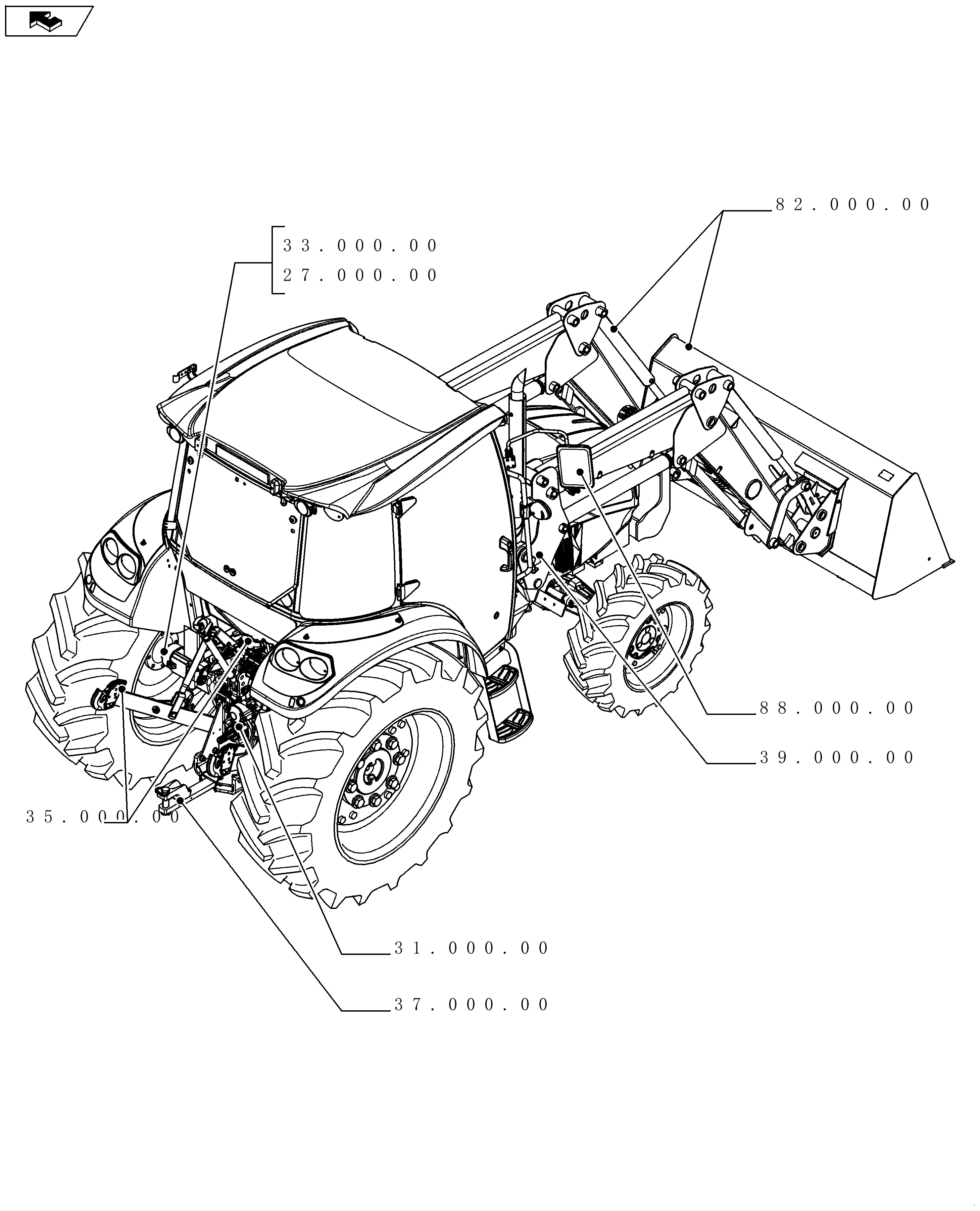

New Holland T4 75 Parts Diagram Overview

When it comes to maintaining agricultural machinery, having a clear understanding of its individual components is essential for optimal performance and longevity. This section delves into the intricacies of a specific model, highlighting its various elements and their functions.

By breaking down the assembly into manageable sections, operators can effectively identify and troubleshoot issues that may arise. This not only aids in routine maintenance but also enhances the overall efficiency of the machine.

Furthermore, familiarizing oneself with the layout of the equipment’s structure empowers users to undertake repairs with confidence. This knowledge ultimately leads to reduced downtime and improved productivity on the farm.

Understanding New Holland T4 75 Parts

Gaining insight into the components of agricultural machinery is essential for effective maintenance and operation. A thorough understanding of each element enhances efficiency and extends the lifespan of the equipment. Knowing how these various sections interact is vital for troubleshooting and optimizing performance.

