Understanding the Generac GP8000E Parts Diagram

When it comes to maintaining and repairing your energy-generating machinery, a clear comprehension of its individual elements is essential. Each component plays a pivotal role in the overall performance and reliability of the unit. By gaining insights into these crucial parts, you can ensure optimal functionality and longevity of your equipment.

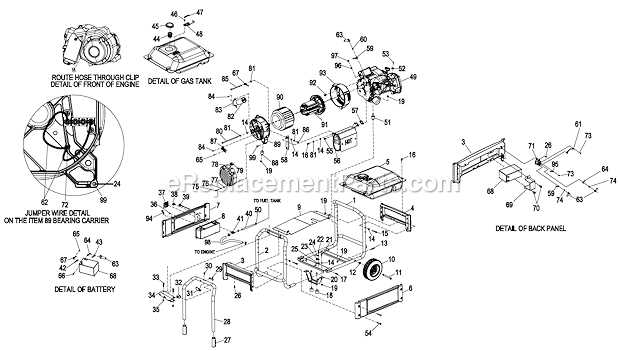

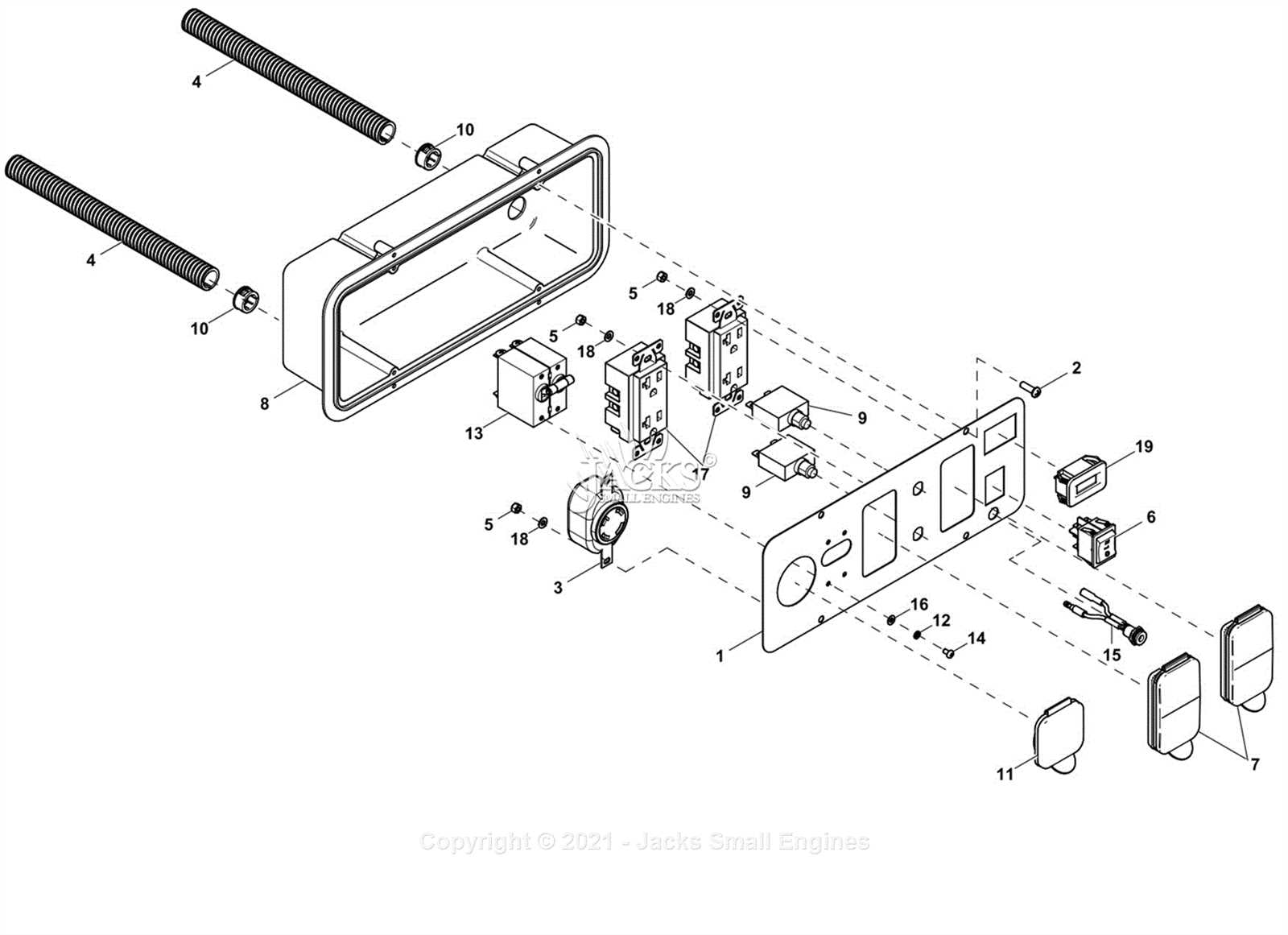

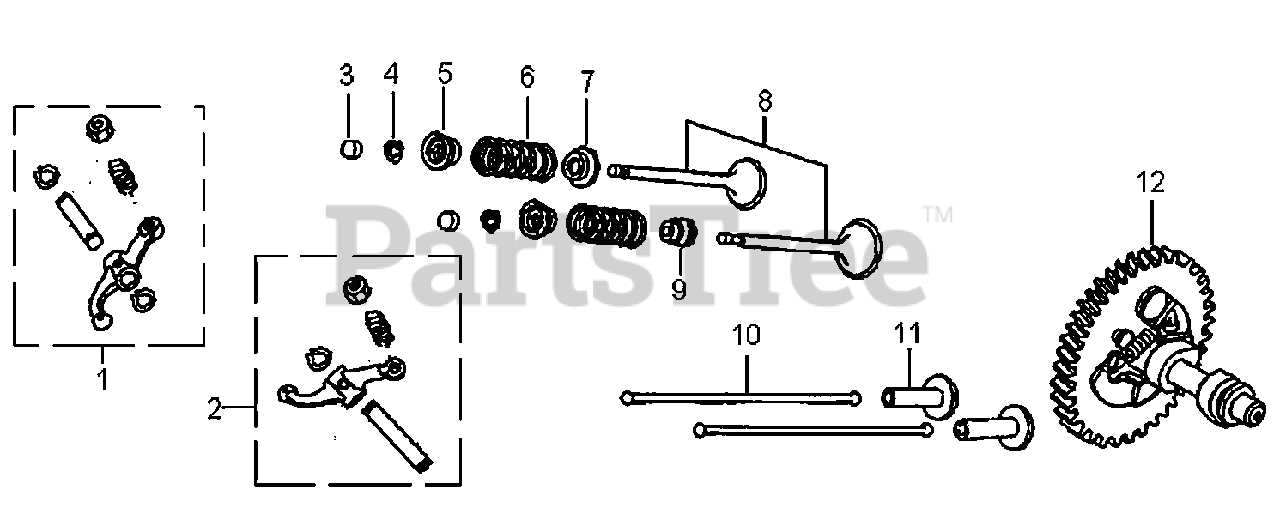

Visual representations of these components can greatly enhance your understanding. They offer a detailed overview, illustrating how each part interconnects and operates within the larger system. This knowledge not only aids in troubleshooting issues but also empowers you to make informed decisions when it comes to repairs or upgrades.

Moreover, familiarizing yourself with the intricacies of your device can lead to more effective maintenance practices. By knowing which components require regular attention, you can prevent potential failures and extend the lifespan of your machinery. This proactive approach is invaluable for anyone relying on such equipment for power needs.

Understanding Generac GP8000E Components

This section aims to provide a comprehensive overview of the various elements that constitute a high-capacity power generator. Each component plays a crucial role in ensuring the efficient operation of the machine, and understanding their functions can enhance maintenance and troubleshooting efforts.

