Exploring the Parts Diagram of New Holland Boomer 50

In the realm of agricultural equipment, comprehending the arrangement and functionality of individual elements is crucial for effective maintenance and operation. This knowledge not only enhances performance but also prolongs the lifespan of the machinery.

Familiarity with the layout of essential components allows operators to swiftly identify and address issues, ensuring that their equipment remains in peak condition. By examining these structures, one can delve into the intricate relationships between various parts and their ultimate contributions to overall efficiency.

Furthermore, having access to clear representations of these configurations facilitates informed decision-making when it comes to repairs and upgrades. Such insights empower users to tackle challenges confidently, ensuring seamless agricultural processes.

Understanding New Holland Boomer 50

This section delves into the intricate details of a compact utility tractor that has gained recognition for its versatility and efficiency. Designed for various agricultural tasks, this machine stands out due to its innovative features and robust performance. Understanding its components is essential for optimal usage and maintenance, ensuring longevity and productivity in various applications.

Key Features and Benefits

Among the numerous advantages, this tractor offers exceptional maneuverability, making it ideal for both small and large-scale operations. Its powerful engine ensures reliable performance, while the ergonomic design enhances user comfort during extended usage. Additionally, the availability of various attachments expands its functionality, catering to diverse farming needs.

Maintenance and Care

Regular upkeep is crucial for sustaining peak performance. Familiarity with the tractor’s structure allows operators to identify potential issues early. Routine checks of fluid levels, filters, and belts can prevent significant problems, ensuring a smooth operation. Following manufacturer guidelines for service intervals will contribute to the machine’s durability and efficiency.

Overview of the Boomer Series

This series represents a remarkable line of compact tractors designed for efficiency and versatility in various agricultural and landscaping tasks. Engineered with precision, these machines offer a blend of power and agility, making them suitable for both small-scale farms and extensive properties.

With a focus on user-friendly operation, the models within this range feature intuitive controls and robust construction. Their compact size allows for easy navigation in tight spaces, while their advanced features enhance productivity across a multitude of applications.

Moreover, these tractors are equipped with powerful engines that ensure optimal performance, even under demanding conditions. The versatility of the series is further enhanced by a wide array of compatible implements, allowing users to tackle diverse challenges with confidence.

Overall, this lineup exemplifies the ideal combination of durability, functionality, and comfort, making it a preferred choice among professionals and enthusiasts alike.

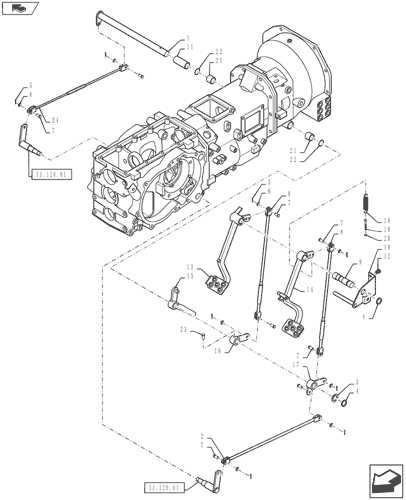

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They provide a clear roadmap for maintenance, repairs, and upgrades, ensuring efficient and effective service.

Benefits of Visual Representations

- Enhances clarity in identifying individual elements

- Simplifies complex repair procedures

- Facilitates communication among technicians

- Helps in locating specific components quickly

Impact on Maintenance Efficiency

- Reduces downtime by streamlining repair processes

- Improves accuracy in parts ordering

- Supports proactive maintenance strategies

Key Components of Boomer 50

Understanding the essential elements of this compact tractor is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and reliability, contributing to the overall functionality of the machine.

| Component | Description |

|---|---|

| Engine | A powerful unit designed for durability and efficiency, providing the necessary torque for various tasks. |

| Transmission | Offers smooth shifting and versatility, allowing operators to handle different terrains with ease. |

| Hydraulic System | Facilitates lifting and moving implements, enhancing productivity and operational flexibility. |

| Chassis | The robust framework that supports all components, ensuring stability and longevity under heavy use. |

| Cab | Provides comfort and protection for the operator, featuring ergonomic controls and visibility. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair tasks. These illustrations provide crucial information about the structure and relationship between various elements, helping users to identify and locate specific items with ease.

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout to grasp the overall configuration. |

| 2 | Identify key symbols and labels that indicate different elements. |

| 3 | Refer to the legend for clarification on any unfamiliar markings. |

| 4 | Cross-reference with the accompanying list for detailed specifications. |

| 5 | Take notes on any critical connections or assembly points. |

Common Issues with Boomer 50 Parts

When it comes to machinery components, several typical challenges can arise, impacting functionality and performance. Understanding these common issues is crucial for maintaining efficiency and ensuring longevity. Identifying potential problems early can prevent costly repairs and downtime.

