Comprehensive Parts Diagram for New Holland 1431 Discbine

In the realm of modern agriculture, efficient machinery plays a pivotal role in enhancing productivity and streamlining operations. A comprehensive exploration of these essential tools reveals the intricacies of their construction and functionality, enabling users to maintain optimal performance. Knowledge of the various elements that constitute these implements is crucial for effective usage and upkeep.

Identifying the elements that make up this equipment is not just about recognizing individual components; it also involves understanding their interconnections and how they contribute to overall efficiency. Each segment serves a specific purpose, ensuring that the machinery operates smoothly and meets the demands of agricultural tasks.

By delving into a visual representation of these components, operators can gain insights into maintenance requirements and potential areas for improvement. Ultimately, mastering the layout of this vital equipment empowers users to make informed decisions, ensuring longevity and effectiveness in the field.

Understanding the New Holland 1431 Discbine

This section explores the intricacies of a specific type of agricultural machinery designed for cutting and conditioning crops. Known for its efficiency and effectiveness, this equipment is essential for farmers looking to enhance their productivity during harvesting seasons. A deeper understanding of its components and functionality can significantly impact operational success.

Key Features of the Equipment

The machinery boasts advanced technology that streamlines the process of crop management. With robust cutting mechanisms and efficient conditioning systems, it ensures that the harvested material is processed swiftly. Additionally, its durability allows for prolonged use in various field conditions, making it a reliable choice for agricultural operations.

Maintenance and Care

Key Features of the 1431 Model

This model is designed to enhance efficiency and performance in agricultural tasks. With its robust construction and innovative technology, it delivers outstanding results while minimizing downtime and maintenance costs.

Durability and Reliability

Engineered with high-quality materials, this equipment ensures long-lasting durability. The components are built to withstand the rigors of demanding environments, providing farmers with a reliable tool for their operations.

Advanced Cutting Technology

Equipped with cutting-edge mechanisms, this model offers precision in harvesting. The innovative blade design guarantees a clean cut, promoting healthy regrowth and optimizing yield quality. Enhanced operational speed allows for increased productivity, ensuring that farmers can cover more ground in less time.

Importance of Regular Maintenance

Consistent upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Routine maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns, which can lead to costly repairs and downtime. By following a structured maintenance schedule, operators can identify potential issues before they escalate, thus safeguarding their investment.

Moreover, regular inspections and servicing can improve safety standards for operators and surrounding personnel. Well-maintained equipment is less likely to malfunction, reducing the likelihood of accidents on the field. Additionally, timely care can help maintain the machine’s resale value, providing financial benefits in the long run.

Incorporating maintenance into the operational routine fosters a culture of responsibility and care among users. This proactive approach not only extends the life of the machinery but also contributes to overall productivity, enabling smoother and more efficient agricultural operations.

Common Parts and Their Functions

This section explores various components found in agricultural machinery and their essential roles in ensuring efficient operation. Understanding these elements helps users maintain their equipment effectively and maximize productivity.

Cutting Blades: These sharp edges are crucial for slicing through crops with precision, allowing for a clean harvest. Their durability affects overall performance.

Drive Belts: These components transfer power from the engine to other parts of the machine, enabling movement and functionality. Regular checks can prevent breakdowns.