The key components of a power generator can be categorized into several main groups. Below is a summary of these essential parts and their functions:

| Component | Description |

|---|---|

| Engine | The heart of the generator, responsible for converting fuel into mechanical energy. |

| Alternator | This component converts mechanical energy from the engine into electrical energy. |

| Fuel System | Consists of the fuel tank and lines that deliver fuel to the engine. |

| Control Panel | Provides user interface and controls for starting and stopping the unit, as well as monitoring output. |

| Cooling System | Prevents the engine from overheating by circulating coolant. |

| Frame | The structural foundation that supports all components and protects them from external damage. |

| Exhaust System | Channels exhaust gases away from the engine and reduces noise. |

Understanding these components and their interactions is essential for optimal performance and longevity of the generator. Regular maintenance and familiarity with these parts can significantly improve reliability during critical times.

Key Features of the GP8000E Model

This model is designed to deliver exceptional performance and reliability, making it a top choice for various power needs. With its robust engineering and advanced technology, it stands out in the competitive market of portable energy solutions.

- Power Output: Offers a significant wattage capacity suitable for both residential and commercial use, ensuring that essential appliances and equipment remain operational during outages.

- Engine Type: Equipped with a durable and efficient engine that provides consistent power while minimizing fuel consumption.

- Electric Start: Features an easy-to-use electric start system, allowing for quick and hassle-free operation without manual cranking.

- Portability: Designed with heavy-duty wheels and a sturdy frame, making it easy to transport and maneuver in various settings.

- Safety Features: Incorporates multiple safety mechanisms, including low-oil shutdown and circuit protection, to prevent damage and enhance user safety.

- Noise Reduction: Built with sound-dampening technology that minimizes operational noise, ensuring a quieter experience during use.

These attributes collectively contribute to the model’s reputation as a reliable power source, perfect for both emergency situations and routine usage.

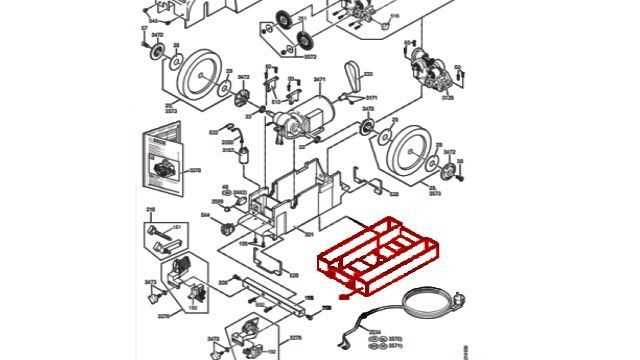

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations help users identify individual pieces, ensuring proper maintenance and repair. Without these visual guides, troubleshooting and rebuilding can become significantly more challenging, leading to potential errors and inefficiencies.

Detailed visuals serve not only as a reference but also enhance the learning process for new users. By breaking down complex structures into understandable segments, individuals can gain confidence in handling equipment. Additionally, these resources facilitate communication among technicians, ensuring everyone is on the same page regarding repairs and replacements.

| Benefits | Description |

|---|---|

| Clarity | Visual aids simplify the understanding of intricate machinery. |

| Efficiency | Quick identification of components reduces downtime during repairs. |

| Learning Tool | Serves as an educational resource for novice operators. |

| Communication | Enhances teamwork by providing a common reference for all users. |

In summary, these illustrations are invaluable for anyone involved in the upkeep of equipment, contributing to a smoother operation and extended longevity of the machinery.

Common Replacement Parts for Generac

When maintaining portable power equipment, understanding the key components that may require replacement is essential for optimal performance. Regular use can lead to wear and tear, necessitating timely updates to ensure reliability and efficiency.

- Air Filters: Essential for keeping the engine clean and functioning smoothly. Regular replacement can enhance performance.

- Oil Filters: Crucial for maintaining engine lubrication. Replacing oil filters helps prevent engine damage.

- Spark Plugs: Vital for proper ignition and engine operation. Regular checks and replacements ensure effective starting and combustion.

- Fuel Filters: Necessary for preventing contaminants from entering the engine. Clean filters improve fuel efficiency and engine longevity.