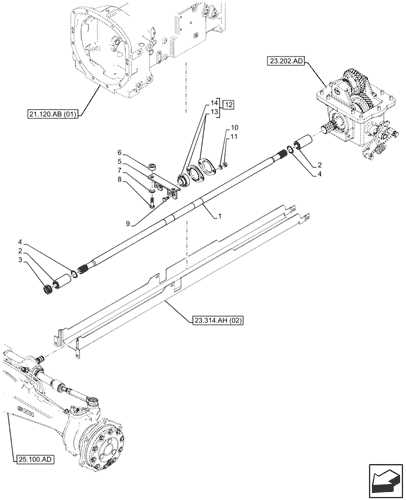

Identifying individual components is the first step towards ensuring that everything functions harmoniously. Each piece plays a crucial role, from the engine to the hydraulic systems. Familiarity with these parts allows operators to recognize signs of wear or malfunction early, preventing costly downtime.

Moreover, having access to detailed schematics can simplify the process of repairs and replacements. Understanding the layout helps users to quickly locate specific sections when issues arise. This knowledge empowers operators to make informed decisions regarding repairs, upgrades, or replacements.

Ultimately, a solid grasp of the machinery’s design not only aids in routine maintenance but also boosts overall productivity in agricultural operations. Investing time in learning about these essential components can yield significant long-term benefits.

Importance of Parts Diagrams

Understanding the intricacies of machinery relies heavily on visual representations of their components. These illustrations serve as vital tools for technicians and operators, enabling them to identify and locate each element within complex systems. By providing clarity, they simplify maintenance and repair processes, ensuring that machinery operates efficiently.

Moreover, such visuals facilitate effective communication among team members. When discussing repairs or upgrades, referring to these representations helps in avoiding misunderstandings and ensures that everyone is on the same page regarding what needs to be addressed.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visuals make it easier to identify components and their relationships within the system. |

| Improved Communication | Facilitates discussions among team members regarding repairs and maintenance. |

| Efficient Maintenance | Streamlines the process of locating and replacing components during service tasks. |

| Training Aid | Serves as a valuable resource for educating new staff about the machinery. |

Common Components of T4 75 Tractor

The T4 75 Tractor features a range of essential elements that contribute to its efficiency and performance in various agricultural tasks. Understanding these components helps users maintain and operate the machine effectively.

- Engine: The heart of the tractor, providing the necessary power for all operations.

- Transmission: Facilitates smooth gear shifts, ensuring optimal speed and torque delivery.

- Hydraulic System: Powers attachments and implements, enhancing versatility in different applications.

- Chassis: The robust framework that supports all other components and ensures stability during operation.

- Wheels and Tires: Designed for traction and maneuverability across various terrains.

Each of these elements plays a crucial role in the overall functionality of the T4 75 Tractor, making it a reliable choice for farmers and landowners alike.

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and repair machinery. These visual representations provide essential information about components and their relationships, making it easier to identify and locate specific elements.

Here are some key tips for interpreting these visual guides:

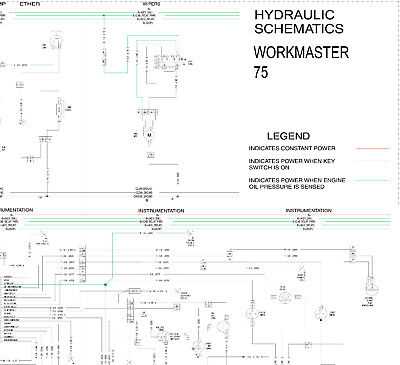

- Familiarize Yourself with the Legend: Most illustrations include a legend that explains symbols and color codes used throughout. Take the time to review this section first.

- Identify Main Components: Look for primary elements that are typically highlighted. This will help you understand the overall structure before diving into details.

- Follow the Flow: Many visual aids are arranged in a way that reflects the assembly or disassembly process. Follow the sequence to see how parts connect.

When reading these guides, it’s beneficial to:

- Start with a high-level overview to grasp the layout.

- Zoom in on areas of interest for finer details.

- Make notes on any specific pieces you may need to replace or inspect.

By honing your skills in interpreting these visuals, you can streamline repairs and ensure your equipment remains in optimal condition.

Key Features of New Holland T4 75

This agricultural machine is designed to enhance efficiency and performance in various farming tasks. It combines robust engineering with advanced technology, making it a reliable choice for both small and large-scale operations. Its versatile design ensures that it can handle a wide range of applications, from tillage to hauling and beyond.

Engine and Performance

The engine is a vital component, offering powerful output while maintaining fuel efficiency. With a focus on durability, this machine is built to operate under demanding conditions, ensuring longevity and reduced maintenance needs. Its compact size allows for easy maneuverability in tight spaces, making it ideal for diverse agricultural environments.

Comfort and Usability

The operator’s cabin is ergonomically designed to provide comfort during long hours of operation. Enhanced visibility and intuitive controls contribute to a user-friendly experience, allowing for precise handling and increased productivity. Additionally, the integration of modern technology simplifies operations and improves overall efficiency.

Where to Find Parts Diagrams

When it comes to maintaining and repairing agricultural machinery, having access to visual guides is essential. These resources help users identify components and understand their interrelations. Fortunately, various avenues exist for obtaining these invaluable references, ensuring that operators can effectively troubleshoot and service their equipment.