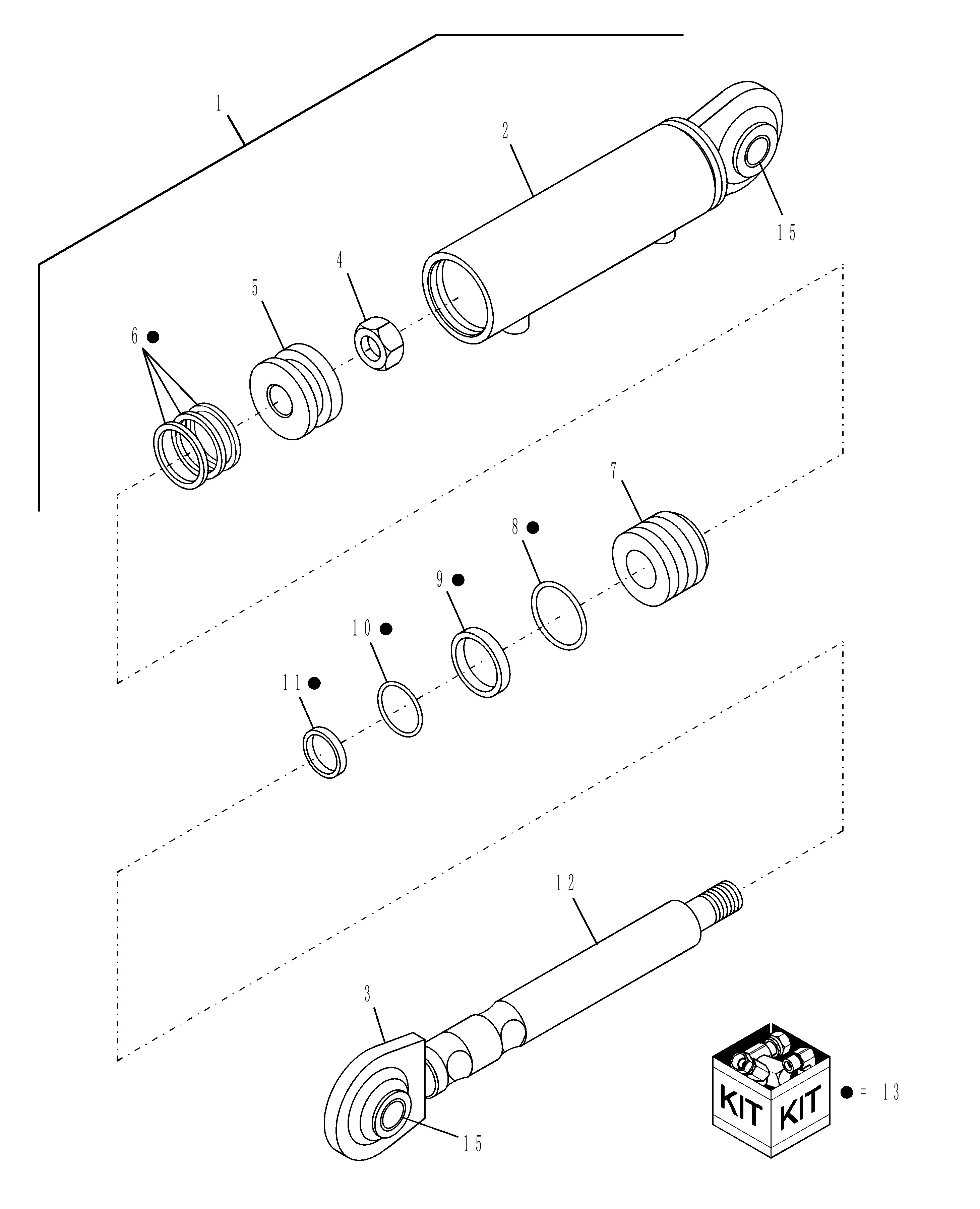

Hydraulic Cylinders: Responsible for moving various parts, these cylinders convert hydraulic pressure into mechanical force, facilitating operations like lifting and lowering.

