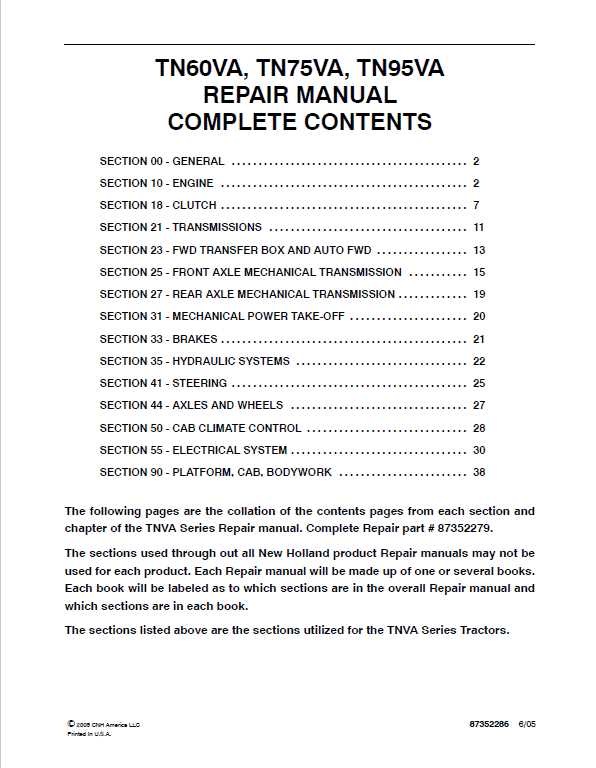

Comprehensive Parts Diagram for New Holland TN65

In the realm of farming equipment, comprehending the intricate layout of various elements is crucial for efficient maintenance and repair. Each component plays a vital role in ensuring that machinery operates at peak performance, allowing farmers to maximize productivity and minimize downtime.

By examining a detailed visual representation of the machinery’s structure, operators can identify specific parts and their functions. This knowledge not only aids in troubleshooting issues but also enhances the overall understanding of how these machines work together harmoniously.

With a focus on precision and functionality, this exploration will guide you through the essential features, empowering you to make informed decisions about repairs and upgrades. Embracing this insight ultimately leads to greater reliability and longevity of your equipment.

Understanding New Holland TN65 Parts

Grasping the components of agricultural machinery is essential for efficient maintenance and repair. A comprehensive knowledge of each element enables operators to ensure optimal performance and longevity of their equipment. This section delves into the various segments, their functions, and the importance of each within the overall system.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit providing the necessary force for operation. | Drives all mechanical systems and accessories. |

| Transmission | System responsible for transferring power from the engine to the wheels. | Allows for speed variation and torque multiplication. |

| Hydraulics | Fluid power system used to lift and move attachments. | Facilitates the operation of implements such as loaders and plows. |

| Chassis | The framework that supports the machinery and components. | Provides stability and structure during operation. |

| Electrical System | Network of wiring and components that manage power distribution. | Supports ignition, lighting, and electronic controls. |

By familiarizing oneself with these essential components, operators can troubleshoot issues more effectively and make informed decisions about repairs and upgrades. Understanding the interplay between these elements is crucial for maximizing the efficiency and reliability of any agricultural machine.

Overview of TN65 Model Features

This section provides a comprehensive look at the essential characteristics and specifications of a prominent agricultural machine. Designed for efficiency and reliability, this model caters to various farming needs, enhancing productivity and ease of use.

