Parts Diagram for New Holland T1520

In the realm of farming equipment, having a clear grasp of the various elements that constitute machinery is crucial for optimal performance and maintenance. This knowledge empowers operators and technicians to make informed decisions regarding repairs and upgrades, ensuring that the equipment functions smoothly and efficiently.

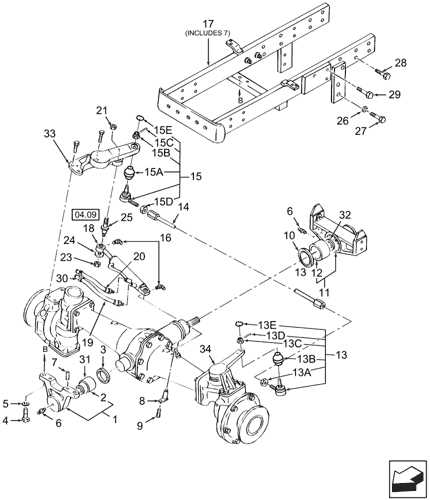

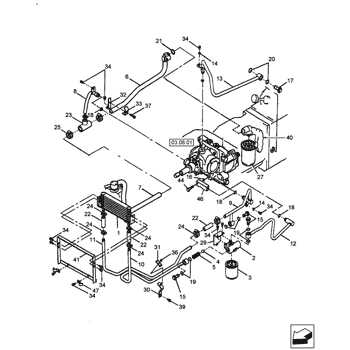

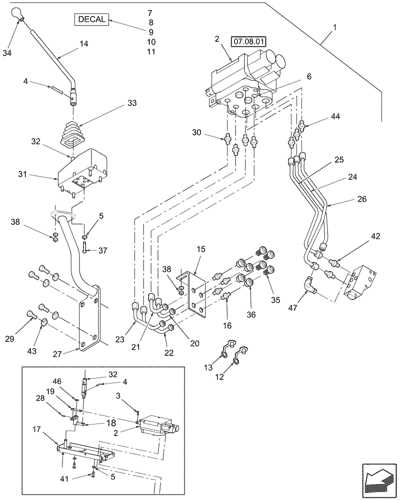

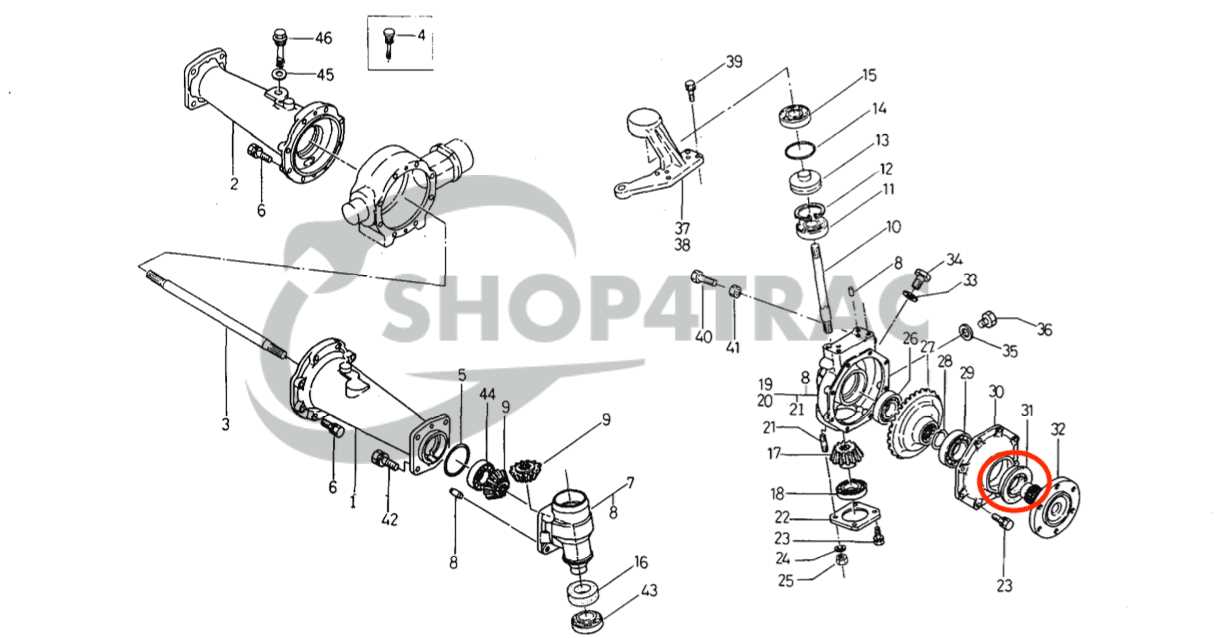

Visual representations of machinery components serve as valuable tools in this understanding. They allow users to identify each segment, facilitating easier troubleshooting and assembly. Such illustrations play a significant role in enhancing the user’s familiarity with the equipment, ultimately leading to improved operational practices.

