Understanding the Predator Generator Parts Diagram

When it comes to efficient operation and maintenance of power devices, a comprehensive understanding of their inner workings is essential. Each element plays a crucial role, contributing to the overall functionality and reliability of the machinery.

In this section, we will explore the various elements that constitute these essential tools. By examining the layout and relationships between different components, users can enhance their ability to troubleshoot issues and perform necessary repairs effectively.

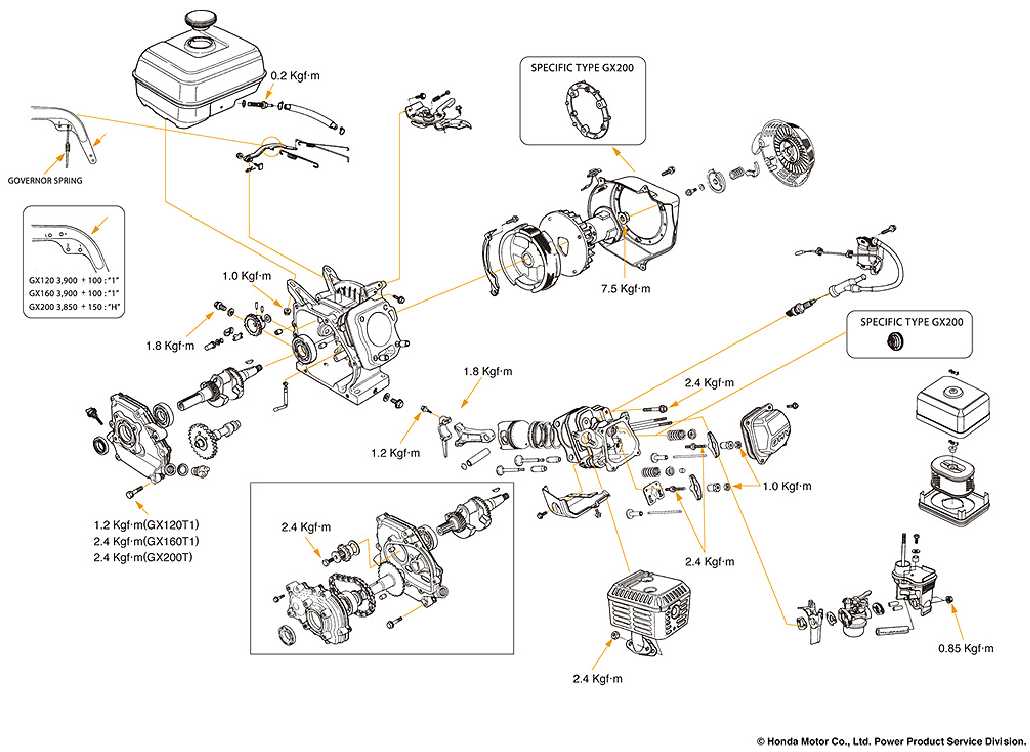

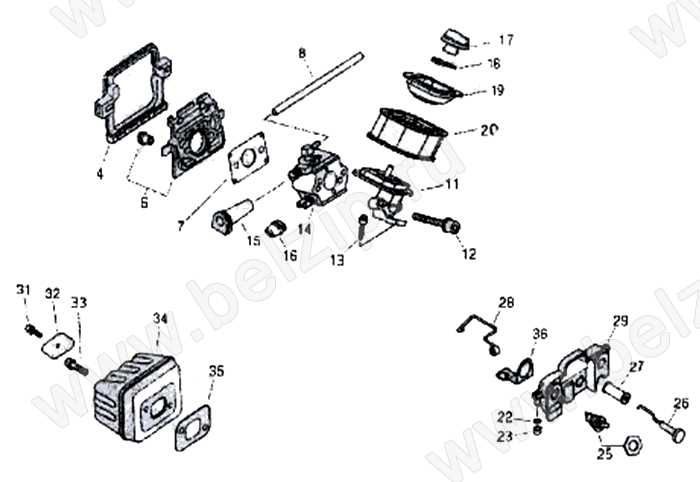

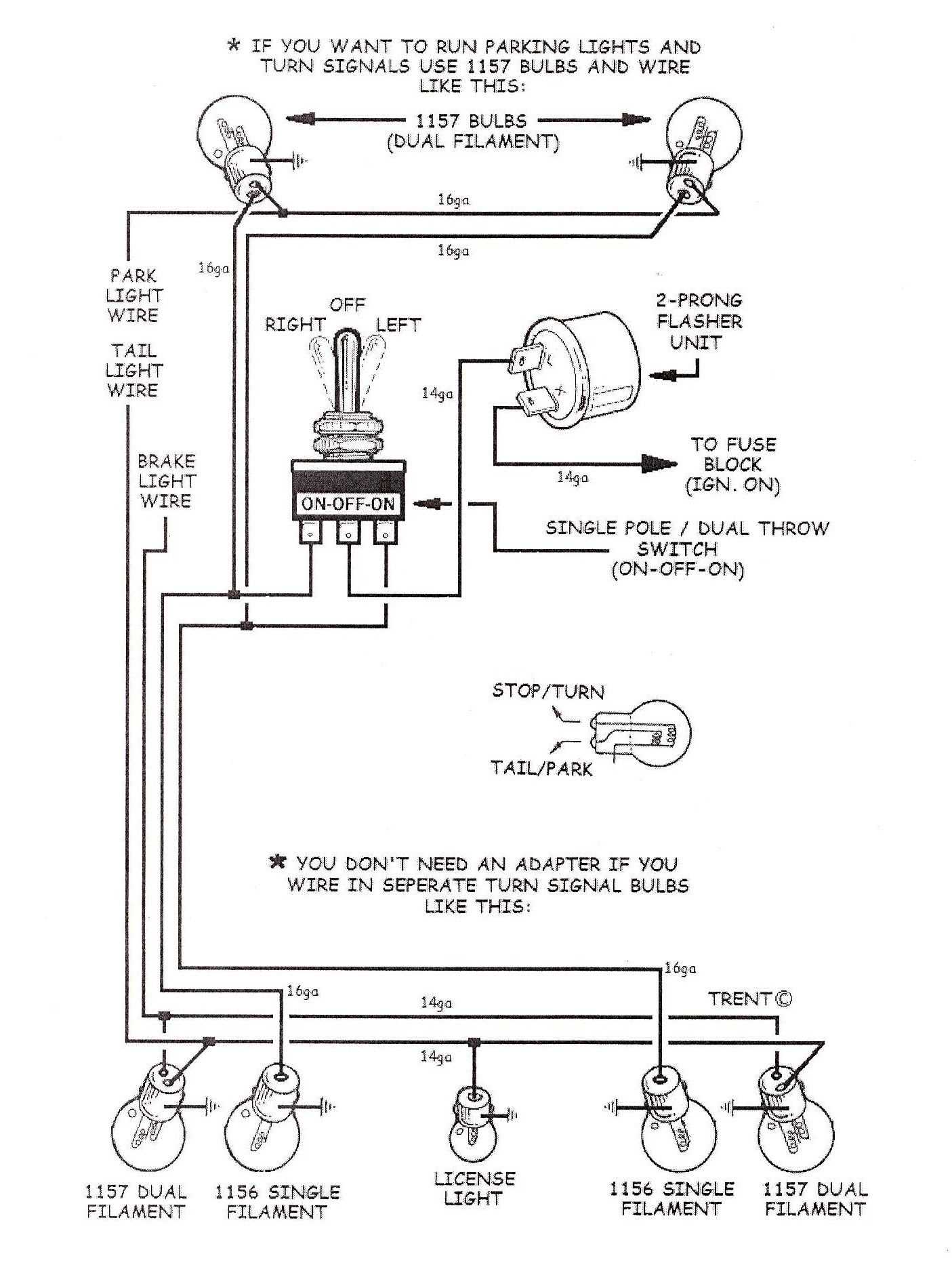

Visual representations of these elements provide invaluable insights, helping enthusiasts and professionals alike navigate through complexities. This exploration will ultimately empower users to maximize performance and extend the lifespan of their equipment.

Understanding Predator Generator Components

In order to fully appreciate the functionality of these machines, it’s essential to grasp the various elements that contribute to their operation. Each component plays a vital role in ensuring efficiency and reliability, making it important to understand their specific functions and interactions.

Main Elements

- Engine: The powerhouse that drives the system, providing the necessary energy for operation.

- Fuel System: Supplies the energy source, ensuring consistent performance.

- Control Panel: Offers user interface and monitoring capabilities, allowing for easy adjustments.

- Exhaust System: Safely directs fumes away, maintaining a safe environment.