| Feature | Description |

|---|---|

| Engine Power | Robust engine performance ensuring optimal output. |

| Transmission | Smooth shifting capabilities for various terrains. |

| Hydraulic System | Advanced hydraulic functions for improved handling. |

| Cab Design | Ergonomically designed for operator comfort and visibility. |

| Fuel Efficiency | Economical fuel consumption without compromising power. |

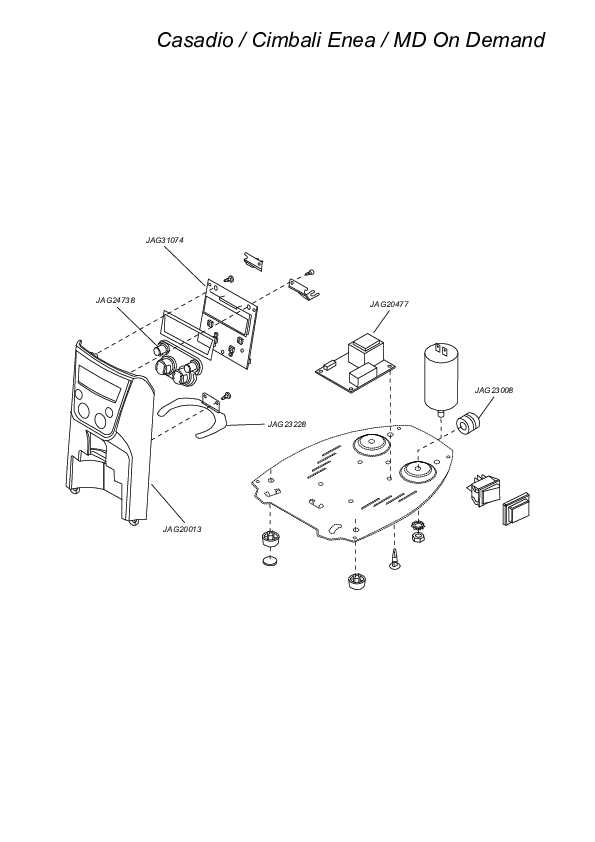

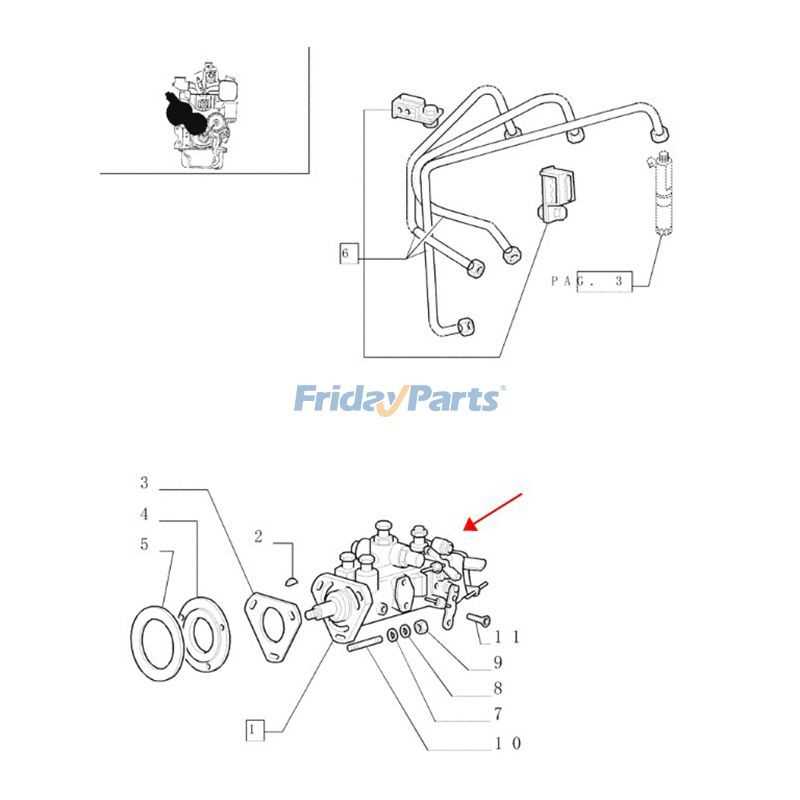

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for both technicians and enthusiasts alike, ensuring clarity and precision in identifying elements.

- Enhances troubleshooting efficiency.

- Facilitates easier ordering of replacements.

- Improves understanding of machinery assembly.

By examining these visuals, users can:

- Identify potential issues quickly.

