Comprehensive Guide to Generac RS5500 Parts Diagram

In the world of portable energy solutions, having a clear understanding of the individual elements that make up these machines is crucial. Each component plays a vital role in the overall functionality and reliability of the equipment. This section aims to explore the intricate arrangement of parts, highlighting their significance and interconnections.

By examining the various segments and their respective roles, users can gain valuable insights into maintenance and troubleshooting. A comprehensive overview will facilitate better decision-making when it comes to repairs and replacements, ensuring optimal performance in various applications.

Whether you are a seasoned technician or a curious owner, familiarizing yourself with the layout and functionality of these components can enhance your experience. By recognizing how each piece contributes to the efficiency of the system, you can take proactive steps in managing and preserving your equipment’s longevity.

Understanding Generac RS5500 Parts

Gaining insight into the components of a portable power generator is essential for effective maintenance and troubleshooting. Each element plays a vital role in the overall functionality and reliability of the machine. Familiarity with these elements allows users to ensure optimal performance and longevity.

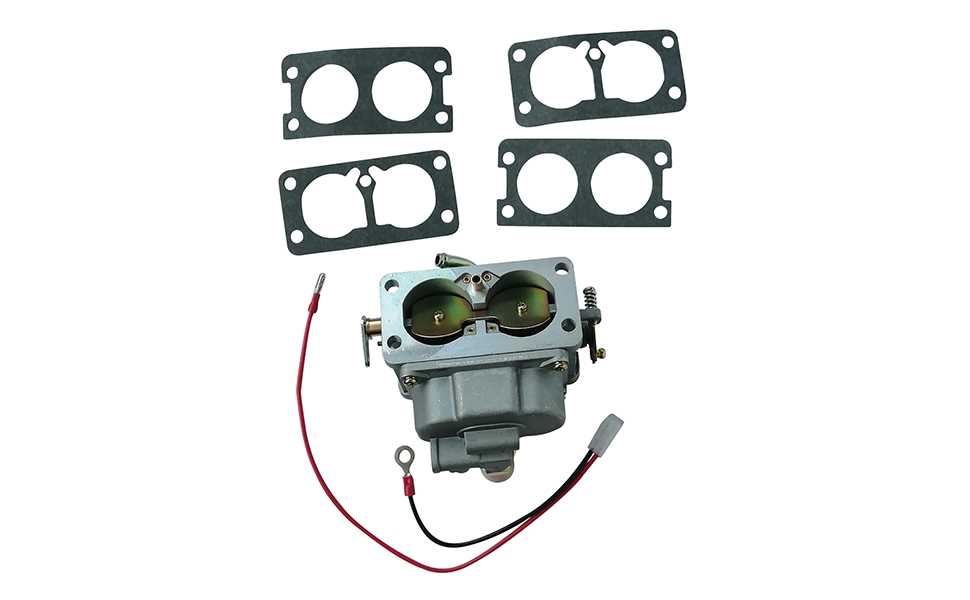

The core of any power-producing unit is its engine, which converts fuel into mechanical energy. Closely associated are the fuel system components, responsible for delivering the necessary energy source efficiently. Additionally, the electrical system, including the alternator and control panel, is crucial for converting that mechanical energy into usable electricity.

Understanding the cooling system is equally important, as it prevents overheating during operation. The chassis and frame provide structural support, while various accessories and protective elements contribute to user safety and convenience. By recognizing each component’s function, users can better navigate maintenance needs and enhance their overall experience with the generator.

Overview of Generator Components

Understanding the essential elements of a power generator is crucial for both maintenance and operation. Each component plays a significant role in ensuring that the machine functions efficiently and reliably, especially during emergencies or power outages. This section provides an overview of the key parts that comprise a typical generator system.

Core Elements

At the heart of any generator is the engine, which converts fuel into mechanical energy. This mechanical energy is then transformed into electrical energy through the alternator. The fuel system is equally important, as it stores and supplies the necessary fuel to the engine. In addition, a robust cooling system is vital to prevent overheating during operation, ensuring that the generator runs smoothly and efficiently.

Support Structures

Supporting components such as the frame provide structural integrity and protect internal parts from external damage. The control panel serves as the interface for users, allowing for easy monitoring and management of the generator’s functions. Additionally, exhaust systems are designed to safely channel emissions away from the unit, contributing to both safety and environmental compliance.

Importance of a Parts Diagram

A visual representation of components is essential for understanding the intricate workings of machinery. It serves as a crucial reference that aids in the identification and organization of various elements within a system. Such illustrations enhance clarity, making it easier to locate specific items and comprehend their relationships with one another.

Enhanced Maintenance and Repair

Having a clear schematic is invaluable during maintenance and repair tasks. It allows technicians to quickly pinpoint issues and determine the necessary replacements. This efficiency can significantly reduce downtime, ensuring that equipment remains operational and productive.