Support Structures

- Chassis: Provides the framework, ensuring stability and durability.

- Wheels: Enhance mobility, allowing for easy transport.

- Cooling System: Regulates temperature, preventing overheating during prolonged use.

By exploring these crucial components, users can optimize performance and maintain their equipment effectively.

Key Parts of a Predator Generator

Understanding the essential components of a power source can greatly enhance your ability to maintain and operate it effectively. Each element plays a critical role in ensuring smooth functionality and reliability, making it crucial for users to familiarize themselves with these integral segments.

Engine: The core of the system, responsible for converting fuel into mechanical energy, driving the entire apparatus.

Alternator: This component transforms mechanical energy into electrical energy, enabling the production of usable power.

Fuel Tank: A vital reservoir that holds the necessary liquid to keep the engine operational for extended periods.

Control Panel: The user interface that allows for monitoring and managing output levels and operational status, ensuring efficient performance.

Chassis: The framework that houses and supports all components, providing stability and durability to the entire setup.

Cooling System: Essential for maintaining optimal operating temperatures, preventing overheating and ensuring longevity of the machinery.

By delving into these key segments, users can better appreciate the complexity and functionality of their power source, leading to improved maintenance and operation practices.

Importance of a Parts Diagram

A comprehensive representation of components serves as a crucial tool for understanding complex systems. It facilitates the identification and organization of various elements, ensuring efficient maintenance and repair processes. Having a visual guide significantly enhances the clarity of assembly and disassembly tasks.

Benefits of Visual Representation

- Streamlines troubleshooting and repairs

- Promotes accurate reassembly of components

- Enhances communication among technicians

Role in Maintenance

- Helps in planning routine inspections

- Assists in the identification of wear and tear

- Facilitates the procurement of necessary replacements

How to Read the Diagram Effectively

Understanding a schematic representation can greatly enhance your ability to work with complex machinery. These illustrations serve as visual guides, providing insight into the arrangement and function of various components. Grasping the layout and symbols used is essential for troubleshooting and maintenance tasks.

Begin by familiarizing yourself with the key symbols and notations that denote different elements within the illustration. Each icon represents a specific function or piece, so recognizing these can streamline your interpretation. Pay attention to the connections shown, as they indicate how parts interact with one another.

Next, consider the flow of energy or information depicted in the representation. Following this flow will help you understand how the system operates as a whole. Look for directional arrows or pathways that illustrate the sequence of actions, as these are crucial for identifying potential issues.

Lastly, take note of any accompanying legends or notes that provide additional context. These explanations can clarify complex aspects and offer insights into troubleshooting. By approaching the schematic with a clear method, you’ll gain confidence in your ability to navigate and utilize these invaluable resources.

Common Issues with Generator Parts

When dealing with machinery that converts mechanical energy into electrical power, various components can present challenges that affect performance and reliability. Identifying these issues early can prevent more significant failures and ensure efficient operation.

Worn Components

One of the most frequent problems arises from the wear and tear of essential components. As these elements undergo repeated stress and strain, their efficiency diminishes, leading to potential malfunctions. Regular inspection and timely replacement of worn-out items are crucial for maintaining optimal functionality.

Electrical Failures

Electrical malfunctions can stem from several sources, including faulty wiring or connections. Such failures not only disrupt operation but can also pose safety risks. Ensuring that all electrical connections are secure and free of corrosion is vital for preventing these issues.

Proactive maintenance and awareness of common challenges can significantly enhance the longevity and efficiency of your machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your machinery. Regular attention to key areas can significantly enhance performance and reliability over time. Implementing a systematic maintenance routine helps identify potential issues before they escalate into costly repairs.

Regular Inspection

- Check fluid levels frequently.

- Examine belts and hoses for wear and tear.

- Ensure air filters are clean and unobstructed.

Scheduled Servicing

- Adhere to manufacturer recommendations for service intervals.

- Replace worn components proactively to avoid failures.

- Keep a maintenance log to track tasks and repairs.

By following these tips, you can greatly enhance the durability and efficiency of your equipment.

Replacing Worn-Out Components

Over time, certain elements within your equipment may deteriorate, impacting overall performance. Identifying and addressing these issues promptly is crucial for maintaining efficiency and longevity.

Here are some key steps to consider when replacing these essential components:

- Assess the Condition

- Regularly inspect components for signs of wear, such as cracks or corrosion.

