Comprehensive Guide to 688 New Holland Baler Parts Diagram

Maintaining agricultural machinery is essential for ensuring optimal performance and longevity. A comprehensive knowledge of its individual elements allows operators to address issues effectively and keep their machines running smoothly. By familiarizing oneself with the various components, one can easily identify wear and tear, facilitating timely repairs and replacements.

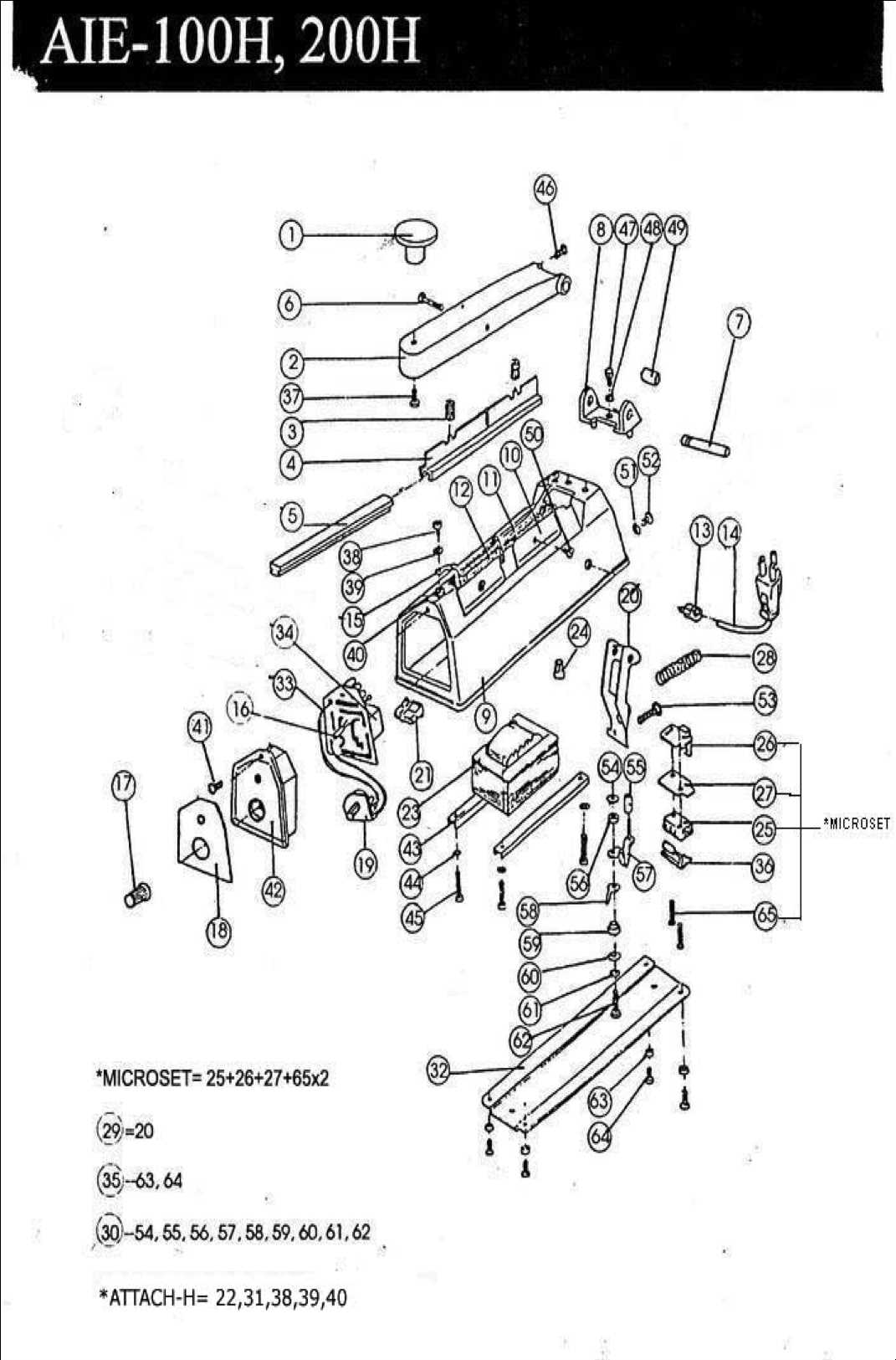

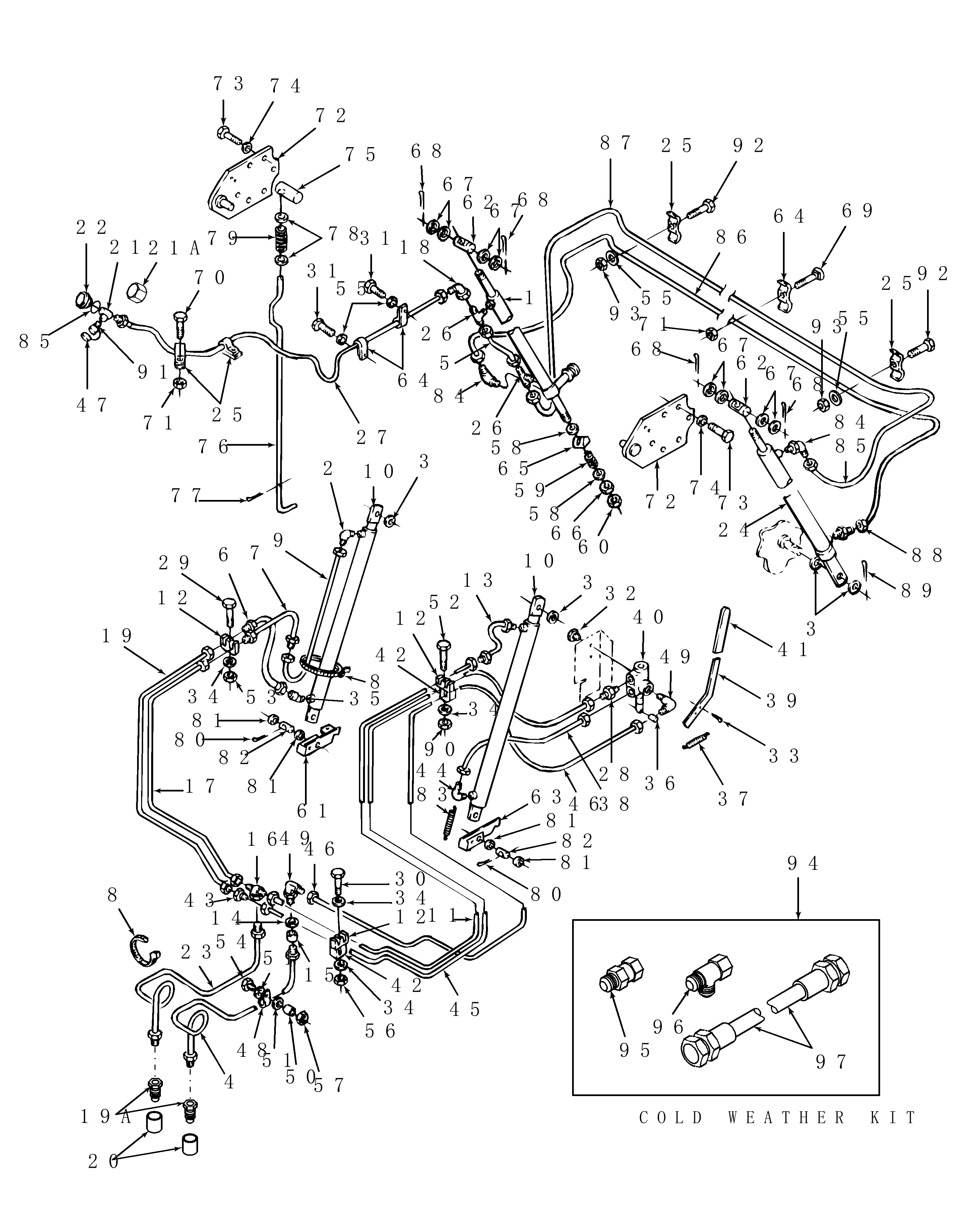

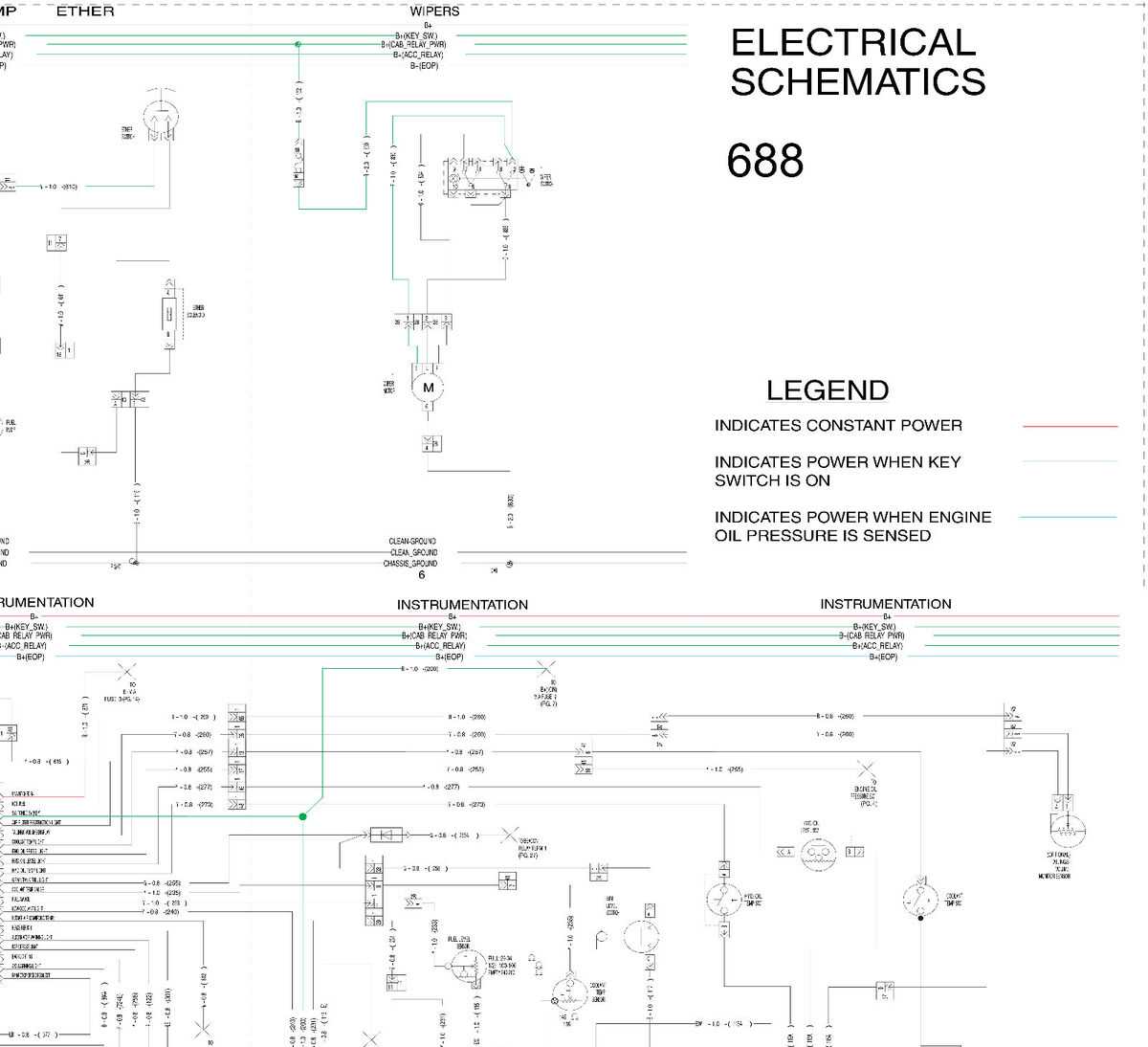

Visual aids play a crucial role in this learning process. Detailed illustrations serve as a valuable resource, providing insights into the intricate relationships between different sections of the machinery. They help users comprehend how each piece fits into the overall system, enhancing troubleshooting and maintenance practices.

By exploring these visual representations, operators can gain a clearer understanding of their equipment’s functionality. This knowledge empowers them to execute repairs with confidence, ensuring that their machinery remains efficient and reliable in the field. Embracing this approach not only saves time and resources but also contributes to a safer working environment.

Understanding the 688 New Holland Baler

This section explores the intricacies of a widely used agricultural implement designed for efficient crop harvesting and processing. By delving into its components and functions, users can enhance their operational knowledge and maintenance skills.

Key Features

- Robust construction for durability and reliability.

- Advanced mechanisms for improved performance and efficiency.

- User-friendly controls for seamless operation.