By exploring detailed schematics, users can delve into the intricate workings of their machinery. This exploration not only demystifies the assembly but also promotes a deeper appreciation for the engineering that underlies these powerful tools. As a result, operators are better equipped to maintain their equipment, contributing to its longevity and reliability.

This section aims to provide a comprehensive framework for exploring the essential components of a specific agricultural machine, detailing its functionalities and interconnections. Each heading will focus on a unique element, enhancing the reader’s understanding of the overall assembly and maintenance requirements.

1. Overview of the Machinery

Begin with a general description of the equipment, highlighting its purpose and capabilities in various agricultural tasks.

2. Key Components

- Engine System

- Transmission Mechanism

- Hydraulic Assembly

- Chassis Structure

3. Functionality of Major Elements

Discuss how each significant part contributes to the overall operation, including efficiency and performance.

4. Maintenance Practices

- Regular Inspections

- Lubrication Requirements

- Wear and Tear Management

5. Troubleshooting Common Issues

Provide guidance on identifying and resolving frequent problems related to the equipment’s operation.

6. Upgrading Components

- Benefits of Enhanced Parts

- Compatibility Considerations

7. Safety Guidelines

Outline essential safety measures to ensure secure handling and operation of the machine.

8. Resources for Owners

- User Manuals

- Online Forums

- Professional Support

9. Accessories and Add-ons

Discuss optional tools and enhancements that can improve functionality and usability.

