Exploring the Generac 20kW Parts Diagram for Ultimate Maintenance

In the realm of energy solutions, a comprehensive grasp of the individual elements that contribute to the overall functionality of a power generator is essential. Each component plays a critical role, ensuring seamless operation and reliability.

Familiarity with the intricate relationships between these parts allows for informed decision-making during maintenance and repairs. An exploration of these segments reveals not only their specific functions but also the significance of their synergy in achieving optimal performance.

By delving into the intricacies of this system, one can better appreciate how each section interconnects to form a cohesive unit. This understanding serves as the ultimate foundation for troubleshooting and enhancing the longevity of the equipment.

Understanding Generac 20kW Generator Parts

Exploring the components of a power unit reveals the intricate system that ensures reliable energy supply. Each element plays a crucial role in functionality and efficiency, contributing to the overall performance of the machine.

Key Components

- Engine: The powerhouse of the unit, responsible for converting fuel into energy.

- Alternator: Converts mechanical energy into electrical energy, vital for power output.

- Control Panel: The interface for monitoring and managing the generator’s operations.

- Fuel System: Supplies the necessary fuel for operation, influencing runtime and efficiency.

- Cooling System: Maintains optimal temperature to prevent overheating during use.

Maintenance Considerations

- Regularly check the oil levels and replace as needed.

- Inspect filters for clogs to ensure clean airflow and fuel supply.

- Test battery health to maintain reliable starting capability.

- Monitor for unusual sounds or vibrations, indicating potential issues.