Maintenance Tips

- Regularly inspect and lubricate moving parts to prevent wear.

- Check tension settings to ensure optimal bale formation.

- Clean components to avoid debris accumulation that can hinder performance.

Understanding these aspects contributes significantly to achieving optimal results in the field, ensuring that the equipment operates at peak efficiency throughout its lifespan.

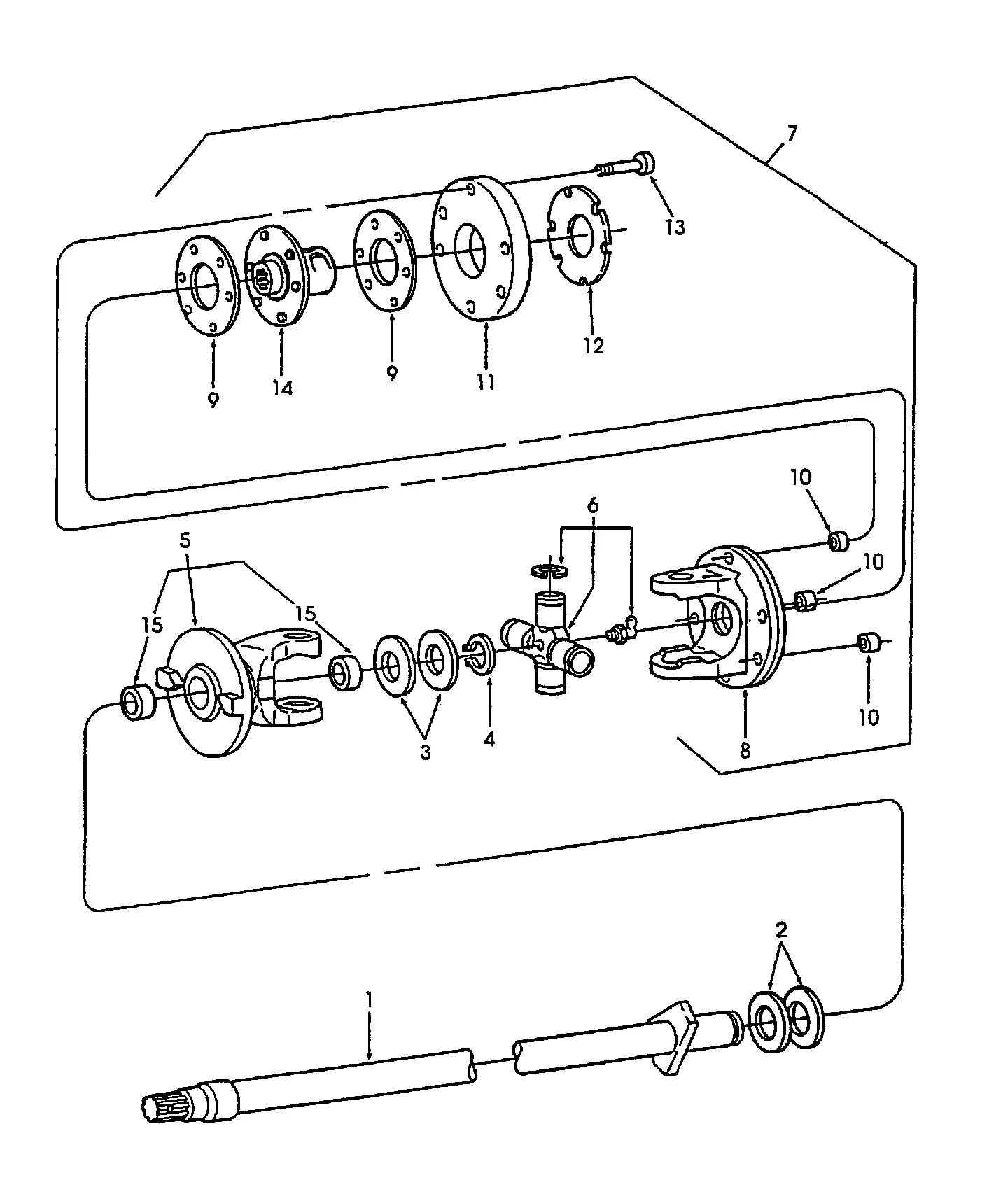

Key Components of the Baler

The efficient operation of a harvesting machine relies on several essential elements, each playing a crucial role in the overall functionality. Understanding these components is vital for proper maintenance and optimal performance during agricultural tasks.

