Understanding the Parts Diagram of Petrol Pump Fuel Dispensers

In the intricate world of refueling systems, each element plays a crucial role in ensuring efficiency and safety. A thorough comprehension of these components allows for better maintenance and improved operational practices. This knowledge is essential for professionals working within this industry, enabling them to enhance performance and minimize downtime.

Key elements within these systems work together seamlessly, facilitating the transfer of liquid to vehicles. Recognizing how each piece interacts with others can significantly influence the overall effectiveness of the operation. Through visual representation, one can appreciate the structure and arrangement of these components, leading to greater insight into their functionality.

Moreover, understanding the mechanisms involved can assist in troubleshooting and optimizing processes. Familiarity with these components not only empowers technicians but also reinforces safety measures, contributing to a secure environment for both workers and customers. Exploring this subject can provide valuable knowledge for those engaged in the maintenance and improvement of refueling systems.

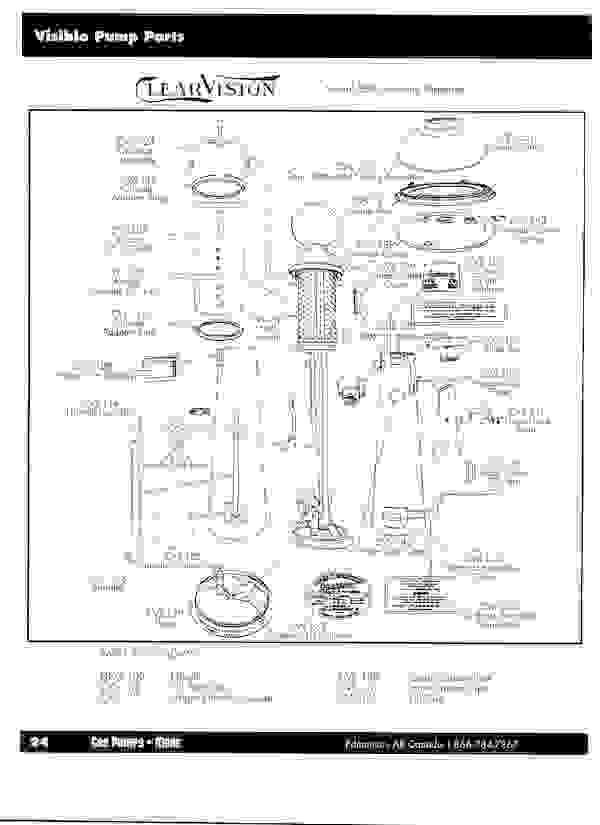

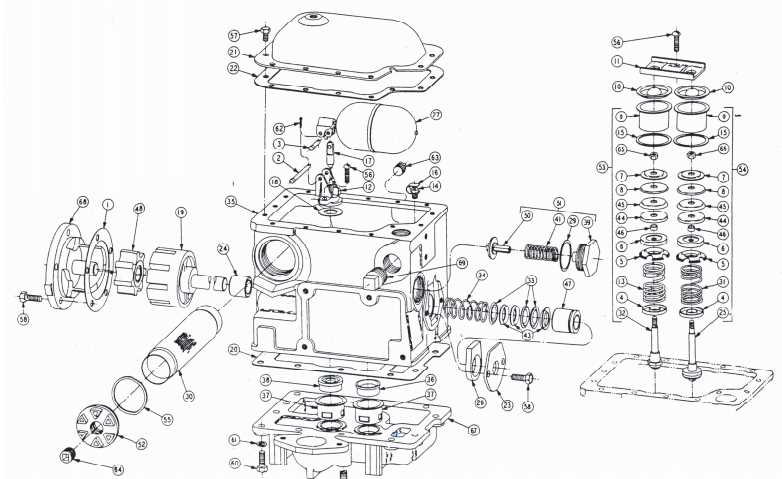

Understanding Fuel Dispenser Components

This section explores the various elements that constitute a fueling system, focusing on their functions and interconnections. Each component plays a vital role in ensuring efficient and safe transfer of energy resources to vehicles.

Main Elements of the System

- Measurement Unit: This mechanism accurately gauges the volume of liquid delivered, ensuring that customers receive the correct amount.

- Delivery Hose: A flexible tube designed to transfer liquid from the source to the vehicle’s tank.

- Control Interface: The user interface that allows customers to initiate and monitor the refueling process.

