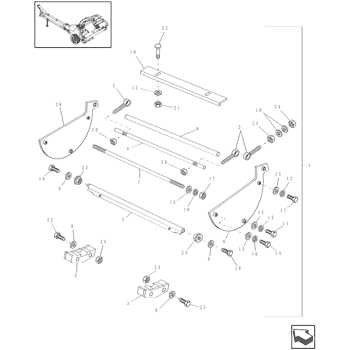

Comprehensive Parts Diagram for New Holland FP230

In the realm of modern farming, comprehending the intricate structure of machinery is essential for optimal performance and maintenance. Each piece of equipment comprises a multitude of elements, each playing a crucial role in overall functionality. This knowledge empowers operators to make informed decisions regarding repairs and enhancements.

Visual aids serve as invaluable tools in this exploration, providing clarity on the specific arrangements and interactions of various components. By studying these illustrations, one can delve into the intricate relationships that exist within the machinery, leading to a deeper understanding of its operation.

Ultimately, mastering the layout of these essential elements not only facilitates better upkeep but also enhances the efficiency of agricultural tasks. With the right insights, farmers can ensure their equipment remains in peak condition, ready to tackle the demands of the field.

Understanding New Holland FP230 Components

Grasping the intricacies of agricultural machinery is crucial for maximizing efficiency and performance. Each element plays a pivotal role, contributing to the overall functionality of the equipment. By familiarizing oneself with the various components, operators can ensure optimal operation and maintenance.

Key Elements of the Machinery

The structure is composed of several fundamental units, each designed to perform specific tasks. These units work in harmony to facilitate smooth operation. Recognizing the importance of each part not only aids in troubleshooting but also enhances the ability to carry out effective repairs and upgrades.

Maintenance and Care

Proper maintenance of individual components is essential for longevity and reliability. Regular inspections and timely replacements can prevent unexpected breakdowns. Understanding the wear patterns and stress points in each element can guide users in implementing preventive measures, ensuring the equipment remains in peak condition for years to come.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They provide clarity, enabling users to identify individual elements and their functions, which is essential for maintenance and repair tasks. With these illustrations, even intricate systems become manageable and accessible.

Enhancing Efficiency

Effective maintenance relies on accurate identification of each element. By utilizing these visual aids, technicians can swiftly locate issues, reducing downtime and enhancing overall productivity. This efficiency is vital in ensuring machinery operates smoothly and reliably.

Facilitating Learning

For those new to a particular machine, visual aids serve as excellent educational tools. They simplify complex concepts, making it easier for individuals to grasp how various components interact, ultimately fostering a deeper understanding of the machinery.

Key Features of FP230 Model

This model is designed to deliver exceptional performance and reliability in various agricultural applications. With a focus on efficiency and user-friendliness, it stands out in its class for its innovative technology and robust construction.

Performance and Efficiency

One of the standout characteristics of this machine is its powerful engine, which ensures optimal performance while minimizing fuel consumption. The advanced engineering allows for swift operation in the field, enhancing productivity during critical harvesting periods.

User-Friendly Design

The intuitive controls and ergonomic layout of the operator’s station make it accessible for users of all experience levels. Additionally, features such as adjustable settings and easy maintenance access contribute to an overall seamless operational experience, ensuring that operators can focus on their tasks without unnecessary interruptions.

Common Issues with FP230 Parts

In the world of agricultural machinery, certain components often face challenges that can hinder performance and efficiency. Understanding these prevalent concerns can aid in maintenance and prolonging the lifespan of equipment. Below are some typical issues that may arise, impacting functionality and requiring attention.

| Issue | Description |

|---|---|

| Wear and Tear | Components can experience degradation over time, leading to decreased efficiency. |

| Corrosion | Exposure to moisture and chemicals may result in rust, compromising structural integrity. |

| Misalignment | Improper installation or wear can cause parts to become misaligned, affecting operation. |

| Sealing Issues | Gaskets and seals may fail, leading to leaks that can cause further damage. |

| Contamination | Debris and dirt can infiltrate systems, causing blockages and inefficiencies. |