Improved Understanding for Users

For end-users, these visual aids facilitate a deeper understanding of their equipment. By providing a detailed overview of how components fit together, users can become more confident in managing their devices, leading to better usage practices and longevity of the machinery.

Common Issues with RS5500 Models

When it comes to portable power solutions, certain models can encounter typical challenges that may hinder their performance and reliability. Understanding these common problems can help users maintain their equipment effectively and ensure uninterrupted operation.

Frequent Problems

- Starting Difficulties: Many users report issues with ignition, which can stem from various factors such as fuel quality, battery condition, or starter malfunctions.

- Overheating: Insufficient ventilation or debris accumulation can lead to overheating, affecting the engine’s efficiency and lifespan.

- Power Fluctuations: Inconsistent voltage output can cause connected devices to malfunction, often linked to internal wiring or generator load issues.

Maintenance Tips

- Regularly check and replace the air filter to ensure optimal airflow.

- Monitor fuel levels and quality, and use the recommended type of fuel.

- Schedule routine inspections to catch potential issues before they escalate.

Identifying Essential Replacement Parts

Understanding the key components of your equipment is crucial for maintenance and longevity. Recognizing which elements may require substitution helps ensure optimal performance and reliability. This section focuses on how to identify and select the necessary items to keep your machine in peak condition.

To begin with, familiarize yourself with the critical segments that commonly need attention:

- Fuel System Components: Look for filters, pumps, and lines that might degrade over time.

- Electrical Parts: Pay attention to the battery, connectors, and wiring that are vital for operation.

- Cooling System Elements: Inspect hoses, radiators, and thermostats to avoid overheating issues.

- Mechanical Components: Check for wear on belts, bearings, and other moving parts that experience friction.

Next, it’s important to consider how to source replacements:

- Consult your user manual for specific information about compatible components.

- Visit authorized retailers or trusted online suppliers for quality options.

- Review product reviews and ratings to ensure reliability.

By understanding these elements and how to obtain them, you can effectively maintain your equipment’s functionality and extend its lifespan.

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed look at individual elements and their relationships within a system, enabling users to identify and locate specific items easily.

Here are key steps to help you interpret these visuals:

- Familiarize Yourself with the Layout: Begin by examining the overall structure. Identify sections that group related components.

- Identify Labels: Pay attention to the annotations and numbers that correspond to specific parts. These often serve as references for ordering replacements.

- Look for Callouts: Many representations include arrows or lines indicating connections or dependencies between elements. Understanding these links is crucial for troubleshooting.

- Refer to the Legend: Most illustrations include a key or legend explaining symbols and color coding. Familiarizing yourself with this guide can clarify any confusion.

By following these guidelines, you can effectively decode the representation and streamline your maintenance tasks.

Maintenance Tips for Generac Generators

Regular upkeep is essential for ensuring optimal performance and longevity of your power units. By adhering to a few straightforward practices, you can enhance the reliability of your equipment and minimize the risk of unexpected failures. This section outlines key strategies for maintaining your generator efficiently.

1. Schedule Routine Inspections: Conduct regular checks to identify any potential issues before they escalate. Look for signs of wear, loose connections, or fluid leaks. Regular inspections can help catch problems early and keep your unit running smoothly.

2. Change the Oil: Just like any other engine, regular oil changes are crucial. Follow the manufacturer’s recommendations regarding the frequency of oil changes. Fresh oil ensures proper lubrication and reduces engine wear.

3. Replace Air Filters: Clean air filters are vital for efficient operation. Inspect and replace filters as needed to maintain optimal airflow and prevent debris from entering the engine.

4. Check the Battery: A healthy battery is critical for reliable startup. Inspect battery terminals for corrosion and ensure connections are secure. Consider testing the battery’s charge regularly, especially before periods of heavy use.

5. Fuel Maintenance: Use fresh fuel and stabilize it if your unit will sit unused for extended periods. Old or contaminated fuel can cause performance issues and may lead to engine damage.

6. Clean the Unit: Keep the exterior of the generator clean and free from debris. Regular cleaning prevents rust and corrosion, extending the life of your equipment.

7. Exercise the Generator: Run your generator periodically under load to keep it in good working condition. This practice helps prevent issues related to inactivity, such as fuel stagnation and component deterioration.

By following these maintenance tips, you can ensure that your power equipment operates effectively when you need it most, providing peace of mind and reliable performance.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining its performance and longevity. Using original replacements ensures compatibility and reliability, allowing your machinery to function at its best. Here are some effective ways to source these essential items.

Authorized Retailers

One of the most reliable methods is to purchase from authorized dealers. These retailers are certified to sell genuine components and often have a comprehensive selection. Check their websites or visit local stores to find what you need.

Online Marketplaces

Numerous online platforms specialize in high-quality equipment components. Make sure to verify the seller’s reputation and confirm that the items are genuine before making a purchase. Look for reviews and ratings from previous customers to ensure a satisfactory buying experience.