- Safety Features: Various mechanisms such as automatic shut-off valves to prevent spills and overflows.

Supporting Mechanisms

- Storage Tank: A reservoir where the energy resource is stored before being dispensed.

- Pumping Mechanism: Responsible for drawing the liquid from the storage tank and pushing it through the delivery hose.

- Filtration System: Ensures that the liquid is clean and free from contaminants before it reaches the vehicle.

- Monitoring Equipment: Systems that track the performance and operational metrics of the entire setup.

Understanding these components is crucial for anyone involved in the maintenance, operation, or design of refueling systems. Each element must work in harmony to provide a reliable service to customers.

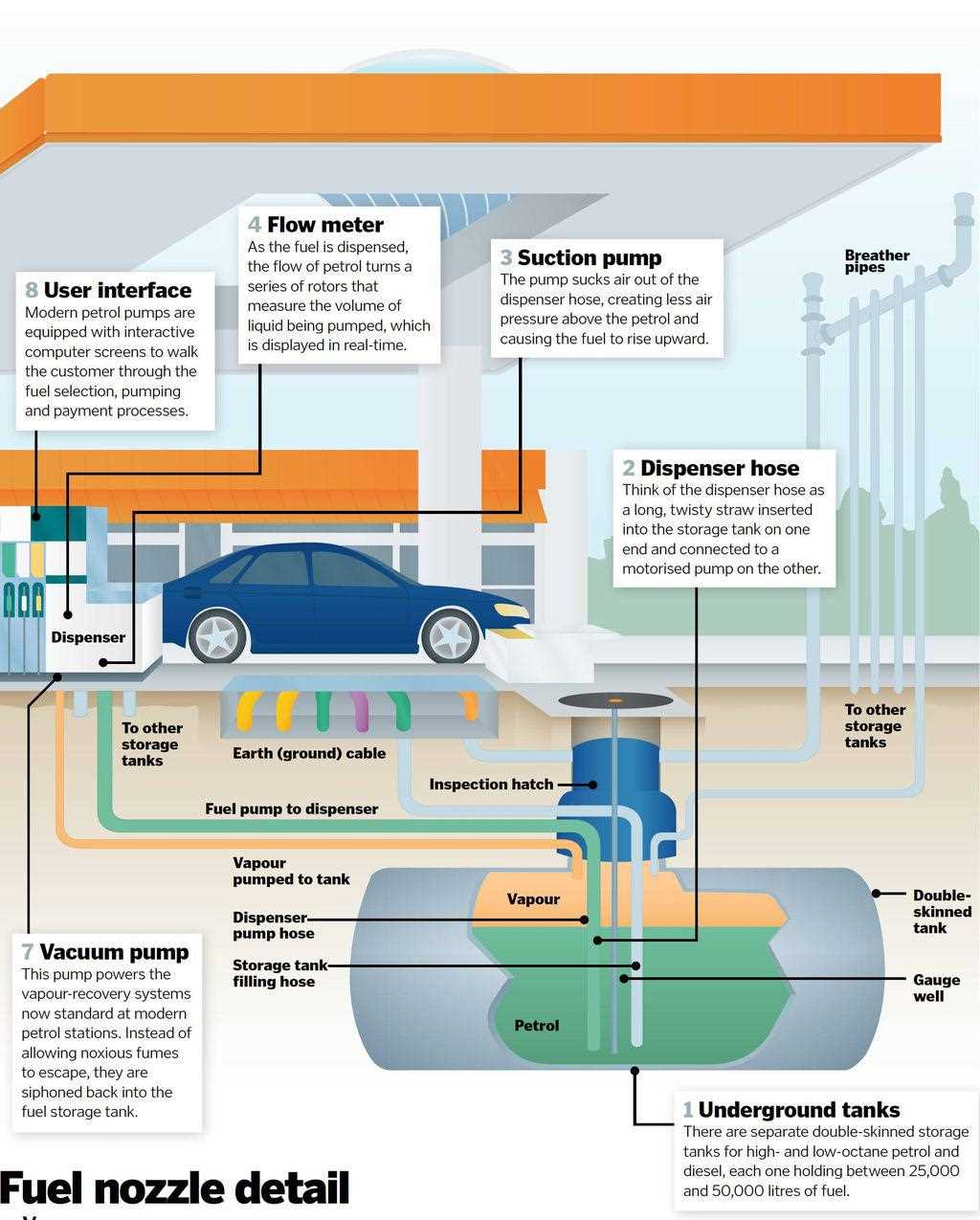

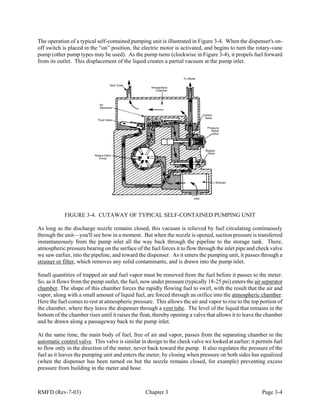

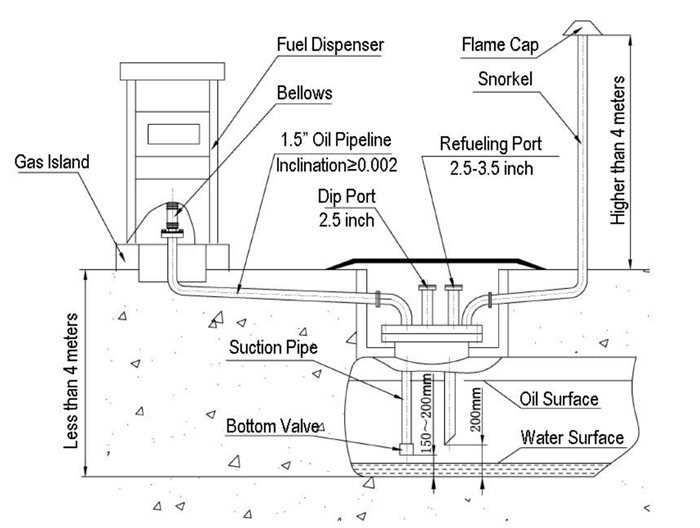

How Petrol Pumps Operate

This section explores the mechanisms behind liquid transfer systems found at service stations. Understanding these processes reveals how these machines ensure efficiency and accuracy in delivering liquid to vehicles.

Components Involved

Central to the operation are several key components that work together seamlessly. These include the motor, measurement systems, and valves, each playing a crucial role in ensuring a steady flow while maintaining precise quantities.

Operational Process

