Comprehensive Parts Diagram for New Holland 116 Haybine

The intricate machinery used in the agricultural sector plays a vital role in enhancing productivity and ensuring quality outputs. Understanding the various elements that comprise these machines is essential for effective maintenance and repair. With a well-organized visual representation of the key components, operators can quickly identify parts and troubleshoot issues, ultimately leading to a smoother operational experience.

In the realm of forage harvesting, specific tools stand out for their efficiency and reliability. Familiarity with these implements not only aids in day-to-day operations but also contributes to long-term performance. An accessible layout showcasing these vital pieces can significantly empower users, providing them with the knowledge needed to maximize their equipment’s lifespan.

As technology evolves, so does the complexity of machinery. Regular reference to detailed schematics can help prevent costly downtimes and ensure that all components function harmoniously. By grasping the layout and relationship between various sections, users can become adept at both identifying necessary replacements and performing regular upkeep.

Understanding New Holland 116 Haybine

This section explores the intricacies of a specific type of agricultural machinery designed for cutting and conditioning crops. It focuses on the essential components that contribute to its efficiency and effectiveness in the field.

Key elements include the cutting mechanism, which plays a crucial role in ensuring clean and precise harvesting. The design and configuration of these elements can significantly impact overall performance.

Additionally, understanding the maintenance and care required for this machinery is vital for its longevity. Regular checks and replacements of wear parts can prevent breakdowns and ensure optimal functioning throughout the season.

In summary, delving into the features and upkeep of this machine provides insight into its ultimate utility in modern agriculture, allowing farmers to maximize productivity and efficiency.

Key Features of Haybine Models

Understanding the essential attributes of mowing equipment can greatly enhance operational efficiency. These machines offer a blend of design and functionality that makes them ideal for various agricultural tasks.

- Cutting Mechanism: Equipped with advanced cutting systems for precision and speed.

- Durability: Built with high-quality materials to withstand harsh conditions.

- Adjustability: Features that allow for height adjustments to suit different crop types.

- Transport Ease: Designed for simple transportation, facilitating movement between fields.

- Maintenance-Friendly: Components that are easy to access for routine checks and repairs.

These attributes contribute to the ultimate performance and reliability of mowing machinery in various agricultural environments.

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a clear visual representation of its components. Such illustrations serve as vital tools for technicians and users, enabling efficient repairs and maintenance.

Enhancing Clarity and Efficiency

Visual aids simplify complex structures, making it easier to identify individual elements. This clarity leads to quicker troubleshooting and minimizes the risk of errors during assembly or disassembly.

Facilitating Communication

Using these visuals promotes effective dialogue among professionals. Whether in a workshop or online forum, everyone can reference the same detailed images, ensuring a shared understanding of specific components and their functions.

Common Replacement Parts for Haybines

Maintaining agricultural machinery is essential for optimal performance and longevity. Various components are subject to wear and tear, requiring timely replacement to ensure that the equipment operates efficiently. Understanding the commonly replaced elements can help operators minimize downtime and improve productivity during the cutting season.