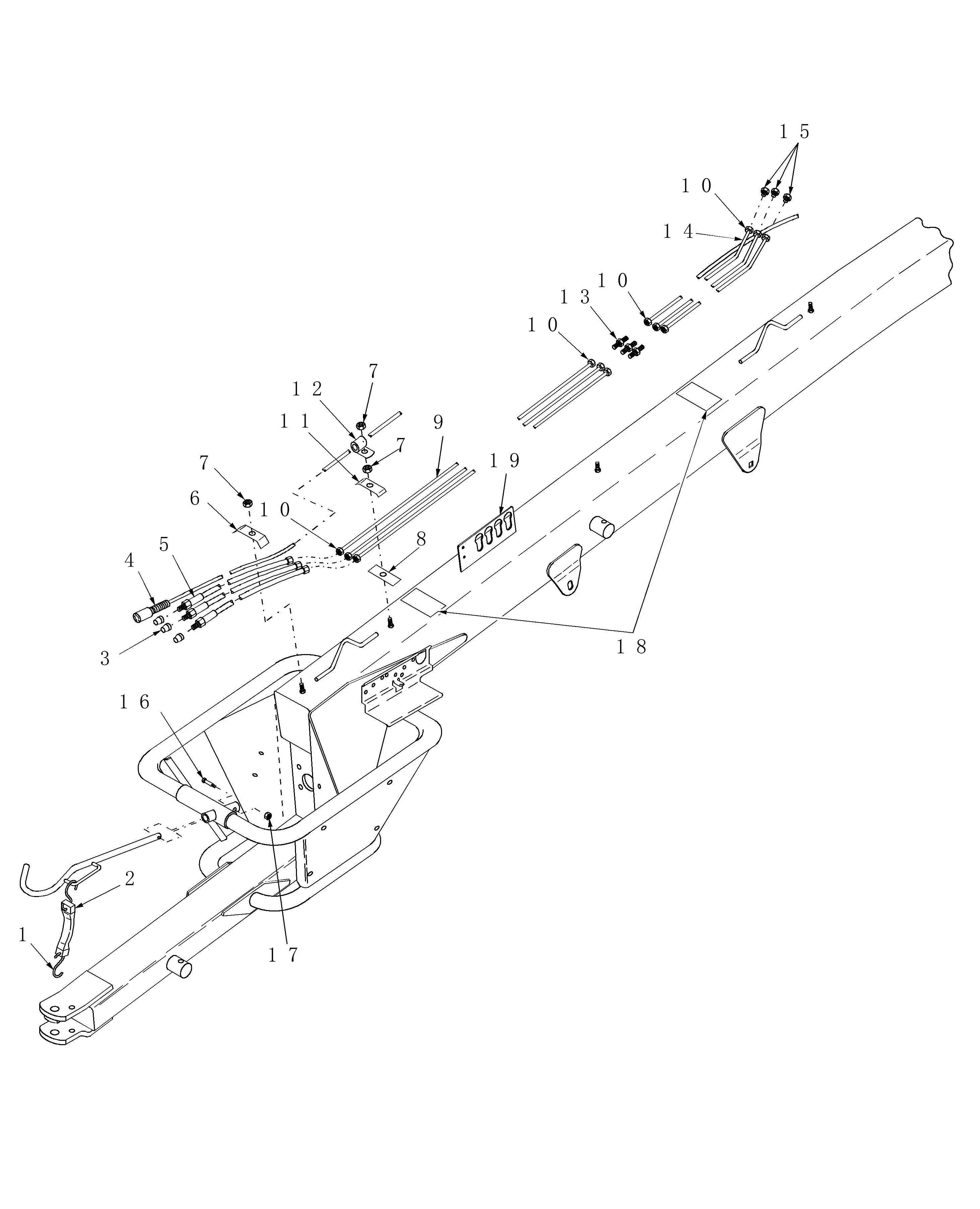

Frame Structure: The backbone of the machinery, the frame provides stability and support, ensuring all components are securely connected for optimal performance.