- Battery: An important component for starting the unit. Replacing a weak or dead battery is critical for dependable operation.

Understanding these essential components can help users maintain their equipment in top condition and avoid unexpected breakdowns. Regular inspections and proactive replacements are key to a longer lifespan and improved performance.

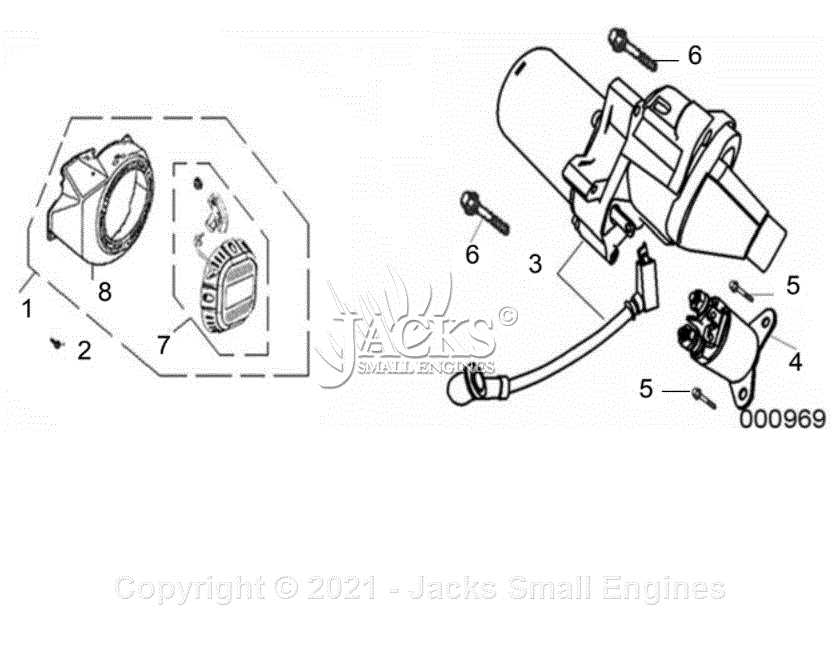

How to Read Parts Diagrams

Understanding schematics is crucial for anyone involved in maintenance or repair work. These visual representations provide essential information about components, their arrangement, and how they interact within a system. By familiarizing yourself with the various elements and symbols used in these illustrations, you can streamline your repair process and ensure that you have the right tools and components for the job.

Key Elements of Illustrations

Typically, these visuals include labeled sections, which denote individual elements, and a legend that explains the symbols used. Identifying each part is the first step in navigating these visuals effectively. Pay close attention to the connections and relationships between components, as this can inform you about assembly and disassembly procedures.

Interpreting Symbols and Annotations

Every schematic employs specific symbols to represent different components, such as switches, connectors, or fasteners. Familiarizing yourself with these icons can enhance your ability to decipher the illustration quickly. Additionally, notes or annotations often accompany these visuals, offering valuable insights regarding installation or troubleshooting tips. Always refer to these explanations to gain a deeper understanding of the depicted elements.

Maintenance Tips for Generac Generators

Regular upkeep is essential for ensuring optimal performance and longevity of power units. By following a few simple guidelines, owners can enhance efficiency and reduce the risk of unexpected failures. Consistent maintenance not only improves reliability but also helps in identifying potential issues before they escalate.

Routine Inspections

Conducting routine checks is vital. Look for signs of wear, loose connections, or any visible damage. Pay attention to the oil level, coolant, and fuel quality. Regularly replacing filters can prevent contaminants from affecting the engine’s performance. Always refer to the user manual for specific intervals and recommendations.

Seasonal Preparations

Before extreme weather conditions, ensure that your unit is ready for operation. Draining old fuel and replacing it with fresh gasoline or diesel can prevent engine problems. Additionally, charge the battery and inspect the electrical components. Keeping your power source in top condition means it’s prepared for when you need it most.

Identifying Faulty Components Easily

Recognizing malfunctioning elements within machinery can significantly enhance maintenance efficiency and prolong the lifespan of equipment. By understanding the common signs of wear and damage, users can swiftly pinpoint issues and address them before they escalate into more serious problems.