Key Components Needing Replacement

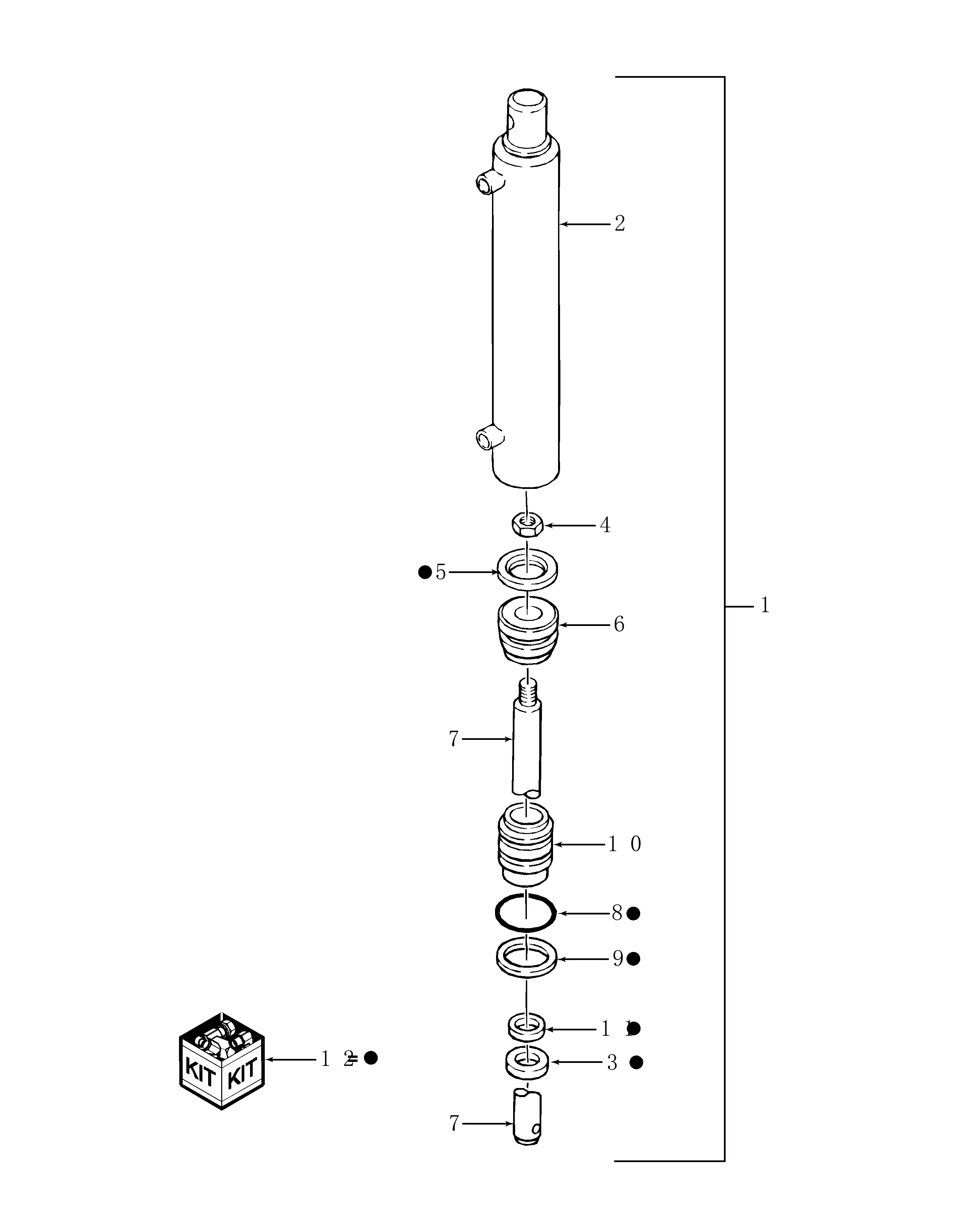

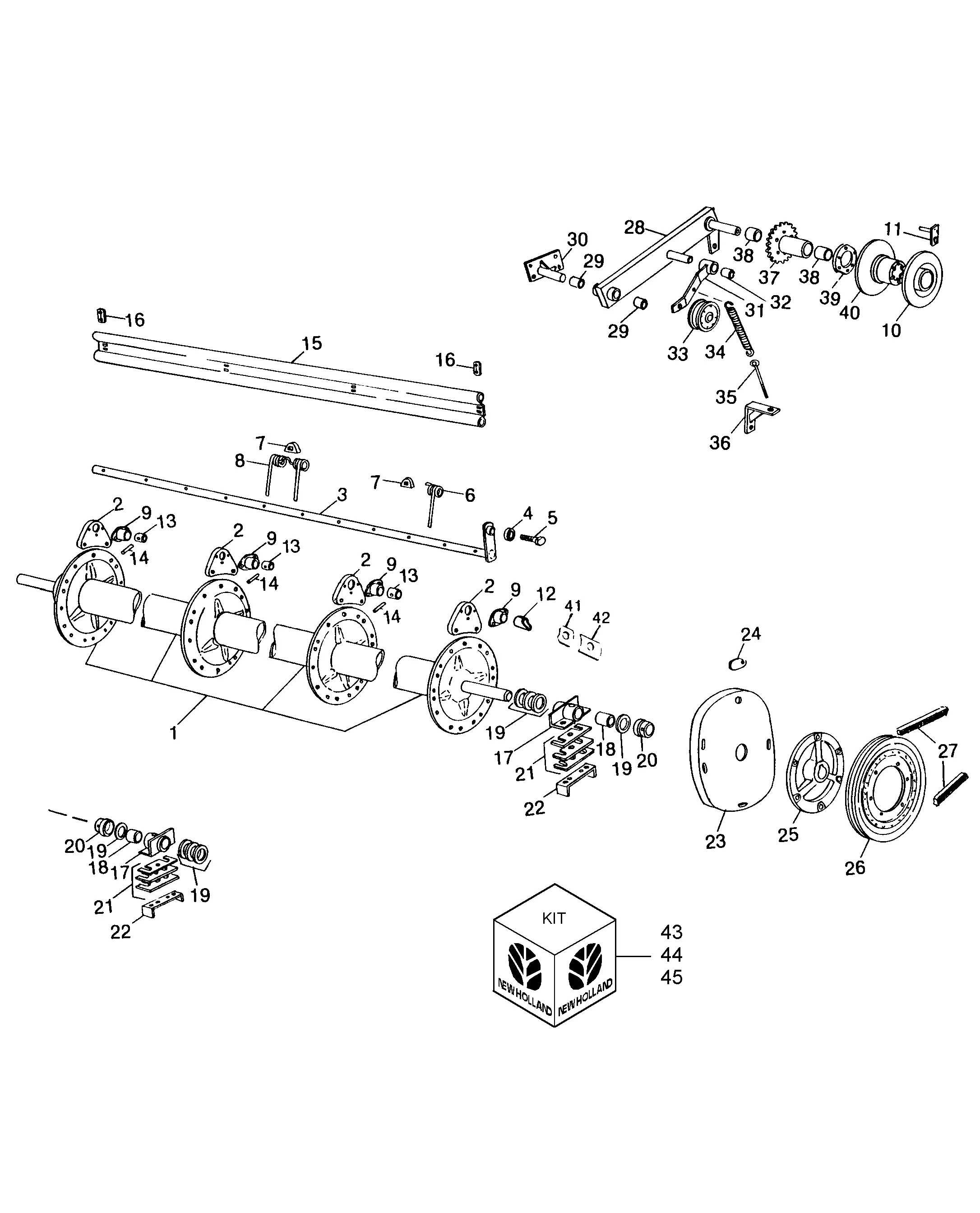

Several vital components frequently need attention. These include cutting mechanisms, belts, and bearings, which play a crucial role in the overall functionality of the machinery. Regular inspection and replacement of these items can prevent more significant issues down the line.

Replacement Parts Overview

| Component | Description | Signs of Wear |

|---|---|---|

| Cutter Bar | The main cutting assembly that performs the mowing action. | Uneven cuts, excessive vibration. |

| Belt | Transfers power from the engine to the cutting components. | Slipping, fraying, or cracking. |

| Bearing | Supports rotating shafts and reduces friction. | Noise during operation, overheating. |

| Knives | Sharp blades that facilitate cutting grass and crops. | Dullness, chipping, or breakage. |

| Hydraulic Hoses | Convey fluids to operate various functions. | Leaks, cracks, or bulging. |

Where to Find Parts Diagrams

Locating visual guides for machinery components can significantly enhance your repair and maintenance efforts. These resources provide clarity on the various elements and their configurations, enabling a more efficient troubleshooting process.

Online Platforms: Many websites specialize in agricultural equipment, offering detailed illustrations for a wide range of models. These platforms often feature searchable databases, making it easy to find the necessary visuals.

Manufacturer Websites: Directly visiting the official sites of equipment manufacturers can yield valuable documentation. They frequently provide comprehensive resources, including schematics and assembly guides.

Forums and Community Groups: Engaging with fellow enthusiasts and professionals in online forums can be a treasure trove of information. Users often share personal findings, including links to useful resources and tips for obtaining specific guides.

Local Dealerships: Establishing a relationship with local equipment dealers can also prove beneficial. They may have access to proprietary resources or be willing to help you locate the materials you need.

By exploring these avenues, you can efficiently delve into the world of machinery maintenance and ensure you have the ultimate tools at your disposal for successful repairs.