- Gain insights into the assembly process.

- Ensure accurate reassembly after repairs.

Ultimately, these representations play a vital role in extending the lifespan of equipment and optimizing its performance.

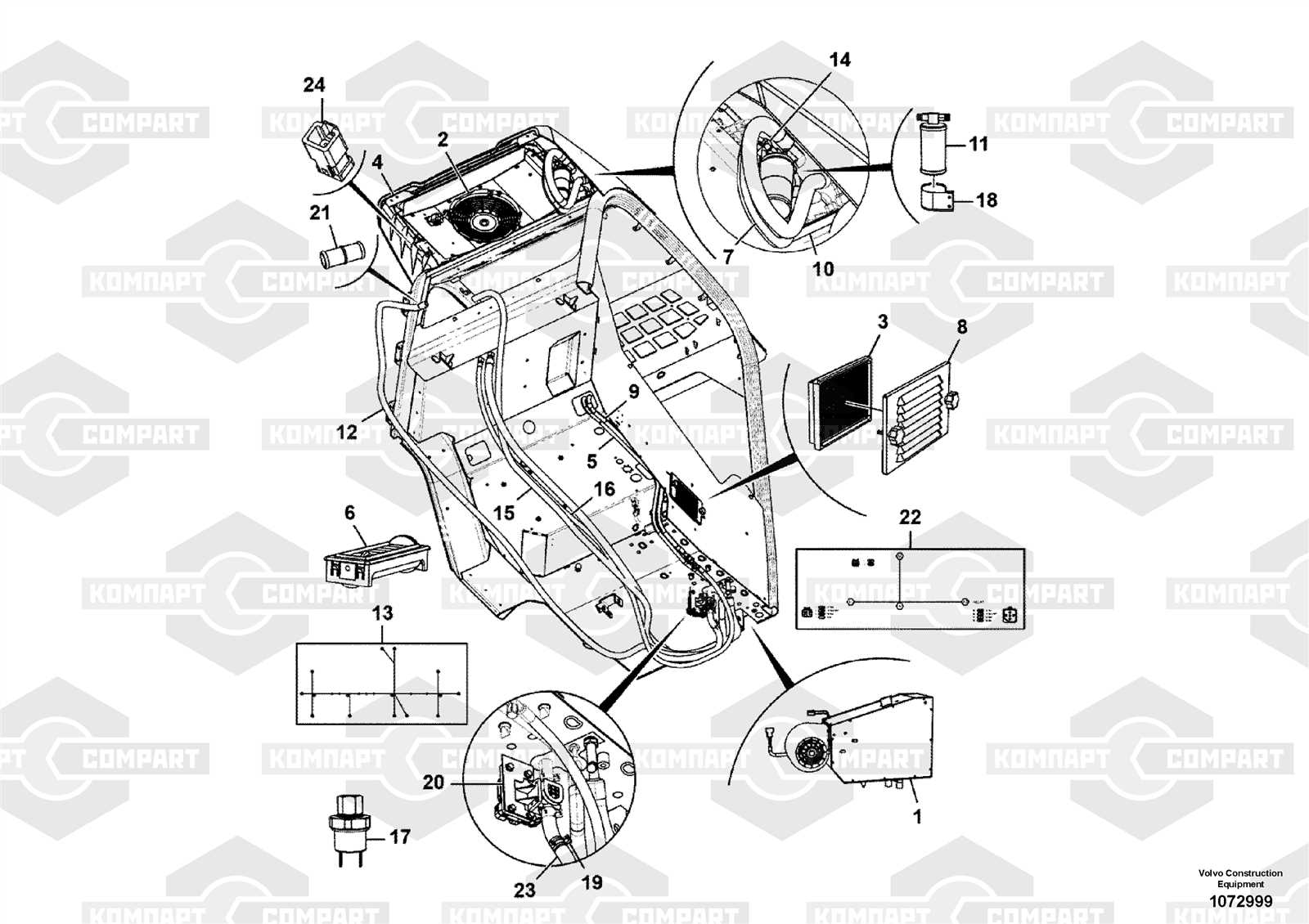

Key Components of TN65 Tractor

This section explores the essential elements that contribute to the functionality and performance of this agricultural machine. Understanding these components is crucial for effective maintenance and operation.