Common Symptoms of Malfunction

Several indicators can help users determine when a component is failing. These symptoms may include unusual noises, decreased performance, or visible damage. Being attentive to these signs can facilitate timely repairs and prevent further complications.

Component Inspection Checklist

To assist in the identification of defective parts, a structured approach can be beneficial. Below is a checklist that outlines essential elements to inspect:

| Component | Inspection Criteria | Common Issues |

|---|---|---|

| Battery | Check for corrosion and voltage | Low charge, swelling |

| Fuel System | Inspect for leaks and clogs | Inconsistent flow, contamination |

| Wiring | Look for fraying and disconnections | Short circuits, poor connectivity |

| Cooling System | Examine for blockages and fluid levels | Overheating, coolant leaks |

By systematically evaluating these components, users can effectively identify and rectify issues, ensuring optimal functionality of their machinery.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Ensuring you acquire high-quality items can prevent issues and enhance the efficiency of your machinery. Here are some reliable sources to consider when searching for these essential items.

Authorized Dealers

- Visit local authorized dealers who specialize in your equipment brand.

- Check their websites for online purchasing options.

- Inquire about warranty options and after-sales support.

Online Retailers

- Look for reputable e-commerce platforms that sell genuine components.

- Read customer reviews to ensure reliability and quality.

- Verify that the retailer offers a return policy for peace of mind.

By utilizing these trusted sources, you can ensure that your machinery operates smoothly and efficiently with the right authentic components.

Common Issues and Their Solutions

When operating a generator, users may encounter various challenges that can affect performance and reliability. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality. Below are some frequent issues along with practical recommendations for resolution.

One prevalent issue is difficulty starting the unit. This may stem from a drained battery, fuel supply problems, or a clogged air filter. To address this, first, check the battery’s charge and connections. Ensure that the fuel tank is filled and that the fuel is fresh. Additionally, inspect the air filter and clean or replace it as needed.

Another common concern is irregular power output. This can often be traced to an overloaded generator or faulty wiring. To resolve this, confirm that the total load does not exceed the generator’s capacity. If the problem persists, it may be necessary to examine the wiring for any signs of damage or wear.

Lastly, some users may experience excessive noise during operation. This could indicate that the unit is not placed on a stable surface or that certain components require lubrication. To minimize noise, ensure the generator is positioned on a flat, solid base, and check for any areas that may need oiling or maintenance.

Upgrading Your Generac Generator

Enhancing your portable power unit can significantly improve its performance and longevity. Upgrades can range from simple modifications to comprehensive enhancements, ensuring that your generator operates at peak efficiency and meets your evolving needs.

Essential Upgrades to Consider

One of the most impactful modifications is increasing the fuel capacity. A larger tank allows for extended run times, making it ideal for prolonged use during outages. Additionally, consider upgrading the air filtration system. A more efficient filter can enhance engine performance by improving airflow and reducing contaminants, ultimately leading to better fuel efficiency.

Improving Portability and Usability

Enhancing mobility is another crucial aspect. Adding wheels or a sturdy frame can make transportation easier, especially for larger units. Furthermore, incorporating advanced control panels with digital readouts can provide real-time data on performance metrics, allowing for more informed management of your energy needs.

By investing in these upgrades, you can ensure that your generator remains a reliable source of power, tailored to your specific requirements.

Resources for Further Learning

Exploring the intricate components of machinery can significantly enhance your understanding and maintenance skills. Accessing various resources allows enthusiasts and professionals alike to deepen their knowledge and stay updated on best practices in equipment management and repair.

Online Tutorials and Videos

Visual aids, such as tutorials and instructional videos, provide step-by-step guidance on troubleshooting and servicing. Platforms like YouTube host a wealth of content created by experienced users, making complex processes more accessible.

Technical Manuals and Guides

Investing time in manuals and reference guides can offer valuable insights into equipment specifications and operational techniques. These documents often include detailed illustrations and troubleshooting tips that are essential for effective maintenance.