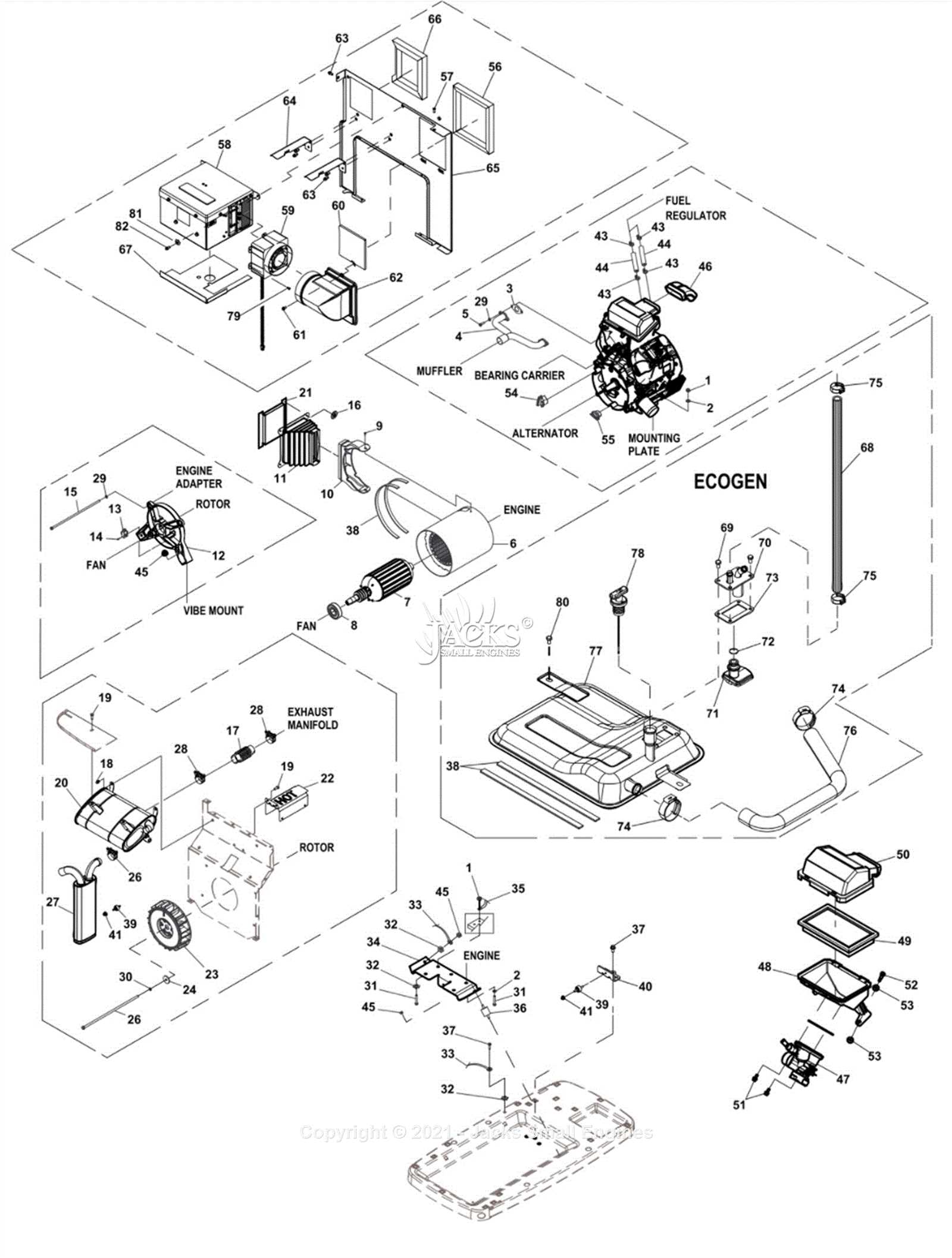

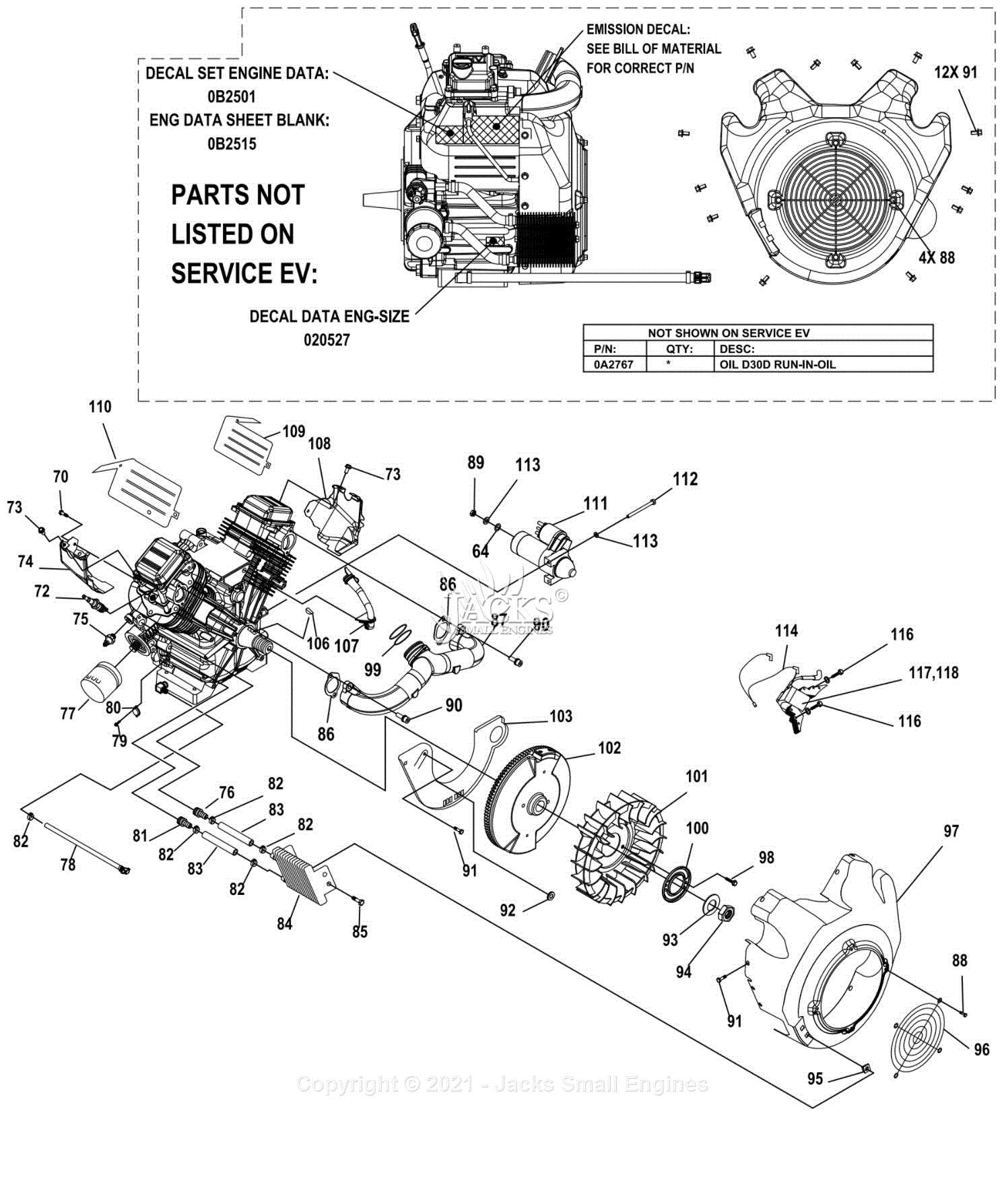

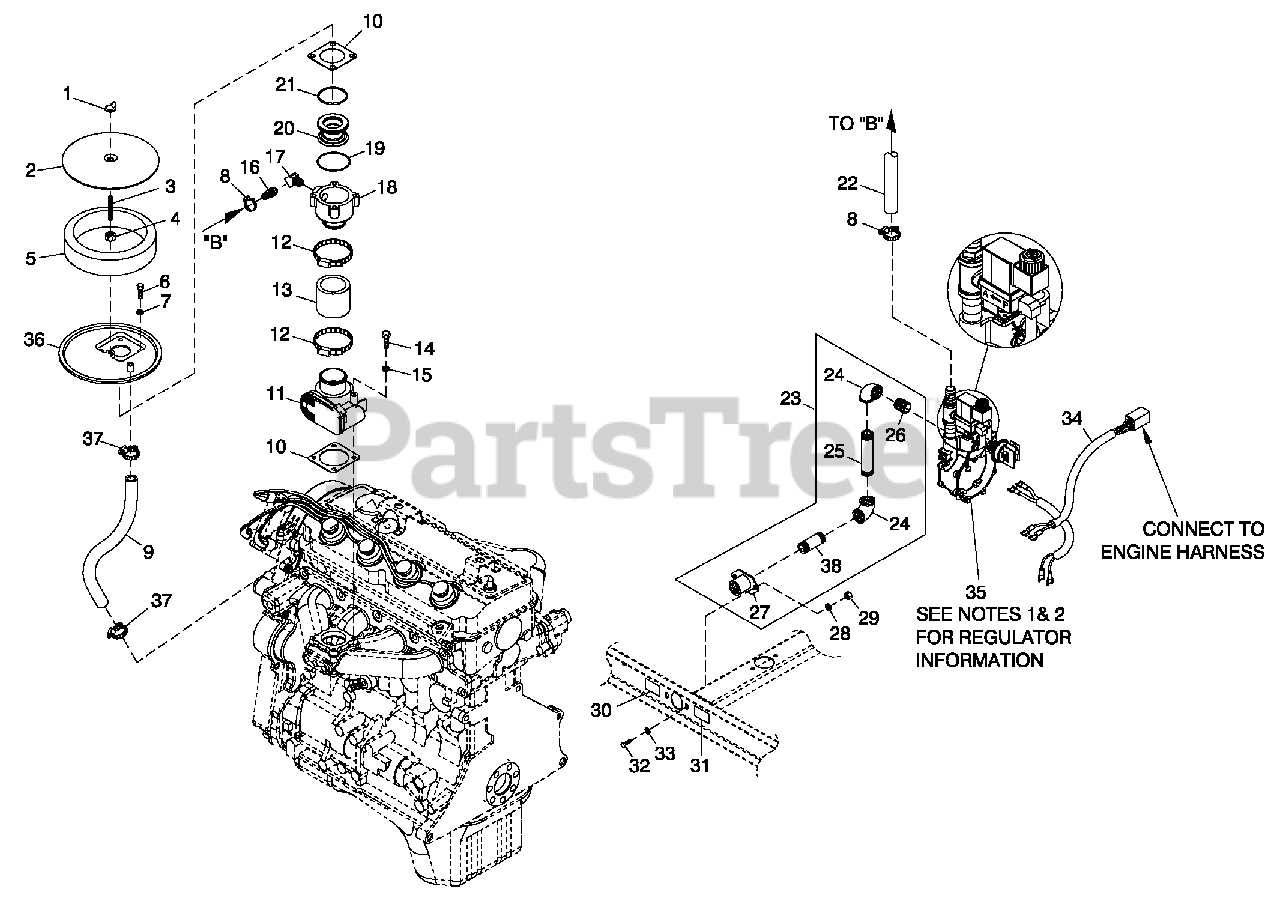

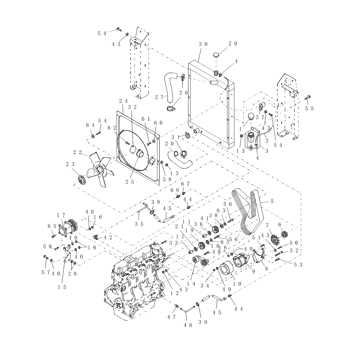

Importance of Parts Diagrams

Understanding the intricacies of mechanical systems is crucial for effective maintenance and repair. Visual representations that illustrate the components and their interconnections serve as invaluable tools for technicians and enthusiasts alike. These illustrations not only enhance comprehension but also streamline the process of identifying and sourcing specific elements.