How to Read Parts Diagrams

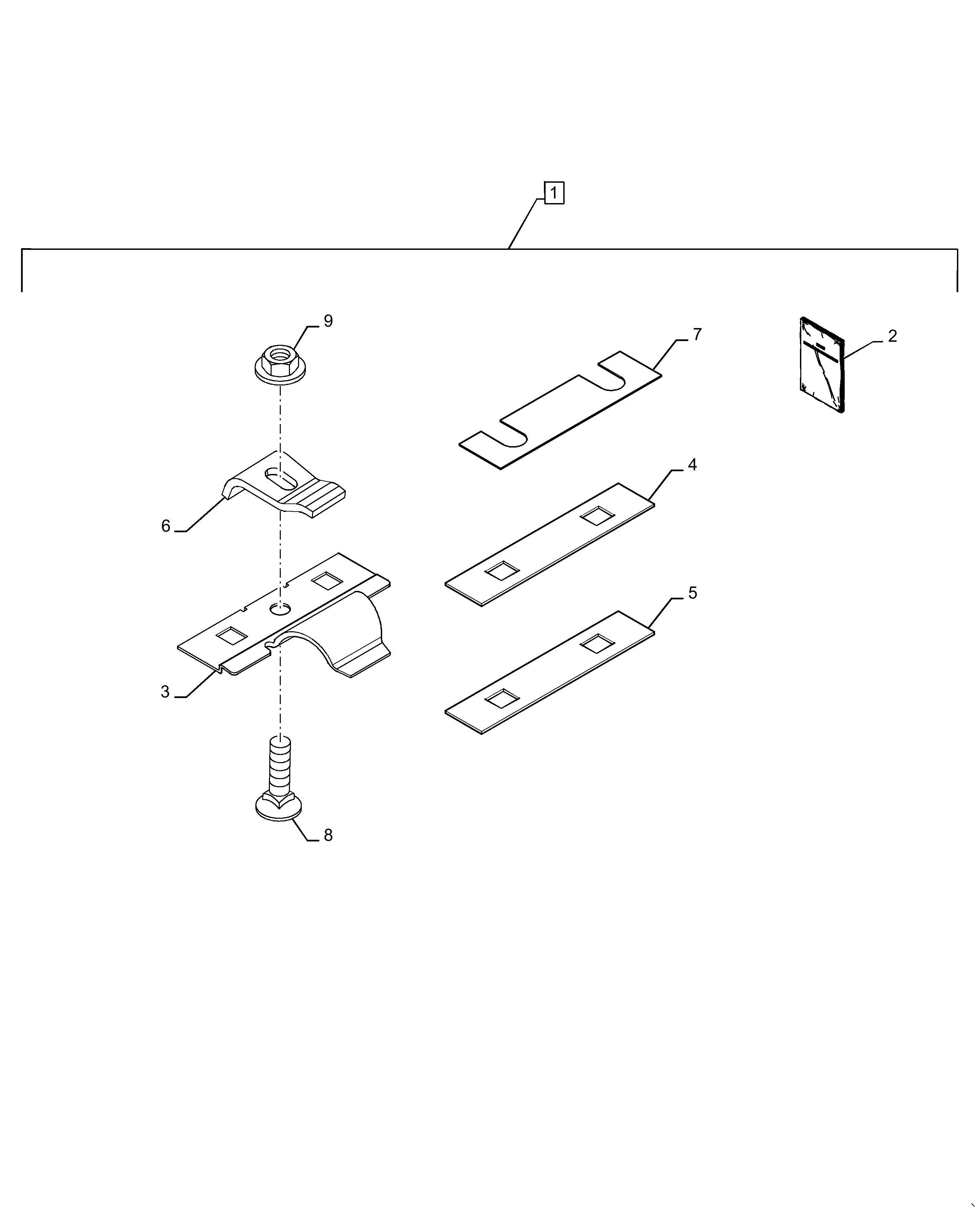

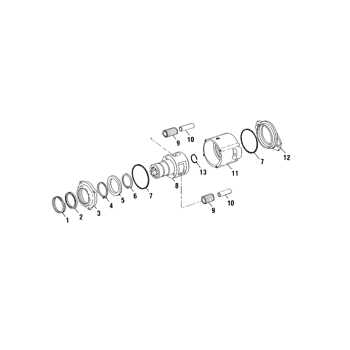

Understanding the visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide, showcasing the arrangement and relationship between various elements. Familiarity with these images can streamline the troubleshooting process and facilitate the identification of necessary components.