Main Parts

- Feeder System: This component is responsible for directing material into the machine for processing.

- Compression Chamber: Here, the gathered material is compacted into manageable sizes.

- Twine or Wire Mechanism: This system secures the compressed bundles, ensuring they remain intact during handling.

- Cutting Mechanism: Some machines feature this to chop the material before it enters the compression chamber.

Support Elements

- Chassis: The framework that supports all other components, providing stability.

- Power Source: Usually a tractor or engine that drives the various functions of the equipment.

- Control System: This allows the operator to adjust settings for different types of materials.

- Tires or Tracks: Essential for mobility, enabling the machine to navigate fields effectively.

Recognizing the significance of these parts enhances understanding and fosters better care of the machinery, ultimately leading to increased productivity in agricultural operations.

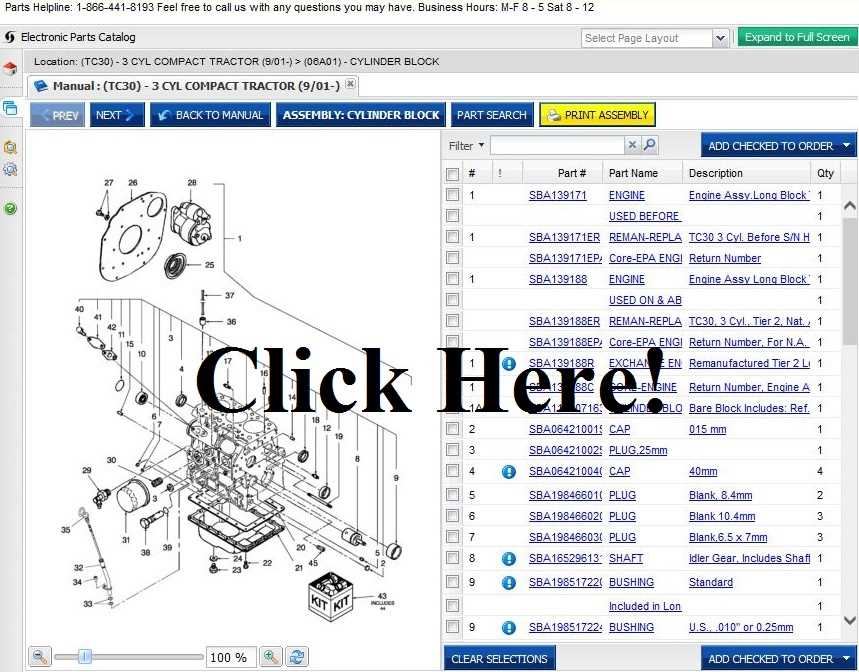

How to Access the Parts Diagram

Finding a visual representation of components for agricultural machinery is essential for effective maintenance and repair. This guide outlines the steps necessary to locate these crucial illustrations, ensuring you can identify each piece and understand its function within the system.

First, visit the official website of the manufacturer or authorized distributors. They typically provide resources, including detailed visuals and manuals. Navigate to the support or resources section, where you can often find downloadable content.

If online resources are insufficient, consider consulting the operator’s manual that came with the equipment. These manuals often include comprehensive illustrations and descriptions of various components.

Additionally, joining online forums or communities focused on agricultural machinery can be beneficial. Many enthusiasts and professionals share links, resources, and personal insights, which can lead you to the necessary visuals.

In case you still encounter difficulties, reaching out to customer support can provide direct assistance. They can guide you through the process of obtaining the necessary materials, ensuring you have the information required for efficient operation.

Importance of Regular Maintenance

Routine upkeep is essential for ensuring the longevity and efficiency of machinery. Consistent attention to maintenance helps to identify potential issues before they escalate, thereby preventing unexpected breakdowns and costly repairs. Additionally, regular checks contribute to optimal performance, ensuring that equipment operates at its best.