- Engine: The heart of the machine, providing the necessary power for various tasks.

- Transmission: Facilitates smooth gear shifting, allowing for optimal speed and torque.

- Hydraulic System: Powers attachments and enhances maneuverability through effective fluid control.

- Chassis: The frame that supports all components, ensuring stability and durability.

- Electrical System: Manages all electronic functions, from starting the engine to powering lights and instruments.

Each component plays a vital role in ensuring the machine operates at peak efficiency, making it essential for operators to familiarize themselves with these systems.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components is essential for efficient repairs and maintenance. These resources provide valuable insights into assembly and individual parts, ensuring that you can effectively address any issues that arise. Understanding where to access these resources can save time and enhance the repair process.

Online Resources

The internet hosts a plethora of websites dedicated to equipment manuals and visual guides. Many manufacturers and third-party platforms offer comprehensive collections of schematics, often searchable by model. Utilizing these online databases can yield quick access to the information needed.

Local Dealerships and Repair Shops

Visiting nearby dealerships or repair facilities can also be a fruitful approach. Often, these establishments maintain archives of technical documents and can provide assistance in locating specific schematics. Engaging with professionals in the field may lead to discovering additional tips and resources.

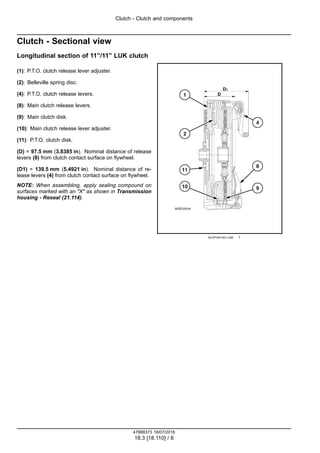

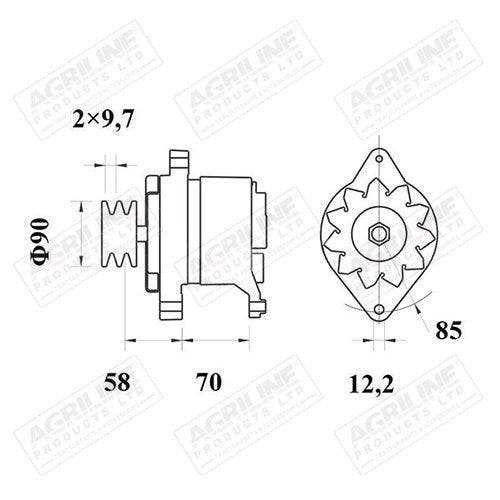

Common Replacement Parts Explained

When it comes to maintaining agricultural machinery, understanding the essential components that may require attention is crucial for optimal performance. Various elements within the equipment can wear down over time, necessitating timely replacements to ensure seamless operation. This section outlines some of the most frequently substituted components, highlighting their roles and importance in the machinery’s functionality.

Filters are among the most vital elements, as they prevent contaminants from entering the system. Regularly changing these components helps maintain fluid cleanliness and efficiency, extending the lifespan of other internal parts.

Belt replacements are common, given their role in transferring power throughout the machine. Over time, exposure to friction and environmental factors can lead to wear and tear, making regular checks essential to avoid unexpected breakdowns.

