation or removing old seals.

Equipping yourself with these essential tools will ensure that you are prepared to handle any repair task effectively and efficiently.

Upgrading Your Ice Maker System

Enhancing your cold beverage production unit can significantly improve your kitchen’s efficiency and convenience. Upgrading components not only boosts performance but can also lead to a more reliable and energy-efficient experience. This process involves selecting the right enhancements that suit your needs while ensuring compatibility with your existing setup.

Benefits of Upgrading

Modern systems offer advanced features such as faster production rates and improved energy consumption. These upgrades can result in reduced operational costs and increased output, making it easier to host gatherings or keep up with daily demands. Additionally, newer models often come with enhanced durability, minimizing maintenance issues and extending the lifespan of your unit.

Choosing the Right Components

When considering upgrades, evaluate your current system’s specifications and compatibility. Look for high-quality replacements that align with your operational needs. Researching reviews and seeking expert advice can guide you in selecting the most effective solutions. With the right components, your unit can achieve optimal performance and efficiency, ultimately enhancing your overall experience.

Exploring Ice Maker Performance Factors

Understanding the various elements that influence the efficiency and output of a cooling unit is essential for optimal operation. Several key components play a crucial role in determining how well these devices function.

- Temperature Regulation: Maintaining the right temperature is vital for effective performance.

- Water Quality: The purity and mineral content of the water significantly affect production rates.

- Energy Source: The power supply type can influence the overall efficiency of the unit.

- Maintenance Practices: Regular cleaning and servicing ensure longevity and functionality.

- Design Features: The layout and technology used in construction can enhance or impede performance.

By delving into these factors, users can better appreciate the intricacies of their cooling systems and make informed decisions regarding maintenance and upgrades.

Safety Precautions During Repairs

When undertaking any repair work, ensuring safety should be the top priority. Adhering to proper protocols can prevent accidents and injuries, safeguarding both the individual and the equipment involved. This section outlines essential guidelines to follow during maintenance tasks.

General Safety Guidelines

- Always disconnect power before starting any repairs to avoid electric shock.

- Use appropriate tools and equipment to prevent injury.

- Wear personal protective gear, such as gloves and safety glasses.

- Keep the workspace clean and free of obstructions to minimize tripping hazards.

- Read the user manual for specific safety instructions related to the device.

Handling Components Safely

- Ensure all components are cool before handling to avoid burns.

- Store sharp objects securely to prevent cuts.

- Handle fragile parts carefully to avoid breakage.

- Be mindful of any sharp edges on the equipment during inspection.

- Dispose of any waste materials properly to avoid environmental hazards.

Where to Find Replacement Parts

Locating the necessary components for your appliance can be straightforward with the right resources. Understanding where to search can save both time and money, ensuring your device functions optimally once again.

| Source | Description |

|---|---|

| Manufacturer’s Website | Often provides direct access to genuine components and guides for your specific model. |

| Authorized Retailers | Store locations that specialize in home appliance supplies, offering reliable parts and advice. |

| Online Marketplaces | Platforms where various sellers offer both new and refurbished items, sometimes at lower prices. |

| Local Repair Shops | Professionals who can assist with finding and installing necessary items. |