Comprehensive Guide to New Holland TC29D Parts Diagram

When it comes to optimizing agricultural equipment, having a clear visual representation of the components is essential. Such illustrations serve as invaluable resources for both experienced operators and those new to machinery maintenance. A detailed breakdown not only simplifies the identification of individual elements but also enhances the efficiency of repairs and replacements.

In the realm of farming machinery, knowledge of how each component interacts within the whole system can lead to improved performance and longevity. Whether you are conducting routine maintenance or troubleshooting unexpected issues, having access to accurate representations can save time and reduce frustration. Furthermore, understanding the layout fosters a greater appreciation for the complexity and engineering behind these powerful tools.

Additionally, exploring these visual guides can aid in the learning process for technicians and operators alike. Familiarity with the arrangement of various elements promotes confidence in handling equipment. This knowledge not only equips users with the skills needed for effective operation but also encourages proactive measures in equipment care.

Understanding the New Holland TC29D

This section aims to explore the key features and functionalities of a popular compact tractor model known for its efficiency and versatility. Designed to meet the needs of both residential and commercial users, this machine offers a range of capabilities that make it a valuable asset for various tasks.

Key Features

This compact tractor is equipped with a powerful engine, providing ample horsepower for various applications. Its design facilitates easy maneuverability, allowing users to navigate tight spaces with ease. Additionally, the robust build ensures durability, making it suitable for both light and heavy-duty tasks.

Applications

The versatility of this equipment allows it to be used in multiple settings, from agricultural work to landscaping. It can effectively handle tasks such as mowing, tilling, and material handling. This adaptability makes it a preferred choice for many operators seeking a reliable machine for diverse projects.

| Feature | Benefit |

|---|---|

| Powerful Engine | High performance for various tasks |

| Compact Size | Easy to maneuver in tight spaces |

| Durable Construction | Long-lasting and reliable |

| Versatile Attachments | Enhanced functionality for different applications |

Key Features of the TC29D Model

The compact utility tractor is designed to deliver exceptional performance and versatility, making it suitable for a variety of tasks. Its robust construction and advanced features enhance productivity while ensuring ease of operation for users of all skill levels.

Engine and Performance

Equipped with a powerful engine, this model offers reliable power output and efficient fuel consumption. The hydrostatic transmission provides smooth acceleration and easy maneuverability, allowing operators to navigate tight spaces with precision.

Ergonomics and Comfort

The operator’s station is thoughtfully designed for comfort and accessibility. With adjustable seating and intuitive controls, users can work for extended periods without fatigue. Ample storage options further enhance convenience, ensuring that essential tools and equipment are always within reach.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining complex machinery. These illustrations serve as a guide, helping users identify each element and its function within the system. By providing clarity, they simplify the process of repair and maintenance, reducing the likelihood of errors.

In addition to aiding in identification, these schematics foster efficient communication among technicians and operators. When discussing repairs or modifications, referring to these visuals ensures that everyone is on the same page, leading to better collaboration and quicker resolutions.

Moreover, having access to detailed representations can significantly enhance the troubleshooting process. By allowing users to pinpoint issues more easily, they can take corrective actions faster, minimizing downtime and improving overall productivity.

Lastly, these graphical tools are invaluable for education and training purposes. They help newcomers familiarize themselves with the equipment, enabling them to understand the intricacies of its design and functionality from the outset.

Common Issues with TC29D Components

When working with compact tractors, certain components can experience frequent challenges that may affect performance and reliability. Understanding these common problems can help owners maintain their equipment effectively and extend its lifespan. This section explores some prevalent issues that users may encounter with specific tractor elements.

Hydraulic System Failures

One of the most critical aspects of any compact tractor is its hydraulic system. Users often report leaks and loss of pressure as common concerns. These issues can stem from worn seals, damaged hoses, or faulty pumps. Regular inspection and timely maintenance of these components are essential to prevent serious breakdowns.

Engine Overheating

Engine performance can significantly impact overall efficiency, and overheating is a frequent issue that many operators face. Factors contributing to this problem include clogged radiators, low coolant levels, or malfunctioning thermostats. Addressing these issues promptly is vital to avoid severe engine damage and ensure smooth operation.

Where to Find Replacement Parts

When seeking components for your equipment, it’s essential to know the best resources available. A variety of outlets cater to different needs, from authorized dealerships to online retailers. Each option provides unique advantages, making it easier for users to find the right items to maintain their machinery efficiently.

Authorized Dealers

Visiting official dealers is often the most reliable way to source components. They typically offer genuine items that guarantee compatibility and quality. Additionally, authorized representatives can provide valuable advice and support for specific models.

Online Marketplaces

The internet has transformed how we shop for equipment necessities. Numerous websites offer a vast selection of components, often at competitive prices. It’s crucial to verify the credibility of these platforms and check customer reviews to ensure you’re purchasing from a trustworthy source.

| Source Type | Advantages |

|---|---|

| Authorized Dealers | Genuine parts, expert advice, warranty support |

| Online Retailers | Wide selection, competitive pricing, convenience |

| Local Repair Shops | Personalized service, potential for used components |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery involves regular care and attention. Implementing effective maintenance practices not only enhances performance but also minimizes the risk of unexpected failures. By adhering to a structured maintenance routine, operators can enjoy optimal functionality and reliability over time.

Regular Inspections

Conducting frequent checks on essential components is vital. Look for signs of wear, corrosion, or leaks. Pay special attention to the engine, hydraulic systems, and belts. Identifying issues early can prevent more significant problems and costly repairs down the line.

Lubrication and Cleaning

Proper lubrication reduces friction and wear on moving parts. Use high-quality lubricants as recommended in the user manual. Additionally, keeping the machinery clean prevents debris accumulation, which can lead to overheating and other operational issues. Make cleaning a part of your routine maintenance schedule to ensure everything runs smoothly.