The operation begins with the activation of the system, triggering the motor to initiate flow. As liquid moves through, the measurement system accurately gauges the amount dispensed. Simultaneously, valves regulate the flow, ensuring safety and efficiency throughout the transfer process.

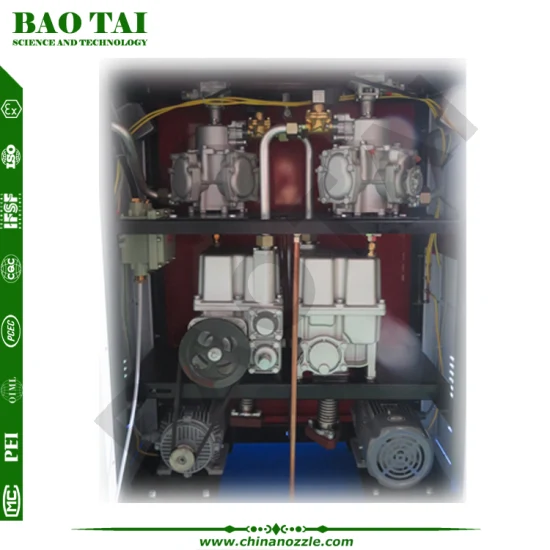

Essential Parts of Fuel Dispensers

Understanding the fundamental components that enable the efficient transfer of liquid from storage to vehicles is crucial for both users and operators. Each element plays a vital role in ensuring smooth operation, safety, and accuracy in measurement.

- Metering Unit: This component accurately measures the quantity of liquid delivered, ensuring that customers receive the correct amount for their payment.

- Control System: It regulates the flow and can manage various operational settings, providing convenience and safety features.

- Hose: A flexible conduit that connects the dispensing unit to the vehicle, allowing for easy access during the refueling process.

- Nozzle: The end piece that facilitates the transfer, designed to prevent leaks and ensure a secure connection to the vehicle’s tank.

- Storage Tank: A large container that holds the liquid, typically situated underground, designed to keep the contents secure and at optimal conditions.

Each of these components works in harmony to provide a seamless experience for users while adhering to industry standards for safety and efficiency.

