Understanding Generac GP3300 Component Layout

In the realm of portable energy sources, the efficient functioning of machinery relies heavily on the intricate interplay of its various components. A thorough grasp of these elements is crucial for optimal performance and maintenance. Whether for home backup or outdoor activities, comprehending how these parts interact can enhance the reliability and longevity of the equipment.

Visual representations of the internal workings serve as invaluable tools for users seeking to familiarize themselves with their devices. By dissecting the arrangement of key elements, one can better appreciate the engineering behind the unit. This understanding not only aids in troubleshooting but also empowers individuals to carry out repairs and replacements effectively.

Exploring the organization of components within a power generation unit can unveil the sophistication involved in their design. Each element plays a vital role, and recognizing their functions facilitates informed decisions regarding maintenance and upgrades. With a clearer perspective, users can ensure their equipment operates at peak efficiency, providing reliable power when it is most needed.

This section aims to provide a comprehensive overview of the essential elements and their functions within a specific generator model. By breaking down the various components, readers can gain a better understanding of how each part contributes to the overall functionality and efficiency of the device. Below is a detailed outline of the key sections that will guide the exploration of these crucial elements.

- Introduction to Generator Components

- Power Generation Mechanism

- Fuel System Overview

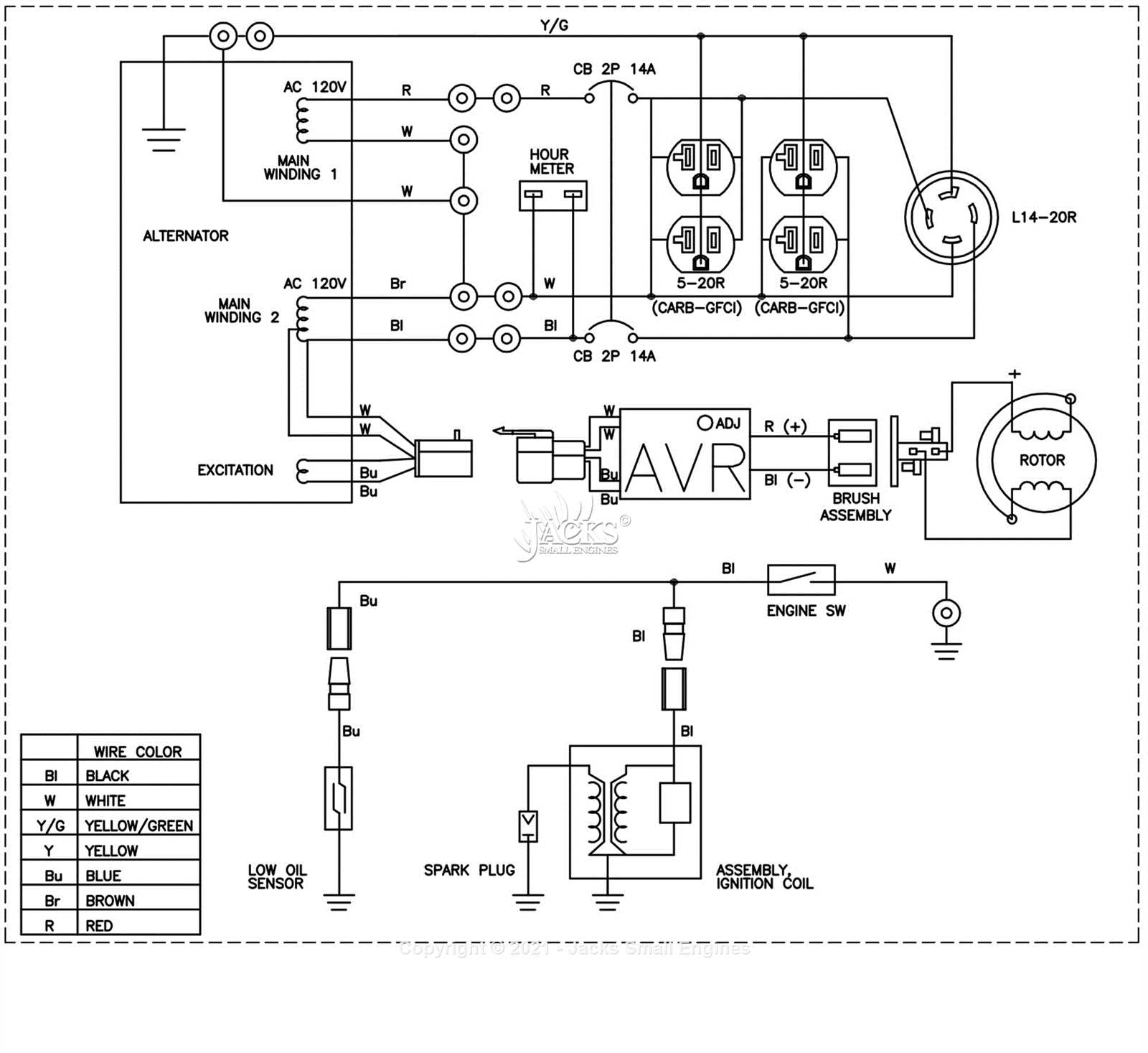

- Electrical System and Wiring

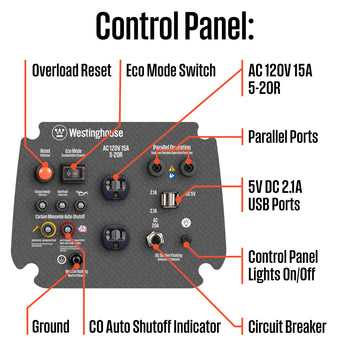

- Control Panel Functions

- Cooling System Design

- Starting Mechanism Insights

- Safety Features Analysis