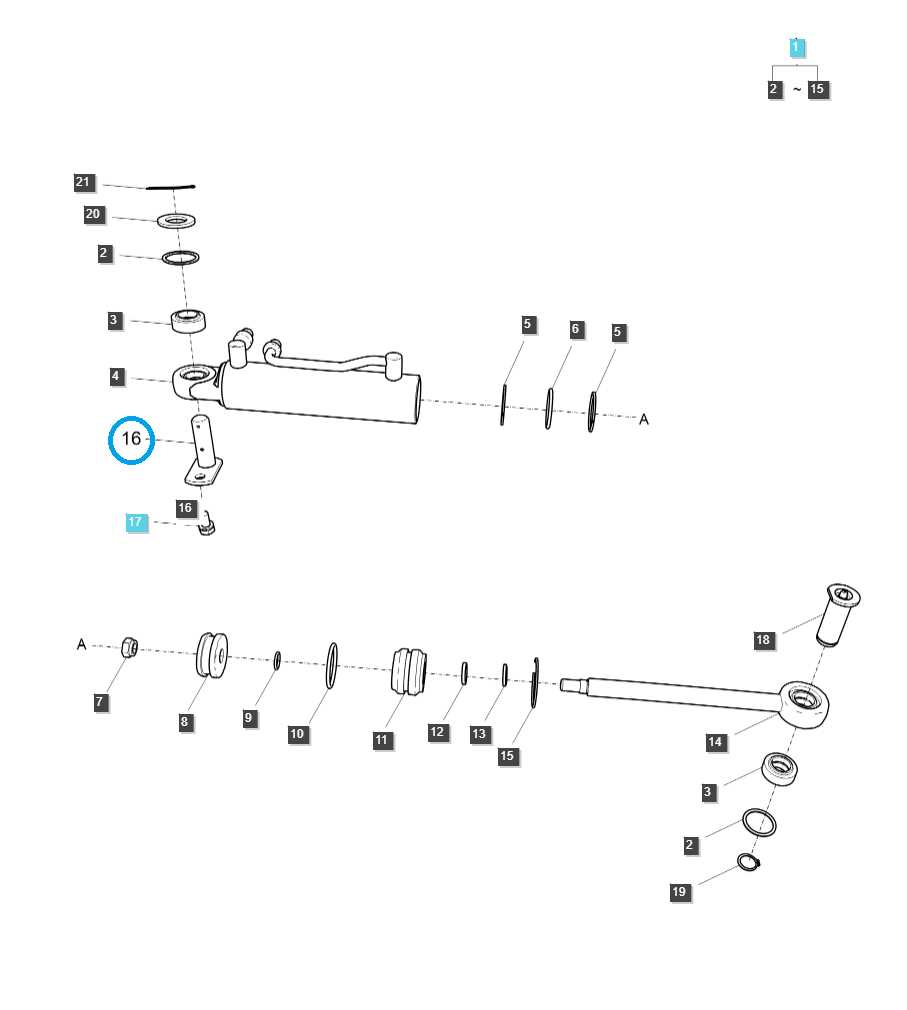

Hydraulic hoses are critical for the movement of fluids within the machinery. Inspecting these for leaks or damage is important, as compromised hoses can lead to significant performance issues or safety hazards.

Seals and gaskets serve as barriers to prevent leaks and maintain pressure within various systems. Replacing these components at the first sign of wear can save time and reduce costly repairs down the line.

Light bulbs may seem minor, but they are essential for visibility and safety during operation. Ensuring they are functioning properly is crucial for both the operator’s efficiency and the machinery’s overall safety.

By understanding these key elements and their functions, operators can better maintain their equipment, ensuring longevity and reliability in the field.