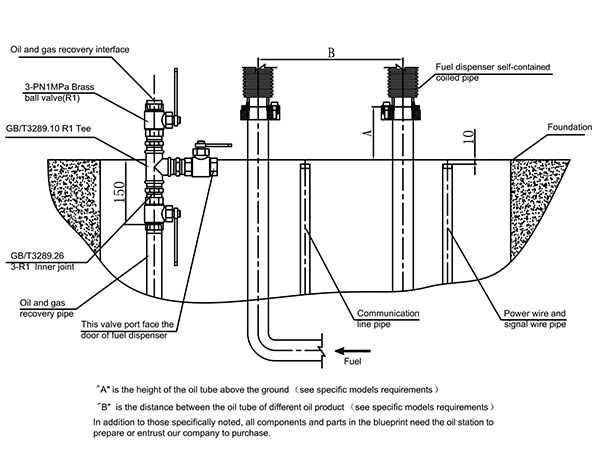

Overview of Dispenser Fuel Systems

The efficiency of modern fueling systems is crucial for ensuring smooth operations at service stations. These mechanisms are designed to deliver liquid energy in a safe and effective manner, combining advanced technology with user-friendly interfaces. Understanding the components and their functions can enhance knowledge about how these systems work and improve maintenance practices.

A typical setup involves several key elements that work in unison to ensure reliable service. The core unit is responsible for the precise measurement and delivery of the liquid, utilizing sensors and meters to ensure accuracy. Supporting systems manage the storage and transfer processes, with safety features implemented to prevent leaks and ensure environmental compliance.

User interaction is facilitated through interfaces that provide essential information such as flow rates and transaction details. Innovations in these systems have led to increased efficiency, reduced wait times, and improved customer experience, making it essential for operators to stay informed about the latest advancements and best practices in the industry.

Key Features of Fuel Pump Designs

Understanding the fundamental characteristics of dispensing mechanisms is crucial for optimal operation and efficiency. These elements not only enhance performance but also ensure reliability and safety in various environments.

Efficiency and Performance

- High flow rates to minimize waiting times.

- Energy-efficient operation to reduce overall costs.

- Accurate measurement systems for precise transactions.

Safety and Reliability

- Robust materials to withstand harsh conditions.

- Fail-safe mechanisms to prevent leaks and spills.

- Advanced filtration systems to ensure product purity.