- Frame and Chassis Composition

- Maintenance Access Points

- Common Issues and Troubleshooting

- Conclusion and Best Practices

Each of these sections will delve into the intricacies of the respective components, offering detailed descriptions and insights to help users navigate and understand their generator more effectively.

Essential Features of the Generator

Understanding the key characteristics of a power-producing device is vital for anyone considering its use. These generators are designed to provide reliable energy solutions, particularly in situations where traditional electricity sources may be unavailable. By exploring their essential features, users can make informed decisions about the most suitable model for their needs.

Power Output and Efficiency

The performance of any generator is primarily determined by its power output and efficiency. It is crucial to assess how much energy the unit can generate and how effectively it converts fuel into electrical power. Higher efficiency not only translates to better fuel consumption but also ensures consistent energy supply for various applications.

Portability and Design

Another important aspect to consider is the portability of the unit. A well-designed generator should be easy to transport, allowing users to move it to different locations as needed. Features such as ergonomic handles, lightweight construction, and compact dimensions enhance usability in various settings.

| Feature | Description |

|---|---|

| Power Output | Measured in watts, indicating the amount of electricity generated. |

| Fuel Efficiency | Represents how effectively the generator utilizes fuel resources. |

| Portability | Ease of transport, often aided by design elements like handles and wheels. |

| Durability | Quality of materials used, impacting the longevity of the device. |

| Noise Level | Measured in decibels, indicating how quiet or loud the operation is. |