Identifying Key Symbols

Each illustration contains specific symbols and notations that indicate different parts. It is crucial to familiarize yourself with these icons, as they provide insights into the function and placement of each item. Look for legends or keys accompanying the visuals; they often explain the meaning behind each symbol, helping you navigate the complexities of the layout.

Understanding Assembly Order

Another important aspect is grasping the sequence in which components are assembled or disassembled. Diagrams typically present a logical flow, guiding you through the necessary steps to ensure everything fits together correctly. Pay close attention to the connections and interfaces; this will prevent errors during reassembly and enhance overall efficiency.

By mastering these techniques, you can effectively interpret visual aids, leading to successful repairs and maintenance endeavors.

Maintenance Tips for Haybines

Regular upkeep of agricultural mowing equipment is crucial for optimal performance and longevity. Proper maintenance not only ensures efficiency but also enhances safety during operation. Here are some essential practices to keep your machinery in top condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Blades | Before Each Use | Check for wear and sharpness; replace if dull or damaged. |

| Lubricate Moving Parts | Weekly | Apply grease to bearings and pivots to reduce friction. |

| Check Fluid Levels | Every Use | Ensure oil, coolant, and hydraulic fluids are at proper levels. |

| Clean Filters | Monthly | Remove and clean or replace air and oil filters as needed. |

| Tighten Bolts and Fasteners | Monthly | Inspect and tighten all bolts to prevent loosening during operation. |

Identifying Wear and Tear Issues

Recognizing signs of degradation in agricultural machinery is crucial for maintaining efficiency and prolonging service life. Regular inspections can help pinpoint potential problems before they escalate, ensuring that equipment operates smoothly and reliably.

Common indicators of wear include:

- Increased vibration during operation.

- Unusual noises, such as grinding or rattling.

- Inconsistent cutting performance or uneven results.

- Excessive heat generation in specific components.

To effectively assess machinery condition, consider the following steps:

- Conduct routine visual inspections to check for physical damage.

- Examine critical components for signs of corrosion or cracking.

- Monitor fluid levels and look for leaks.

- Test moving parts for smooth operation and alignment.

Timely identification of these issues not only enhances productivity but also reduces the likelihood of costly repairs in the future.

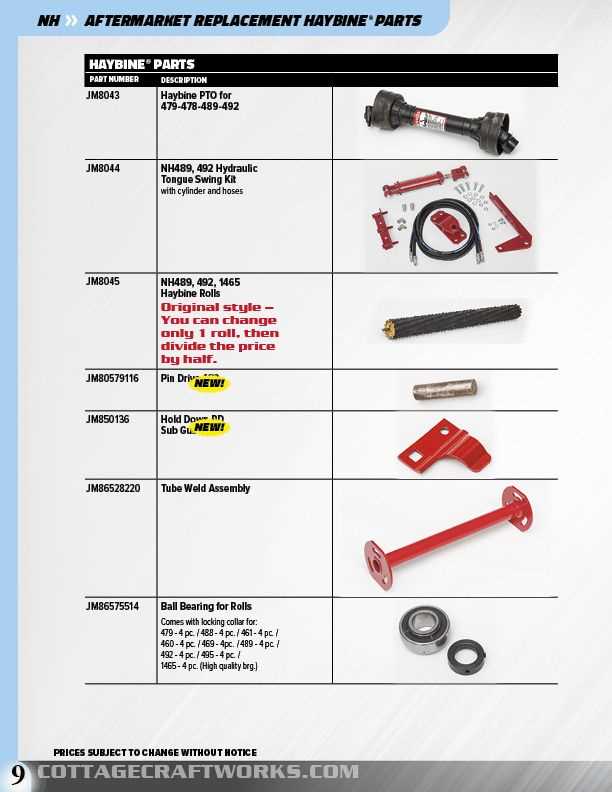

Popular Aftermarket Parts Options

In the world of agricultural machinery, selecting quality components can significantly enhance performance and longevity. Many operators seek alternatives that offer reliability and cost-effectiveness. This section explores various popular aftermarket choices that cater to diverse needs.