Clarity and Efficiency: Detailed visual aids provide a clear overview of a system, allowing users to quickly locate components and understand their functions. This clarity minimizes confusion during troubleshooting and reduces the time spent on repairs.

Guidance for Repairs: When a malfunction occurs, having a visual reference simplifies the repair process. Users can easily identify which parts need attention and understand how to disassemble and reassemble them correctly, ensuring that repairs are conducted efficiently and accurately.

Assistance in Ordering Components: Accurate illustrations facilitate the ordering process by clearly delineating each part. This is particularly helpful for ensuring that the correct replacements are acquired, thereby avoiding delays and potential compatibility issues.

Enhanced Learning: For those looking to deepen their knowledge, visual guides provide an excellent educational resource. They offer insights into the design and functionality of systems, promoting a better understanding of mechanical principles.

Common Components of Generac Generators

Understanding the essential elements of standby power systems is crucial for effective operation and maintenance. These devices are designed to provide reliable energy during outages, and each component plays a vital role in ensuring efficiency and longevity.

Power Unit

The power unit is the heart of any standby energy system. It converts fuel into electrical energy, utilizing an internal combustion engine that operates with optimal efficiency. Regular maintenance of this unit is essential for consistent performance.

Control Panel

The control panel serves as the command center for monitoring and managing operations. It displays vital information such as voltage levels and operational status, allowing users to make informed decisions. A well-functioning control panel enhances the overall user experience.

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to maintain and repair equipment effectively. This visual guide serves to simplify complex assemblies by providing a clear illustration of individual elements and their interconnections.

Identifying Components

Begin by familiarizing yourself with the various symbols and labels used in the illustration. Each element is usually marked with a specific identifier that correlates with a detailed list or legend. Pay attention to these markers, as they will direct you to the relevant information regarding specifications and replacements.

Understanding Connections

Next, observe how the components are linked together. Lines and arrows often indicate how parts interact or fit together, allowing you to visualize the assembly process. This insight is crucial for troubleshooting and ensuring that all pieces function harmoniously within the system.

Key Features of the 20kW Model

This model offers a blend of reliability and advanced technology, designed to meet a variety of power needs effectively. Its innovative characteristics ensure optimal performance in diverse conditions, making it a standout choice for both residential and commercial applications.

- Robust Power Output: Capable of delivering substantial energy to support essential appliances and systems.

- Quiet Operation: Engineered to operate with minimal noise, enhancing user comfort during use.

- Automatic Transfer Switch: Ensures seamless power transition in case of outages, maintaining continuous supply.

- Durable Design: Constructed with high-quality materials for long-lasting durability and resistance to harsh weather conditions.

- User-Friendly Interface: Equipped with an intuitive control panel for easy operation and monitoring.

These features collectively enhance the model’s appeal, providing both peace of mind and effective energy management for users.

Maintenance Tips for Generac Generators

Regular upkeep of your power unit is essential for optimal performance and longevity. Following a structured maintenance routine not only enhances reliability but also prevents costly repairs down the line. Here are some practical tips to ensure your generator remains in peak condition.

Routine Checks

- Inspect the oil level and change it according to the manufacturer’s recommendations.

- Examine the air filter for dirt and debris; clean or replace it as needed.

- Check fuel levels and ensure proper fuel quality to avoid operational issues.

- Look for any signs of wear or damage in electrical connections and components.

Seasonal Maintenance

- Run the generator for a short period every month to keep it functioning smoothly.

- Clean the exterior and remove any debris to prevent rust and corrosion.

- Inspect battery connections and clean terminals to maintain strong performance.

- Schedule a professional inspection annually to address any potential issues.

Identifying Replacement Parts Easily

When maintaining your energy system, recognizing the right components for replacement is crucial. Understanding how to efficiently identify these items can save you time and ensure that your unit operates smoothly. Here, we’ll explore methods to simplify this process, allowing for quick and accurate identification of the necessary elements.

To begin, it’s important to familiarize yourself with the common components and their functions. Having a general knowledge of the key parts will facilitate easier identification when you need to make replacements. Below is a table that highlights essential components along with their descriptions and common symptoms indicating a need for replacement.

| Component | Description | Signs of Wear |

|---|---|---|

| Battery | Supplies power to the system during outages. | Slow start, reduced runtime. |

| Fuel Filter | Cleans the fuel before it reaches the engine. | Clogging, reduced efficiency. |

| Air Filter | Filters incoming air to the engine. | Increased noise, poor performance. |

| Oil Filter | Removes contaminants from the oil. | Excessive smoke, overheating. |

Utilizing manuals or online resources can further aid in pinpointing the exact components needed for your system. With the right approach, identifying and replacing necessary items can become a straightforward task, ensuring optimal functionality of your energy equipment.