10. Historical Context

- Evolution of Similar Machinery

- Impact on Agriculture

11. Conclusion and Future Trends

Summarize the significance of understanding

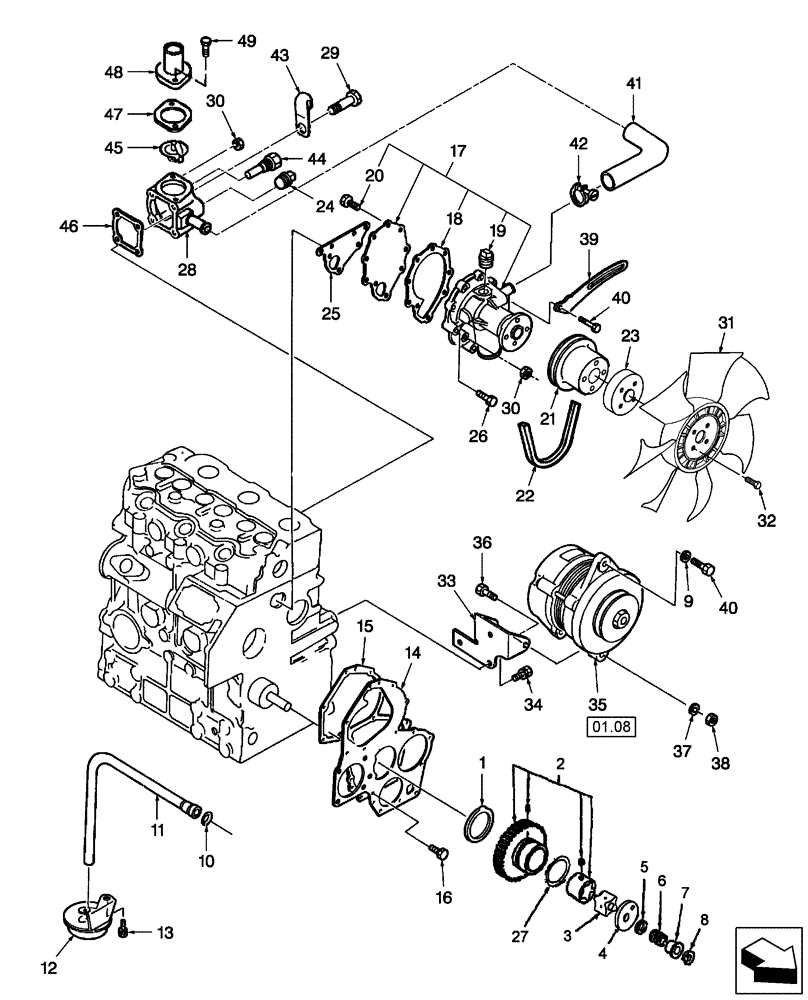

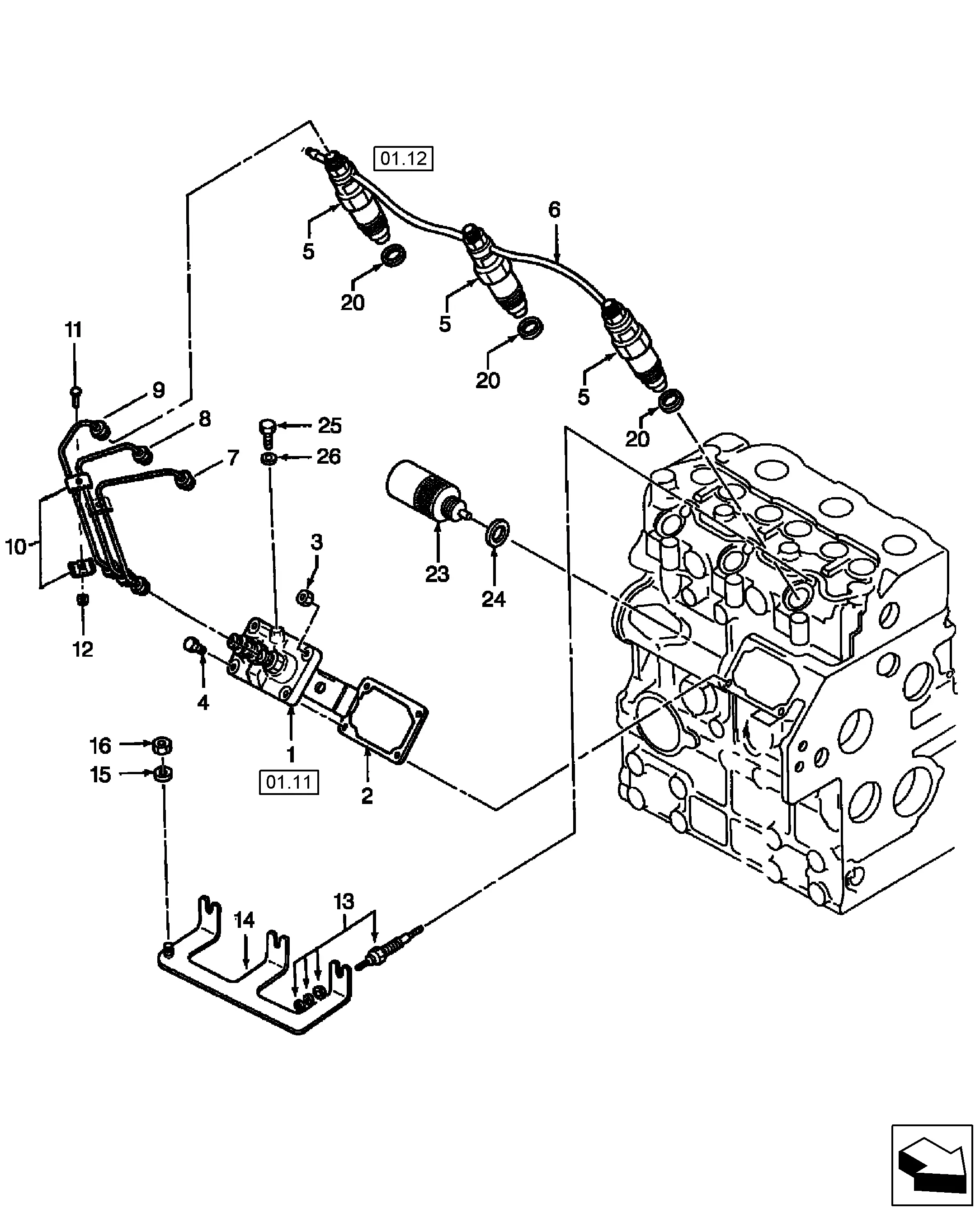

Key Components of the T1520

The functionality of agricultural machinery relies heavily on its essential elements, which work in harmony to enhance performance and efficiency. Understanding these vital components is crucial for operators and maintenance personnel alike, ensuring optimal operation and longevity of the equipment.

Engine and Transmission

The engine serves as the powerhouse, providing the necessary energy to drive the machine. Coupled with a robust transmission system, it allows for seamless power distribution, enabling operators to tackle various tasks with ease. Regular checks on these components are essential for maintaining peak performance.