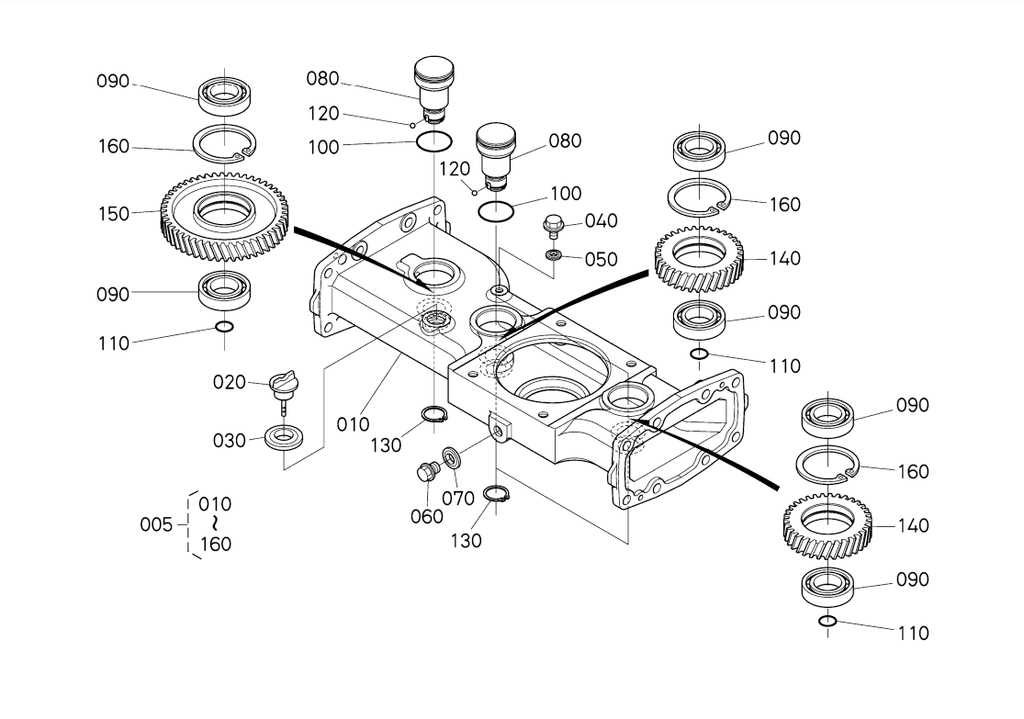

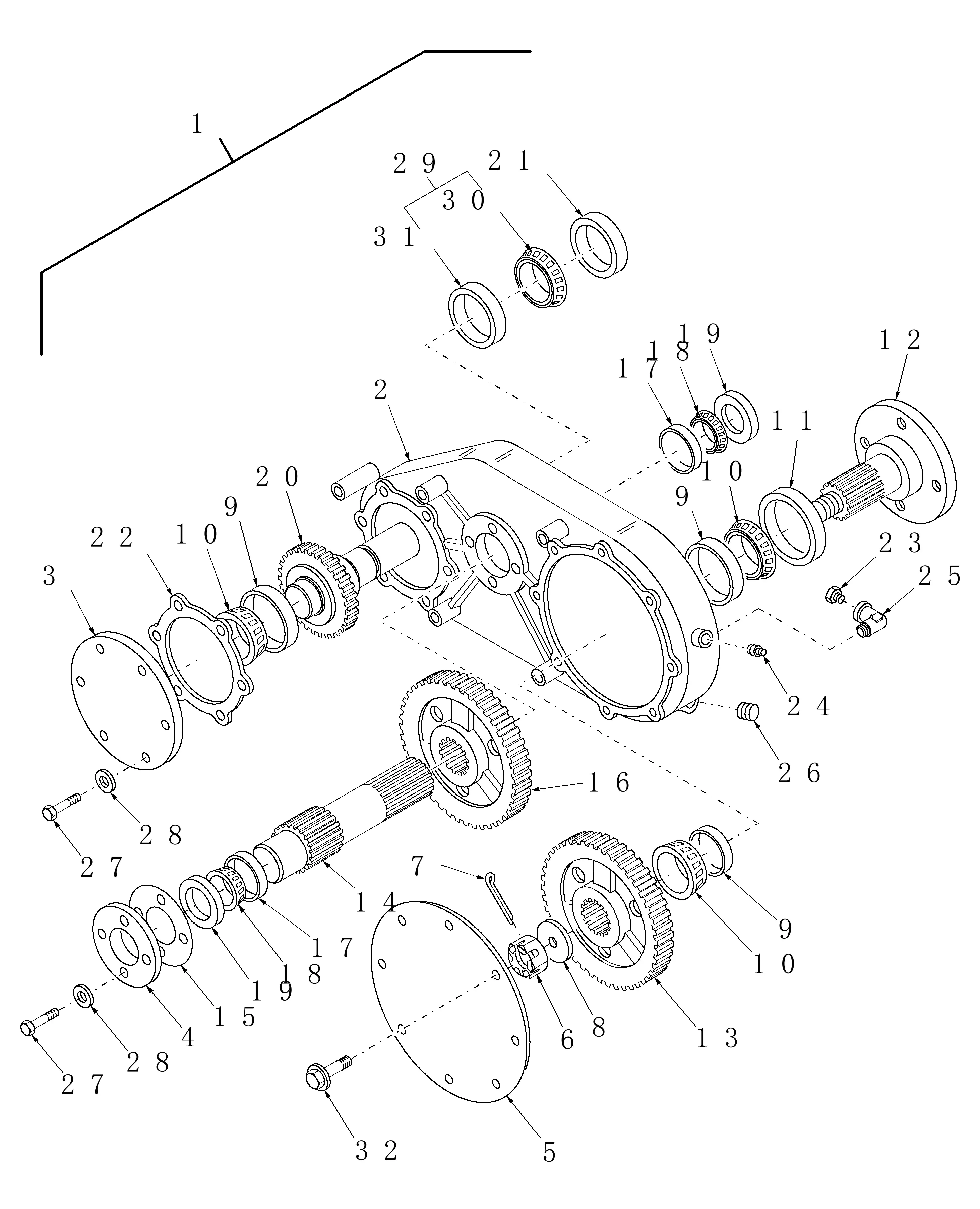

Gearbox: This unit adjusts speed and torque, allowing the machine to operate efficiently under different conditions. Proper maintenance ensures longevity and reliability.

Wheel Assemblies: Vital for mobility, these parts enable smooth navigation across fields. Their condition directly impacts traction and stability during use.