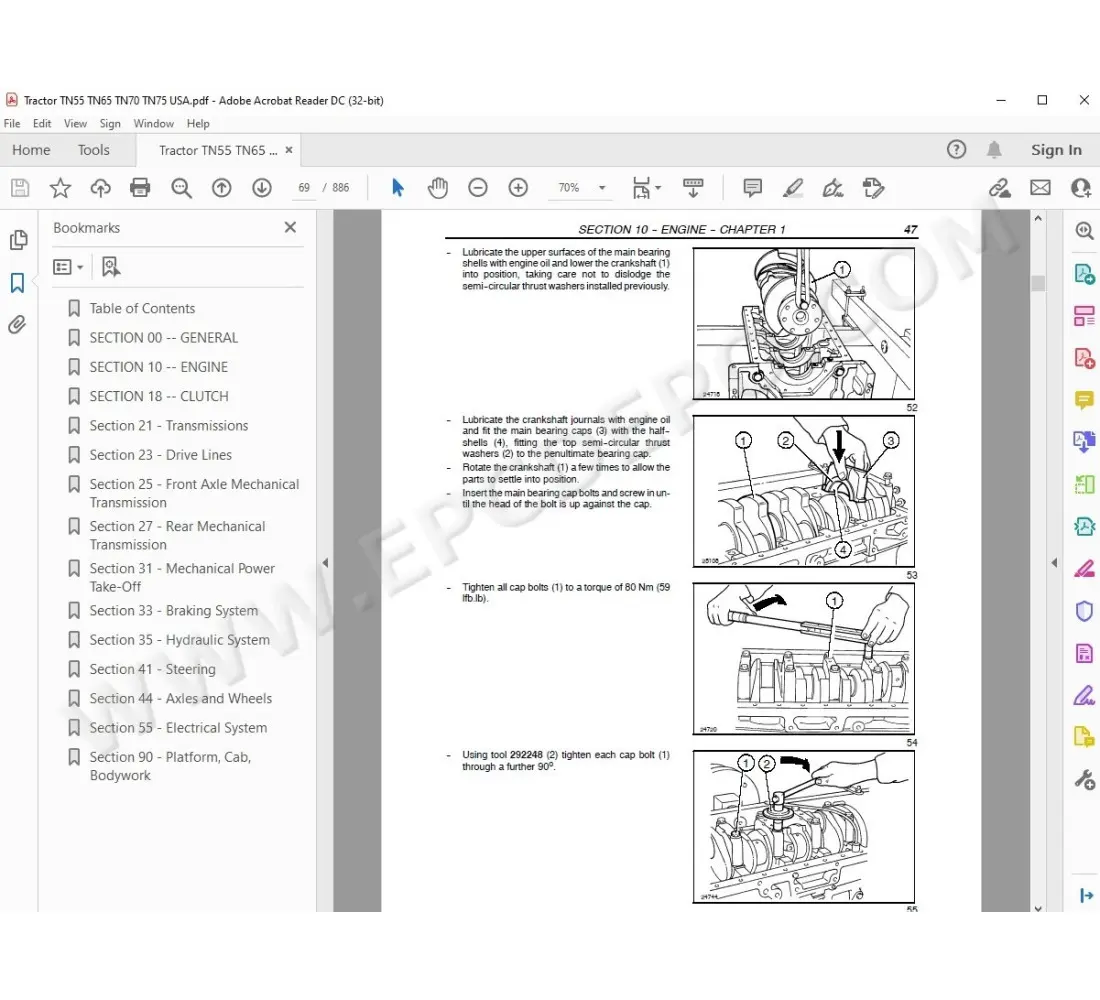

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repairs. These visual guides help users identify individual pieces and their arrangements within a larger assembly. Mastering this skill enhances the ability to source replacements and execute repairs efficiently.

Key Elements to Identify

- Labels: Each component typically has a label that corresponds to a part number.

- Connections: Arrows or lines often indicate how parts fit together or interact.

- Legend: Many illustrations include a legend that explains symbols used throughout.

Steps for Effective Reading

- Start by examining the overall layout to understand the main assembly.

- Identify and locate specific components using the labels provided.

- Cross-reference part numbers with your inventory or suppliers for replacements.

- Take notes on any missing or damaged pieces to streamline your repair process.

Maintenance Tips for TN65

Proper upkeep of machinery is essential for ensuring longevity and optimal performance. Regular attention to key components can significantly reduce the risk of breakdowns and enhance overall efficiency. This section explores practical strategies for maintaining your equipment effectively.

Regular Inspections

Conduct frequent checks on vital parts to identify any wear or damage early. Look for signs of leaks, unusual noises, or vibrations. Addressing these issues promptly can prevent costly repairs down the line.