Blades: High-performance blades are essential for optimal cutting efficiency. Look for those made from durable materials to withstand tough conditions.

Belts: Replacement belts are crucial for maintaining smooth operation. Opt for reinforced options that ensure longevity and reduce the risk of breakdowns.

Rollers: Upgrading to heavy-duty rollers can improve the overall functionality of your machinery, providing better support and reducing wear over time.

Gearboxes: A reliable gearbox is vital for power transmission. Aftermarket gearboxes often offer enhanced specifications, ensuring smoother operation.

Hydraulic Components: Consider aftermarket hydraulic parts that offer improved performance and compatibility, helping maintain efficient operation across various tasks.

By exploring these options, operators can make informed decisions that enhance their equipment’s effectiveness and efficiency in the field.

Original Equipment Manufacturer (OEM) Parts

When it comes to maintaining and repairing machinery, choosing components from the original equipment manufacturer is crucial. These items are designed to meet the specific requirements and standards of the machinery, ensuring optimal performance and longevity. Utilizing these components helps preserve the integrity of the equipment and supports its overall efficiency.

Benefits of Using OEM Components

- Quality Assurance: OEM items are manufactured to the exact specifications of the original design, guaranteeing reliability.

- Perfect Fit: These components are designed specifically for your equipment, reducing the risk of compatibility issues.

- Longevity: OEM options typically offer a longer lifespan, minimizing the need for frequent replacements.

- Warranty Protection: Using OEM items can help maintain the warranty coverage on your equipment.

Considerations When Choosing OEM

- Compatibility: Ensure the selected components are suitable for your specific model.

- Supplier Reputation: Purchase from authorized dealers or trusted suppliers to avoid counterfeit items.

- Cost: While often more expensive, consider the long-term savings from reduced repairs and downtime.

- Availability: Check the availability of parts to prevent delays in maintenance.

Cost Considerations for Replacement Parts

When maintaining agricultural equipment, understanding the financial implications of substituting components is crucial. Proper budgeting ensures that the machinery operates efficiently while minimizing downtime and maximizing productivity. Evaluating the expenses associated with various alternatives can lead to informed decisions that enhance the overall longevity of the equipment.

Factors influencing costs include brand reputation, availability, and compatibility with existing machinery. Premium brands often provide reliable options but may come with a higher price tag. Conversely, aftermarket solutions can be more economical, yet their quality and performance may vary. Assessing these aspects thoroughly helps in identifying the most suitable financial approach.

Additionally, considering the potential savings from improved efficiency and reduced operational interruptions can provide a clearer picture of the overall value. Investing in high-quality substitutes may incur higher upfront costs but could lead to significant long-term benefits. Balancing initial expenses with future returns is essential for making sound purchasing choices.

Improving Haybine Efficiency

Enhancing the performance of cutting machinery involves various strategies that optimize both functionality and output. By focusing on maintenance, adjustments, and operational techniques, users can significantly increase productivity while minimizing downtime.

Regular Maintenance

- Check and replace worn blades to ensure clean cuts.

- Lubricate moving parts to reduce friction and wear.

- Inspect belts and chains for signs of wear or damage.

Operational Adjustments

- Set the correct cutting height for optimal forage management.

- Adjust speed settings based on field conditions.

- Monitor moisture levels to determine the best cutting time.

Implementing these practices can lead to a more effective operation, ensuring better yields and quality in forage production.

Resources for Haybine Owners

Maintaining and operating a mowing machine can be a rewarding experience, especially when equipped with the right resources. Owners benefit greatly from access to manuals, guides, and online communities that provide valuable information and support. Understanding your equipment and how to care for it can enhance performance and extend its lifespan.

Below is a table summarizing various resources available for users seeking assistance and information:

| Resource Type | Description | Link |

|---|---|---|

| Owner’s Manual | Official guide detailing operation, maintenance, and troubleshooting. | View Manual |

| Online Forums | Community discussions where users share experiences and solutions. | Join Forum |

| Parts Suppliers | Websites offering replacement components and accessories. | Find Parts |

| How-To Videos | Visual tutorials covering maintenance and repairs. | Watch Videos |

By utilizing these resources, owners can enhance their understanding and proficiency, ensuring their machinery operates efficiently and effectively.