Direct Manufacturer Websites often offer the most accurate inventory and latest updates on available components. It’s wise to visit these sites to compare options and check for any promotions that might save you money.

Remember, using authentic components not only preserves the integrity of your equipment but also protects your investment in the long run.

Comparison with Other Generac Models

When evaluating different models from a prominent power equipment brand, it’s essential to consider their specifications, features, and overall performance. This analysis highlights how certain models stand out in terms of power output, fuel efficiency, and user-friendliness.

For instance, while some units may offer higher wattage capabilities, they might lack in portability or ease of use compared to others. The compact design of some variants makes them more suitable for residential use, whereas larger models are better suited for heavy-duty applications.

Moreover, variations in fuel consumption can significantly impact long-term operational costs. A more efficient generator will not only reduce the frequency of refueling but also provide substantial savings over time. Features like noise reduction technology can also differ, influencing the user experience depending on the intended application.

Ultimately, selecting the right model requires a careful consideration of these factors to ensure that the chosen generator aligns with the user’s specific needs and expectations.

Assembly and Disassembly Instructions

This section provides essential guidance for the proper assembly and disassembly of the equipment, ensuring efficient operation and maintenance. Following these steps will help you to safely handle components and avoid any potential issues during the process.

To begin the assembly process, gather all necessary tools and components in a clean, organized workspace. Start by referencing the instruction manual to identify each piece and its corresponding placement. Carefully align the parts, ensuring they fit together correctly, and securely fasten them according to the specified torque settings. It is crucial to double-check connections to prevent future malfunctions.

When disassembling, make sure the device is powered down and disconnected from any power source. Begin by removing any protective covers or enclosures, if applicable. Take note of the order in which parts are removed, and store small components in labeled containers to avoid misplacement. Gently detach each piece, being mindful of any attached wiring or fasteners. Documenting your process can be helpful for reassembly.

By adhering to these instructions, you can ensure a smooth and effective handling of the equipment, maximizing its longevity and performance. Proper care during both assembly and disassembly will lead to a more reliable and efficient operation.

Using Diagrams for Troubleshooting

Visual aids play a crucial role in identifying and resolving issues in various mechanical systems. By utilizing these representations, users can systematically assess components and connections, facilitating a clearer understanding of potential problems. This method not only enhances efficiency but also minimizes the likelihood of overlooking critical details during the diagnostic process.

Benefits of Visual Representations

Employing visual schematics offers several advantages when it comes to troubleshooting. They provide a straightforward way to visualize complex structures and relationships among parts. Here are some key benefits:

| Benefit | Description |

|---|---|

| Enhanced Clarity | Visuals simplify intricate layouts, making it easier to spot discrepancies. |

| Time Efficiency | Quickly identify problematic areas without extensive manual checks. |

| Improved Accuracy | Reduces human error by providing a reliable reference for analysis. |

Steps to Utilize Visual Aids Effectively

To maximize the benefits of these tools during troubleshooting, consider the following steps:

- Examine the visual guide closely to understand the layout.

- Identify any irregularities or damage in the components depicted.

- Cross-reference the visual with the actual setup to confirm findings.

- Document any issues for further analysis or repair.

Upgrades and Accessories for RS5500

Enhancing your portable power solution can significantly improve its performance and usability. A variety of add-ons and upgrades are available to help you maximize efficiency, extend functionality, and ensure reliability during critical moments. Whether you are looking to boost power output or increase convenience, there are options to consider that cater to diverse needs.

Performance Enhancements

To optimize the output and reliability of your generator, consider upgrading to a higher-capacity fuel tank or installing a more efficient air filter. These enhancements can lead to longer run times and improved fuel efficiency, ensuring that your equipment is ready when you need it most. Additionally, utilizing a battery maintenance system can help keep your starter battery in peak condition, reducing the risk of unexpected failures.

Convenience Accessories

For added convenience, various accessories can enhance usability. A transfer switch allows for seamless integration with home wiring, making it easier to switch between grid power and your portable generator during outages. Furthermore, investing in a protective cover can safeguard your unit from the elements, prolonging its lifespan and maintaining its performance. Other accessories like mobility kits and parallel connection cables can also provide greater flexibility for various applications.

FAQs About Generac RS5500 Parts

This section aims to address common inquiries related to components and accessories of a popular power equipment model. Understanding the intricacies of these elements can enhance performance and longevity, ensuring users make informed decisions regarding maintenance and replacement.

What components are essential for optimal performance?

Key elements that contribute to efficiency include the engine, fuel system, and electrical components. Regular checks on these parts ensure the unit operates smoothly and reduces the likelihood of unexpected breakdowns.

How often should I replace individual components?

The frequency of replacement varies based on usage and maintenance practices. Filters should typically be changed every season, while other elements like batteries and spark plugs may require attention annually. Always consult the user manual for specific guidelines.