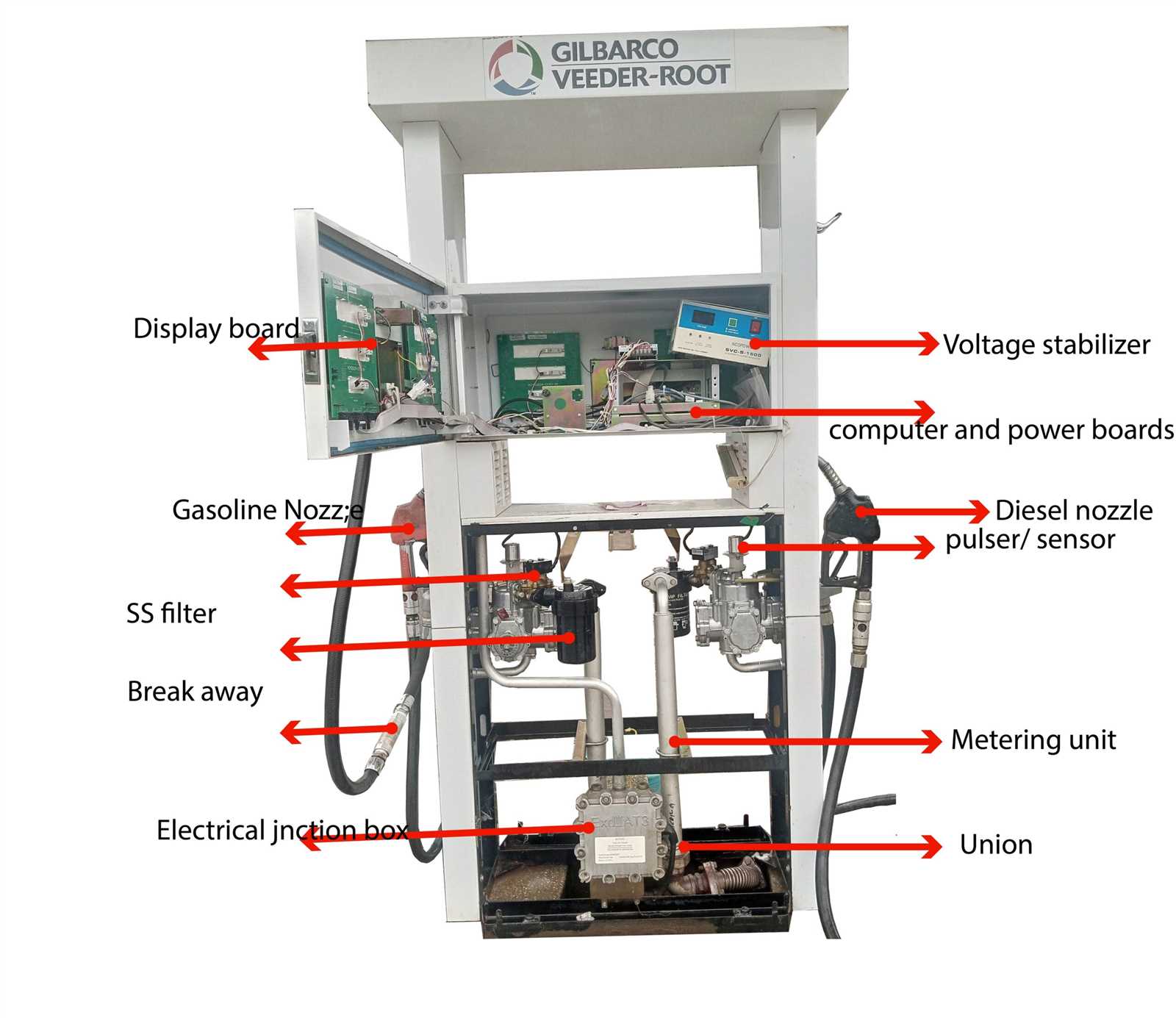

Importance of Metering Systems

Accurate measurement systems play a crucial role in ensuring efficiency and trust in various industries. Their effectiveness not only impacts operational performance but also influences customer satisfaction and regulatory compliance.

Key Benefits

- Precision: Ensures that every transaction is recorded accurately.

- Accountability: Reduces the risk of discrepancies and fraud.

- Efficiency: Streamlines operations by providing reliable data for decision-making.

- Regulatory Compliance: Meets industry standards and legal requirements.

Impact on Business Operations

Implementing effective metering systems can ultimately lead to improved profitability and customer loyalty. By delivering consistent results, businesses can delve deeper into market trends and enhance their service offerings.

Valves: Function and Types Explained

In any fluid management system, specific components play crucial roles in controlling the flow and direction of liquids. Among these components, valves are essential for ensuring proper operation and efficiency. They serve as gatekeepers, managing the movement of substances through various channels and maintaining the desired conditions within the system.

Function of Valves

Valves regulate flow by opening or closing pathways, allowing or restricting the passage of liquids. This function is vital for achieving optimal performance, preventing leaks, and protecting against pressure fluctuations. By adjusting the position of the valve, operators can control the volume and velocity of the liquid, ensuring that the system runs smoothly and safely.

Types of Valves

There are several types of valves, each designed for specific applications. Gate valves are commonly used for on/off control, providing a clear path when fully opened. Globe valves, on the other hand, are better suited for throttling, allowing for more precise flow adjustments. Ball valves offer quick operation and excellent sealing capabilities, while check valves prevent backflow, ensuring that liquids move in one direction only. Each type has its advantages, and the choice depends on the requirements of the system.

Electrical Components in Fuel Dispensers

The intricate machinery involved in liquid transfer systems relies heavily on electrical elements to ensure seamless operation and efficiency. These components play a vital role in controlling various functions, enhancing safety, and facilitating user interaction.

Control Systems

At the heart of these mechanisms are control units, which manage the overall functionality by processing inputs and executing commands. They ensure that all operations run smoothly and respond accurately to user requests.

Safety Features

Moreover, integrated sensors and alarms are essential for monitoring and preventing potential hazards. These features enhance the reliability of the system, ensuring that any irregularities are promptly addressed to maintain a safe environment.