Common Issues and Solutions

When operating a power generation unit, various challenges can arise, affecting its performance and efficiency. Identifying these common problems and understanding their solutions is essential for ensuring reliable functionality. This section outlines typical issues that users may encounter and offers effective remedies to enhance the overall operation of the equipment.

1. Insufficient Power Output

This issue often manifests when the unit fails to deliver the expected electrical output. It can be caused by factors such as improper load management or a malfunctioning regulator. To address this, check the load distribution and ensure it aligns with the generator’s capacity. If the problem persists, inspect the voltage regulator and consider professional assistance.

2. Frequent Overheating

Overheating can lead to serious damage and is typically the result of inadequate ventilation or low coolant levels. To remedy this, ensure that the unit is positioned in a well-ventilated area and regularly check coolant levels, refilling as necessary.

3. Starting Difficulties

Issues with starting can be frustrating and are often linked to battery failure or fuel supply problems. Inspect the battery for charge and connections, and verify that the fuel system is free of obstructions. Regular maintenance of the fuel filter can also prevent this issue.

4. Excessive Noise

Unusual noise levels can indicate mechanical problems or loose components. Inspect the unit for any loose parts or signs of wear, and consider using soundproofing materials if noise is a recurring concern in residential areas.

5. Warning Indicators

Warning lights on the control panel may signal various operational issues. Refer to the user manual to interpret these signals correctly. Taking immediate action based on these alerts can prevent more significant problems down the line.

Where to Find Official Diagrams

Finding reliable illustrations for maintenance and repair is crucial for effective troubleshooting and part replacement. Accessing authentic resources ensures you have the correct information to keep your equipment running smoothly.

Manufacturer’s Website

The best starting point is the official website of the manufacturer. They often provide downloadable resources, including comprehensive visual guides that detail component layouts and specifications.

Authorized Dealers and Service Centers

Another valuable option is to consult authorized dealers or service centers. These professionals can offer access to proprietary resources and assist in locating the necessary documentation tailored to your specific model.

Ordering Parts from Authorized Dealers

Acquiring components from certified distributors ensures reliability and quality. These suppliers are equipped with the necessary knowledge and resources to provide genuine items that meet the specifications of your equipment. Utilizing authorized channels not only enhances performance but also extends the lifespan of your machinery.

Benefits of purchasing through official dealers include access to comprehensive support and expert guidance. They are familiar with the specific needs of the equipment and can assist in identifying the correct items quickly. Furthermore, ordering from trusted sources often comes with warranties, giving you peace of mind regarding your investment.

To facilitate a seamless ordering experience, it’s advisable to have your model and serial numbers readily available. This information allows dealers to assist you efficiently and ensures you receive the correct replacements. Additionally, many authorized distributors offer online platforms, making it convenient to browse inventory and place orders from the comfort of your home.

In summary, sourcing components from recognized suppliers not only guarantees authenticity but also fosters a more effective operational environment. By choosing to order through these channels, you invest in the longevity and reliability of your equipment.

DIY Repairs and Safety Precautions

When undertaking repairs on your equipment, it is essential to approach the task with caution and preparedness. Understanding the components involved and following safety guidelines can significantly reduce risks and enhance efficiency during the process. This section will explore key practices for successful maintenance and necessary precautions to keep in mind.

Understanding the Basics

Before diving into repairs, familiarize yourself with the machinery’s layout and functions. Consult manuals or online resources to gain insights into the different sections. Knowledge is your best ally in identifying issues effectively and executing repairs without unnecessary complications.

Safety First

Always prioritize safety by wearing appropriate protective gear, such as gloves and goggles. Ensure the device is powered down and disconnected from any power source before beginning any work. Maintaining a clean and organized workspace also minimizes hazards, allowing you to focus on the task at hand without distractions.

Upgrading Your Generac Generator

Enhancing your power backup system can significantly improve its efficiency and longevity. Whether you’re looking to boost performance or incorporate modern features, careful consideration of available upgrades is essential. Understanding the various components that can be enhanced will ultimately lead to a more reliable energy solution.

Start by evaluating the existing setup and identifying areas that could benefit from enhancement. Upgrading the engine or adding advanced control systems can lead to more efficient fuel consumption and improved overall performance. Additionally, incorporating smart technology allows for better monitoring and management of energy needs.

Another aspect to consider is the incorporation of additional safety features. Upgrades such as improved automatic transfer switches can ensure seamless operation during outages, providing peace of mind. Finally, regular maintenance and replacement of worn components can also serve as an essential part of your upgrade strategy, ensuring that your system remains in optimal condition.