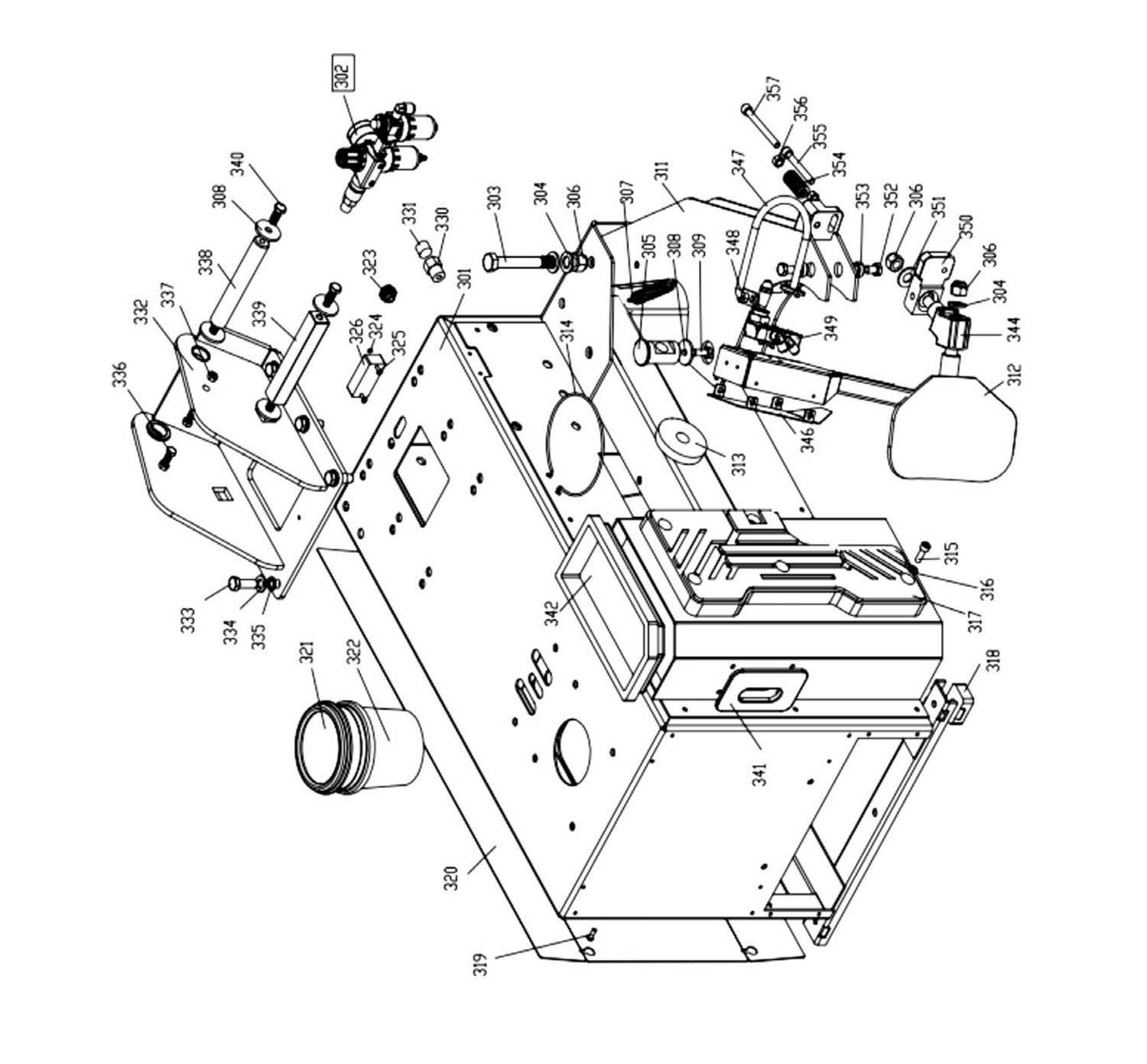

Detailed Parts Breakdown and Functionality

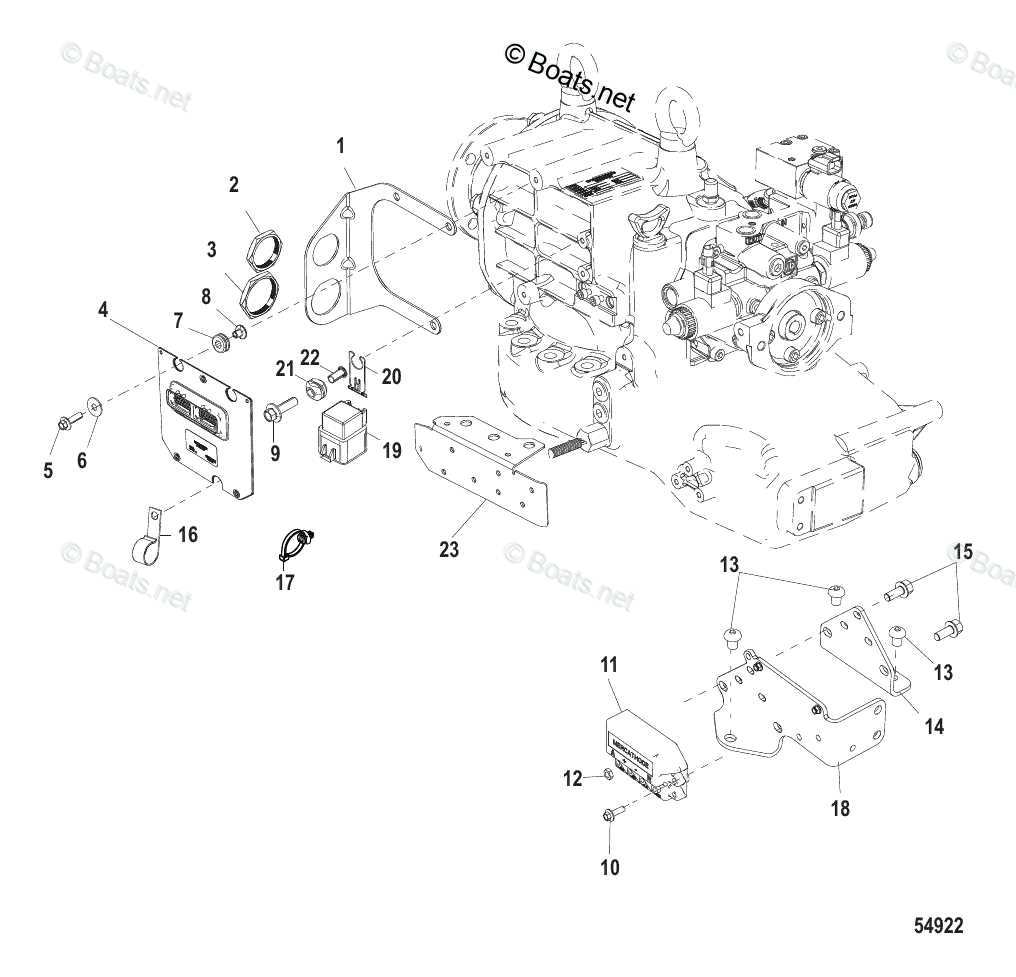

Understanding the various components of a power generator is essential for effective maintenance and optimal performance. Each element plays a critical role in the overall functionality, ensuring that the device operates smoothly and efficiently. Below is an overview of the key components, their functions, and how they contribute to the generator’s operation.

Main Components Overview

- Engine: This is the powerhouse of the generator, responsible for converting fuel into mechanical energy.

- Alternator: This component transforms mechanical energy from the engine into electrical energy, supplying power to connected devices.

- Fuel System: Comprising the fuel tank, lines, and pump, this system delivers the necessary fuel to the engine for operation.