Benefits of Consistent Care

Implementing a regular maintenance schedule offers numerous advantages, including:

| Benefit | Description |

|---|---|

| Increased Lifespan | Regular servicing helps to extend the operational life of equipment. |

| Enhanced Performance | Routine checks ensure that machinery operates efficiently and effectively. |

| Cost Savings | Preventive maintenance can reduce the need for costly repairs and replacements. |

| Safety Assurance | Regular inspections help to identify safety hazards, promoting a safer work environment. |

Best Practices for Maintenance

To maximize the benefits of upkeep, it is crucial to adopt best practices, such as creating a maintenance schedule, keeping detailed records of inspections, and utilizing high-quality replacement components. By prioritizing maintenance, operators can ensure that their machinery remains reliable and effective for years to come.

Common Issues and Troubleshooting

In the world of agricultural machinery, occasional malfunctions can arise, impacting efficiency and productivity. Understanding these common challenges and their solutions is crucial for maintaining optimal performance. Below are some frequent problems encountered and effective strategies for resolution.

Frequent Problems

- Jamming: Material can often become stuck, leading to a halt in operations.

- Inconsistent Bale Formation: Bales may not form correctly, resulting in uneven sizes.

- Unusual Noises: Strange sounds during operation can indicate mechanical issues.

- Hydraulic Failures: Problems with the hydraulic system can cause a range of malfunctions.

- Worn Components: Over time, parts may wear down, affecting overall functionality.

Troubleshooting Tips

- Inspect for blockages and clear any debris that may cause jamming.

- Adjust tension settings to improve bale consistency and quality.

- Conduct regular maintenance checks to identify and replace worn components.

- Listen carefully for unusual sounds and address potential mechanical issues promptly.

- Check hydraulic fluid levels and connections to prevent failures.

By proactively addressing these common issues, operators can enhance the longevity and reliability of their machinery, ensuring seamless agricultural operations.

Replacement Parts Availability

Ensuring the continuous operation of agricultural machinery is crucial for productivity. Access to suitable components is essential for maintaining efficiency and minimizing downtime. Availability of quality replacements can significantly influence the longevity and performance of equipment.

Source Options

Numerous suppliers offer a wide range of alternatives for machinery components. Online retailers, local distributors, and specialized shops often provide options to suit different budgets and requirements. It is advisable to compare offerings and select reliable sources to ensure compatibility and durability.

Quality Considerations

When seeking replacements, the quality of materials and craftsmanship plays a vital role in performance. Opting for reputable brands or verified aftermarket solutions can help avoid frequent replacements and enhance overall machine reliability. Conducting research and reading reviews can guide decisions effectively.

Step-by-Step Repair Guide

This guide provides a systematic approach to fixing common issues encountered in agricultural machinery. By following each step carefully, you can restore functionality and ensure optimal performance. A thorough understanding of the components involved is essential for successful repairs.

Identifying the Problem

Begin by observing the machine during operation. Look for unusual noises, decreased efficiency, or visible damage. Make notes of any specific symptoms to help narrow down the potential causes. Understanding the operational context will aid in diagnosing the issue accurately.

Repair Process

Once the problem is identified, gather the necessary tools and components for the repair. Disconnect the power supply before starting any work to ensure safety. Follow a step-by-step approach: dismantle the affected area, replace or repair the faulty components, and reassemble the machinery according to the manufacturer’s guidelines. After reassembly, conduct a thorough test to confirm that the repairs were successful.

Documentation of the repair process can be invaluable for future maintenance and troubleshooting. Regular upkeep not only prolongs the life of the equipment but also enhances its efficiency.

Upgrading Your Baler Equipment

Enhancing your harvesting machinery can significantly improve efficiency and output. Investing in modern components can lead to smoother operation, reduced downtime, and better overall performance. By focusing on the latest innovations and technologies, you can ensure your equipment meets the demands of contemporary agricultural practices.

Benefits of Modernization

Upgrading can lead to numerous advantages. Firstly, enhanced efficiency allows for faster processing and less fuel consumption. Secondly, newer technologies often include advanced safety features that protect both operators and equipment. Furthermore, increased reliability reduces the frequency of repairs, saving you both time and money in the long run.

Choosing the Right Components

Selecting appropriate replacements is crucial for maximizing performance. Research the latest advancements in machinery design and consult with industry experts to identify components that best suit your needs. Consider compatibility with your existing equipment to ensure seamless integration and optimal functionality.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a keen awareness of safety measures to prevent accidents and ensure a secure working environment. Prioritizing these precautions not only protects the individual performing the repairs but also safeguards the integrity of the machinery and surrounding equipment.