Frequent Mechanical Failures

Mechanical failures often stem from wear and tear over time. Components subjected to heavy use may experience issues such as:

| Component | Common Issues | Symptoms |

|---|---|---|

| Transmission | Slipping gears, fluid leaks | Delayed response, strange noises |

| Hydraulic System | Leaks, slow response | Weak lifting power, erratic movement |

| Electrical System | Wiring faults, battery issues | Starting problems, intermittent failures |

Wear and Tear on Components

Components are prone to wear over time, leading to reduced performance. Commonly affected areas include:

| Component | Signs of Wear | Impact |

|---|---|---|

| Filters | Clogging, discoloration | Poor performance, engine strain |

| Belt Systems | Fraying, cracking | Reduced efficiency, potential breakdowns |

| Tires | Uneven wear, loss of tread | Decreased traction, safety risks |

Where to Find Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. It ensures that you are using high-quality materials specifically designed for your machine, thereby enhancing reliability and efficiency.

Authorized Dealers

One of the best places to start your search is with authorized distributors. These vendors are certified to sell original components and often provide the latest updates and support.

Online Retailers

Several online platforms specialize in genuine components. Look for retailers that focus on agricultural machinery and offer verified products.

| Source | Benefits |

|---|---|

| Authorized Dealers | Assured authenticity, expert advice |

| Online Retailers | Convenience, often competitive pricing |

| Manufacturer’s Website | Direct access to original components, latest models |

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of any machinery. Regular attention to detail ensures optimal performance and minimizes the likelihood of costly repairs. By following a few key practices, operators can effectively enhance reliability and durability.

Routine Inspections: Conduct frequent checks on all components to identify wear or damage early. This proactive approach can prevent larger issues from developing.

Fluid Management: Keep all fluids at the recommended levels and replace them according to the manufacturer’s schedule. Clean and high-quality fluids support efficient operation and reduce wear.

Cleanliness is Key: Regularly clean the exterior and interior areas of the machine. Removing debris and buildup helps maintain performance and prevents overheating.

Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule and procedures is crucial. Utilizing the right techniques and parts ensures everything functions as intended.

Training and Familiarity: Ensure that all operators are well-trained and familiar with the equipment. Knowledgeable use reduces the risk of damage and promotes safe handling.

Repair vs. Replacement Decisions

When faced with equipment issues, one must carefully evaluate whether to fix the existing unit or invest in a new one. This decision hinges on multiple factors, including cost, efficiency, and long-term usability. Understanding the nuances can significantly impact operational productivity and financial outcomes.

| Factor | Repair | Replacement |

|---|---|---|

| Cost | Typically lower immediate expense | Higher upfront investment |

| Time | May require significant downtime | Instant upgrade, but sourcing takes time |

| Longevity | May only extend life temporarily | Often offers enhanced durability |

| Performance | Restores functionality to a point | Implements latest technology and efficiency |

Upgrading Components for Performance

Enhancing the efficiency and capability of machinery can significantly impact overall productivity. By focusing on key elements that contribute to performance, operators can achieve optimal results in various applications. This section explores potential improvements that can elevate functionality and reliability.

Essential Upgrades

Prioritizing specific components such as engines, transmissions, and hydraulic systems can lead to remarkable advancements. Upgrading to higher-performance versions or optimizing existing parts can result in better power delivery and efficiency, allowing for heavier workloads and improved operational speed.

Maintenance Considerations

Regular maintenance is crucial when upgrading elements. Ensuring that all new components are compatible with the existing system and conducting routine checks will maximize longevity and performance. This proactive approach guarantees that enhancements deliver the ultimate benefits for users.

Resources for Further Research

This section aims to provide valuable sources for individuals seeking deeper knowledge about equipment maintenance and component specifications. Accessing a variety of platforms can enhance understanding and aid in efficient repairs.

Online Databases

Several online resources offer extensive catalogs and technical documents. Utilizing these can streamline your research process.

| Resource | Description |

|---|---|

| Manufacturer’s Website | Official source for manuals and specifications. |

| Online Forums | Community-driven discussions for tips and advice. |

| Parts Retailers | Sites providing detailed listings of available components. |

Books and Guides

Literature focusing on machinery can serve as an excellent supplement. Referencing these texts can clarify complex topics.

User Experiences and Testimonials

This section highlights the valuable insights and feedback from users who have interacted with various models in the series. Their shared experiences provide a unique perspective on performance, reliability, and overall satisfaction.

Positive Feedback

- Users appreciate the ease of operation and intuitive controls.

- Many highlight the durability of components under challenging conditions.

- Operators frequently mention excellent fuel efficiency.

Areas for Improvement

- Some users suggest enhancements in service accessibility.

- A few have expressed the need for more detailed maintenance guides.

- There are recommendations for improved warranty options.