Understanding the Generac CW10K Parts Diagram for Efficient Maintenance

In the realm of machinery and equipment, a comprehensive understanding of the layout of various elements is crucial for efficient maintenance and operation. Each assembly consists of numerous components that work in harmony to ensure optimal performance. Familiarity with these intricate arrangements empowers users to diagnose issues swiftly and execute repairs effectively.

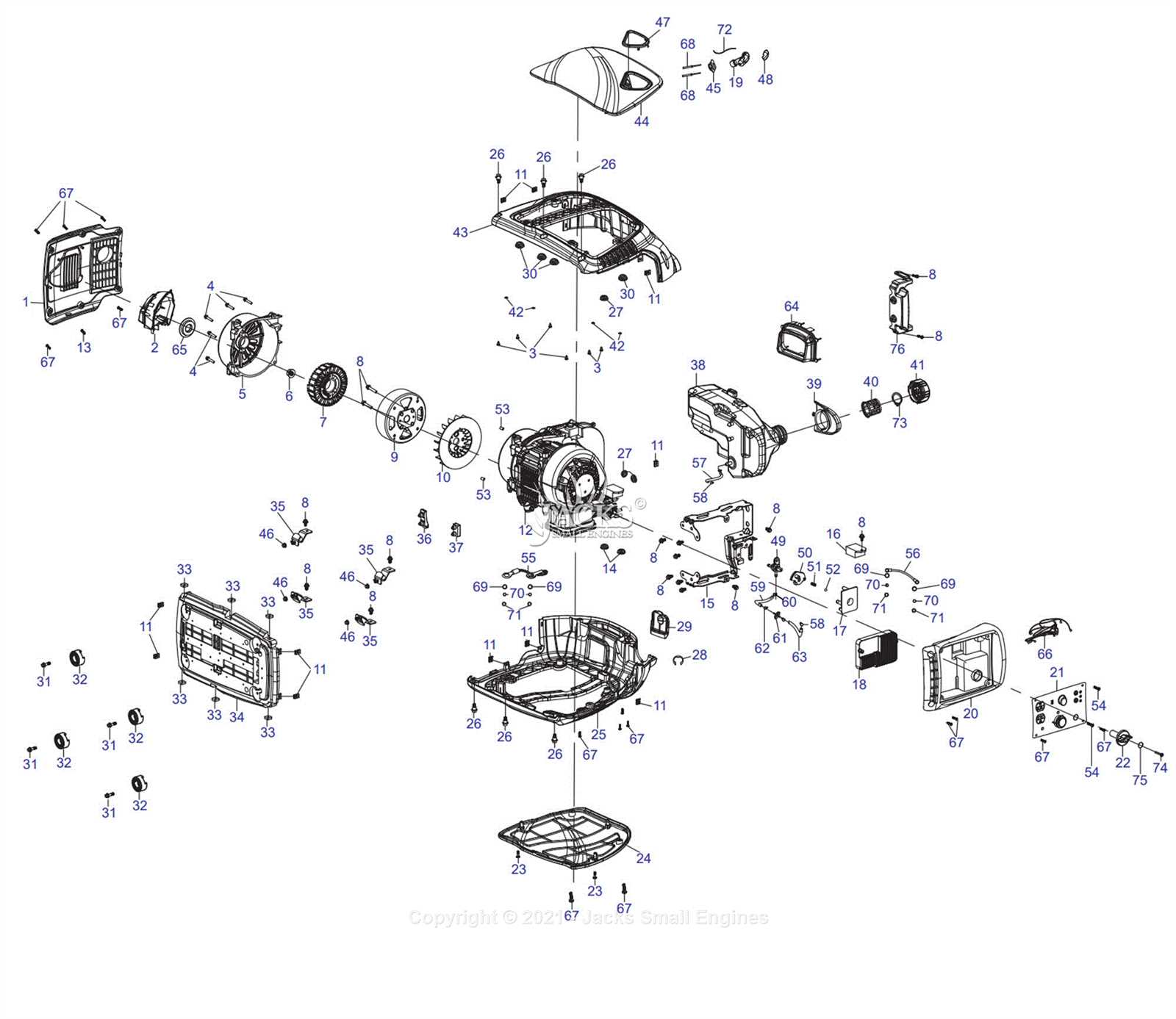

Visual representations play a vital role in conveying complex information regarding these assemblies. By illustrating the relationship between different parts, these schematics provide invaluable insights that enhance the troubleshooting process. They serve as essential tools for technicians and enthusiasts alike, enabling them to navigate the intricate web of components with confidence.

Moreover, grasping the arrangement of elements fosters a deeper appreciation for the engineering behind the equipment. Understanding how each part contributes to the overall functionality not only aids in repairs but also inspires innovation and improvements. In the following sections, we will explore these layouts in detail, ensuring a solid foundation for anyone looking to deepen their knowledge in this field.