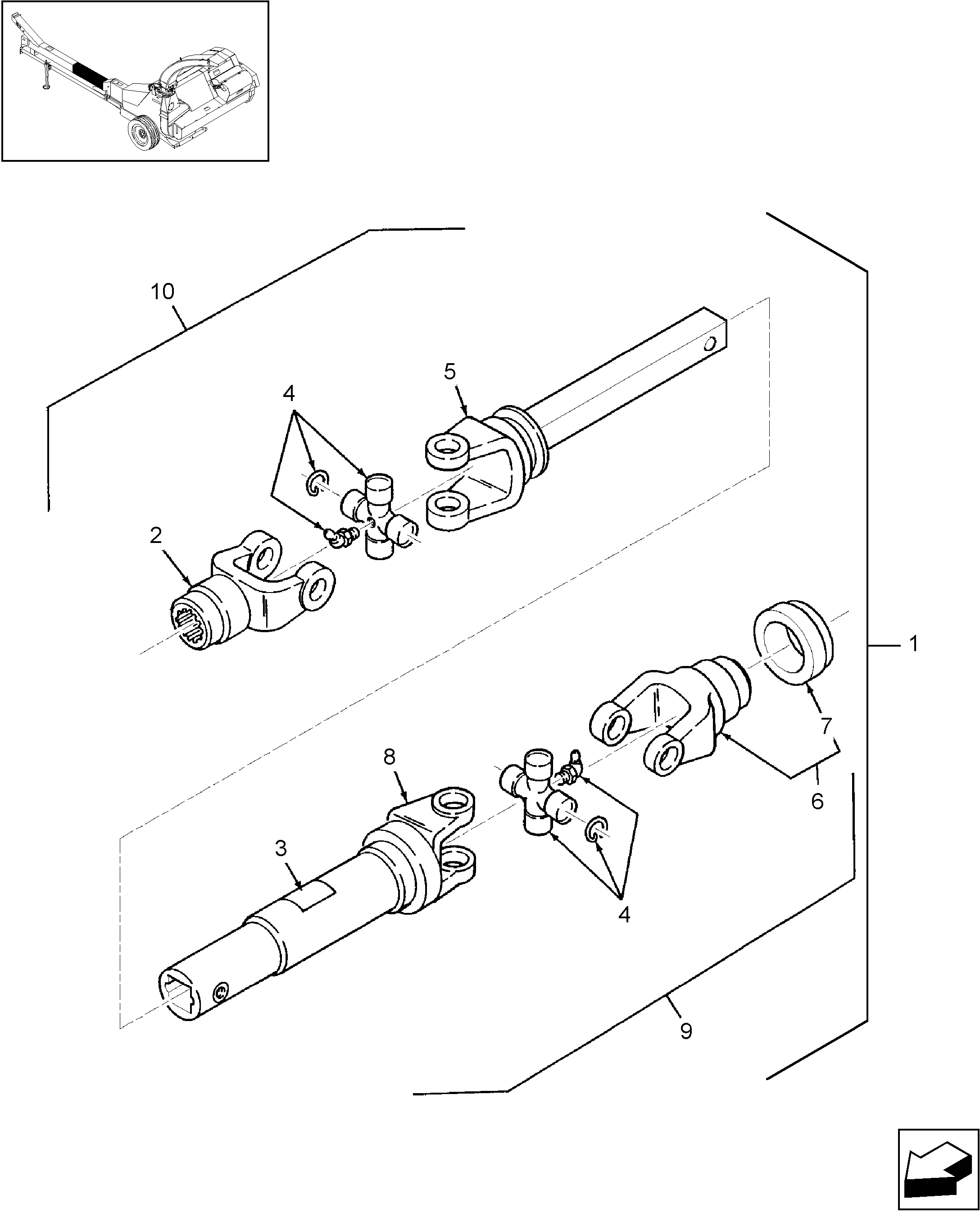

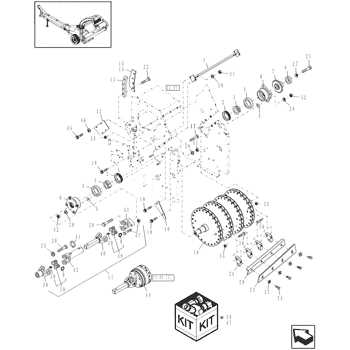

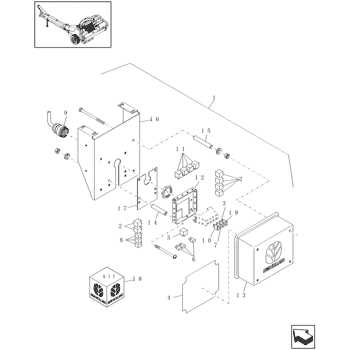

How to Read a Parts Diagram

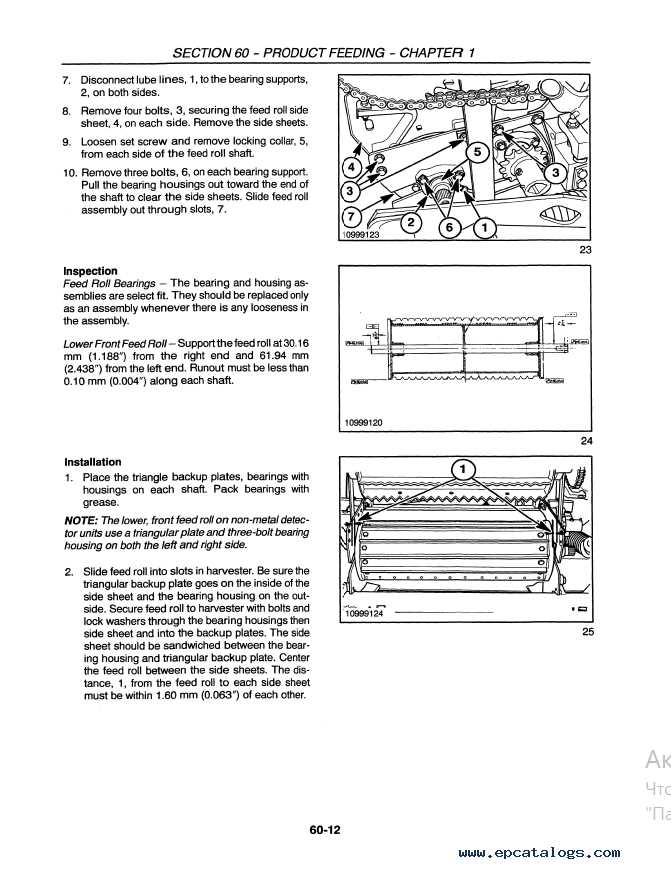

Understanding an illustration of components is essential for effective maintenance and repair. Such visuals provide a clear layout, allowing users to identify individual elements and their relationships within a system. Familiarizing oneself with these images can enhance troubleshooting skills and improve overall efficiency.

Familiarizing with Symbols and Labels

Each element in the illustration typically comes with unique identifiers. Labels help clarify function and location, while symbols can indicate specific types of connections or mechanical features. Take time to decode these markings, as they are crucial for accurate assembly or disassembly.

Understanding Component Relationships

It’s important to recognize how each part interacts with others. By studying the layout, one can see how components fit together and operate as a whole. This knowledge not only aids in repairs but also enhances comprehension of the entire system.

Replacing Worn Out Components

Regular maintenance and timely replacement of aged elements are essential for optimal machine performance. Over time, components can wear down, leading to decreased efficiency and potential malfunctions. Identifying these worn parts and replacing them promptly is crucial for ensuring longevity and reliability.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blades | Dullness, chips | Replace with new blades |

| Belt | Cracks, fraying | Install a new belt |

| Bearings | Noisy operation, excessive play | Replace bearings immediately |

| Filters | Clogging, discoloration | Change filters regularly |

By addressing these issues proactively, users can maintain peak functionality and avoid costly repairs in the future.

Maintenance Tips for FP230

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to specific guidelines, you can significantly enhance its reliability and efficiency.

- Routine Inspections: Check components frequently for signs of wear and tear.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

- Cleaning: Keep surfaces and filters clean to prevent blockages and overheating.

Incorporate these practices into your maintenance schedule for improved functionality.

- Review the manufacturer’s recommendations for specific maintenance intervals.

- Replace any worn-out parts promptly to avoid further damage.

- Document maintenance activities for future reference.

Implementing these strategies will help you achieve the ultimate performance from your machinery.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial for maintaining performance and longevity. Using high-quality replacements ensures that your equipment operates smoothly and efficiently. Here are some reliable sources to consider when searching for original elements.

Authorized Dealers

One of the most dependable options is to purchase from certified dealers. These establishments specialize in genuine items and often provide expert advice. Look for:

- Local dealerships with a good reputation

- Online platforms run by authorized vendors

- Service centers that offer maintenance packages

Manufacturer Websites

Another effective method is to visit the official websites of the equipment manufacturers. They typically have sections dedicated to their offerings, where you can:

- Browse available items by model

- Access installation guides and manuals

- Find contact information for support

Choosing the right source for your replacement components not only enhances performance but also provides peace of mind regarding quality and compatibility.