Safety Mechanisms in Petrol Pumps

Ensuring the safety of users and the surrounding environment is paramount in the operation of refueling systems. These systems are equipped with various mechanisms designed to prevent accidents and minimize risks associated with the transfer of liquids. Understanding these safety features is essential for both operators and customers to promote a secure refueling experience.

| Safety Mechanism | Description |

|---|---|

| Automatic Shut-off | Stops the flow of liquid when the tank is full, preventing overflow and spills. |

| Emergency Stop Button | Allows for immediate cessation of operation in case of an emergency, ensuring rapid response to hazardous situations. |

| Leak Detection Systems | Monitors for any leaks in the transfer system, alerting operators to potential issues that could lead to spills. |

| Anti-static Devices | Reduces the risk of static electricity build-up, which can ignite flammable vapors during the transfer process. |

| Vapor Recovery Systems | Captures vapors released during refueling to prevent them from escaping into the atmosphere, minimizing environmental impact. |

By incorporating these safety features, the operation of refueling stations becomes significantly safer, safeguarding both personnel and the environment from potential hazards associated with the transfer of combustible liquids.

Maintenance Tips for Fuel Dispensers

Regular upkeep is essential to ensure optimal performance and longevity of equipment used for liquid transfer. By implementing a structured maintenance routine, operators can prevent unexpected failures and enhance efficiency, ultimately benefiting their operations.

Routine Inspections

Conducting periodic evaluations is crucial. Check for leaks, worn-out seals, and overall integrity of components. Timely identification of potential issues can avert larger problems in the future.

Cleaning and Calibration

Keeping surfaces clean helps prevent contamination. Additionally, regular calibration ensures accurate measurements. Proper maintenance not only extends the lifespan but also maintains customer trust in your services.

Common Issues with Fuel Dispensing Units

In the realm of liquid distribution systems, several challenges may arise that affect their efficiency and reliability. Understanding these common obstacles is crucial for maintaining optimal performance and ensuring user satisfaction.

Calibration Errors

One prevalent issue involves inaccuracies in measurement. Miscalibration can lead to discrepancies between the amount dispensed and the actual volume, resulting in customer dissatisfaction and potential financial losses.

Mechanical Failures

Wear and tear on components can result in malfunctions, such as leaks or inconsistent flow rates. Regular maintenance and prompt repairs are essential to mitigate these mechanical challenges and prolong the lifespan of the system.

Upgrading Older Fuel Dispenser Models

Modernizing legacy refueling equipment is essential for maintaining efficiency, safety, and compliance with current regulations. As technology advances, it becomes crucial to evaluate the existing infrastructure and consider enhancements that can lead to improved performance and user experience.

Several key factors should be taken into account when upgrading older systems:

- Compatibility: Ensure that new components can seamlessly integrate with existing setups.

- Efficiency: Upgrading can lead to reduced operational costs through improved energy consumption.

- Compliance: Stay updated with local regulations regarding safety and environmental standards.

- Technology Integration: Implement digital solutions for better data management and customer interaction.

When planning the upgrade, consider the following steps:

- Assess the current state of the equipment.

- Identify specific areas for improvement, such as speed, accuracy, and user interface.

- Research and select modern alternatives that meet the identified needs.

- Implement changes in phases to minimize disruption.

- Train staff on new technologies and processes.

By embracing advancements, operators can not only enhance their service offerings but also extend the lifespan of their infrastructure, ultimately leading to higher customer satisfaction and increased revenue.

The Future of Fuel Dispensing Technology

The evolution of liquid delivery systems is poised to undergo significant transformations driven by advancements in technology and environmental considerations. As the world shifts towards more sustainable energy sources, the mechanisms through which these liquids are delivered to consumers will also change dramatically.

Innovations such as smart metering and automated transactions are set to enhance user experiences, ensuring efficiency and convenience. With the integration of IoT devices, users may soon benefit from real-time monitoring of liquid levels and predictive analytics that optimize refilling schedules.

Moreover, the increasing adoption of renewable energy solutions will lead to a rethinking of traditional infrastructure. The rise of electric and alternative energy vehicles necessitates the development of specialized systems that cater to a diverse range of energy sources, ultimately promoting a cleaner environment.

Additionally, the focus on safety and reliability will drive further enhancements in technology, ensuring that delivery mechanisms are not only efficient but also secure. As society moves towards a greener future, the landscape of liquid distribution will undoubtedly reflect these changes, prioritizing both user convenience and ecological sustainability.