- Keep an eye out for unusual noises or performance drops that may indicate failure.

- Ensure you have the right tools for disassembly and installation.

- Prepare safety equipment, like gloves and goggles, for protection.

- Refer to manuals for specific replacement instructions.

- Adhere to recommended specifications for new components.

- After installation, conduct a thorough test to ensure everything operates smoothly.

- Monitor performance for a few days to confirm stability.

Identifying Faulty Parts Easily

Recognizing malfunctioning components is crucial for maintaining optimal performance and longevity of your equipment. By understanding how to systematically evaluate various elements, you can effectively pinpoint issues before they escalate into more significant problems. This approach not only enhances efficiency but also reduces downtime and repair costs.

Begin by conducting regular inspections, focusing on common signs of wear or damage. Look for unusual noises, vibrations, or changes in operation, as these can indicate underlying faults. Additionally, familiarize yourself with the typical symptoms associated with specific failures, as this knowledge will streamline your diagnostic process.

Utilizing a methodical checklist can further simplify the identification of problematic areas. Documenting observations and changes over time can provide valuable insights into patterns of failure, allowing for proactive measures. Moreover, collaborating with experienced technicians can enhance your understanding and ensure that you address issues promptly.

Finally, investing in quality tools and resources is essential for accurate assessments. Proper equipment can facilitate thorough evaluations and help you swiftly determine the integrity of each component. By prioritizing these practices, you will enhance your ability to detect malfunctions early and maintain the reliability of your machinery.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for efficient and effective work. This section outlines essential equipment that will facilitate the repair process, ensuring you are well-prepared for any challenges that may arise.

Essential Instruments

Gathering the proper tools can significantly impact the success of your repair efforts. Here are some of the most common items you’ll need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and secure screws in various components. |

| Wrench Set | To tighten or loosen nuts and bolts. |

| Pliers | To grip, twist, and cut wires or small parts. |

| Multimeter | To measure voltage, current, and resistance. |

| Socket Set | For efficient fastening and unfastening of various sizes of fasteners. |

Safety Gear

In addition to tools, safety equipment is paramount. Ensure you have gloves, goggles, and a mask to protect yourself while working. Prioritizing safety will enhance your overall repair experience.

Safety Precautions During Maintenance

Ensuring a secure environment while performing upkeep tasks is crucial for both the individual and the equipment involved. Proper precautions help prevent accidents and facilitate a smooth process, leading to optimal performance and longevity of the machinery.

Essential Safety Measures

- Always disconnect power sources before starting any maintenance work.

- Utilize appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets.

- Maintain a clean workspace to avoid hazards and enhance visibility.

- Ensure that all tools are in good condition and suitable for the tasks at hand.

Emergency Preparedness

- Familiarize yourself with emergency shut-off procedures.

- Keep first aid kits readily available and stocked with essential supplies.

- Have a fire extinguisher accessible and ensure it is suitable for electrical fires.

- Inform others of your maintenance activities and estimated duration to prevent unexpected interruptions.

Finding Quality Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential for ensuring optimal performance and longevity. Selecting the right substitutes can significantly impact functionality and reliability.

Here are some key considerations to keep in mind:

- Research Reputable Suppliers: Look for vendors with positive reviews and a strong reputation in the industry.

- Check Compatibility: Ensure the items you choose are suitable for your specific model to avoid issues.

- Examine Materials: High-grade materials often lead to better durability and performance. Opt for components made from robust substances.

- Warranty and Support: Prefer suppliers who offer guarantees and customer assistance in case of defects or inquiries.

By following these guidelines, you can make informed decisions and find reliable replacements that will keep your machinery running smoothly.

Where to Buy Authentic Components

Finding genuine replacements for your machinery is essential for ensuring optimal performance and longevity. Numerous options are available for sourcing these essential items, but identifying reliable suppliers is crucial.

Authorized Dealers

One of the best ways to acquire original components is through authorized dealers. These vendors are certified to sell authentic merchandise, ensuring that you receive high-quality products that meet the manufacturer’s standards.

Online Marketplaces

Reputable online marketplaces also offer a wide selection of genuine items. When purchasing from these platforms, always check seller ratings and reviews to confirm the authenticity of the products. This diligence can save you from counterfeit alternatives.

In summary, prioritize quality by choosing trusted sources for your components, whether through official dealers or vetted online platforms. This approach guarantees that your machinery will operate at its best.