- Cooling System: Essential for preventing overheating, this system circulates coolant to maintain optimal engine temperatures.

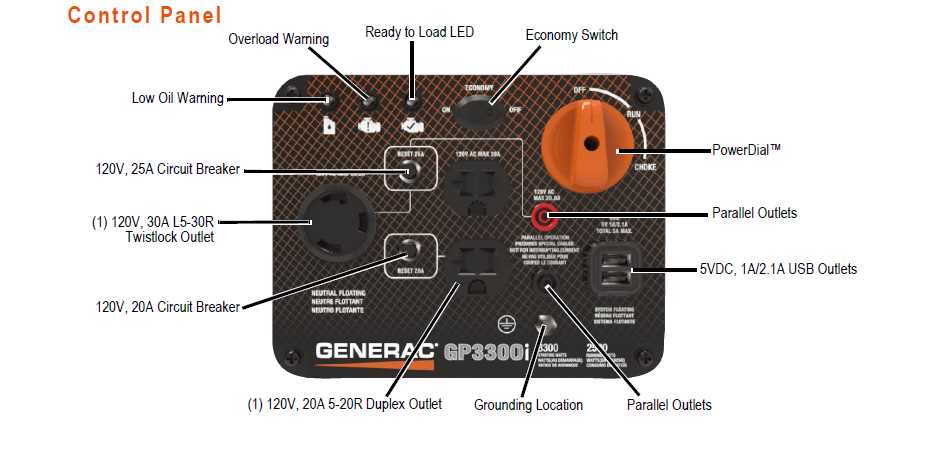

- Control Panel: This interface allows users to monitor performance metrics and control generator operations.

Functionality Insights

Each component interacts with others to ensure seamless operation. The engine ignites fuel, generating power that the alternator converts into usable electricity. The fuel system must deliver the correct amount of fuel at the right time, while the cooling system protects against overheating. Meanwhile, the control panel provides critical information, allowing users to make informed decisions during operation.

Regular inspection and understanding of these components enhance longevity and reliability, ensuring that the generator performs at its best when needed.