Online Resources

The internet is a treasure trove for enthusiasts and professionals alike. Numerous websites provide detailed illustrations and breakdowns of machinery. Manufacturer websites often feature downloadable manuals that include exploded views, while dedicated forums and community sites may share user-generated content and tips. Utilizing search engines with specific model numbers can lead to comprehensive resources tailored to particular machines.

Local Dealers and Service Centers

Benefits of Genuine Parts Usage

Using authentic components for machinery maintenance is crucial for optimal performance and longevity. These specialized items are designed to fit perfectly and function seamlessly with your equipment, ensuring reliability and efficiency in every operation.

Durability is one of the primary advantages of opting for original components. They are crafted from high-quality materials that withstand wear and tear, significantly reducing the likelihood of frequent replacements. This not only saves time but also minimizes overall costs associated with repairs.

Another significant benefit is compatibility. Genuine components are engineered to meet the exact specifications of your machine, which helps to maintain its integrity. Using off-brand alternatives may lead to unforeseen complications, potentially jeopardizing the equipment’s functionality.

Furthermore, manufacturer support is a vital aspect of choosing authentic items. When you invest in genuine components, you often receive access to comprehensive warranty coverage and customer service, ensuring that any issues encountered are promptly addressed.

Lastly, using original items enhances resale value. Prospective buyers often look for well-maintained machinery that has only ever used authentic components, making your equipment more attractive on the market.

Maintenance Tips for T4 75 Owners

Proper upkeep of your machinery is essential to ensure its longevity and optimal performance. By following a few key practices, you can maintain efficiency and prevent potential issues before they arise. Regular attention to detail can save time and resources in the long run.

Regular Inspections: Conduct frequent checks on various components, including filters, fluids, and belts. This proactive approach helps identify wear and tear early, allowing for timely replacements.

Fluid Changes: Change the oil and other vital fluids as per the manufacturer’s recommendations. Clean fluids enhance engine performance and reduce the risk of damage.

Cleaning and Debris Removal: Keep the exterior and undercarriage free from dirt and debris. This not only improves aesthetics but also prevents overheating and mechanical failures.

Tire Maintenance: Regularly inspect tire pressure and tread depth. Properly inflated and well-maintained tires improve traction and fuel efficiency.

Follow the Manual: Always refer to the user manual for specific maintenance guidelines tailored to your model. Adhering to these recommendations ensures that your machine operates smoothly.

By implementing these maintenance strategies, you can significantly enhance the performance and durability of your equipment, ultimately leading to a more productive experience.

Comparing T4 75 with Other Models

When evaluating agricultural machinery, it’s essential to understand how various models stack up against each other. This comparison highlights key features, performance metrics, and suitability for specific tasks, providing insights for potential buyers and users.

Key Features

- Engine Power: Different models offer varying horsepower, impacting efficiency and productivity.

- Size and Weight: Compact versus larger units can influence maneuverability and transport options.

- Transmission Type: Options range from manual to automatic, affecting ease of use and control.

Performance Metrics

- Fuel Efficiency: Comparing consumption rates helps in long-term cost management.

- Lift Capacity: Important for assessing the model’s capability to handle loads.

- Hydraulic System: Variances in hydraulic power can affect attachment functionality.

By analyzing these aspects, users can make informed decisions tailored to their operational needs.

Resources for Parts Replacement

Finding reliable sources for component replacements is essential for maintaining the efficiency and longevity of your machinery. Accessing the right information can greatly enhance the repair and upkeep process, ensuring that your equipment operates at its best. Whether you are looking for original components or high-quality alternatives, several resources can assist you in making informed decisions.

Manufacturer’s Website

The official website of the equipment manufacturer is a primary resource. It typically offers comprehensive catalogs, including specifications, installation guides, and even troubleshooting advice. By utilizing these resources, you can ensure that you are selecting components that are compatible and meet the required standards.

Online Retailers and Marketplaces

Several online platforms specialize in offering machinery components, often at competitive prices. These retailers usually provide detailed descriptions and customer reviews, which can help you assess the quality and reliability of the items. Additionally, forums and communities dedicated to equipment maintenance can be valuable for recommendations and shared experiences regarding various suppliers.

FAQs About T4 75 Components

This section addresses common inquiries regarding the various elements and mechanisms of the T4 75 model. Understanding these components can enhance maintenance practices and operational efficiency.

| Question | Answer |

|---|---|

| What types of engine parts are crucial for performance? | The engine assembly, fuel injectors, and air filters play vital roles in ensuring optimal functionality and efficiency. |

| How often should hydraulic components be serviced? | Regular checks every 100 hours of operation are recommended to maintain hydraulic efficiency and prevent failures. |

| Are there specific maintenance tips for the transmission system? | Ensure regular fluid changes and inspect for leaks to prolong the life of the transmission system. |

| What should be considered when replacing electrical components? | Compatibility with the existing system and adherence to manufacturer specifications are essential for reliable performance. |

| How can wear and tear be minimized on exterior parts? | Routine cleaning and protective coatings can help reduce damage from environmental factors. |