Understanding Generac CW10K Overview

This section provides a comprehensive insight into a particular model of power generation equipment, focusing on its structure and functionality. Such systems are vital for ensuring a reliable energy supply, particularly in areas prone to outages or for use in various applications where consistent power is crucial.

Key Features: The equipment is designed with various components that contribute to its overall efficiency and reliability. Each element plays a significant role, from the core generating unit to the auxiliary systems that support operation.

Operational Benefits: Users can expect enhanced performance and longevity from these units, making them a sound investment for both residential and commercial applications. Understanding how each part functions within the whole can greatly aid in maintenance and troubleshooting.

Key Components of CW10K Generator

The intricate design of this power unit incorporates several essential elements that work together to ensure efficient operation and reliability. Understanding these components is crucial for anyone looking to maximize performance and maintain longevity.

Engine and Alternator

The heart of the system lies in the engine, which generates mechanical energy. Coupled with the alternator, this energy is converted into electrical power, forming the backbone of the entire setup.

Control Panel and Fuel System

The control panel acts as the interface for monitoring performance and settings, while the fuel system ensures a steady supply of energy. Together, these components enhance user experience and operational efficiency.

Importance of Parts Diagram

A visual representation of components is crucial for effective maintenance and repair of machinery. Such illustrations serve as a guide for technicians and users, allowing for quick identification of individual elements and their arrangement within the system.

Understanding the layout of various components offers several advantages:

- Facilitates Troubleshooting: A clear visual reference aids in diagnosing issues by showing how parts interact.

- Enhances Efficiency: Technicians can quickly locate and access necessary elements, reducing downtime during repairs.

- Improves Communication: A well-structured representation helps convey complex information clearly among team members.

- Supports Proper Reassembly: Understanding the configuration ensures that everything is put back together correctly after maintenance.

In summary, these illustrations are invaluable tools that promote a thorough understanding of machinery, leading to improved performance and longevity.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate these illustrations, making it easier to identify various elements and their relationships within the system.

Here are some key points to consider when examining such visual guides:

- Familiarize Yourself with the Layout: Start by identifying the overall structure. Look for any labels that indicate sections or groupings of parts.

- Identify Symbols and Legends: Most illustrations include a legend explaining the symbols used. Take time to review this key, as it will provide context for the components.

- Note Component Numbers: Each item is often assigned a unique identifier. Make sure to jot down these numbers for reference when ordering replacements.

- Understand Connections: Pay attention to how components are connected. Arrows or lines typically indicate relationships, showing how parts interact with one another.

By following these steps, you can gain a clearer understanding of the components involved and enhance your ability to work with mechanical systems effectively.

Common Issues with Generac CW10K

Every mechanical system can experience challenges over time, and understanding these potential pitfalls can enhance longevity and performance. Users often encounter specific complications that require attention and maintenance to ensure optimal functioning.

Power Output Problems

One of the frequent challenges involves inconsistencies in power generation. Users may notice fluctuations or inadequate output, often due to issues with the fuel supply or electrical connections. Regular checks can mitigate these concerns.

Noise and Vibration

Excessive noise and vibration can indicate underlying mechanical issues. Problems with mounting or internal components can lead to disturbances. Addressing these concerns early can prevent further damage and ensure smoother operation.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular attention and care. By following a structured maintenance routine, you can enhance performance, prevent unexpected breakdowns, and ultimately save on costly repairs. Here are some effective strategies to keep your machinery in optimal condition.

Regular Inspections

Performing routine checks is essential for identifying potential issues before they escalate. Examine components for wear and tear, look for signs of corrosion, and ensure all connections are secure. Scheduled inspections can help you spot minor problems and address them promptly.

Proper Cleaning and Lubrication

Maintaining a clean environment around your equipment prevents dirt and debris buildup, which can lead to operational inefficiencies. Additionally, applying the right lubricants to moving parts minimizes friction and reduces the risk of overheating. Establish a cleaning and lubrication schedule to promote smooth operation.

Identifying Replacement Parts

Understanding how to pinpoint essential components for equipment maintenance is crucial for ensuring optimal performance. By familiarizing oneself with various elements, users can easily locate and replace any malfunctioning or worn-out sections, thus prolonging the life of their machines.

Recognizing Key Components

Begin by examining the overall structure of the device. Pay attention to the layout and arrangement of each segment, as this will aid in identifying which elements require attention. Utilize manuals and online resources to familiarize yourself with the specific features and functions of each component.

Utilizing Resources for Assistance

Leveraging available tools, such as online forums and manufacturer guides, can significantly enhance your understanding of individual sections. Engage with communities that delve into equipment maintenance, where you can ask questions and share insights to uncover the ultimate solutions for your replacement needs.

Where to Purchase Parts

Finding the right components for your equipment is essential for ensuring optimal performance and longevity. There are various avenues to explore when seeking high-quality replacements, from authorized distributors to online marketplaces. This section will guide you on where to effectively source the necessary items for your machinery.