How to Identify Each Component

Recognizing the various elements of a power generator is essential for effective maintenance and repair. Understanding how to distinguish each part allows users to troubleshoot issues efficiently and ensure optimal performance. This section outlines key features to look for when identifying components.

| Component | Description | Identification Tips |

|---|---|---|

| Engine | Power source that drives the generator. | Look for the manufacturer’s label and check for model specifications. |

| Fuel Tank | Container for holding fuel. | Check the capacity marked on the tank, often located near the fill cap. |

| Control Panel | Interface for operation and monitoring. | Identify buttons and indicators; reference the user manual for specific functions. |

| Chassis | Framework that supports all components. | Examine the structure for serial numbers or model tags, typically found on the side. |

| Exhaust System | Directs gases away from the engine. | Inspect for any visible signs of wear or damage, and listen for unusual noises during operation. |

Common Issues with GP3300 Parts

When it comes to troubleshooting components of portable energy generators, several typical challenges can arise. Understanding these issues can significantly enhance the reliability and performance of the equipment. Below are some common problems associated with the various elements of these power systems.

- Fuel System Problems:

- Clogged fuel filters can restrict flow, leading to poor engine performance.

- Old or contaminated fuel may cause starting issues or stalling.

- Electrical Component Failures:

- Dead batteries are a frequent cause of starting failures.

- Loose connections can lead to intermittent power supply issues.

- Cooling System Malfunctions:

- Overheating can result from blocked vents or dirty cooling fins.

- Low coolant levels may lead to engine damage if not addressed promptly.

- Noise and Vibration Issues:

- Worn or damaged mounts can cause excessive vibrations during operation.

- Loose components may result in increased noise levels.

By being aware of these common issues, users can take proactive measures to ensure the longevity and efficiency of their equipment.