Fluid Management

Ensure all fluids, including oil and coolant, are at appropriate levels and in good condition. Regularly replace fluids as per the manufacturer’s recommendations to maintain peak performance and protect against overheating.

Emphasizing consistent maintenance will lead to a more reliable and efficient machine, ultimately saving you time and resources.

Identifying Faulty Components

Recognizing malfunctioning elements within machinery is crucial for maintaining optimal performance and longevity. Early detection of issues can prevent extensive damage and costly repairs, ensuring that equipment operates efficiently. This section will explore common signs and methods to assess the condition of various parts, aiding in prompt troubleshooting and resolution.

Typical indicators of defects may include unusual noises, vibrations, or decreased efficiency. Visual inspections are essential; looking for wear, corrosion, or leaks can provide valuable insights. Utilizing diagnostic tools can further aid in pinpointing problematic areas, enabling targeted interventions.

Ultimately, a systematic approach to identifying and addressing faulty components enhances reliability and extends the lifespan of machinery. Regular maintenance checks and proactive monitoring are key practices for any operator seeking to uphold performance standards.

Aftermarket Parts vs. OEM

The choice between alternative components and original manufacturer offerings often presents a crucial decision for equipment owners. Each option carries its unique advantages and disadvantages, impacting performance, longevity, and cost-effectiveness.

Cost Considerations

Alternative components generally provide a more budget-friendly solution compared to original offerings. However, it’s essential to assess whether the lower price compromises quality or durability.

Quality and Performance

While original components guarantee compatibility and reliability, alternative options may offer competitive performance. Evaluating customer reviews and specifications can aid in making an informed choice.

| Aspect | Aftermarket | OEM |

|---|---|---|

| Cost | Lower | Higher |

| Compatibility | Varies | Guaranteed |

| Quality | Variable | Consistent |

| Warranty | Limited | Full |

Cost Factors for Replacement Parts

Understanding the financial implications of acquiring components for machinery is essential for effective maintenance and budgeting. Several elements influence the overall expenses, including quality, sourcing, and market demand.

| Factor | Description |

|---|---|

| Quality | High-quality components often come at a premium but can offer better durability and performance. |

| Sourcing | Obtaining items from authorized dealers may increase costs compared to aftermarket alternatives. |

| Market Demand | Fluctuations in supply and demand can lead to price variations, affecting overall costs. |

| Compatibility | Specialized components for specific machinery may be priced higher due to limited availability. |

Benefits of Using Accurate Diagrams

Utilizing precise illustrations offers numerous advantages in various fields, enhancing understanding and efficiency. These visual representations serve as essential tools, simplifying complex information and facilitating communication among professionals and enthusiasts alike.

Improved Clarity

Clear visuals eliminate ambiguity, providing a straightforward representation of components and their relationships. This clarity aids users in grasping intricate systems quickly, leading to better decision-making and fewer errors.

Enhanced Troubleshooting

Accurate illustrations are invaluable during maintenance and repair tasks. They allow technicians to identify issues swiftly and locate specific elements, reducing downtime and improving overall operational effectiveness.

Resources for TN65 Parts Support

Accessing reliable information and assistance is crucial for maintaining and repairing machinery effectively. This section provides valuable resources for users seeking support and information about components specific to their equipment. From online forums to official manuals, the following options can enhance your understanding and aid in troubleshooting.

Online Communities

Engaging with online forums can connect you with other users who share insights and solutions. Platforms dedicated to agricultural machinery often host discussions where members exchange experiences and advice.

Official Manuals

Consulting official documentation is essential for accurate information regarding specifications and assembly. These manuals usually provide detailed explanations and troubleshooting tips to assist users in their maintenance efforts.

| Resource Type | Description |

|---|---|

| Forums | Interactive platforms for user discussions and advice. |

| Documentation | Official manuals offering specifications and maintenance guidance. |

| Retailers | Suppliers providing components and expert advice. |