Hydraulic System

This system plays a pivotal role in facilitating various movements and functions of the machinery. It operates through a network of hoses, pumps, and cylinders, allowing for the lifting and controlling of attachments. Proper maintenance of the hydraulic system is vital to prevent leaks and ensure smooth operation.

Importance of Accurate Diagrams

Clear representations play a crucial role in various technical fields. They provide essential visual guidance for understanding complex systems, ensuring that users can effectively assemble, maintain, or repair equipment.

Here are several key reasons why precise illustrations are vital:

- Enhanced Understanding: Detailed visuals help individuals grasp intricate components and their relationships, facilitating better comprehension of how a system operates.

- Time Efficiency: Accurate illustrations can significantly reduce the time required for assembly or maintenance tasks, minimizing the risk of errors during the process.

- Improved Safety: Clear and precise visuals help ensure that safety protocols are followed, reducing the likelihood of accidents or mishaps during operation.

- Cost-Effectiveness: By preventing errors and ensuring correct procedures, detailed representations can save costs associated with incorrect installations or repairs.

Ultimately, the value of well-crafted illustrations cannot be overstated, as they contribute to the successful functioning of equipment and promote user confidence.

Common Parts for Maintenance

Regular upkeep of agricultural machinery ensures optimal performance and longevity. Familiarity with essential components is crucial for efficient servicing and timely replacements, preventing costly downtime.

Key Components

- Filters: Vital for keeping fluids clean and ensuring smooth operation.

- Batteries: Essential for reliable starting and powering electrical systems.

- Belts: Crucial for driving various engine accessories and maintaining functionality.

- Hoses: Necessary for fluid transfer, requiring regular inspection for wear.

Maintenance Tips

- Check filters regularly and replace them as needed to maintain fluid integrity.

- Inspect batteries for corrosion and ensure secure connections to prevent starting issues.

- Monitor belts for signs of fraying or damage and replace them promptly to avoid system failures.

- Examine hoses for leaks or cracks, replacing them to prevent fluid loss and operational hazards.

Where to Find Replacement Parts

Locating suitable components for machinery maintenance is essential for optimal performance and longevity. Various sources provide access to necessary items, ensuring that repairs and upgrades can be efficiently executed.

Online Retailers

Numerous websites specialize in supplying machinery components. Consider the following:

- Dedicated equipment suppliers often have extensive inventories.

- Marketplace platforms can connect you with individual sellers and retailers.

- Manufacturer websites typically offer original components directly to consumers.

Local Distributors

Physical stores can also be valuable resources. Look for:

- Authorized dealerships that provide genuine items and expert assistance.

- General hardware stores may carry a selection of compatible options.

- Specialty shops focused on machinery might offer rare or specific components.

Visual Identification of T1520 Parts

This section aims to provide an overview of how to visually recognize various components of the equipment. By familiarizing yourself with the specific characteristics and features of each element, you can enhance maintenance and repair efficiency.

Understanding the unique attributes of each element not only aids in identification but also contributes to better decision-making during repairs and replacements. Below is a table that highlights key identifiers for the equipment’s components.

| Component | Key Features | Common Issues |

|---|---|---|

| Engine | Check for model markings and size specifications. | Overheating, oil leaks. |

| Transmission | Look for fluid levels and any unusual noises. | Slipping gears, fluid leaks. |

| Hydraulic System | Inspect hoses and cylinders for wear and tear. | Loss of pressure, leaks. |

| Electrical Components | Identify wiring and connectors by color coding. | Electrical failures, short circuits. |

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components can significantly enhance the performance and longevity of machinery. These elements are specifically designed to meet the precise specifications of the equipment, ensuring optimal functionality and reliability.

Some key advantages of opting for genuine components include:

- Quality Assurance: Authentic components undergo rigorous testing to meet industry standards, ensuring superior quality and durability.

- Perfect Fit: OEM items are crafted to fit seamlessly, reducing the risk of malfunctions or installation issues.

- Enhanced Performance: Using original components can improve the overall performance of the machinery, leading to greater efficiency and productivity.

- Warranty Protection: Many manufacturers offer warranties on OEM products, providing additional peace of mind and protection for investments.

- Resale Value: Maintaining equipment with genuine components can help preserve its value, making it more attractive to potential buyers.

In summary, choosing original manufacturer components is a wise decision that ensures the reliability and efficiency of machinery, ultimately leading to better long-term outcomes.