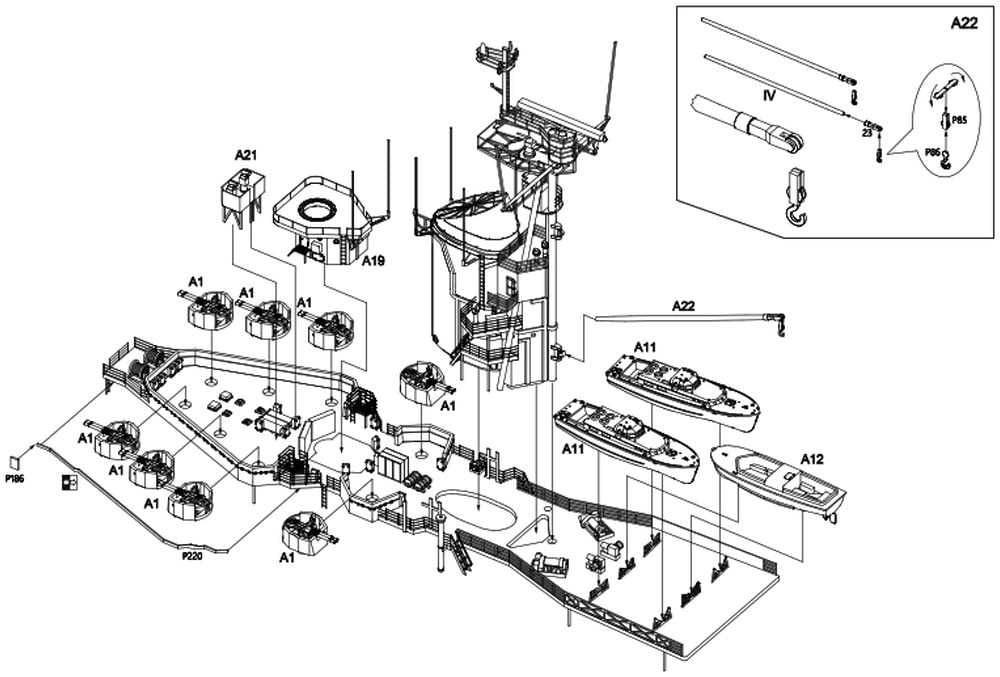

Identifying Parts in Diagrams

Understanding how to recognize components in visual representations is crucial for effective maintenance and repairs. Such illustrations provide a comprehensive overview of machinery, allowing users to pinpoint specific elements that require attention. This knowledge enhances efficiency and facilitates problem-solving by providing clarity in complex systems.

Key Components to Recognize

When examining a visual guide, it’s essential to familiarize yourself with the various parts and their functions. Each section typically corresponds to a specific area of the machinery, highlighting critical components that contribute to overall performance.

Utilizing Reference Tables

Reference tables can greatly aid in the identification process. Below is an example of how components might be categorized:

| Component Name | Description | Function |

|---|---|---|

| Frame | The main structure that supports all other elements. | Provides stability and strength. |

| Cutter Bar | The part that engages with the crop. | Facilitates cutting through vegetation. |

| Gearbox | Transfers power from the engine to the cutting mechanism. | Ensures efficient operation and speed regulation. |

By studying these references, users can develop a deeper understanding of the machinery, leading to more informed decisions regarding repairs and upkeep.

Replacement Parts: Where to Buy

When it comes to maintaining agricultural machinery, sourcing quality components is crucial for optimal performance. Identifying reliable suppliers can save time and ensure that equipment runs smoothly. Whether you need essential components or specialized items, understanding where to look is key.

| Supplier Type | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers of brand components. | Genuine items, warranty support. |

| Aftermarket Providers | Third-party manufacturers offering similar components. | Cost-effective options, diverse inventory. |

| Online Marketplaces | Websites where various sellers list components. | Convenience, competitive pricing. |

| Local Repair Shops | Regional businesses specializing in machinery upkeep. | Expert advice, immediate availability. |

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear layout of each element, helping users identify and locate various parts within a complex system.

When approaching these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each diagram uses specific icons and notations. Learning these will aid in quick identification of parts.

- Identify the Sections: Diagrams are often divided into sections based on function or location. Recognizing these divisions can streamline your search.

- Trace Connections: Follow lines and arrows to understand how components interact. This is crucial for troubleshooting issues.

- Check the Legend: Most illustrations include a legend or key. This will clarify any unclear symbols or abbreviations.