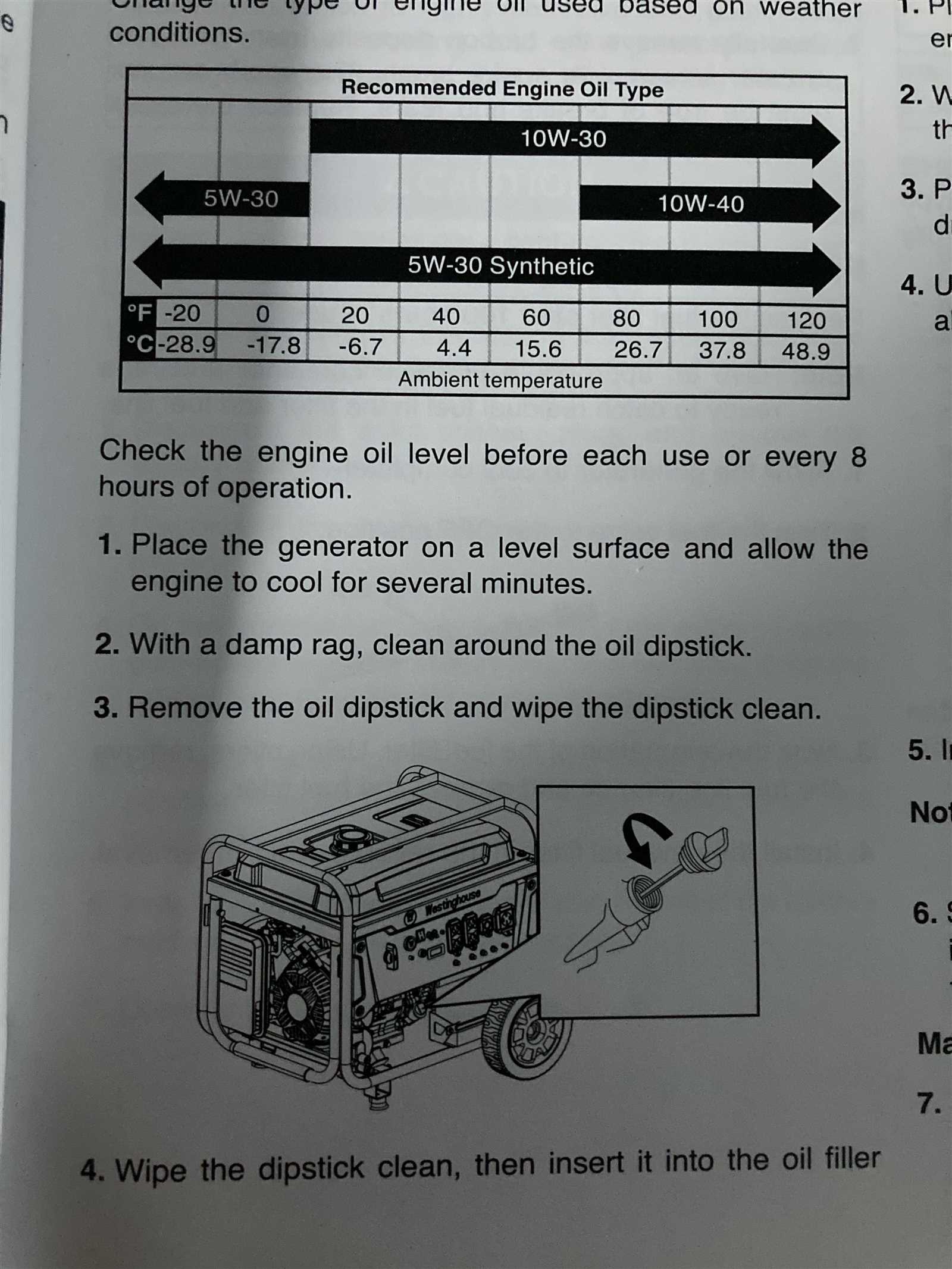

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery and enhance its efficiency. This section provides practical advice to help you keep your unit in peak condition.

Regular Inspection and Cleaning

Routine checks are vital for identifying potential issues before they escalate. Examine the external components for any signs of wear or damage. Additionally, keeping the machinery clean from dust and debris helps prevent overheating and maintains proper airflow. Regularly clean air filters and remove any obstructions that could hinder performance.

Proper Storage and Usage

When not in use, store your device in a dry and sheltered area to protect it from environmental factors that may cause deterioration. Always follow the manufacturer’s guidelines regarding operational limits and best practices. Using the equipment within its recommended parameters minimizes strain and enhances reliability.

Tools Required for Repair and Maintenance

Proper upkeep and repair of equipment demand specific instruments to ensure effective functionality. Utilizing the right tools not only facilitates the process but also enhances safety and efficiency. Below is a compilation of essential instruments that should be on hand for servicing tasks.

- Socket Set: A comprehensive set of sockets allows for the loosening and tightening of various bolts and nuts.

- Screwdrivers: Both flat-head and Phillips-head screwdrivers are crucial for removing and securing screws.

- Pliers: These are useful for gripping, twisting, and cutting wires or other materials.

- Wrenches: An adjustable wrench or a set of fixed wrenches helps in handling nuts and bolts of different sizes.

- Torque Wrench: This tool ensures that fasteners are tightened to the specified torque, preventing damage.

Having these tools readily available can significantly streamline the repair and maintenance process, ensuring that equipment operates optimally and reliably.

Where to Find Replacement Parts

Locating suitable components for your generator can be a straightforward process if you know where to look. Various resources are available that provide a range of options, ensuring you find the right fit for your needs.

Consider the following avenues when searching for compatible items:

- Authorized Dealers: These outlets often have a comprehensive selection of authentic components and can provide expert guidance.

- Online Retailers: Numerous e-commerce platforms specialize in generator supplies, offering the convenience of home delivery.

- Local Hardware Stores: Many community stores stock commonly needed items, making it easy to find what you need without waiting for shipping.

- Manufacturer Websites: Official sites may offer direct purchasing options, along with detailed specifications to help you make informed choices.

Utilizing these resources will streamline your search for the necessary components, ensuring your equipment operates efficiently and reliably.

Step-by-Step Assembly Instructions

Proper assembly of your energy generation unit is crucial for optimal performance and longevity. Following a systematic approach ensures that each component is installed correctly, minimizing the risk of malfunction.

- Gather Your Tools and Components

- Screwdriver set

- Wrench set

- Pliers

- Safety gloves

- Owner’s manual

- Prepare the Workspace

Ensure that your assembly area is clean and well-lit. Lay out all components in an organized manner for easy access during assembly.