Essential Personal Protective Equipment

Before starting any repair work, it is crucial to don appropriate personal protective equipment (PPE). This may include gloves, safety goggles, and steel-toed boots to shield against potential hazards. Wearing durable clothing that fits well can also minimize the risk of entanglement in moving parts.

Proper Tool Usage and Handling

Utilizing the correct tools for the job is vital for both effectiveness and safety. Always inspect tools before use, ensuring they are in good condition and free from defects. Following the manufacturer’s instructions when operating equipment not only enhances safety but also extends the lifespan of the tools.

Comparative Analysis of Baler Models

In the world of agricultural machinery, various models serve distinct purposes, each offering unique features and benefits. This analysis aims to highlight key differences and similarities among several models, helping users make informed decisions based on their specific needs and operational contexts.

Performance and Efficiency

When evaluating the effectiveness of different machines, performance and efficiency are crucial factors. Some models excel in speed, allowing for quicker processing of materials, while others may prioritize durability and consistent output quality. Analyzing specifications such as throughput and energy consumption can provide valuable insights into which machinery best meets operational demands.

Technology and Innovation

The integration of modern technology significantly influences the capabilities of these machines. Innovations such as automated systems, precision controls, and advanced monitoring tools enhance usability and productivity. Understanding how these technological advancements are applied across different models can aid users in selecting equipment that aligns with their farming practices and efficiency goals.

Cost of Replacement Parts

Understanding the financial implications of sourcing components for agricultural machinery is essential for effective maintenance and operation. The expense associated with these essential items can vary significantly based on several factors, including brand, quality, and availability. Proper budgeting for these expenditures ensures that your equipment remains operational and efficient.

Factors Influencing Prices

Several elements contribute to the overall cost of these components. Quality is paramount; premium items may carry a higher price but often result in enhanced durability and performance. Market demand also plays a critical role; components in high demand or low supply can see inflated prices. Additionally, shipping costs and supplier pricing strategies can further affect the final expense.

Strategies for Cost Management

To manage expenses effectively, consider bulk purchasing or establishing a long-term relationship with a reliable supplier. Researching various vendors for competitive pricing can also yield significant savings. Lastly, evaluating the long-term value of components instead of just the initial cost can lead to more informed decisions that benefit your operations over time.

Resources for Baler Owners

Maintaining and operating agricultural equipment efficiently is crucial for productivity. Owners of such machinery can benefit significantly from various resources that provide essential information, support, and tools to ensure optimal performance and longevity.

Here are some valuable resources that can assist owners in managing their equipment:

- Manufacturer Websites: These platforms often feature user manuals, troubleshooting guides, and FAQs that are invaluable for understanding specific models and their functions.

- Online Forums: Engaging with fellow operators in online communities can provide practical tips and shared experiences, helping to resolve common issues.

- Social Media Groups: Joining dedicated groups on platforms like Facebook or Reddit allows for real-time discussions and access to a wealth of shared knowledge.

- Video Tutorials: Websites like YouTube host numerous instructional videos that demonstrate repair techniques, maintenance routines, and best practices.

Additionally, consider the following:

- Local Agricultural Supply Stores: These stores often have knowledgeable staff who can offer advice and may carry essential tools and supplies.

- Workshops and Training Sessions: Participating in hands-on learning opportunities can enhance skills and understanding of machinery operation.

- Mobile Apps: There are numerous applications designed to assist with scheduling maintenance, tracking repairs, and even calculating efficiency metrics.

Utilizing these resources can greatly enhance the experience and efficiency of operating agricultural machinery, leading to improved outcomes in the field.

Customer Reviews and Experiences

This section highlights the insights and reflections of users who have interacted with the machinery. Feedback from customers plays a crucial role in understanding performance, reliability, and overall satisfaction.

Positive Experiences

Many users have shared their success stories, emphasizing the efficiency and productivity they achieved. Key points include:

- High durability, leading to long-term use.

- Ease of operation, making it accessible for operators of all skill levels.

- Exceptional support from manufacturers, ensuring quick resolutions to issues.

Challenges and Considerations

While experiences are largely positive, some customers have noted areas for improvement. Common challenges mentioned include:

- Availability of replacement components.

- Initial setup requiring time and technical knowledge.

- Occasional need for specialized tools for maintenance.

Overall, the shared experiences offer valuable perspectives for potential buyers, guiding them in making informed decisions regarding their equipment.