How to Read Parts Diagrams

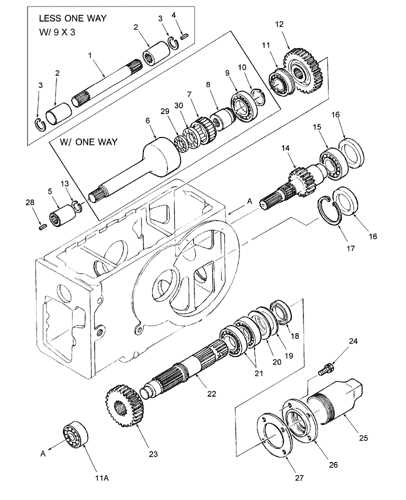

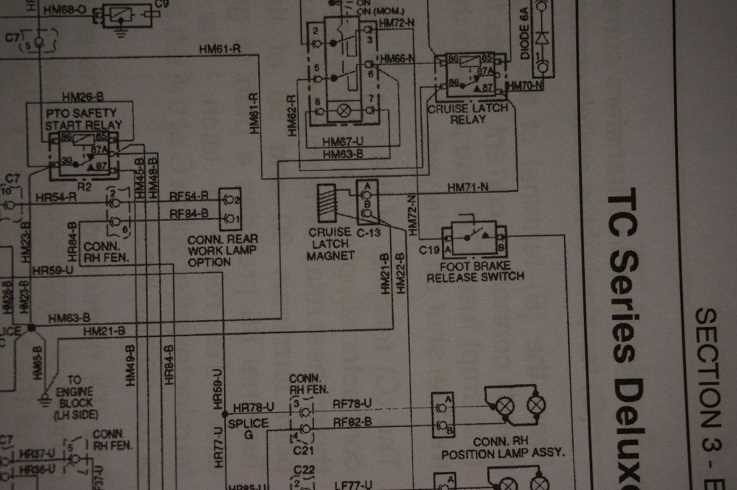

Understanding technical illustrations is essential for effective maintenance and repairs. These visual representations serve as invaluable tools, providing clarity on the assembly and components of machinery. By familiarizing yourself with their structure, you can streamline your troubleshooting process and ensure accurate replacements.

Start by identifying the key sections of the illustration. Typically, each component is labeled with a unique identifier that corresponds to a list, detailing specifications and availability. Familiarize yourself with common symbols used, as they indicate various functions or types of elements.

Next, pay attention to the layout. Often, these visuals are arranged to show how parts interact within the system, allowing you to grasp the relationships between different components. This contextual understanding is crucial for diagnosing issues effectively.

Lastly, use these illustrations as a reference when ordering replacements. Having a clear visual can prevent confusion and ensure you acquire the correct items needed for repairs. With practice, interpreting these images will become second nature, enhancing your overall efficiency in maintenance tasks.

Top Suppliers for TC29D Parts

Finding reliable sources for essential components is crucial for maintaining the performance and longevity of agricultural machinery. This section highlights leading suppliers that specialize in providing high-quality replacements and accessories, ensuring operators have access to the necessary items for optimal operation.

Reputable Online Retailers

Numerous online platforms offer a vast selection of components, often at competitive prices. These retailers frequently provide detailed specifications, customer reviews, and convenient shipping options, making them ideal for operators seeking quick solutions. Look for platforms with strong customer support to assist with any inquiries.

Local Dealerships and Service Centers

Many local dealerships and service centers provide specialized knowledge and support for machinery. Establishing a relationship with these businesses can be beneficial, as they often stock essential items and can offer personalized advice. Additionally, local suppliers may have insights into region-specific needs and common issues.

Cost-Effective Repair Strategies

Implementing budget-friendly approaches to maintenance and repair can significantly reduce costs while ensuring optimal performance of your equipment. By focusing on strategic planning and resourcefulness, you can maximize the lifespan of your machinery without compromising quality.

Prioritize Regular Maintenance

Consistent upkeep is essential for preventing costly breakdowns. Here are some steps to consider:

- Schedule routine inspections to identify potential issues early.

- Clean and lubricate components regularly to minimize wear and tear.

- Replace consumable parts before they fail to avoid more extensive repairs.

Utilize Quality Aftermarket Components

Choosing high-quality replacement parts can be a cost-effective alternative to original manufacturer options. Consider the following:

- Research reputable suppliers who offer reliable aftermarket options.

- Compare prices and warranties to find the best deals.

- Read reviews to ensure parts meet performance standards.

By adopting these strategies, you can effectively manage repair costs while maintaining the functionality and efficiency of your machinery.

Upgrading vs. Replacing Components

When considering the maintenance of machinery, two primary approaches often arise: enhancing existing elements or substituting them entirely. Each method has its unique advantages and considerations, making the decision process crucial for optimal performance and cost-effectiveness.

Upgrading typically involves improving the functionality or efficiency of current components. This can lead to increased performance without the need for a complete overhaul. Here are some benefits of upgrading:

- Cost-effective solutions that extend the life of existing parts.

- Improved efficiency and performance through modern technology.

- Less downtime compared to full replacements.

On the other hand, replacing components might be necessary in certain situations. This approach can ensure reliability and eliminate issues caused by outdated or worn-out parts. Consider the following advantages of replacement:

- Complete restoration of functionality with new components.

- Elimination of potential failures associated with aging parts.

- Opportunity to upgrade to the latest technology that may not be compatible with older components.

Ultimately, the choice between upgrading and replacing will depend on the specific circumstances, including the condition of the existing components, budget constraints, and desired performance outcomes. Careful evaluation can lead to informed decisions that enhance operational efficiency and longevity.