- Make Notes: As you review, jot down important information regarding part numbers and specifications for future reference.

By mastering these techniques, you’ll enhance your ability to interpret complex illustrations, making maintenance tasks more efficient and accurate.

Troubleshooting Common Issues

Addressing mechanical challenges is essential for maintaining optimal performance in agricultural machinery. Identifying and resolving frequent problems can significantly enhance efficiency and extend the lifespan of your equipment. This section provides a systematic approach to diagnosing and fixing typical issues that may arise during operation.

Common Symptoms and Solutions

- Unusual Noises:

If you hear grinding or rattling sounds, check for:

- Loose or damaged components

- Worn bearings or belts

- Misalignment of parts

- Poor Cutting Performance:

When cutting quality diminishes, consider:

- Inspecting blade sharpness

- Ensuring correct tension on cutting mechanisms

- Verifying the height setting for optimal cutting

- Hydraulic Issues:

In case of inadequate hydraulic function, examine:

- Fluid levels and quality

- Leaking hoses or fittings

- Functionality of hydraulic pumps

Preventive Maintenance Tips

- Regularly inspect and clean all components.

- Replace worn or damaged parts promptly.

- Follow the manufacturer’s guidelines for lubrication and maintenance schedules.

- Keep an eye on operational performance for early detection of issues.

By staying proactive and attentive to the equipment’s condition, operators can mitigate the risk of significant breakdowns and ensure smooth operation during peak seasons.

Assembly Instructions for New Parts

When integrating replacement components into your machinery, it’s essential to follow a structured approach to ensure optimal performance and longevity. This section outlines the necessary steps for assembling fresh elements effectively, minimizing the risk of errors and enhancing operational efficiency.

Begin by gathering all required tools and components. A well-organized workspace will facilitate the assembly process. Ensure that each element is free from damage and matches the specifications for your equipment. This will not only streamline the installation but also improve the overall functionality.

Next, consult the provided documentation for detailed instructions specific to each component. Pay attention to any torque specifications or sequence guidelines that may be indicated. Following these instructions precisely is crucial to achieving a secure and reliable assembly.

As you proceed, take care to align components accurately. Misalignment can lead to premature wear or failure, so double-check positioning before securing each piece. Utilize appropriate fasteners and ensure they are tightened to the specified torque levels to maintain integrity during operation.

Once all elements are installed, conduct a thorough inspection to confirm that everything is assembled correctly. This final check helps identify any potential issues before the machinery is put back into service. A successful installation not only enhances performance but also contributes to the longevity of the equipment.

Comparison with Other Discbine Models

When evaluating different models of mower-conditioners, it is essential to consider their unique features, efficiency, and adaptability in various farming conditions. This section explores how specific models stack up against each other, highlighting strengths and weaknesses that may influence a farmer’s choice.

Key Features to Consider

- Cutting Width: Different models offer various cutting widths, impacting productivity and maneuverability.

- Weight and Build: Heavier models may provide stability, while lighter ones can improve mobility in uneven terrain.

- Conditioning Options: Some units come with advanced conditioning systems, enhancing drying times and overall forage quality.

- Maintenance Requirements: Ease of access to components for routine checks can significantly affect long-term usability.

Performance Metrics

- Efficiency: Comparing fuel consumption and cutting speed gives insight into operational costs.

- Durability: Materials used in construction influence longevity and resistance to wear.

- Adaptability: The ability to perform in different weather conditions and soil types is crucial for optimal performance.

- User Feedback: Customer reviews and expert ratings can provide valuable real-world insights.

Ultimately, selecting the right mower-conditioner model depends on individual farming needs and specific operational requirements. A thorough comparison will help in making an informed decision.

Maximizing Efficiency in Operation

Enhancing operational effectiveness is crucial for achieving optimal performance in any agricultural machinery. By focusing on key aspects such as maintenance, calibration, and user training, operators can significantly improve productivity and reduce downtime.

Regular maintenance is essential for keeping equipment running smoothly. Routine checks and timely repairs can prevent minor issues from escalating into major problems, ensuring consistent performance throughout the season.

Proper calibration of machinery settings is vital. This allows for precise adjustments based on field conditions, leading to improved crop yields and resource utilization. Operators should familiarize themselves with the equipment to optimize its capabilities effectively.

Investing in operator training can yield substantial benefits. Well-trained personnel are better equipped to handle machinery efficiently, troubleshoot issues promptly, and implement best practices, which ultimately contributes to enhanced overall productivity.