Cost Considerations for Replacement Parts

When it comes to maintaining machinery, understanding the financial implications of substitute components is crucial. The expense of these items can vary significantly based on several factors, including quality, availability, and sourcing options. This section explores the key aspects that influence costs and provides guidance for making informed decisions.

Quality vs. Price

One of the primary factors to consider is the balance between quality and cost. While cheaper alternatives may be tempting, they often lead to higher long-term expenses due to increased wear and tear or frequent replacements. Investing in high-quality components can result in improved performance and durability, ultimately saving money over time.

Sourcing and Availability

The source of the components can greatly affect their price. Local suppliers may offer competitive rates, but online marketplaces might provide better deals, especially if bulk purchasing is an option. Additionally, understanding the lead time for delivery can prevent costly downtime in operations, making it essential to factor in shipping costs and availability when budgeting.

Upgrading FP230 Performance Features

Enhancing the functionality and efficiency of agricultural equipment can significantly impact productivity and operational costs. By implementing targeted modifications and upgrades, users can unlock better performance, improved reliability, and increased versatility in their machinery. This section explores various approaches to elevating the capabilities of your equipment.

Key Areas for Enhancement

- Engine Optimization: Fine-tuning engine settings and components can lead to better fuel efficiency and power output.

- Hydraulic System Upgrades: Improving hydraulic performance can enhance lifting capacity and speed.

- Transmission Modifications: Adjusting gear ratios can optimize speed and torque for specific applications.

Recommended Accessories and Add-ons

- Performance Exhaust: Upgrading to a high-flow exhaust system can improve engine efficiency.

- Advanced Control Systems: Installing modern electronic controls can enhance precision and responsiveness.

- Enhanced Tires: Using specialized tires can improve traction and reduce soil compaction.

By focusing on these key areas and considering valuable accessories, operators can significantly improve the functionality of their machinery, leading to greater efficiency and reduced downtime.

Tools Needed for Repairs

When it comes to maintenance and fixing machinery, having the right equipment is essential for ensuring efficiency and precision. The appropriate tools not only facilitate the repair process but also enhance safety and longevity of the machine.

Wrenches and sockets are crucial for loosening and tightening bolts, while screwdrivers are needed for various fastening tasks. For intricate components, pliers and cutters may also be necessary to manipulate small parts effectively.

Additionally, measuring tools like calipers and rulers help ensure that adjustments are accurate, while lubricants are important for maintaining moving parts. To delve deeper, a reliable toolbox is essential for organization and accessibility during repairs.

Ultimately, investing in quality tools can significantly impact the outcome of repair work, making it smoother and more effective.

Expert Advice on Component Compatibility

Understanding the intricacies of machinery components is crucial for ensuring optimal performance and longevity. When seeking replacements or upgrades, it’s vital to consider not just the part itself, but also how it integrates with existing systems. This section offers insights into achieving the best compatibility for your equipment.

Factors to Consider

Before purchasing components, evaluate the following aspects:

| Factor | Description |

|---|---|

| Specifications | Ensure dimensions, material, and functionality match your requirements. |

| Manufacturer Recommendations | Follow guidelines provided by the original equipment maker to avoid issues. |

| Reviews and Feedback | Check user experiences for insights on performance and durability. |

Benefits of Proper Compatibility

Choosing compatible components enhances efficiency, reduces downtime, and minimizes repair costs. Investing time in research pays off with improved machine reliability and performance.

Resources for Further Learning

Expanding your knowledge on agricultural machinery can greatly enhance your understanding and efficiency in the field. Numerous resources are available to help you dive deeper into the various components and functionalities of these machines. Whether you’re a seasoned professional or just starting out, leveraging the right materials can provide invaluable insights.

Online Tutorials and Courses

There are many online platforms offering comprehensive courses on machinery maintenance and operation. Websites like Coursera and Udemy feature expert-led tutorials that cover everything from basic principles to advanced techniques. Engaging in these courses allows you to learn at your own pace and acquire practical skills that are essential in the industry.

Technical Manuals and Guides

Accessing official technical manuals and user guides is crucial for anyone seeking to understand machinery specifications and maintenance procedures. Many manufacturers provide downloadable resources on their websites, which include detailed descriptions of components and troubleshooting tips. These documents serve as excellent references for both novice and experienced operators.