DIY Repairs Using the Diagram

Understanding the layout and components of your machinery is essential for effective maintenance and troubleshooting. By utilizing a visual representation, you can easily identify specific sections and elements that may require attention. This knowledge empowers you to tackle repairs with confidence and precision.

Before commencing any repair work, ensure you have the necessary tools and replacement components on hand. Familiarize yourself with the various assemblies and how they interact. Step-by-step instructions derived from the visual guide can greatly simplify the repair process. Always remember to follow safety protocols to prevent accidents.

For straightforward tasks, such as replacing worn-out components or addressing minor issues, having a clear reference can save time and minimize frustration. By engaging in DIY repairs, you not only save on labor costs but also gain valuable insights into the functionality of your equipment, ultimately enhancing its performance and longevity.

Assembly and Disassembly Guidelines

This section provides essential instructions for the proper assembly and disassembly of machinery components. Following these guidelines ensures that the process is efficient, safe, and minimizes the risk of damage to any parts. Understanding the necessary steps and techniques is crucial for maintaining the longevity and performance of the equipment.

When assembling components, begin by organizing all necessary tools and parts. Ensure that the workspace is clean and free of obstructions. Follow a systematic approach, attaching parts sequentially as per the manufacturer’s recommendations. Pay close attention to alignment and fitting to avoid misplacement.

For disassembly, it is vital to reverse the assembly process carefully. Document each step as you progress to aid reassembly. Utilize the correct tools to prevent damage to the components. Handle all parts with care, and store them in a designated area to avoid loss or contamination.

Adhering to these guidelines will facilitate a smooth operation, allowing for efficient maintenance and repair of the equipment over time.

Common Issues and Troubleshooting

Every machine can encounter challenges over time, and understanding these common issues can significantly enhance performance and longevity. This section explores frequent problems users may face and provides effective strategies for troubleshooting.

- Engine Starting Problems:

- Check the battery connections for corrosion or looseness.

- Inspect the fuel level and ensure it’s adequate.

- Examine the ignition system for any faulty components.

- Hydraulic System Failures:

- Look for leaks in hoses and fittings.

- Verify the hydraulic fluid level and quality.

- Test the hydraulic pump for proper function.

- Overheating Issues:

- Ensure the cooling system is filled with appropriate fluid.

- Clean the radiator and air filters to improve airflow.

- Inspect the thermostat for any malfunctions.

- Unusual Noises:

- Identify the source of the noise, whether from the engine or other components.

- Check for loose parts that may require tightening.

- Lubricate any moving parts that may be dry or worn.

By regularly monitoring these common issues and applying troubleshooting techniques, operators can maintain their equipment’s efficiency and prevent more severe breakdowns.

Upgrading Components for Performance

Enhancing the efficiency and effectiveness of machinery can be achieved by carefully selecting and replacing certain elements. By focusing on critical areas such as the engine, transmission, and hydraulics, users can significantly improve overall operation and longevity. Optimizing these components not only boosts performance but also contributes to fuel efficiency and reduces wear and tear over time.

Engine Enhancements

One of the most impactful modifications involves the engine. Upgrading to a higher-efficiency intake and exhaust system can facilitate better airflow, leading to improved combustion and increased power output. Additionally, installing a performance chip can optimize fuel delivery and ignition timing, further enhancing engine responsiveness.

Hydraulic System Upgrades

Another key area for enhancement lies within the hydraulic system. Incorporating more efficient pumps and actuators can enhance response times and lifting capabilities. Furthermore, utilizing advanced hydraulic fluids can reduce friction and heat generation, ensuring smoother operation and extending the lifespan of hydraulic components.

Resources for Further Information

For those seeking to enhance their knowledge and understanding of specific machinery, a variety of resources are available. These materials can provide insights into operation, maintenance, and troubleshooting, aiding users in maximizing the efficiency of their equipment.

Consider exploring the following options for comprehensive information:

- Manufacturer Websites: Official sites often provide manuals, technical documents, and product specifications.

- Online Forums: Community-driven platforms where users share experiences, solutions, and advice related to equipment usage.

- Repair Manuals: Detailed guides that outline repair procedures, common issues, and maintenance tips.

- YouTube Tutorials: Video content that demonstrates repairs and maintenance techniques visually, making learning easier.

- Local Dealers: Authorized dealers can offer expert advice and genuine components for repairs and upgrades.

By utilizing these resources, users can better navigate challenges and enhance their equipment’s performance, ensuring longevity and reliability.