Authorized Dealers

One of the most reliable options is to purchase from certified dealers. These establishments often carry genuine components that are specifically designed for your model, ensuring compatibility and quality. In addition, they may offer expert advice and customer support, helping you make informed decisions.

Online Marketplaces

For convenience and variety, online platforms can be an excellent choice. Websites dedicated to industrial supplies frequently provide a wide range of options at competitive prices. Be sure to check customer reviews and seller ratings to ensure you are buying from reputable sources. Additionally, many online retailers offer warranties and return policies that can provide peace of mind with your purchase.

In summary, whether opting for physical stores or digital platforms, it is crucial to prioritize quality and reliability when sourcing replacements for your equipment.

Understanding Electrical Connections

Grasping the fundamentals of electrical connections is essential for anyone working with power systems. These connections serve as the pathways through which electricity flows, ensuring that components function harmoniously. Understanding the nuances of these interconnections can significantly impact the efficiency and safety of any electrical setup.

Types of Connections

There are several varieties of electrical connections, each designed for specific applications. Wiring can be classified as either permanent or temporary, with permanent connections often involving soldering or crimping. In contrast, temporary connections may utilize plugs and sockets, allowing for easy disassembly. Each type has its advantages, depending on the requirements of the system.

Importance of Proper Connections

Ensuring that electrical connections are secure and well-maintained is crucial for optimal performance. Poor connections can lead to voltage drops, overheating, or even system failures. Regular inspection and maintenance help identify potential issues before they escalate, ensuring a safe and efficient operation of electrical systems.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential for preventing accidents and injuries. Whether you are working on machinery or electrical systems, adhering to proper guidelines can significantly reduce risks. Awareness of your environment and the equipment you are handling is key to executing repairs effectively and safely.

Personal Protective Equipment

Always wear appropriate personal protective gear when performing repairs. This may include gloves, goggles, and steel-toed boots to safeguard against potential hazards. Depending on the nature of the work, hearing protection and respirators might also be necessary to shield yourself from noise and airborne particles.

Proper Tools and Techniques

Utilizing the right tools for the job is crucial for both efficiency and safety. Ensure that all equipment is in good condition and specifically designed for the task at hand. Following proper techniques, such as securing loose components and maintaining a clean workspace, minimizes the likelihood of accidents. Always consult the manufacturer’s guidelines to ensure compliance with safety standards.

Upgrading Generac CW10K Components

Enhancing the efficiency and performance of your power system involves carefully selecting and upgrading its various elements. This process not only improves reliability but also extends the lifespan of the entire setup. Identifying the right components for enhancement is crucial for achieving optimal results.

When considering upgrades, focus on the following key areas:

- Engine Performance: Replacing or tuning the engine can lead to significant gains in output and efficiency.

- Control Systems: Upgrading the control interface can enhance monitoring capabilities and improve user experience.

- Fuel Efficiency: Incorporating high-efficiency fuel systems can reduce consumption and lower operational costs.

- Cooling Systems: Ensuring that the cooling mechanisms are up to date can prevent overheating and maintain optimal performance.

- Noise Reduction: Implementing noise reduction technologies can make the unit quieter, enhancing its usability in residential areas.

Before proceeding with upgrades, it’s essential to evaluate the compatibility of new components with your existing setup. Thorough research and professional consultations can help in selecting the most effective parts for your needs.

- Assess the current condition of each component.

- Research available upgrades and their benefits.

- Consult with experts or technicians for recommendations.

- Plan the installation process to minimize downtime.

- Test the system after upgrades to ensure everything functions correctly.

By strategically enhancing various elements, you can achieve a more reliable and efficient power solution tailored to your specific requirements.

Frequently Asked Questions

This section addresses common inquiries related to the components and functionality of specific equipment. Here, we provide insights that can help users understand their systems better and troubleshoot potential issues effectively.

- What should I do if a component fails?

If a part stops working, check the user manual for troubleshooting steps. Ensure all connections are secure and that there are no visible damages.

- How often should I perform maintenance?

Regular maintenance is recommended at least once a year, or more frequently if the unit is used heavily. Follow the guidelines in the user manual for specific recommendations.

- Where can I find replacement parts?

Replacement components can typically be sourced from authorized dealers or online retailers that specialize in equipment parts.

- Is there a warranty on parts?

Warranties vary by manufacturer and specific items. It’s important to check the warranty details at the time of purchase or consult the seller.

- Can I install components myself?

While some parts can be installed without professional help, it’s advisable to refer to the installation instructions. Complex installations may require a technician.

cssCopy code

Resources for Further Learning

To deepen your understanding of equipment components and their functionalities, exploring various educational materials and platforms is essential. These resources can enhance your knowledge and provide valuable insights into maintenance and operation.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Structured learning paths covering fundamentals to advanced topics. | Coursera |

| Technical Manuals | Comprehensive guides detailing specifications and assembly instructions. | ManualsLib |

| Forums | Community discussions providing tips and troubleshooting advice. | Reddit DIY |

| YouTube Channels | Visual tutorials and walkthroughs for practical applications. | YouTube |