- Start with the Base

Secure the base of the unit to prevent movement during assembly. Make sure it is on a flat surface for stability.

- Install the Frame

Attach the frame to the base using the provided fasteners. Ensure each connection is tight and secure.

- Connect the Engine

Position the engine onto the frame and align it with the mounting holes. Fasten it securely using the appropriate hardware.

- Attach the Fuel System

Connect the fuel lines, ensuring that all fittings are snug. Check for leaks once connections are made.

- Complete Electrical Connections

Follow the wiring diagram to connect all electrical components. Double-check each connection for accuracy.

- Final Checks

Review each assembly step to ensure everything is correctly installed. Perform a visual inspection for any loose parts.

- Test the Unit

Once assembled, conduct a test run to ensure proper functionality. Monitor for any unusual sounds or behaviors.

By following these detailed instructions, you can ensure a successful assembly process, leading to reliable operation of your energy generation equipment.

Safety Precautions When Repairing

When undertaking any repair work on equipment, it is crucial to prioritize safety to prevent accidents and ensure a successful outcome. Familiarizing oneself with the essential safety measures can significantly reduce the risk of injury and damage.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, to shield yourself from potential hazards. This simple step can help prevent injuries from sharp objects, heavy components, or harmful substances.

Before beginning any repairs, disconnect the power source to avoid electrical shock. Ensure that all components are properly de-energized, and use lockout/tagout procedures to prevent accidental reactivation while you work.

Additionally, work in a well-ventilated area to minimize exposure to fumes and ensure adequate airflow. If you are dealing with gasoline or other flammable materials, keep fire extinguishers nearby and follow proper storage practices.

Finally, always refer to the manufacturer’s guidelines and repair manuals. These resources provide essential information regarding safety protocols and specific instructions that can help facilitate a safe repair process.

Upgrading Components for Better Performance

Enhancing the efficiency of your energy-producing unit can significantly improve its overall functionality and longevity. By replacing outdated or underperforming elements with high-quality alternatives, users can experience enhanced output, reliability, and efficiency.

When considering upgrades, it is essential to focus on several key components:

- Engine Enhancements: Upgrading to a more powerful engine can lead to better fuel efficiency and increased power output.

- Fuel System: Installing a premium fuel system can enhance combustion efficiency, resulting in cleaner emissions and improved performance.

- Electrical Components: Upgrading the alternator and battery can lead to better power management and reliability during operation.

- Cooling System: Enhancing the cooling system ensures optimal temperature regulation, which prevents overheating and prolongs engine life.

- Exhaust System: A more efficient exhaust system reduces back pressure and improves engine performance.

Incorporating these upgrades not only boosts performance but also contributes to a more sustainable and cost-effective operation in the long run.

Frequently Asked Questions

This section addresses common inquiries related to the components and assembly of portable power generators. Here, users can find essential information to enhance their understanding of the system, troubleshoot issues, and ensure optimal performance.

What should I do if my generator fails to start? Ensure that all connections are secure and that the fuel supply is adequate. If problems persist, consult the user manual for specific troubleshooting steps.

How often should I perform maintenance on my generator? Regular maintenance is crucial for longevity. It is recommended to conduct inspections every few months and perform servicing as outlined in the user guidelines.

Where can I find replacement components? Authorized dealers and online retailers typically stock replacement items for portable generators. Always verify that the parts are compatible with your specific model.

Is it necessary to use specific fuel types? Yes, using the recommended fuel type is essential for the efficient operation of the generator. Refer to the user manual for specifications on fuel requirements.

Resources for Further Assistance

When tackling issues related to your power generator, having access to reliable resources can make a significant difference. Whether you are seeking technical specifications, user manuals, or support forums, numerous platforms offer valuable information to enhance your understanding and troubleshooting skills. This section will guide you to some essential resources that can aid you in maintaining and repairing your equipment effectively.

Here are some recommended avenues for obtaining further assistance:

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer’s Website | Official site providing user manuals, safety guidelines, and FAQs. | Visit Here |

| Online Forums | Community-driven platforms for sharing experiences and solutions. | Visit Here |

| Instructional Videos | Visual guides for repairs and maintenance on popular video platforms. | Visit Here |

| Local Repair Shops | Expert technicians available for hands-on assistance and repairs. | Visit Here |